Phakathi kwenkqubela phambili ekhawulezileyo kwitekhnoloji ye-automation ngo-2025, imfuno yezixhobo ezichanekileyo ezifana nemigca yesilayidi yesilayidi iye yanda. Eli nqaku lijonge kwizinto eziphambili zokukhetha la macandelo abalulekileyo, enika abathengi abaqeqeshiweyo isikhokelo esibanzi sokwenza izigqibo ezinolwazi. Isebenzisa iinguqulelo zamva nje kunye namandla entengiso, esi siqwenga sibonelela ngezimvo ezixabisekileyo zokwandisa isicwangciso sakho sokuthenga kunye nokuqinisekisa umgangatho ophezulu kunye nokusebenza kuluhlu lwakho lwempahla.

Isiqulatho:

-Umbono weMakethi yeeSilayidi zeSilayidi eziLayini

-Uhlalutyo oluneenkcukacha lweMakethi yeSilayidi sikaLoliwe

-Izinto eziphambili xa ukhetha iiSilayidi zeSilayidi eziLayini

-Iimpawu eziPhambili kunye nezinto ezintsha kwii-Linear Slide Rails

I-Industry Applications ye-Linear Slide Rails

-Ushwankathelo

Isishwankathelo seMarike yeeSilayidi zeSilayidi

Imakethi yelizwe jikelele yesilayidi sikaloliwe ibone ukukhula olomeleleyo, ikhula ukusuka kwi-USD 391.13 yezigidi ngo-2023 ukuya kwi-USD 419.14 yezigidi ngo-2024. Oku kukhula kulindeleke ukuba kuqhubeke, ngesantya sokukhula esiqikelelwayo sonyaka (CAGR) se-7.67%, sifikelele kwi-USD 656.24 yezigidi ngeenkqubo kunye nenkqubo echanekileyo yokwenziwa kwezixhobo ngo-2030. ukwamkelwa kokuzenzekela kuwo onke amashishini ahlukeneyo, kuqhuba le ndlela inyukayo.

Ngokwengingqi, imakethi yaseAsia-Pacific, ngakumbi iTshayina, ikhokela ngenxa yokukhula ngokukhawuleza kwemizi-mveliso kunye notyalo-mali olubalulekileyo kubunjineli obuchanekileyo kunye nokuveliswa kombane. Amazwe aseMelika, aqhutywa yi-United States, akwabonisa ukukhula olomeleleyo ngenxa yokwanda kokwenziwa komatshini wokwenza izinto ezizisebenzelayo kunye nokubuyela umva kwicandelo leemoto. IYurophu, kunye necandelo layo leemoto kunye ne-aerospace eqhubela phambili, ihleli iyimakethi ebalulekileyo, ngelixa uMbindi Mpuma kunye ne-Afrika ngokuthe ngcembe ifumana utyalo-mali olwandisiweyo kwiziseko ezingundoqo kunye nokuveliswa kwemizi-mveliso.

Amandla emarike aphenjelelwa yimfuneko yesikhokelo sokukhuhlana okuphantsi kunye nokuqina okuphezulu kwemithwalo enzima, kunye nokwanda kokusasazwa komgca wesilayidi kumashishini okwakha kunye ne-aerospace. Nangona kunjalo, iindleko eziphezulu zokuqala kunye neemfuno zokulondolozwa zenza imingeni. Nangona le mingeni, amathuba amaninzi kunye nokuqaliswa kokusebenza okuphezulu kunye nexabiso eliphantsi le-linear linear slide rails kunye nesicelo sabo esikhulayo kwizixhobo ze-optical kunye nezonyango.

Uhlalutyo olunzulu lweMarike yeSilayidi sikaLoliwe

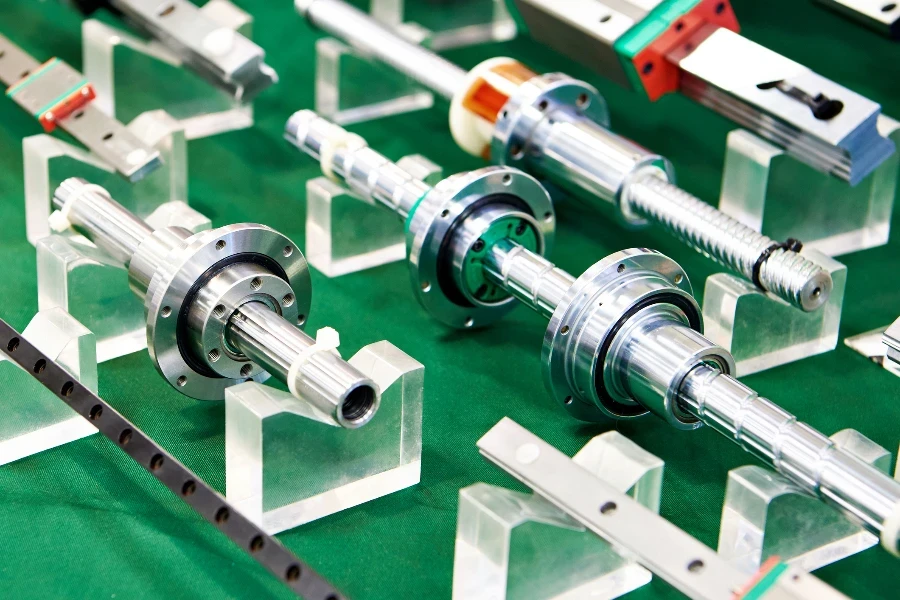

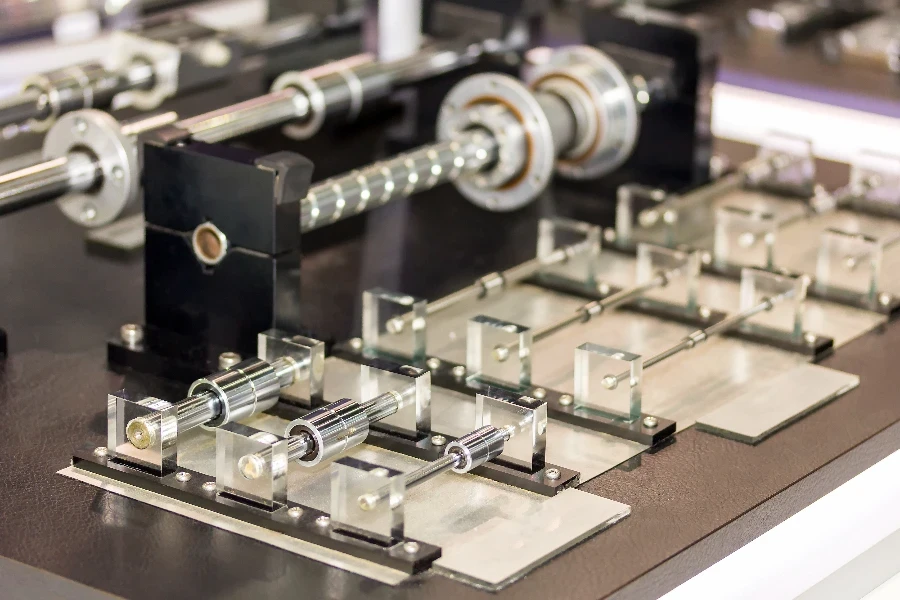

Iireyile zesilayidi ezinomgca ziyimfuneko kwizicelo ezichanekileyo ezinje ngomatshini weCNC, iirobhothi, kunye nemigca yendibano entsonkothileyo. Ziquka umzila wesitimela osebenza njengomzila kunye nokuthwala okanye ibhloko ehamba kulo mzila, ukunciphisa ukungqubuzana kunye nokugcina uzinzo. Iimpawu eziphambili zokusebenza ziquka ukuchaneka, umthamo womthwalo, kunye nokuqina. Izinto ezintsha ezifana ne-corrosion-resistant kunye ne-self-lubricating features ziye zawuphucula kakhulu ukusebenza kunye nobomi bala macandelo.

Imakethi ibonakalisa uluhlu olwahlukeneyo lwezixhobo ezisetyenziselwa ukwenza iileyili zesilayidi, kubandakanya ialuminium, ubhedu, kunye nobhedu. I-aluminiyam ikhaphukhaphu kwaye iyamelana nomhlwa, ngelixa ubhedu kunye nobhedu zinika ukuqina okugqwesileyo kunye nesakhono sokuthwala umthwalo. Ukuphuhliswa komzila omncinci wesilayidi esincinci kwizixhobo ezincinci kukwavule iimarike ze-niche ezintsha, ngakumbi kwizixhobo zonyango kunye nezixhobo zamehlo.

Ukuziphatha kwabathengi kutshintshela kwiinkqubo ezizihambelayo ezizihambelayo, ziqhuba imfuno yeenkqubo ezithembekileyo nezisebenzayo zolawulo lwentshukumo. Iziteshi zokusasaza ziye zavela, ngokukhetha ukuthengisa ngokuthe ngqo kunye nobudlelwane bexesha elide kunye ne-OEMs ukuqinisekisa ukunikezelwa kwamacandelo aphezulu. Umjikelo wobomi bemveliso yemigca yesilayidi yesilayidi iphenjelelwa kakhulu yinkqubela phambili yetekhnoloji kunye nesidingo sokugcinwa rhoqo ukuqinisekisa ukusebenza ngokupheleleyo.

Izinto ezintsha ezisandula ukwenziwa kwimarike ziquka uphuhliso lwe-NSK lwetekhnoloji eshukumayo egudileyo kwizikhokelo ezihambelanayo, ukuqinisa ukungaguquguquki okuguquguqukayo kunye nokufanelekileyo kuhlolo oluchanekileyo kunye nezixhobo zokulinganisa. Ngokufanayo, u-Igus uye wazisa i-hygienic design linear guide ezenza i-lubricating kwaye ifanele ukusetyenziswa ekutyeni kunye nokulungiswa kwesiselo kunye nobuchwepheshe bezonyango, ukujongana neenkxalabo malunga nokucoceka komatshini kunye nokhuseleko.

Iimpembelelo zoqoqosho ezinje ngesidingo sokunciphisa ixesha lemveliso kunye neendleko zabasebenzi ziqhuba utyalo-mali kubuchwepheshe obuzisebenzelayo, apho iileyili zesilayidi ezihambelanayo zidlala indima ebalulekileyo. Iindlela zentlalo ezibhekiselele ekunyukeni kwe-automation kunye nokuchaneka kweenkqubo zokwenziwa kwemveliso ziqhubela phambili ukukhula kwemarike. Nangona kunjalo, iintlungu zabathengi ezifana neendleko eziphezulu zokuqala kunye neemfuno zokugcinwa kufuneka ziqwalaselwe ngeendlela ezintsha kunye nezisombululo ezingabizi kakhulu.

Imiba ephambili xa ukhetha iiSilayidi zeSilayidi eziLayini

Ukuthwala amandla

Xa ukhetha umzila kaloliwe wesilayidi, umthamo womthwalo ubalulekile. Umthamo womthwalo ubhekisa kubunzima obuninzi umzila kaloliwe onokubuxhasa ngaphandle koguquko olusisigxina okanye ukusilela, ngokuqhelekileyo kulinganiselwa ngeepounds (lbs) okanye iikhilogram (kg). Umzekelo, isiporo esinomthwalo we-200 kg sifanelekile kwizicelo zemizi-mveliso ezinzima, ngelixa umzila wesitimela osezantsi ungcono kwimisebenzi elula njengezixhobo zebhubhoratri. Ukuqinisekisa umthamo womthwalo uhambelana neemfuno zesicelo kubalulekile ekugcineni ukuthembeka kunye nokusebenza koomatshini.

Umthamo womthwalo uphenjelelwa zizinto ezifana nesixhobo sikaloliwe kunye nohlobo lweebheringi ezisetyenzisiweyo. Iintsimbi ezenziwe ngentsimbi ephezulu okanye i-aluminium alloys ngokubanzi zinika amandla aphezulu omthwalo ngenxa yamandla kunye nokuqina. Ukongeza, iibheringi zebhola okanye iibheringi zeenaliti zinokuphucula amandla okuthwala umthwalo ngokusabalalisa umthwalo ngokulinganayo kumzila kaloliwe.

Kukwabalulekile ukuqwalasela umthamo womthwalo oguqukayo, obhekisa kumthwalo umzila kaloliwe onokuwuphatha ngelixa ushukuma. Oku kubaluleke ngakumbi kwizicelo ezibandakanya intshukumo eqhubekayo okanye ephindaphindwayo, njengoko amandla omthwalo oguqukayo ahlala ephantsi kunomthamo we-static ngenxa yoxinzelelo olongezelelweyo olusuka kwintshukumo.

Ukuchaneka nokuchaneka

Ukuchaneka kunye nokuchaneka kubaluleke kakhulu kwizicelo ezifuna indawo echanekileyo kunye nokuphindaphinda. Iireyile zesilayidi ezinomgca ngokuchaneka okuphezulu kunye nokuchaneka ziqinisekisa ukuba izinto ezihambayo zigcina indlela yazo ekujoliswe kuyo ngokutenxa okuncinci. Oku kubalulekile kwizicelo ezinje ngoomatshini be-CNC, izixhobo zonyango, kunye nokuveliswa kwe-semiconductor, apho iimpazamo ezincinci zinokubangela imiba ebalulekileyo.

Ukuchaneka kudla ngokugqitywa yinkqubo yokuvelisa kunye nomgangatho wecandelo. Umzila kaloliwe ukuya kunyamezelo oluphezulu ngokuqhelekileyo unika ukuchaneka okungcono kunezo zenziwe ngoomatshini ngokulula. Uhlobo lweebheringi ezisetyenzisiweyo nalo ludlala indima ebalulekileyo; iibheringi zebhola kunye neebheringi ezinqamlezileyo zibonelela ngokuchaneka okuphezulu ngokunciphisa ukungqubuzana kunye nokugcina uqhagamshelwano oluhambelanayo nomzila.

Ukuchaneka kuphenjelelwa yinkqubo yokuqhuba. Iinjini zomgca kunye nezikrufu zebhola lukhetho oluqhelekileyo lwezicelo ezichaneke kakhulu. Izikrufu zebhola, ngakumbi, zibonelela ngokuphinda-phinda okugqwesileyo kunye nokubuyela umva okuncinci, zizenza zilungele imisebenzi echanekileyo. Ukuchaneka kukaloliwe kubalwa ngokweeparamitha ezinjengokutenxa komgca wohambo kunye nokuchaneka kwendawo, edla ngokuchazwa ngumenzi.

Ukufaneleka kokusingqongileyo

Ubume bokusebenza buchaphazela kakhulu ukukhethwa kweereyili zesilayidi ezinemigca. Iindawo ezisingqongileyo ezifana namagumbi okucoca okanye amagumbi okufunxa zifuna iileyili eziyilelwe ukuhlangabezana nococeko olungqongqo kunye nemigangatho yolawulo longcoliseko. Iireyile ezihlanjululwe kwigumbi lokucoceka zenziwe ukuze kuqinisekiswe ukuveliswa kwamasuntswana amancinci kwaye zihlala zenziwe ngezinto ezingaphumiyo okanye zichithe amasuntswana.

Kwiindawo ezirhabaxa, njengalezo ezinothuli, ukungcola, okanye izinto ezidlayo, iireyile zifuna izinto ezikhuselayo. Indlela yokugquma okanye imivumbo ikhusela iileyili kwizinto ezingcolisayo, ngelixa izinto ezifana nentsimbi engatyiwayo okanye imiphezulu egqunywe ngokukodwa inika ukuxhathisa ukubola kunye nokuguga. Iireyili ezinama-wipers adibeneyo okanye i-scrapers zinceda ukugcina ukucoceka ngokususa i-debris ngexesha lokusebenza.

Ubushushu obugqithisileyo bukwachaphazela ukusebenza komzila wesilayidi sesilayidi. Iireyili ezisetyenziswe kwiindawo eziphezulu zokushisa kufuneka zigcine ingqibelelo yesakhiwo kunye nokusebenza ngaphandle kokwandiswa okubalulekileyo okanye ukucutha. Ngokwahlukileyo, izicelo kwiimeko ze-cryogenic zifuna izixhobo kunye nezithambiso ezisebenzayo kumaqondo obushushu aphantsi kakhulu.

Ukufakwa kunye nokugcinwa

Ukufakela ngokulula kunye nokugcinwa kolunye uqwalaselo olubalulekileyo xa ukhetha iileyili zesilayidi ezinomgca. Iintsimbi ezilula ukuzifaka zinokunciphisa kakhulu ixesha lokuphumla kunye neendleko zabasebenzi. Iimpawu ezinje ngemingxuma yokuxhoma esele igrunjiwe ngaphambili, iidowuli zolungelelwaniso, kunye noyilo lweemodyuli zenza kube lula ukufakwa ngokukhawuleza nokuchanekileyo. Ezinye iileyili ziyafumaneka kunye neendlela ezidibeneyo zokuqhuba, ukwenza lula inkqubo yokufakela.

Iimfuno zokugcina ziyahluka ngokuxhomekeke kuyilo lukaloliwe kunye namacandelo. Iireyili ezineebheringi zokuzithambisa okanye ukuyila okungenazo ukulungiswa kunciphisa isidingo sokuthanjiswa rhoqo kunye nohlengahlengiso. Oku kunenzuzo kwizicelo apho ukufikelela kumzila kaloliwe kulinganiselwe okanye amaxesha okulungisa kufuneka kwandiswe. Iireyile ezinamalungu anokutshintshwa ngokulula, njengeebheringi okanye ii-wipers, ziqinisekisa ukugcinwa ngokukhawuleza nangokufanelekileyo, ukunciphisa ixesha lokuphumla.

Ukugcinwa okufanelekileyo kubalulekile ekwandiseni ubomi kunye nokusebenza kweereyili zesilayidi ezihambelanayo. Ukuhlolwa rhoqo ukunxiba kunye nomonakalo, ukuthambisa ngokweengcebiso zomenzi, kunye nokugcina iireyile zicocekile kwaye zingenazo izinto ezingcolisayo ziindlela eziphambili. Ezinye iileyili eziphambili ziza zixhotyiswe ngeenzwa kunye neenkqubo zokubeka iliso ezibonelela ngengxelo yexesha langempela kwimeko kaloliwe, evumela ukugcinwa kwangaphambili kunye nokunciphisa umngcipheko wokungaphumeleli okungalindelekanga.

Iindleko kunye neXabiso

Iindleko zihlala zibalulekileyo ekukhetheni iileyili zesilayidi ezihambelanayo, kodwa kufuneka ziqwalaselwe kumxholo wexabiso elipheleleyo. Iireyili eziphezulu ezineempawu eziphambili kunye nezixhobo eziphezulu zinokuba neendleko eziphezulu zokuqala kodwa zihlala zibonelela ngokusebenza okungcono, ixesha elide lokuphila, kunye neemfuno zokugcinwa okuphantsi, okukhokelela kwixabiso eliphantsi lilonke lobunini.

Xa uvavanya iindleko, qwalasela iimfuno ezithile zesicelo. Umzekelo, uloliwe ochaneke kakhulu onomthwalo ophezulu unokuba yimfuneko kumatshini we-CNC kodwa ugqithise ubuninzi benkqubo yokuhambisa elula. Ukulinganisa iindleko kunye neenkcukacha eziyimfuneko ziqinisekisa ukuba uloliwe okhethiweyo ubonelela ngexabiso elifanelekileyo lesicelo.

Ukongezelela, ukufumaneka kwamalungu okutshintshwa kunye neenkonzo zenkxaso yomenzi kunokuchaphazela ixabiso elipheleleyo. Iireyili ezivela kubavelisi abahloniphekileyo zihlala ziza kunye neziqinisekiso ezibanzi, inkxaso yobugcisa, kunye neendawo ezifumanekayo ezifumanekayo, eziqinisekisa ukusonjululwa ngokukhawuleza kwemiba, ukunciphisa ixesha lokuphumla kunye neendleko ezongezelelweyo.

Iimpawu eziPhezulu kunye nezinto ezintsha kwii-Linear Slide Rails

Ukudityaniswa ne-Smart Technologies

Ukudityaniswa kobuchwepheshe bobuchule kwiziporo zesilayidi kutshintshe ishishini loomatshini. Iireyile zale mihla ziya zixhotyiswa ngakumbi ngeenzwa kunye nezakhono ze-IoT, zibonelela ngedatha yexesha langempela kwiimethrikhi zokusebenza njengomthwalo, isantya, ubushushu, kunye nokungcangcazela. Le datha ingasetyenziselwa ukulungiswa kwangaphambili, ukuvumela abaqhubi ukuba bajongane nemiba enokubakho ngaphambi kokuba baholele kwixesha lokuphumla.

Ngokomzekelo, i-sensor ezifakwe kumzila kaloliwe zinokubeka iliso kwi-bearing wear kwaye zinikeze izilumkiso xa ukugcinwa kuyadingeka. Le ndlela yokuqalisa ukusebenza yandisa ubomi bukaloliwe kwaye yongeza ukusebenza kakuhle xa iyonke. Ukongeza, iileyili ezinikwe i-IoT zinokudityaniswa kwiinkqubo ezinkulu ezizenzekelayo, ezivumela unxibelelwano olungenamthungo kunye nokulungelelaniswa namanye amacandelo.

Ukwenziwa ngokwezifiso kunye neModularity

Ukwenza ngokwezifiso kunye nokumodareyitha kubaluleke ngakumbi ekukhetheni iileyili zesilayidi ezinomgca. Abavelisi ngoku babonelela ngeenketho ezilungiselelwe iimfuno ezithile zesicelo, kubandakanya ubude obahlukeneyo, amandla omthwalo, izixhobo, kunye neendlela zokuqhuba. Oku bhetyebhetye kuqinisekisa ukuba umzila kaloliwe ulungiselelwe iimfuno ezithile, ukwandisa ukusebenza kunye nokusebenza kakuhle.

Uyilo lwemodyuli luvumela ukudityaniswa lula kunye nohlengahlengiso lwenkqubo kaloliwe. Oku kunenzuzo kwizicelo apho iimfuno zinokutshintsha ngokuhamba kwexesha, njengakummandla wophando kunye nophuhliso. Iintsimbi zemodyuli zinokwandiswa ngokulula, zifinyezwe, okanye ziphinde ziqwalaselwe ukuze zihambelane nemigaqo emitsha, zibonelela ngesisombululo esingabizi kakhulu nesiguquguqukayo.

Ukusebenza kwamandla

Ukusebenza kakuhle kwamandla yinkxalabo ekhulayo kumashishini oomatshini, kwaye iileyili zesilayidi ezihambelanayo azinjalo. Ukuqhubela phambili kwezixhobo kunye noyilo kukhokelele ekuphuhliseni iileyili ezifuna amandla amancinci ukuze zisebenze. Umzekelo, iireyili ezineebheringi ezisezantsi-zokhuhlane kunye neendlela zokuqhuba eziphuculweyo zinciphisa amandla afunekayo ukuhambisa inqwelo, okukhokelela ekusetyenzisweni okuphantsi kwamandla.

Ukongeza, ukusebenzisa imathiriyeli ekhaphukhaphu efana ne-aluminiyam okanye i-composites kunciphisa ubunzima benkqubo kaloliwe, okomeleza ngakumbi ukusebenza kakuhle kwamandla. Iireyile ezonga amandla zithoba iindleko zokusebenza kwaye zinegalelo kwiinzame zozinzo ngokunciphisa indawo yekhabhoni yomatshini.

Usetyenziso lweShishini lweSilayidi seSilayidi seMila

Imveliso kunye ne-Automation

Iireyile zesilayidi ezinomgca zidlala indima ebalulekileyo kwimveliso kunye ne-automation, ukubonelela ngentshukumo echanekileyo nethembekileyo yomgca kwiinkqubo ezahlukeneyo. Kwi-CNC machining, iileyili zesilayidi ezihambelanayo ziqinisekisa ukubekwa ngokuchanekileyo kwesixhobo sokusika, okwenza kube lula ukuveliswa kwamacandelo achanekileyo. Ngokufanayo, kwimigca yokuhlanganisa i-robotic, iileyili zesilayidi ezihambelanayo ziququzelela ukuhamba okugudileyo kunye nokuchanekileyo kweengalo zerobhothi, ukuphucula inkqubo yokuhlangana kunye nokuchaneka.

Izixhobo zokupakisha zixhomekeke kakhulu kumzila wesilayidi esinemigca kwimisebenzi efana nokuzalisa, ukutywina, kunye nokuleyibheli. Ukuchaneka okuphezulu kunye nokuphindaphinda kweereyili zesilayidi ezihambelanayo ziqinisekisa iinkqubo zokupakisha ezingaguqukiyo ezihlangabezana neenkcukacha ezifunekayo. Ukongeza, ukuqina kunye nomthamo womthwalo wemigca yesilayidi ehambelanayo ibenza bafaneleke ukuphatha iipakethi ezinzima kunye nezixhobo.

Izixhobo zonyango

Kwicandelo lezonyango, iileyili zesilayidi ezihambelanayo zisetyenziselwa izixhobo ezahlukeneyo kunye nezixhobo ezifuna ulawulo oluchanekileyo noluthembekileyo. Ngokomzekelo, kwizixhobo zokucinga ezifana ne-MRI kunye ne-CT scanners, iileyili zesilayidi ezihambelanayo ziqinisekisa ukunyakaza okugudileyo kunye nokuchanekileyo kwamacandelo emifanekiso, ukubonelela ngemifanekiso ephezulu yokuxilongwa. Ngokukwanjalo, kwiirobhothi zotyando, iileyili zesilayidi ezihambelanayo zenza kube lula ukulawula iingalo zerobhothi, ukomeleza ukuchaneka kunye nokhuseleko lweenkqubo zotyando.

Igumbi elicocekileyo elilinganisiweyo kunye neenguqu ezifakwe kwi-vacuum ye-linear slide rails zibaluleke kakhulu kwizicelo zonyango, apho ukulawula ukungcola kubaluleke kakhulu. Ezi ziporo ezikhethekileyo zenzelwe ukusebenza kwiindawo ezineemfuno ezingqongqo zococeko, ukuqinisekisa ukuba izixhobo zonyango kunye nezixhobo zihlangabezana nemigangatho eyimfuneko yokhuseleko lwesigulane.

I-Aerospace kunye noKhuselo

Imizi-mveliso ye-aerospace kunye neyokhuselo ifuna i-high-performance linear slide rails ezinokumelana neemeko ezinzima kunye nokubonelela ngokusebenza okuthembekileyo. Kwizicelo ze-aerospace, i-linear slide rails isetyenziselwa ukuveliswa kunye nokugcinwa kweenqwelo-moya, ukuqinisekisa ukulungelelaniswa okuchanekileyo kunye nokuhamba kwamacandelo. Umthamo ophezulu womthwalo kunye nokuqina kweereyile zesilayidi ezihambelanayo zibenza bafaneleke ukuphatha iindawo ezinzima kunye nezinzima ezisetyenziswa kwinqwelomoya.

Kwizicelo zokhuselo, iileyili zesilayidi ezihambelanayo zisetyenziswa kwizixhobo ezahlukeneyo kunye neenkqubo, ezinje ngeenkqubo zesikhokelo somjukujelwa, izixhobo zeradar, kunye neenqwelo zomkhosi. Ukukwazi ukusebenza kwiimeko ezinzima, kubandakanywa nokuvezwa kumaqondo obushushu agqithisileyo kunye nezinto ezidliwayo, zibalulekile kwezi zicelo. Ukongeza, ukuchaneka okuphezulu kunye nokuthembeka kweentsimbi zesilayidi ezihambelanayo ziqinisekisa ukuba izixhobo zokukhusela zisebenza ngokufanelekileyo kwaye zihlangabezana neemfuno ezingqongqo zeshishini.

isishwankathelo

Iireyile zesilayidi ezinomgca ziyinxalenye ebalulekileyo kumashishini ahlukeneyo, ukubonelela ngentshukumo echanekileyo nethembekileyo yomgca woluhlu olubanzi lwezicelo. Xa ukhetha iileyili zesilayidi ezinomgca, kubalulekile ukuqwalasela izinto ezifana nomthamo womthwalo, ukuchaneka kunye nokuchaneka, ukufaneleka kokusingqongileyo, ukufakela kunye nokugcinwa, kunye neendleko kunye nexabiso. Inkqubela phambili yetekhnoloji ikhokelele kuphuhliso lwezilayidi zesilayidi ezikrelekrele, ezinokwenziwa ngokwezifiso, kunye nezamandla eziphucula ukusebenza koomatshini kunye nokusebenza kakuhle. Ngoluhlu lwabo olubanzi lwezicelo, ukusuka kwimveliso kunye ne-automation ukuya kwizixhobo zonyango kunye ne-aerospace, iileyili zesilayidi ezihambelanayo ziqhubeka ziyinto ebalulekileyo kumashishini oomatshini.