Ngo-2025, imakethi yokusika intsimbi ifumana ukukhula okubonakalayo, okuqhutywa kukuqhubela phambili kwetekhnoloji kunye nokunyuka kweemfuno zemizi-mveliso. Eli nqaku linika uhlalutyo olunzulu lwemiba ebalulekileyo ekufuneka iqwalaselwe xa ukhetha isarha yentsimbi yokusika, inika ulwazi oluxabisekileyo kubathengi abaziingcali. Ngokugxila ekusebenzeni, ukuqina, kunye nokhuseleko, esi sikhokelo siya kunceda amashishini enze izigqibo zokuthenga ezinolwazi.

Isiqulatho:

-Metal Cutting Band wabona Overview Market

-Uhlalutyo olunzulu lwe-Metal Cutting Band Saw Market

-Izinto eziphambili xa ukhetha i-Metal Cutting Band Saw

-Ubuchwephesha obuphezulu kwi-Metal Cutting Band Saws

-IiNdlela zeMarike kunye neNjongo yexesha elizayo

-Iingcinga zokugqibela

I-Metal Cutting Band yabona umboniso weMarike

Imakethi yehlabathi yeMetal Cutting Band Saws ibone ukukhula okuzingileyo, okukhuthazwa kukunyuka kwemfuno kuwo wonke amacandelo oshishino. Imakethi ngo-2023 yayixabisa malunga ne-1.6 yeebhiliyoni zeedola kwaye kuqikelelwa ukuba iya kufikelela kwi-2.2 yeebhiliyoni zeedola ngo-2030, ikhula kwi-CAGR ye-5% ngexesha loqikelelo. Oku kukhula kuqhutywa ikakhulu kukusetyenziswa okwandisiweyo kweesarha zentsimbi yokusika kwimizi-mveliso yeemoto, ulwakhiwo kunye ne-aerospace.

Ngokwengingqi, imakethi yase-US ibixabisa i-USD 412.9 yezigidi ngo-2023, kunye ne-China kulindeleke ukuba ibonise i-CAGR eyomeleleyo ye-7.4%, ifikelele kwi-USD 472.9 yezigidi ngo-2030. Kummandla we-Asia-Pacific, imakethi ikulungele ukwandiswa okukhulu ngenxa yokukhula ngokukhawuleza kwemizi-mveliso kunye nophuhliso lweziseko ezingundoqo.

Amacandelo aphambili phakathi kwemarike abandakanya i-Speed Speed Steel (HSS) i-Band Saw Blades kunye ne-Carbide Tipped Band Saw Blades. Icandelo le-HSS kulindeleke ukuba lifike kwi-USD 1.2 yeebhiliyoni ngo-2030, likhula kwi-CAGR ye-5.3%, ngelixa icandelo leCarbide Tipped limiselwe ukukhula nge-4.5% CAGR. La macandelo agxininisa usetyenziso olwahlukeneyo kunye nenkqubela phambili yetekhnoloji eqhuba imfuno yeesarha zokusika intsimbi kwihlabathi jikelele.

Uhlalutyo olunzulu lwe-Metal Cutting Band Saw Market

Iimpawu zokuSebenza kunye noLwabelo lweMarike olutshintshayo

Imilinganiselo yokusebenza yeesarha zentsimbi yokusika ibalulekile ekumiseleni ukukhuphisana kwazo kwimarike. Iimpawu eziphambili zokusebenza ziquka isantya sokusika, ukuchaneka, ukuqina, kunye nobude be-blade. I-Speed Speed Speed Steel (i-HSS) ii-saw blades zebhendi zithandwa ngenxa yokulinganisela kokuqina kunye nokusebenza kakuhle kokusika, okwenza ukuba zilungele uluhlu lwezicelo ukusuka ekusikeni kwesinyithi ngokubanzi ukuya kwimisebenzi ekhethekileyo ngakumbi. I-Carbide Tipped band saw blades inikezela ukusebenza okuphezulu ekusikeni izinto ezinzima, ukubamba isabelo esibalulekileyo kumashishini afuna ukuchaneka okuphezulu.

Amandla esabelo semakethi atyhila indawo ekhuphisanayo kunye nabadlali ababalaseleyo abanje nge-AMADA, WIKIS, kunye ne-LENOX ekhokela ukuthengisa. Ezi nkampani zinobukho obuluqilima bengingqi kunye nehlabathi jikelele, zisebenzisa iR&D ephucukileyo kunye nothungelwano olubanzi lokuhambisa. Ukwamkelwa okwandayo kwezisombululo zedijithali kunye ne-automation kwiinkqubo zokwenziwa kwemveliso kuphucula ngakumbi ukusebenza kakuhle kunye nesabelo sentengiso saba badlali baphambili.

Iimpembelelo zezoQoqosho kunye neeShifts zokuziphatha kwaBathengi

Imiba yezoqoqosho efana nokukhula kwemizi-mveliso, utyalo-mali kwiziseko ezingundoqo, kunye nenkqubela phambili kwitekhnoloji yokuvelisa inempembelelo enkulu kwimakethi yokusika intsimbi. Ukuchacha koqoqosho emva kobhubhane kukhokelele ekwandeni kwemisebenzi yokuvelisa, ukonyusa imfuno yezixhobo zokusika isinyithi. Ukongeza, ukutshintshela kwiindlela ezizinzileyo nezisebenzayo zokwenziwa kwemveliso kukhuthaza abathengi ukuba batyale imali kwiisarha zebhendi ezisebenza kakuhle ezibonelela ngokusebenza kakuhle kwamandla kunye nokunciphisa inkcitho yezinto eziphathekayo.

Indlela yokuziphatha yabathengi nayo iyavela, ngokukhula kokukhetha amajelo okuthenga kwi-intanethi. Uncedo lwamaqonga e-intanethi, kunye nokufumaneka kwengcaciso yemveliso eneenkcukacha kunye nophononongo lwabathengi, kuqhuba utshintsho kumajelo aqhelekileyo angaxhunyiwe kwi-intanethi. Lo mkhwa kulindeleke ukuba uqhubeke, kunye neeplatifti ze-e-commerce zidlala indima ebalulekileyo kwisicwangciso sokusasaza abavelisi beesaha zentsimbi.

Utshintsho lwakutsha nje kunye neMveliso yeLifecycle Stages

Izinto ezintsha zamva nje kwibhendi yokusika isinyithi yabona intengiso igxile ekuphuculeni ukuchaneka kokusika, ukuqina kweblade, kunye nokusebenza kakuhle. Izinto ezintsha ezinje ngejiyometri yamazinyo ephucukileyo, uyilo oluguquguqukayo lwepitch, kunye nokuphuculwa kweencakuba zokugquma zinegalelo ekusebenzeni okuphuculweyo. Ngaphaya koko, ukudityaniswa kwetekhnoloji ye-IoT kunye ne-AI kumatshini weesaha zebhendi iguqula intengiso ngokwenza ugcino oluqikelelweyo kunye nokujongwa kwexesha lokwenyani lokusebenza.

Umjikelo wobomi bemveliso kwimakethi yokusika intsimbi ibandakanya amanqanaba okwazisa, ukukhula, ukukhula, kunye nokwehla. Okwangoku, imakethi ikwinqanaba lokukhula, ephawulwa kukwanda kokwamkelwa kwemveliso, ukuqhubela phambili kwetekhnoloji, kunye nokwandisa usetyenziso kumashishini ahlukeneyo. Iinzame eziqhubekayo ze-R&D kunye nokwaziswa kweemveliso ezintsha, ezisebenza ngokufanelekileyo kulindeleke ukuba zigcine le ntshukumo yokukhula kwiminyaka ezayo.

Izinto eziphambili xa ukhetha i-Metal Cutting Band Saw

Ubungakanani beBlade kunye noHlobo

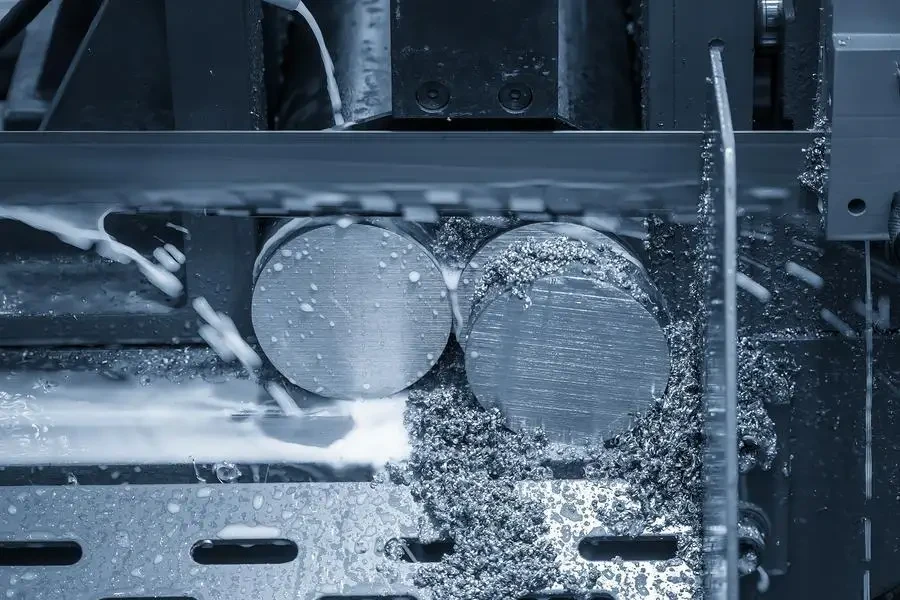

Ubungakanani be-Blade kunye nohlobo luchaphazela kakhulu ukusebenza kwe-metal cutting band saw. Ubungakanani beblade, obulinganiswa ngee-intshi, bumisela ububanzi kunye nobukhulu bezinto ezinokuthi zisikwe isarha. Iisayizi ezinkulu zeblade zivumela ukusika izinto ezityebileyo nezibanzi, eziyimfuneko kwizicelo zamashishini. Ngokomzekelo, ii-blades ukusuka kwi-1/2 intshi ukuya kwi-intshi e-1 ububanzi ziqhele ukusetyenziselwa imisebenzi enzima, ukubonelela ukuzinza okukhulu kunye nokuchaneka.

Uhlobo lwe-blade tooth ludlala indima ebalulekileyo. Iiblade ezinenani eliphezulu lamazinyo nge-intshi nganye (TPI) zilungele ukusika amacwecwe esinyithi acekethekileyo, njengoko zibonelela ngokusikeka okugudileyo kunye nokunciphisa inkcitho yezinto eziphathekayo. Ngokuchaseneyo, iiblade ezine-TPI ezimbalwa zifaneleke ngcono iziqwenga zetsimbi ezityebileyo, ezinikezela ngesantya esikhawulezayo sokusika kunye nokunxitywa kweblade. Iiblayidi ezikhethekileyo, ezinje nge-bi-metal kunye ne-carbide-tipped blades, ziyilelwe ukusika izinto ezithile ezifana nentsimbi engatyiwa kunye ne-titanium, eyomeleza ukuqina kunye nokusika ukusebenza kakuhle.

Amandla eMotor kunye nesantya

Amandla emoto kunye nesantya simisela isarha yentsimbi yokusika amandla kunye nokusebenza kakuhle. Amandla eMotor, alinganiswe ngamandla ehashe (HP), aphembelela ngokuthe ngqo ukukwazi kwesarha ukusika iintlobo ngeentlobo zesinyithi kunye nobukhulu. Ukusetyenziswa kwemizi-mveliso, ii-saws zebhendi ezinamandla emoto ukusuka kwi-1.5 HP ukuya kwi-3 HP zikhethwayo, zibonelela nge-torque efunekayo kwimisebenzi yokusika enzima.

Isantya sokusika, esilinganiswa ngeenyawo ngomzuzu (FPM), yenye into ebalulekileyo. Iisaha zebhendi eziguquguqukayo zibonelela ngokuguquguquka ukuhlengahlengisa isantya sokusika ngokusekelwe kwizinto ezisikwayo. Umzekelo, izantya ezisezantsi (malunga ne-100 FPM) zifanelekile ukusika isinyithi esiqinileyo njengensimbi engenasici, ngelixa isantya esiphezulu (ukuya kwi-300 FPM) sifanelekile kwiintsimbi ezithambileyo njenge-aluminium. Iimodeli ezikwinqanaba eliphezulu zibonisa ulawulo lwesantya sedijithali, ukuvumela uhlengahlengiso oluchanekileyo kunye nokuphucula ukusebenza kokusika.

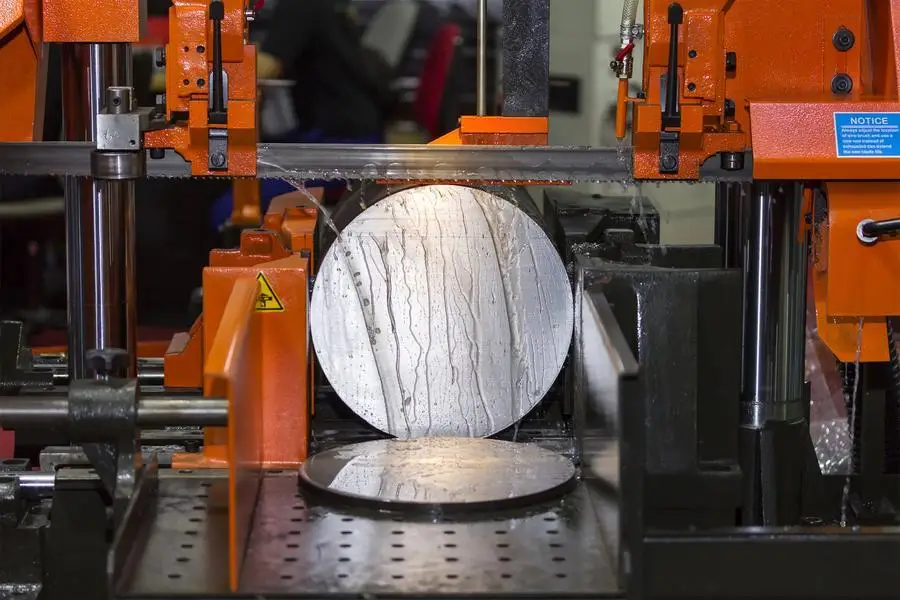

Ukusika Umthamo kunye nobunzulu boMqala

Ukusika umthamo kunye nobunzulu bomqala bumisela ubungakanani obukhulu bezinto ezinokunqunyulwa. Umthamo wokusika ubhekisela kububanzi obuninzi kunye nobude bezinto eziphathekayo ezinokusingatha. Iibhendi zebhendi ezinamakhono amakhulu okusika zifanelekile kwizicelo zoshishino, apho ukusika iziqwenga ezinkulu zetsimbi kuyimfuno eqhelekileyo. Umzekelo, isarha yebhendi ekwaziyo ukusika i-intshi ezili-12 nge-intshi ezili-18 inokuphatha ngokufanelekileyo iintsimbi ezinkulu.

Ubunzulu bomqala, umgama phakathi kwencakuba kunye nesakhelo esithe nkqo sesarha, yenye ingqwalasela ebalulekileyo. Ubunzulu bomqala omkhulu buvumela ukusika izinto ezibanzi ngaphandle kokubeka ngokutsha, ukuphucula ukusebenza kunye nokuchaneka. Iisarha zebhendi ezinobunzulu bomqala ukusuka kwi-intshi ezi-9 ukuya kwi-intshi ezili-14 ziqhele ukusetyenziswa kumashishini esinyithi, zibonelela ngesithuba esaneleyo semisebenzi eyahlukeneyo yokusika.

Yakha umgangatho kunye nokuqina

Umgangatho wokwakha kunye nokuqina kwe-metal cutting band saw yeyona nto ibalulekileyo ekuqinisekiseni ukusebenza kwexesha elide kunye nokuthembeka. Iisaha zebhendi ezikumgangatho ophezulu zakhiwe kusetyenziswa izinto eziqinileyo ezifana nentsimbi kunye nentsimbi, ezibonelela ngokuthembeka kwesakhiwo kunye nokuchasana nokunxiba kunye nokukrazula. Isakhelo kunye netafile yesarha kufuneka ibe ngqongqo kwaye izinzile, inciphise ukungcangcazela kunye nokuqinisekisa ukusikwa okuchanekileyo.

Ukuqina kwakhona kuphenjelelwa ngumgangatho wamacandelo, njengezikhokelo zeblade, iibheringi kunye neepuli. I-Premium band saws ibonisa izikhokelo ze-blade ezinzima ezenziwe ngentsimbi eqinile okanye i-carbide, enika inkxaso engcono ye-blade kunye nokuphila ixesha elide. Iibheringi ezitywiniweyo kunye neepulleys ezichanekileyo zifaka isandla ekusebenzeni kakuhle kunye nokunciphisa iimfuno zokugcina. Utyalo-mali kwisarha yebhendi enomgangatho wokwakha ophezulu kunye namacandelo ahlala ehlala iqinisekisa ukusebenza okungaguqukiyo kwaye yandisa ubomi bomatshini.

Iimpawu zoKhuseleko kunye neMigangatho

Ukhuseleko luqwalaselo olubalulekileyo xa ukhetha i-saw yentsimbi yokusika, ngakumbi kwiindawo zoshishino. Iisarha zanamhlanje zebhendi ziza zixhotyiswe ngeempawu ezahlukeneyo zokhuseleko ukukhusela abaqhubi kunye nokuthintela iingozi. Abalindi be-Blade bavala iindawo ezicacileyo ze-blade, ukunciphisa umngcipheko wokulimala koqhagamshelwano. Iindlela zokuvala ngokuzenzekelayo zimisa isarha xa i-blade iphuka okanye i-jam, ukukhusela umonakalo ongakumbi kunye nokuqinisekisa ukhuseleko lomsebenzisi.

Ukuthotyelwa kwemigangatho yokhuseleko kunye neziqinisekiso nako kubalulekile. Iisaha zebhendi ezihlangabezana nemigaqo ye-OSHA (uKhuseleko loMsebenzi kunye noLawulo lwezeMpilo) kwaye ziqinisekiswa yimibutho efana ne-UL (Underwriters Laboratories) okanye i-CE (Conformité Européene) inika isiqinisekiso sokhuseleko kunye nomgangatho. Ukongeza, izinto ezinje ngamaqhosha okumisa unxunguphalo, izitshixo zokhuseleko, kunye nezixhobo zokunqanda ukukhaba ziphucula ukhuseleko lokusebenza kunye nokunciphisa umngcipheko weengozi.

Ubuchwephesha obukwinqanaba eliphezulu kwiisarha ze-Metal Cutting Band

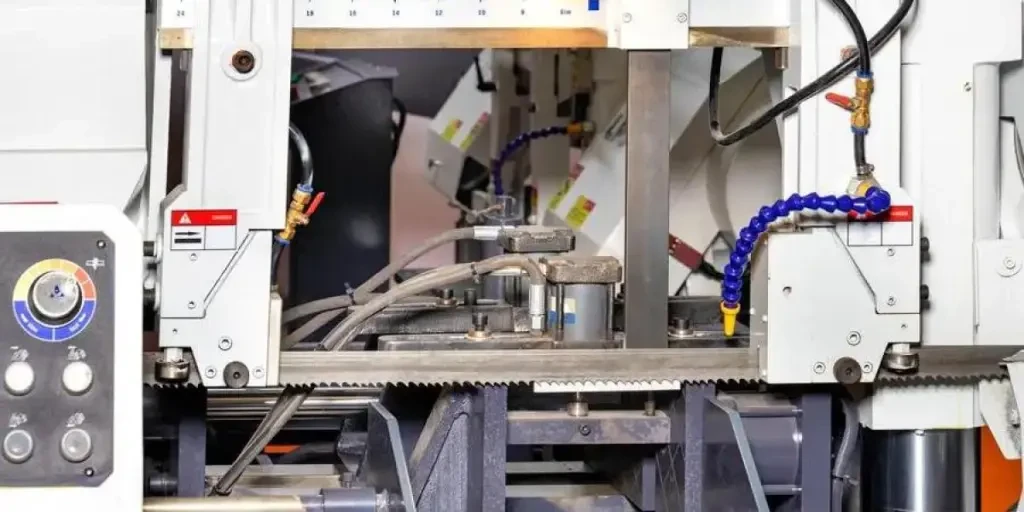

Iisarha zentsimbi yokusika zibone inkqubela phambili yetekhnoloji, ephucula ukusebenza kwazo, ukuchaneka, kunye nokulula kokusetyenziswa. Iisaha zebhendi zanamhlanje zixhotyiswe ngolawulo lwedijithali kunye neempawu ezizenzekelayo, ezivumela uhlengahlengiso oluchanekileyo kunye neziphumo zokusika ezingaguqukiyo. I-CNC (i-Computer Numerical Control) ii-saws zebhendi yenza imisebenzi yokusika ngokuzenzekelayo, ukunciphisa ukungenelela ngesandla kunye nokuphucula ukusebenza kakuhle.

Enye intuthuko ephawulekayo kukudityaniswa kwe-smart sensors kunye neenkqubo zokubeka iliso. Ezi nkqubo zibonelela ngengxelo yexesha langempela kwiiparameters ezifana noxinzelelo lwe-blade, isantya sokusika, kunye nomthwalo wemoto, okuvumela abaqhubi ukuba benze uhlengahlengiso olunolwazi kunye nokwandisa ukusebenza kokusika. Ezinye iimodeli eziphambili zikwabonisa ubunakho bokuqikelela ugcino, ilumkisa abasebenzisi ngemiba enokubakho ngaphambi kokuba ikhokelele kwixesha lokuphumla.

Ukusebenza kwamandla ngenye indawo apho iteknoloji yenze impembelelo enkulu. Iimotor ezisebenza kakuhle kakhulu kunye ne-variable frequency drives (VFDs) zinciphisa ukusetyenziswa kwamandla kunye nokuphucula ukusebenza kakuhle kwamandla. Ukongeza, iinkqubo zokupholisa eziphambili kunye neendlela zokuthambisa zongeza ubomi beblade kunye nokusika ukusebenza, ukunciphisa iindleko zokusebenza kunye nefuthe lokusingqongileyo.

IiNdlela zeMarike kunye neNkalo yekamva

Imakethi yokusika ibhendi yentsimbi ilungele ukukhula ngokuthe chu, iqhutywa kukukhula kwemfuno evela kumashishini ahlukeneyo afana neenqwelomoya, i-aerospace, kunye nokwakha. Ukunyuka kwe-automation yemizi-mveliso kunye nokwamkelwa kweendlela zokwenziwa kobuchule kulindeleke ukuba ziqhubele phambili imfuno yeesaha zebhendi eziphambili ezinolawulo lwedijithali kunye neempawu ezizenzekelayo.

Uzinzo lukwayinto ephambili ekugxilwe kuyo, nabavelisi betyala imali kubuchwepheshe obulungele indalo kunye nemathiriyeli. Ukuphuhliswa kweesaha zebhendi ezisebenza ngamandla kunye nokusetyenziswa kwezinto ezinokuphinda zisetyenziswe kulwakhiwo lwazo zihambelane neenjongo zokuzinza kwihlabathi jikelele kunye neemfuno zolawulo.

Kwixesha elizayo, sinokulindela ukuqhubela phambili kwi-automation kunye nedijithali, kunye ne-AI (Artificial Intelligence) kunye ne-IoT (i-Intanethi yeZinto) edlala indima ebalulekileyo. Iisaha zebhendi ezinikwe amandla e-AI ezinesakhono sokusika esiguquguqukayo kunye neempawu zexesha lokwenyani zokuphucula imveliso kunye nokuchaneka. Iisaha zebhendi ezinikwe i-IoT ezinokubeka iliso okude kunye nobuchule bokulawula ziya kubonelela ngokuguquguquka okukhulu kunye nokusebenza kakuhle, ukuqhuba amaza okutsha okutsha kwimarike yeesaha zentsimbi.

Iingcinga Final

Ukukhetha i-saha yentsimbi echanekileyo yokusika ifuna ukuqwalaselwa ngononophelo kwizinto ezahlukeneyo, kubandakanya ubungakanani be-blade kunye nohlobo, amandla emoto kunye nesantya, amandla okusika, umgangatho wokwakha, kunye neempawu zokhuseleko. Itekhnoloji ephucukileyo kunye neendlela zentengiso zibumba ikamva leesarha zebhendi, zibonelela ngokusebenza okuphuculweyo, ukuchaneka, kunye nozinzo. Ngokuhlala enolwazi malunga nolu phuhliso, amashishini anokwenza izigqibo ezinolwazi kwaye atyale imali kwii-saws zebhendi ezihlangabezana neemfuno zabo ezithile kwaye ziqhube ukusebenza kakuhle.