Ngowama-2025, imfuno yokupakishwa ekumgangatho ophezulu kunye neemveliso zephepha zokuhombisa iyaqhubeka nokukhula, iqhuba imarike yoomatshini bokubhala bephepha abaphambili. Eli nqaku linika uhlalutyo olunzulu lwezinto eziphambili ekufuneka ziqwalaselwe xa ukhetha umatshini wokubhala iphepha, kubandakanywa neentlobo, ukusebenza, ukucaciswa kobugcisa, kunye neempawu zeteknoloji zakutshanje. Abathengi abaziingcali baya kufumana ulwazi oluxabisekileyo ukwenza izigqibo ezinolwazi, ukuqinisekisa ukusebenza kakuhle kwemveliso kunye nemveliso ekumgangatho ophezulu.

Isiqulatho:

-Isishwankathelo seMarike: Umzi-mveliso woShishino wokuBonisa iPhepha

– Uhlahlelo oluneenkcukacha lweMarike yoMatshini wokuBonisa iPhepha

-Izinto eziphambili xa ukhetha uMtshini wokuBonisa iPhepha

-Izinto zeTekhnoloji zamva nje koomatshini bokuBonisa iPhepha

– UkuSebenza koMbane kunye neMpembelelo yokusiNgqongileyo

– Umgangatho wokuPakisha kunye nokuThotyelwa kweMigaqo

– Ubomi kunye nexabiso lokuthengisa kwakhona

– Iingcamango zokugqibela

Isishwankathelo seMarike: Umzi-mveliso woShishino wokuBonisa iPhepha

Imakethi yomatshini wokufaka amaphepha ehlabathi ikhule kakhulu kwiminyaka yakutshanje ngenxa yokunyuka kwemfuno yokupakishwa okukumgangatho ophezulu kunye neemveliso zephepha zokuhombisa. Ngo-2024, imakethi yayixabisa malunga ne-0.72 yeebhiliyoni zeedola, kunye noqikelelo olubonisa ukunyuka ukuya kwi-0.9 yeebhiliyoni zeedola ngo-2028, emele isantya sokukhula sonyaka (CAGR) se-5.7%. Oku kukhula kuqhutywa kukuhambela phambili kwitekhnoloji yokufaka i-embossing, ukubaluleka okukhulayo kwesibheno sobuhle ekupakishweni, kunye nokwandisa izicelo kuwo wonke amashishini ahlukeneyo, kubandakanya ukutya nesiselo, amayeza, kunye nokhathalelo lomntu.

Ummandla we-Asiya-Pacific ubambe esona sabelo sikhulu semakethi, esibalelwa ngaphezulu kwe-45% yemarike yehlabathi ngo-2024. Olu lawulo lubangelwa kushishino olukhawulezayo kunye nokwanda kwemfuno yabathengi kumazwe afana ne-China, i-Indiya, ne-Japan. UMntla Melika kunye neYurophu zilandela ngokusondeleyo, ziqhutywa lizinga eliphezulu lokwamkelwa koomatshini abakwizinga eliphezulu kunye nendlela ekhulayo yokupakishwa kweprimiyamu. Uqoqosho olusahlumayo kuMbindi Melika nase-Afrika kulindeleke ukuba lubone ukukhula okubonakalayo, okuphenjelelwa kukunyuka kotyalo-mali kwicandelo lezemveliso nokunyusa ingeniso enokulahlwa.

Ukuqhubela phambili kwezobuchwepheshe, okufana nokudityaniswa kolawulo lwedijithali kunye ne-automation, kuye kwaphucula kakhulu ukusebenza kakuhle kunye nokuchaneka koomatshini bokufaka amaphepha. Olu lutsha kulindeleke ukuba luqhubele phambili ukukhula kwemarike njengoko abavelisi befuna ukuphucula umgangatho wemveliso kunye nokunciphisa iindleko zokusebenza. Ukongeza, ukugxila okwandayo kuzinzo kunye nezisombululo zokupakishwa kwe-eco-friendly kukukhuthaza ukwamkelwa kweendlela eziphuculweyo zokuhombisa ezinciphisa inkcitho kunye nokusetyenziswa kwamandla.

Uhlalutyo olunzulu lweMarike yoMatshini wokuBonisa iPhepha

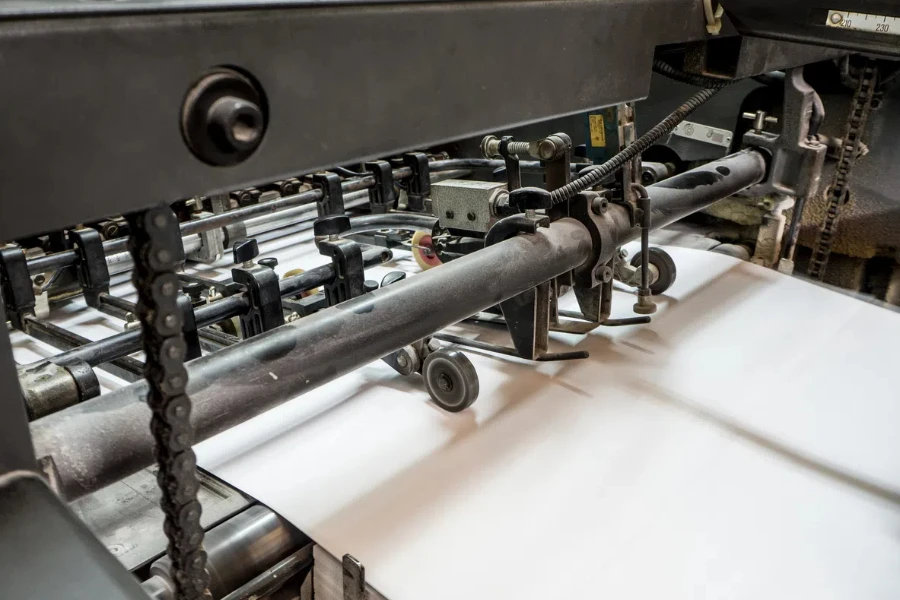

Oomatshini bokufaka amaphepha bongeza ukuthungwa kunye nobunzulu kwiimveliso zephepha, ukuphucula ukubukeka kwabo okubonakalayo kunye neempawu ezithintekayo. Iimpawu eziphambili zokusebenza kwaba matshini ziquka isantya sokufaka i-embossing, ukuchaneka, kunye nokukwazi ukuphatha iintlobo ezahlukeneyo zephepha kunye nobukhulu. Oomatshini banamhlanje be-embossing banokufikelela kwisantya ukuya kuthi ga kwi-200 yeemitha ngomzuzu, ngokuchaneka okuphezulu kuqinisekisa umgangatho ongaguqukiyo kuyo yonke imveliso enkulu. Imarike ibonelela ngeendidi ezahlukeneyo zoomatshini, ukusuka kwiimodeli ze-manual kunye ne-semi-automatic ukuya kwiinkqubo ezizenzekelayo ngokupheleleyo ezinolawulo lwedijithali kunye nokukwazi ukujonga ixesha lokwenyani.

Iinkampani eziphambili ezifana neBobst Group SA, iHeidelberg, kunye neKoenig & Bauer zilawula urhwebo, zisebenzisa amandla azo abanzi e-R&D kunye nothungelwano oluluqilima lokusasaza. Ezi nkampani ziphuhlisa izisombululo ezitsha, ezinje ngoomatshini be-hybrid embossing abadibanisa ubuchule bemveli bokufaka i-embossing kunye nobuchule bokushicilela bedijithali. Lo mkhwa obhekiselele kwizisombululo ezixubeneyo uqhutywa yimfuneko yokuguquguquka okukhulu kunye nokwenza ngokwezifiso ukupakisha kunye nezicelo zokuprinta.

Iimpembelelo zoqoqosho, eziquka ukuguquguquka kwamaxabiso ezinto ezikrwada kunye nemigaqo-nkqubo yorhwebo, zinefuthe elimandla kwimarike yomatshini wokufaka amaphepha. Ukunyuka kweendleko zephepha kunye nezinye izinto ezikrwada kunokuchaphazela iindleko zemveliso, ngelixa imigaqo-nkqubo encomekayo yorhwebo kunye nenkuthazo karhulumente inokunyusa ukukhula kwemarike. Ukutshintsha kokuziphatha kwabathengi, ngakumbi ukonyuka kokukhetha kwiprimiyamu kunye nokupakishwa komntu siqu, kukwaqhuba imfuno yezisombululo eziphuculweyo zokuhombisa. Imijelo yokusasaza iyaguquka, ngokugxininiswa okukhulayo kwiintengiso ze-intanethi kunye neemodeli ezithe ngqo kubathengi, okwenza abavelisi bafikelele kwisiseko esibanzi sabathengi.

Izinto ezintsha ezisandula ukwenziwa kwimarike ziquka uphuhliso lweendlela zokuhombisa eco-friendly ezisebenzisa i-inki esekwe emanzini kunye nezinto ezinokubola, ezihambelana noxinzelelo lwehlabathi olusingise kuzinzo. Oomatshini bokufaka amaphepha bephepha bahlala bephila ixesha elide, kunye nokugcinwa rhoqo kunye nokuphuculwa kokuqinisekisa ukusebenza kakuhle. Amanyathelo okwenziwa kweDijithali kunye noShishino lwe-4.0 aqhubela phambili ekuguquleni imarike, ngoomatshini be-smart embossing abanoqhagamshelo lwe-IoT, ukuxilonga okukude, kunye nokukwazi ukugcinwa kwangaphambili.

Iindlela zentlalo, ezinje ngemfuno ekhulayo yeemveliso zobugcisa kunye neemveliso ezenziwe ngesandla, zenza iimarike ze-niche zoomatshini abakhethekileyo be-embossing. Amanqaku entlungu yabathengi, kubandakanywa iindleko eziphezulu zokuqala zotyalo-mali kunye nesidingo sabaqhubi abanezakhono, ziqwalaselwa ngeenkqubo zoqeqesho kunye neenketho zemali ezinikezelwa ngabavelisi. Izicwangciso zokubeka uphawu ziqaqambisa umgangatho, ukuthembeka, kunye nokuveliswa kwezinto ezintsha, kunye nezicwangciso zokwahlula ezigxininisa iimpawu eziphambili, iinketho zokwenza ngokwezifiso, kunye nezenzo ezizinzileyo.

Imiba ephambili xa ukhetha uMtshini wokuQinisa iPhepha

Ukukhetha umatshini wokufaka amaphepha afanelekileyo kubalulekile ekuqinisekiseni imveliso ekumgangatho ophezulu kunye nemveliso esebenzayo. Ziliqela izinto ekufuneka ziqwalaselwe ukwenza isigqibo esinolwazi. Ngezantsi kukho iingxoxo ezineenkcukacha kwimiba ebalulekileyo ekufuneka ikhokele inkqubo yakho yokhetho.

Iintlobo kunye neZimbo

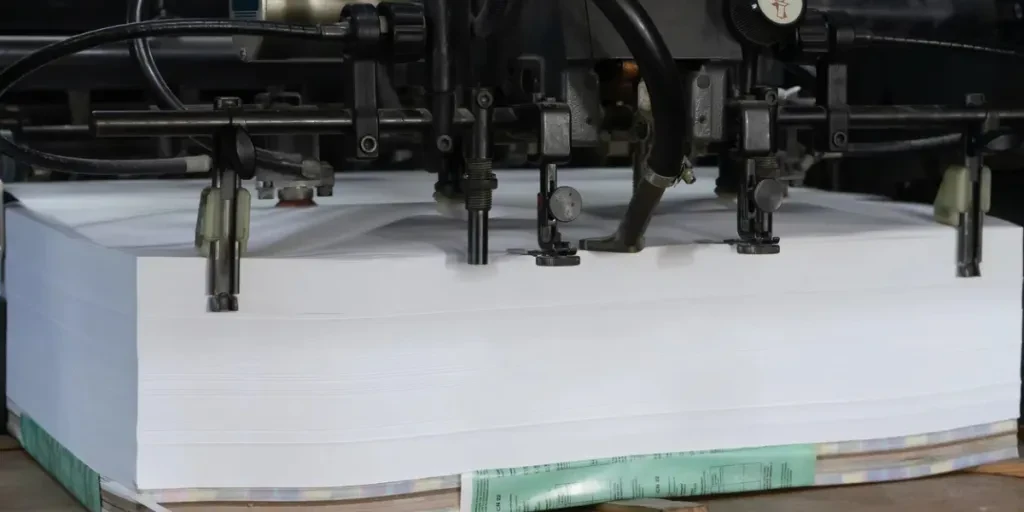

Oomatshini bokufaka amaphepha bafika kwiindidi ezahlukeneyo kunye nezitayile, nganye ifanele izicelo ezithile. Imishini yokufaka i-Manual embossing ilungele imisebenzi encinci okanye iiprojekthi zesiko, ezinikezela ngokuchanekileyo kunye nokulawula, kodwa zifuna umsebenzi obalulekileyo kunye nexesha. Ngokwahlukileyo, oomatshini be-embossing ngokuzenzekelayo benzelwe ukuveliswa kwevolumu ephezulu, equkethe i-automation ephuculweyo enciphisa ukungenelela ngesandla kunye nokwandisa umthamo.

Oomatshini be-Rotary embossing basebenzisa i-cylindrical rollers ukudala iipatheni eziqhubekayo kwiphepha kwaye zilungele imisebenzi emikhulu. Oomatshini bokuhombisa be-Flatbed bacinezela uyilo ephepheni besebenzisa umphezulu osicaba, benikezela ngezinto ezahlukeneyo kwiiprojekthi ezahlukeneyo zokuhombisa. Uhlobo ngalunye luneenzuzo kunye nokunciphisa, kwaye ukhetho lwakho kufuneka luhambelane neemfuno zakho zemveliso kunye nomthamo.

Ukusebenza kunye nokusebenza

Ukusebenza komatshini wokufaka iphepha kuchaphazela ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Iimpawu zokusebenza eziphambili ziquka isantya sokufaka i-embossing, amandla oxinzelelo, kunye nokuchaneka. Oomatshini abanesantya esiphezulu banokunyusa kakhulu amazinga emveliso kodwa banokufuna ukulungiswa rhoqo. Oomatshini abaneesethingi zoxinzelelo olulungelelaniswayo babonelela ngokuguquguquka, okuvumela abaqhubi ukuba bagxininise ubukhulu bamaphepha ahlukeneyo kunye nokwakheka ngaphandle kokubeka esichengeni umgangatho.

Ukusebenza kunwenwela kubuchule bomatshini bokuphatha ii-embossing ezahlukeneyo kunye neepateni. Imifuziselo ekwinqanaba eliphezulu ibonakalisa useto olucwangcisiweyo oluvumela utshintsho olukhawulezayo phakathi koyilo, ukunciphisa ixesha lokuphumla kunye nokwandisa imveliso. Ukongezelela, qwalasela oomatshini abaneenkqubo ezidibeneyo zokulawula umgangatho eziqinisekisa ubunzulu obuhambelanayo kunye nokuchaneka kwepateni.

Izikhankanyi Technical

Ukuqonda iinkcukacha zobugcisa bomatshini wokubhala iphepha kubalulekile ukuhambelana neemfuno zakho zokusebenza. Iinkcukacha ekufuneka ziqwalaselwe zibandakanya ububanzi kunye nobude be-embossing, ubukhulu bephepha obukhulu, kunye nokusetyenziswa kwamandla. Oomatshini abanendawo enkulu yokufaka i-embossing banokuphatha amaphepha amakhulu ephepha, abenze bafaneleke kwiinkqubo ezahlukeneyo.

Ukusetyenziswa kwamandla ngomnye umba obalulekileyo, ngakumbi kumashishini ajonge ukunciphisa iindleko zokusebenza. Oomatshini abasebenzisa umbane abapheleli nje ekunciphiseni amatyala ombane kodwa banegalelo kwimisebenzi yokuvelisa ezinzileyo. Ukongeza, qwalasela ukuhambelana komatshini kunye nezixhobo ezikhoyo kunye nesoftware yokuqinisekisa ukudityaniswa komthungo kumgca wakho wokuvelisa.

Ukusebenziseka ngokulula kunye nobunzima bokuSeta okuQala

Ukulula kokusetyenziswa komatshini wokufaka iphepha kuchaphazela ukusebenza kakuhle kwabaqhubi kunye nemveliso yonke. Ujongano olusebenziseka lula kunye nolawulo olune-intuitive lunokunciphisa kakhulu ijika lokufunda, livumela abaqhubi ukuba balawule umatshini ngokukhawuleza. Oomatshini abaneziboniso zedijithali kunye nezicwangciso ezicwangcisiweyo zibonelela ngolawulo olukhulu kunye nokuguquguquka, okwenza ulungelelwaniso oluchanekileyo lweeprojekthi ezahlukeneyo zokufaka i-embossing.

Ubunzima bokuseta okokuqala ngomnye uqwalaselo olubalulekileyo. Oomatshini abafuna ukusetwa okubanzi kunye nokulinganisa banokulibazisa ukuqaliswa kwemveliso kunye nokunyusa iindleko zabasebenzi. Khangela iimodeli ezinemiyalelo yendibano ethe ngqo kunye neemfuno zokuseta ezincinci. Ukongeza, qwalasela oomatshini ababonelela ngenkxaso ekude kunye nokusombulula ingxaki yokujongana nayo nayiphi na imiba yokuseta ngokukhawuleza.

Ukuqina kunye noKwakha uMgangatho

Ukuqina kunye nomgangatho wokwakha kubaluleke kakhulu ekuqinisekiseni ixesha elide kunye nokuthembeka komatshini wokufaka iphepha. Oomatshini abakhiwe kwizinto ezikumgangatho ophezulu ezifana nentsimbi engatyiwayo kunye namacandelo akwimigangatho yemizi-mveliso axhathisa ngakumbi ukunxitywa kunye nokukrazula, ukunciphisa imfuno yokulungiswa rhoqo kunye nokutshintshwa. Khangela oomatshini abanolwakhiwo olomeleleyo olunokumelana nobunzima bokusebenza ngokuqhubekayo.

Umgangatho wokwakha uphinde ufikelele ekuchanekeni kweendawo ezihambayo kunye nokuzinza komatshini ngexesha lokusebenza. Oomatshini abanezinto ezenziwe kakuhle kunye neefreyimu eziqinileyo zinciphisa ukungcangcazela kwaye ziqinisekisa umgangatho wokufaka i-embossing. Utyalo-mali kumatshini ozinzileyo lunokuba neendleko eziphezulu zangaphambili kodwa luya kuhlawula ekuhambeni kwexesha ngokuncipha kweendleko zolungiso kunye nobomi benkonzo obude.

Iimpawu zeTekhnoloji zamva nje koomatshini bokuBonisa iPhepha

Inkqubela phambili yezobuchwephesha iphucule kakhulu izakhono kunye nokusebenza kakuhle koomatshini bokukrola amaphepha. Oomatshini banamhlanje babandakanya izinto ezilula ukusebenza, ukuphucula umgangatho, kunye nokubonelela ngokuguquguquka okukhulu.

Digital Control Systems

Enye yenkqubela phambili ephawulekayo kumatshini wokukrola amaphepha kukudityaniswa kweenkqubo zolawulo lwedijithali. Ezi nkqubo zivumela ulawulo oluchanekileyo kwiiparameters ze-embossing ezifana noxinzelelo, isantya, kunye nokulungelelaniswa kwepateni. Abasebenzisi banokucwangcisa ngokulula kwaye bagcine useto oluninzi, baququzelele utshintsho olukhawulezayo phakathi kwemisebenzi eyahlukeneyo yokubhala. Iinkqubo zolawulo lwedijithali zikwavumela ukubeka iliso kude kunye nokuxilongwa, ukunciphisa ixesha lokuphumla kunye nokuqinisekisa ukusebenza kakuhle komatshini.

Ulawulo loMgangatho oluzenzekelayo

Iimpawu zolawulo lomgangatho oluzenzekelayo ziyiguqule inkqubo yokubhala iphepha. Oomatshini abaxhotyiswe ngeesenso kunye neekhamera banokuqhubeka bebeka iliso kwikhwalithi yokufaka embossing, babone nakuphi na ukutenxa ngexesha lokwenyani. Oku kuqinisekisa imveliso ehambelanayo kunye nokunciphisa umngcipheko weziphene, obaluleke kakhulu kwimveliso ephezulu. Iinkqubo ezizenzekelayo zokulawula umgangatho nazo ziyakwazi ukuvelisa iingxelo ezineenkcukacha, ukubonelela ngengqiqo kwiimetriki zemveliso kunye nokunceda ukuchonga iindawo zokuphucula.

I-Advanced Die Technologies

Uphuhliso lwetekhnoloji ye-die ephuculweyo yandise amathuba okuyilwa kokubhala iphepha. Iifati zanamhlanje zenziwe ngezinto ezinokuqina okuphezulu ezinikezela ukomelela kunye nokuchaneka okongeziweyo. Abanye oomatshini ngoku babonisa iinkqubo zokufa ezitshintshisanayo, ezivumela abaqhubi ukuba batshintshe ngokukhawuleza phakathi kweepateni ezahlukeneyo kunye nokwenziwa. Oku bhetyebhetye kubaluleke kakhulu kumashishini afuna ukubonelela ngeendidi ezahlukeneyo zeemveliso ezifakwe kwi-embossed.

UkuSebenza koMbane kunye neMpembelelo yokusiNgqongileyo

Ukusebenza kakuhle kwamandla kuyinkxalabo ekhulayo kumashishini oomatshini, kunye noomatshini bokufaka amaphepha anjalo. Abavelisi baya kugxininisa ngakumbi ekuphuhliseni iimodeli ezisebenza ngamandla ezinciphisa ukusetyenziswa kwamandla ngaphandle kokunciphisa ukusebenza.

IiMoto ezonga amandla

Iinjini ezonga umbane yeyona nto iphambili koomatshini banamhlanje bokufaka amaphepha. Ezi motors zisebenzisa amandla amancinci ngelixa zihambisa umgangatho ofanayo wokusebenza njengeenjini zemveli. Ngokunciphisa ukusetyenziswa kwamandla, aba matshini banceda ukunciphisa iindleko zokusebenza kunye negalelo ekuzinzeni kwendalo. Ukongeza, iimoto ezonga amandla zivelisa ubushushu obuncinci, zinciphisa imfuno yeenkqubo zokupholisa ezibanzi kunye nokuphucula ukusebenza kakuhle.

Izinto ezizinzileyo

Ukusetyenziswa kwezixhobo ezizinzileyo ekwakhiweni koomatshini bokufaka amaphepha ngomnye umkhwa obalulekileyo. Abavelisi bakhetha izinto ezinokuphinda zisetyenziswe kunye ne-eco-friendly ezinciphisa impembelelo yokusingqongileyo. Ngokomzekelo, oomatshini abenziwe ngentsimbi ehlaziyiweyo okanye ngealuminiyam abapheleli nje ekunciphiseni inkunkuma kodwa bafuna amandla amancinane ukuze bavelise. Oku kuhambelana nemfuno ekhulayo yezenzo zokwenziwa kwemveliso ezizinzileyo kwaye kunceda amashishini ahlangabezane neemfuno zolawulo lokuthotyelwa kokusingqongileyo.

Iimpawu zokuNcitshiswa kweNkunkuma

Oomatshini banamhlanje bokuhombisa amaphepha bayilwe beneempawu ezinciphisa inkunkuma. Iinkqubo zokulawula ngokuchanekileyo ziqinisekisa ukuba kuphela inani elifunekayo lezinto eziphathekayo, ukunciphisa ukusetyenziswa kwephepha elingaphezulu. Abanye oomatshini bakwabandakanya iindlela zokuphinda zisetyenziswe yinkunkuma eziqokelela ziphinde zisebenzise izinto ezilahliweyo. Ngokunciphisa inkunkuma, aba matshini banceda amashishini ukuba anciphise indawo yawo yokusingqongileyo kunye nokuphucula ukusebenza kakuhle.

Umgangatho wokuPakisha kunye nokuThotyelwa kweMigaqo

Umgangatho wokupakisha kunye nokuthotyelwa kwemithetho yingqwalasela ebalulekileyo kumashishini atyala imali koomatshini bokuthunga amaphepha. Ukuqinisekisa ukuba umatshini udibana nemigangatho yoshishino kwaye uvelise ukupakishwa komgangatho ophezulu kubalulekile ukugcina ukwaneliseka kwabathengi kunye nokuthobela iimfuno zomthetho.

Imveliso yokuPakisha ekumgangatho ophezulu

Umgangatho wokupakishwa oveliswa ngumatshini we-embossing wephepha uchaphazela ngokuthe ngqo ixabiso elibonwayo lemveliso. Oomatshini abanobuchule bokuhombisa obuphambili banokwenza iipateni ezintsonkothileyo nezineenkcukacha eziphucula umtsalane wobuhle bepakethe. I-embossing ekumgangatho ophezulu yongeza into ebambekayo, eyenza ukupakishwa kubandakanyeke ngakumbi kubathengi. Ukutyala imali kumatshini ohambisa umgangatho ophezulu wokupakisha unokunika amashishini ukhuphiswano kwimarike.

Ukuthotyelwa kweMigangatho yoShishino

Ukuthotyelwa kwemigaqo yeyona nto ibalulekileyo xa ukhetha umatshini wokufaka amaphepha. Oomatshini kufuneka bahambelane nemigangatho yoshishino kunye neziqinisekiso zokuqinisekisa ukusebenza okukhuselekileyo nokuthembekileyo. Umzekelo, ukuthotyelwa kwemigangatho ye-ISO kuqinisekisa ukuba umatshini uyahlangabezana nemigangatho yamazwe ngamazwe kunye neemfuno zokhuseleko. Ukongeza, oomatshini abathobela imigaqo yokusingqongileyo, efana ne-RoHS kunye ne-REACH, banceda amashishini aphephe imiba yomthetho kunye nezohlwayo.

Isiqinisekiso kunye noVavanyo

Ngaphambi kokuthenga umatshini wokufaka iphepha, kubalulekile ukuqinisekisa ukuqinisekiswa kwayo kunye neempawu zokuvavanya. Abavelisi abahloniphekileyo banikezela ngamaxwebhu aqinisekisa ukuthotyelwa komatshini kunye nemigangatho efanelekileyo. Oku kuquka iziqinisekiso zokhuseleko, iingxelo zoqinisekiso lomgangatho, kunye nezatifikethi zokuthobela indalo esingqongileyo. Ukuqinisekisa ukuba umatshini uhlolwe ngokucokisekileyo kwaye uqinisekisiwe kunika uxolo lwengqondo kwaye uqinisekisa ukusebenza okuthembekileyo.

Ubomi kunye nexabiso lokuthengisa kwakhona

Ubomi kunye nexabiso lokuthengisa kwakhona umatshini we-embossing wephepha yimiba ebalulekileyo yokuqwalasela utyalo-mali lwexesha elide. Oomatshini abanobomi obude kunye nexabiso eliphezulu lokuthengisa kwakhona banikezela ngembuyekezo engcono kutyalo-mali kwaye banciphise ixabiso lilonke lobunini.

Ubomi obude kunye noLondolozo

Ubomi obude bomatshini wokubhala iphepha buxhomekeke kumgangatho wokwakha, iimfuno zokugcinwa, kunye neemeko zokusetyenziswa. Oomatshini abenziwe ngezinto ezihlala ixesha elide kwaye beyilelwe ukusetyenziswa komsebenzi onzima bahlala bephila ixesha elide. Ukugcinwa rhoqo kukwabalulekile ekwandiseni ubomi benkonzo yomatshini. Utyalo-mali kumatshini onesicwangciso esibanzi sokulondolozwa kunye nezixhobo ezifumaneka lula ziqinisekisa ukuba uhlala usebenza iminyaka emininzi.

Ukuphuculwa Okunokwenzeka

Ikhono lokuphucula umatshini wokufaka iphepha lokufaka i-embossing yenye into ebalulekileyo yokuqwalaselwa. Oomatshini abahambelana nokuphuculwa kwexesha elizayo kunye nobuchwepheshe obutsha banokuqhelana nokutshintsha iimfuno zemveliso kwaye bandise ubomi babo obuluncedo. Umzekelo, oomatshini bemodyuli abavumela ukongezwa kweempawu ezintsha okanye amacandelo banokuqhubeka nokuhambela phambili kwetekhnoloji kwaye bahlale befanelekile kwintengiso.

Ixabiso lokuhlaziya

Ixabiso lokuphinda lithengiswe lomatshini wokuhombisa iphepha liphenjelelwa luphawu lwawo, imeko, kunye nemfuno yemarike. Oomatshini abakumgangatho ophezulu ovela kubakhiqizi abahloniphekileyo bavame ukuba nexabiso elingcono lokuthengisa, njengoko beyaziwa ngokuthembeka kunye nokusebenza kwabo. Ukugcina umatshini ukwimeko entle kunye nokugcina iirekhodi ezineenkcukacha zokugcinwa kunye nembali yenkonzo kunokunyusa ixabiso layo lokuthengisa kwakhona. Xa kufika ixesha lokuphucula okanye ukubuyisela umatshini, ixabiso eliphezulu lokuthengisa linokunciphisa iindleko zotyalo-mali olutsha.

Iingcinga Final

Ukukhetha umatshini wokufaka iphepha elichanekileyo kubandakanya ukuqwalaselwa ngokucokisekileyo kwezinto ezahlukeneyo, kubandakanywa iintlobo kunye nezitayela, ukusebenza, iinkcukacha zobugcisa, ukukhululeka kokusetyenziswa, ukuqina, kunye nokunye. Ngokuqonda le miba kunye nokuhlala unolwazi malunga nenkqubela phambili yetekhnoloji yamva nje, amashishini anokwenza isigqibo esinolwazi esihlangabezana neemfuno zabo zemveliso kwaye siqinisekise imveliso ekumgangatho ophezulu. Utyalo-mali kumatshini wokukrola wephepha othembekileyo nosebenzayo unokwandisa kakhulu imveliso, unciphise iindleko, kwaye ube negalelo kwimpumelelo yexesha elide.