Inkqubela phambili yakutsha nje kwi-automation iqhubele imarike ye-Ball Screw ukuba ibe kubude obutsha ngo-2025. Eli nqaku lijonga imiba ebalulekileyo yokukhetha isikrufu sebhola esifanelekileyo, iimpawu zoyilo lokugquma, iinkqubo zokuvelisa, kunye noqwalaselo lweendleko. Abathengi abaziingcali baya kufumana ulwazi oluxabisekileyo ukwenza izigqibo ezinolwazi, ukuqinisekisa ukusebenza kakuhle kunye nokuphila ixesha elide.

Isiqulatho:

-I-Global Precision Ball Screw Market: Umbono onzulu

-Izinto ezingundoqo ekufuneka ziqwalaselwe xa ukhetha isikruru sebhola

-Izinto eziPhambili kunye neTekhnoloji kwiZikrufu zeBhola

-Izicelo zezikrufu zeBhola koomatshini banamhlanje

-Ukugcinwa kunye noBude beBhola izikrufu

-Iingcinga zokugqibela

I-Global Precision Ball Screw Market: Ujongo olunzulu

Ubume bemivuzo

Imarike yebhola echanekileyo yehlabathi jikelele ikhule kakhulu, yafikelela kwi-1.6 yeebhiliyoni zeedola ngo-2023. Uqikelelo lubonisa ukwanda ukuya kwi-2.3 yeebhiliyoni zeedola ngo-2032, ngesantya sokukhula sonyaka esihlanganisiweyo (CAGR) se-4.1% ukusuka ku-2023 ukuya ku-2032. Izikrufu zebhola ezichanekileyo zibaluleke kakhulu kwiimoto, i-aerospace, i-electronics, kunye namacandelo ezempilo, ezixabiswa ngokuchaneka kwazo okuphezulu kunye nokusebenza kakuhle ekuguquleni ukunyakaza okujikelezayo kwintshukumo yomgca.

IAsia Pacific ibambe esona sabelo sikhulu semarike ngenxa yokukhula ngokukhawuleza kwemizi-mveliso kunye nokukhula koqoqosho kumazwe afana neTshayina, iJapan kunye neIndiya. Ukukhula kweshishini leemoto kulo mmandla kunye notyalo-mali kumandla ahlaziyekayo kunye neeprojekthi zeziseko ezingundoqo nazo zinegalelo kwimfuno ephezulu yezikrufu zebhola ezichanekileyo.

Uhlalutyo oluneenkcukacha lweMarike

Izikrufu zebhola ezichanekileyo ziyimfuneko kwizicelo ezifuna ulawulo lwentshukumo oluchanekileyo, olufana noomatshini be-CNC, iirobhothi, i-aerospace, kunye nezixhobo zonyango. Imarike yahlulahlulwe ngokwezikrufu zebhola ezichanekileyo kunye nezikrufu zebhola eziqengqelekayo. Izikrufu zebhola ezichanekileyo emhlabeni zilawula ngenxa yokuchaneka kwazo okuphezulu kunye nokuthembeka, okubaluleke kakhulu kwizicelo ezichanekileyo kwi-aerospace, ukukhusela kunye nokuveliswa kwe-semiconductor. Umkhwa obhekiselele kwiminiaturization kwizixhobo zonyango kunye ne-electronics iqhubela phambili ifuthe kwimfuno yezikrufu ezincinci, ezichanekileyo ezichanekileyo zebhola.

Ngokwesicelo, ishishini le-semiconductor libambe esona sabelo sikhulu semakethi. Intshukumo yoshishino ekudityanisweni kwe-3-dimensional (XNUMXD) kunye nobuchwepheshe bokupakisha obuphambili bufuna ulungelelwaniso oluchanekileyo kunye neenkqubo zokudityaniswa, ukwenza izikrufu zebhola ezichanekileyo zibe yimfuneko. Imfuno ye-elektroniki yabathengi, i-automotive electronics, kunye nezixhobo ze-IoT zikwaqhuba imfuno yeenkqubo zokuvelisa ezichanekileyo ezixhomekeke kwizikrufu zebhola ezichanekileyo.

Izinto ezintsha zamva nje ziquka uphuhliso lwezikrufu ezincinci zebhola zezixhobo ezincinci kunye nokudityaniswa kweempawu ezihlakaniphile zokuphucula ukusebenza kunye nokuthembeka. Olu phuculo lusabela kwimfuno yeshishini lokuphucula imveliso, ukunciphisa ixesha lokuphumla, kunye nomgangatho wemveliso obalaseleyo. Njengoko amashishini eqhubeka nokubeka phambili le miba, ukuthengisa izikrufu zebhola ezichanekileyo kulindeleke ukuba zikhule kakhulu.

Abaqhubi beMarike abaPhambili kunye neendlela

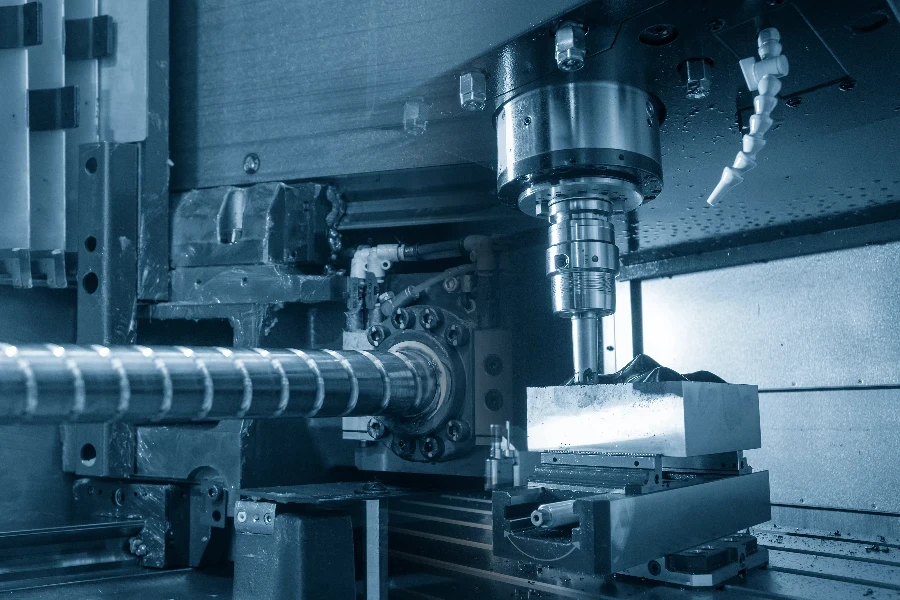

- Ukwandisa i-Automation kunye ne-Advanced Manufacturing Technologies: I-automation yeyona nto iphambili ekuqhubeni phambili ekukhuleni kwebhola echanekileyo. Izikrini zebhola ezichanekileyo zisetyenziswa kakhulu kwiinkqubo ezizenzekelayo, kubandakanywa oomatshini be-CNC, iirobhothi, kunye neenkqubo zokuzenzekelayo zoshishino, apho ukubekwa okuchanekileyo kunye nokulawula ukuhamba kubalulekile. Ukwamkelwa kobuchwephesha bokwenziwa kwemveliso, kubandakanya ukwenziwa okongeziweyo kunye nokuveliswa ngobuchule, kuqhubela phambili imfuno.

- Gxininisa ekuSebenzeni kwamandla kunye neNkqubo ye-Electromechanical: Ukutshintshela kwizisombululo ezonga amandla kukhuthaza amashishini ukuba atshintshe iisistim ze-hydraulic kunye ne-pneumatic eziqhelekileyo kunye ne-actuator yombane eqhutywa zizikrufu ezichanekileyo zebhola. Ezi nkqubo zibonelela ngobuchule obuphezulu, ukucuthwa kokusetyenziswa kwamandla, ukusebenza okuthe cwaka, kunye nokulungiswa okuphantsi, okuzenza zibe nomtsalane kwizicelo ezahlukeneyo, ngakumbi kumacandelo eemoto, i-aerospace, kunye noomatshini boshishino.

- UShishino oluKhawulezayo noPhuhliso lweZiseko zoPhuhliso: Uqoqosho olusahlumayo lufumana ushishino olukhawulezayo kunye nophuhliso lweziseko ezingundoqo, okukhokelela ekwandeni kotyalo-mali kwizixhobo zoomatshini kunye noomatshini boshishino. Izikrufu zebhola ezichanekileyo zibalulekile kwizicelo ezinje ngokusika isinyithi, ukugaya, kunye neenkqubo zokuhlanganisa, ziqhuba imfuno yazo kwimimandla efana neAsia Pacific. Ukukhula kwamashishini afana nombane, ukhathalelo lwempilo, kunye neempahla zabathengi kule mimandla nako kunegalelo ekwandeni kwentengiso.

Njengoko amashishini eqhubeka nokuphonononga itekhnoloji ye-cutting-edge kwaye efuna ukusebenza okuphezulu kwezixhobo, izikrufu zebhola ezichanekileyo ziya kuhlala zibalulekile ekuphumezeni umgangatho wemveliso ophuculweyo kunye nokugqwesa kokusebenza. Ikamva lemakethi lijongeka lithembisa, kunye nezinto ezintsha eziqhubekayo kunye nokugxila okukhulayo ekusebenziseni amandla kunye nokuzenzekelayo.

Imiba ephambili ekufuneka iqwalaselwe xa ukhetha isikruru sebhola

Impawu zoKwakha

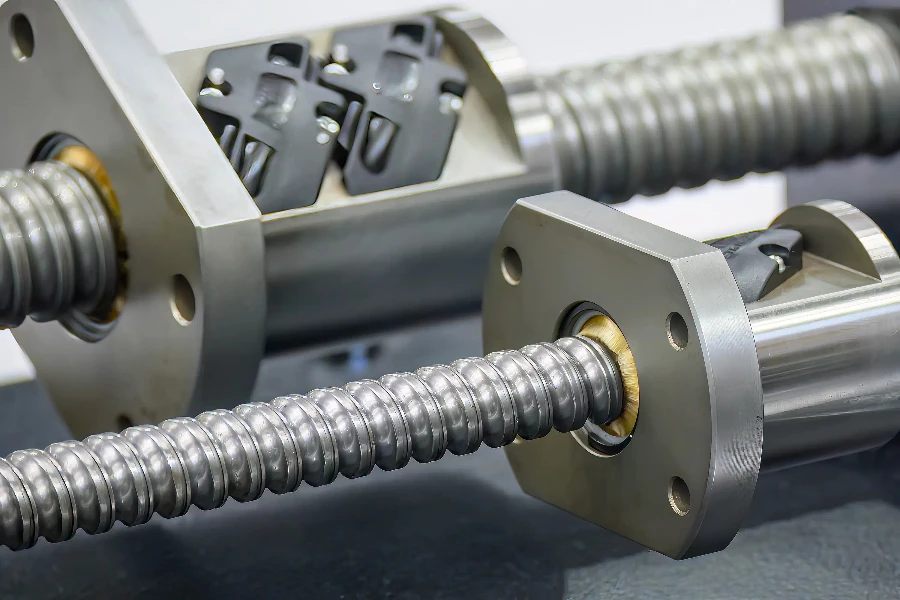

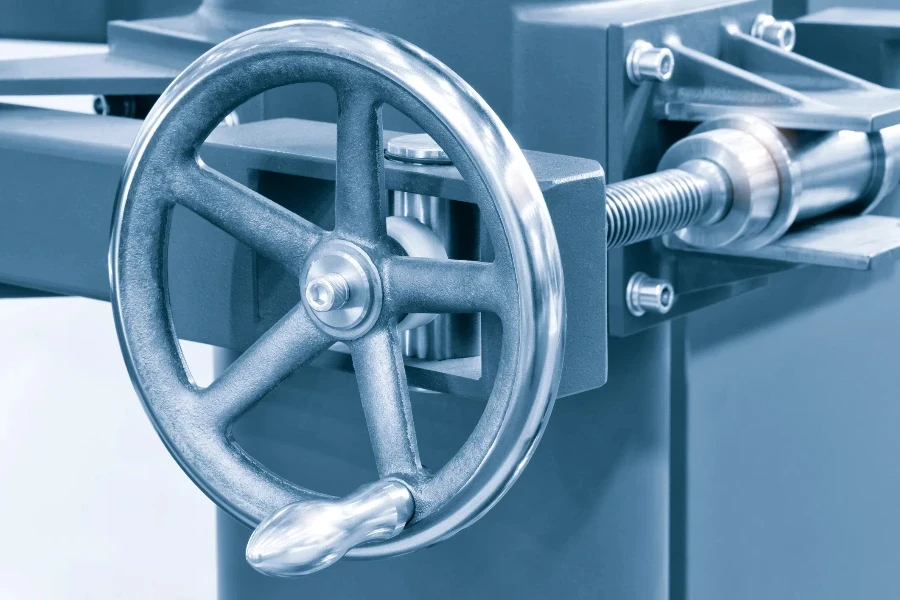

Xa ukhetha isikrufu sebhola, qwalasela iimpawu ezahlukeneyo zoyilo ezichaphazela ukusebenza kunye nokufaneleka. Olunye uphawu olubalulekileyo luyilo lwe-backlash oluyi-zero, olunciphisa intshukumo yasimahla ye-axial phakathi kwentongomane kunye nesikrufu, iphucula ukuqina kunye nokuchaneka. I-lubrication ye-screw eyiyo iqinisekisa ukusebenza kakuhle kunye nokuphila ixesha elide. Ukhetho phakathi kwentambo yesandla sasekunene kunye nesandla sasekhohlo sichaphazela ulwalathiso lwentshukumo kunye nokuhambelana kwenkqubo.

Amawele akhokelayo aluncedo kwizicelo ezifuna isindululo esiphindwe kabini esichasayo ngenkqubo enye yokuqhuba. Olu luyilo lubandakanya zombini intambo yesandla sasekhohlo kunye nesandla sasekunene, okwenza kube lula ukunyakaza. Impahla ye-nut, ngokuqhelekileyo iplastiki okanye i-bronze, inefuthe lokumelana nokunxiba kunye nokusebenza phantsi kwemithwalo eyahlukeneyo. Ukuqinisekisa ukuba ezi mpawu zoyilo zihambelana neemfuno zokusebenza kubalulekile ekusebenzeni ngokugqibeleleyo kunye nokuphila ixesha elide.

Inkqubo yokuThengisa

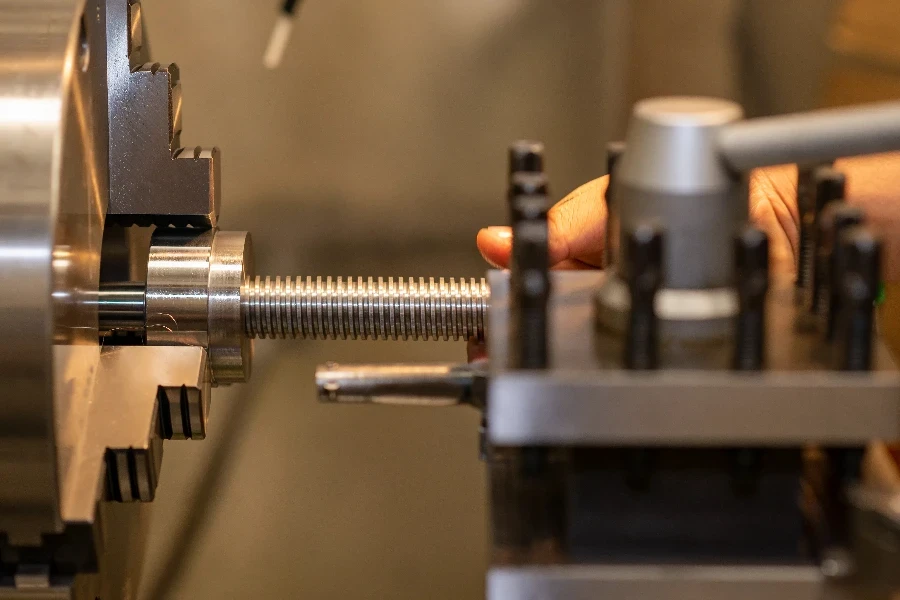

Inkqubo yokwenziwa kwezikrufu zebhola ichaphazela ukuchaneka kwazo, ukuqina, kunye neendleko. Kukho iinkqubo ezintathu eziphambili: ukuqengqeleka, ukugaywa, kunye nomhlaba. Izikrufu eziqengqelekayo, eziveliswe ngenkqubo yokuqengqeleka ebandayo, zinokuchaneka malunga ne-0.004 intshi ngenyawo kwaye zingabizi kakhulu kwizicelo jikelele. Izikrufu ezigayiweyo, ezenziwe kusetyenziswa umatshini wokungqusha kunye ne-Acme form cutter, zifezekisa ukuchaneka okuphezulu malunga nee-intshi ze-0.002 ngenyawo, zilungele izicelo ezifuna ukuchaneka okuphakathi.

Izikrini eziphantsi komhlaba, ezenziwe kusetyenziswa ivili lokugaya kunye nefom ye-Acme, zinikezela ngokuchaneka okuphezulu ngokuchaneka kwe-intshi ye-0.0005 ngeenyawo, ezifanelekileyo kwizicelo ezichanekileyo. Ukuqonda lo mahluko wokuvelisa kunceda ekukhetheni isikrufu sebhola esihlangabezana nokuchaneka okuthe ngqo kunye neemfuno zokusebenza, ukulinganisa iindleko kunye nokusebenza ngokufanelekileyo.

Ukucaciswa ngokomzimba

Iimpawu eziphambili zomzimba zimisela ukufaneleka kwesikrufu sebhola kwisicelo. Ubude be-screw kufuneka buhambelane nomgama wokuhamba ofunekayo. Idayamitha ye-screw yangaphandle ichaphazela umthamo wokuthwala umthwalo kunye nokuqina. Screw lead, umgama we-axial ohanjwayo sisikrufu ngexesha elinye, iphembelela isantya kunye nesisombululo sentshukumo yomgca.

Umlinganiselo womthwalo oguqukayo ubonisa umthwalo onokuthi ugcinwe ngelixa ushukuma, ngelixa umthamo omkhulu we-static uchaza umthwalo oxhaswayo xa umile. Ezi zilinganiso zomthwalo ziqinisekisa ukuba isikrufu sebhola sinokusingatha imithwalo elindelekileyo yokusebenza ngaphandle kokubeka esichengeni ukusebenza okanye ukhuseleko. Ukuqwalaselwa ngononophelo kwezi nkcukacha kunceda ukukhetha isikrufu sebhola esihlangabezana neemfuno zoomatshini nezokusebenza.

Imigangatho kunye nokuqinisekiswa

Ukuthotyelwa kwemigangatho yoshishino kunye neziqinisekiso kuqinisekisa umgangatho, ukusebenza, kunye nokhuseleko lwezikrufu zebhola. I-ISO 3408 iseka isigama kunye neenkcukacha zezikrufu zebhola, kubandakanywa ukutyunjwa kwazo kunye needayamitha eziqhelekileyo. I-BS 6101-2 isebenza kwi-recirculating ball screw assemblies ezenziwe ngentsimbi eqinile, eqinisekisa ukuqina kwizicelo ezifunayo. Ukubambelela kule migangatho kuqinisekisa ukuba izikrufu zebhola ziyahlangabezana nemilinganiselo engqongqo yobume bemizi-mveliso.

Izatifikethi ezivela kwimibutho ethembekileyo ziqinisekisa ukusebenza kwemveliso kunye nokhuseleko. Umzekelo, izikrufu zebhola ezisetyenziswa kwi-aerospace okanye izicelo zonyango zinokufuna izatifikethi ezongezelelweyo ukuhlangabezana neemfuno ezithile zolawulo. Ukuqinisekisa ukuthotyelwa kwemigangatho efanelekileyo kunye neziqinisekiso kwandisa ukuthembeka, kuququzelela ukuthotyelwa kwemithetho, kunye nokunciphisa ukungaphumeleli kokusebenza.

IiNdleko noHlahlo-lwabiwo-mali

Iindleko zichaphazela kakhulu uhlahlo lwabiwo-mali lweprojekthi. Ukhetho lwenkqubo yokuvelisa, izinto eziphathekayo, kunye neempawu zokuyila zichaphazela ixabiso le-screw yebhola. Izikrufu eziqengqelekayo zineendleko-zokusebenza kwiimfuno zokuchaneka okuphakathi, ngelixa izikrufu zomhlaba zibonelela ngokuchaneka okuphezulu kwixabiso leprimiyamu. Ukulungelelanisa imfuno yokuchaneka kunye nemiqobo yohlahlo lwabiwo-mali kubalulekile kukhetho olungenandleko.

Ukuqwalasela iindleko ezipheleleyo zobunini, kubandakanywa ukugcinwa kunye neendleko ezinokuthi zibe khona zokubuyisela, kubalulekile. Ukwenza utyalo-mali kwizikrufu eziphezulu zebhola ezinemathiriyeli ephezulu kunye neempawu zokuyila kunokubangela iindleko eziphantsi zogcino kunye nobomi benkonzo obude, ukubonelela ngexabiso elingcono lemali. Ukuvavanya iindleko kunye nokuqwalaselwa kohlahlo lwabiwo-mali ngokupheleleyo kunceda ukukhetha isikrufu sebhola esihlangabezana neemfuno zokusebenza kunye nezemali.

IiMathiriyeli eziPhezulu kunye nobuChwephesha kwiZikrufu zeBhola

Izinto eziphambili kunye nobuchwepheshe bonyuse ukusebenza kunye nokuqina kwezikrufu zebhola. Enye intuthuko kukusetyenziswa kweebheringi ze-ceramic hybrid, ezibandakanya amakhonkco entsimbi angaphakathi nangaphandle aneebhola ze-ceramic. Ezi bheringi zibonelela ngesantya esiphezulu kunye nokukwazi ukukhawulezisa, ukonyuka kokuqina, kunye nokunciphisa ukungqubana kunye nokuveliswa kobushushu. Izinto zeCeramic nazo zandisa ubomi bokusebenza kwezikhonkwane zebhola, zenza ukuba zilungele izicelo eziphezulu.

Ubuchwephesha obuphezulu bokugquma, obufana ne-titanium nitride (TiN) kunye ne-diamond-like carbon (DLC) iingubo, ziye zaphucula ukunxiba kunye nokumelana nokubola. Ezi zogquma zibonelela ngomphezulu onzima, ophantsi-ophantsi owandisa ubomi benkonzo kunye nokunciphisa iimfuno zokugcina. Ukudibanisa ezi zixhobo eziphambili kunye nobuchwepheshe buqinisekisa ukusebenza okuthembekileyo kwiindawo ezinzima kunye nezicelo ezifunayo.

Usetyenziso lwezikrufu zeBhola koomatshini banamhlanje

Izikrufu zebhola zidlala indima ebalulekileyo kwiinkqubo ezahlukeneyo zoomatshini bale mihla, zibonelela ngentshukumo echanekileyo yomgca kunye nomthamo ophezulu wokuthwala umthwalo. Kwishishini le-aerospace, izikrufu zebhola zisetyenziswa kwiinkqubo zokulawula inqwelomoya, ii-actuator zegiya zokumisa, kunye nezinye izinto ezibalulekileyo ezifuna ukuchaneka okuphezulu kunye nokuthembeka. Ubomi babo benkonzo eqikelelweyo kunye nezinga eliphantsi lokunxiba libenza balungele izicelo ezibaluleke kakhulu kukhuseleko.

Kwicandelo lezonyango, izikrufu zebhola ziqeshwe kwiirobhothi zotyando, izixhobo zokucinga, kunye neenkqubo zokuphatha isigulane. Ukuchaneka kwabo okuphezulu kunye nokunyakaza okugudileyo kwenza ulawulo oluchanekileyo kwizixhobo zonyango, ukuphucula ukusebenza kunye nokhuseleko lweenkqubo zonyango. Izinto eziphucukileyo ziqinisekisa ukuba izikrufu zebhola zinokumelana nococeko olungqongqo kunye neemfuno zokuvala inzala.

Izikrufu zebhola zikwasetyenziswa ngokubanzi kwimizi-mveliso, kuquka oomatshini be-CNC, izixhobo zokupakisha, kunye nemigca yendibano. Ukukwazi kwabo ukuguqula intshukumo ejikelezayo ukuya kwintshukumo ehambelana nokusebenza okuphezulu kunye nokuchaneka kubenza babaluleke kakhulu kwiinkqubo ezizenzekelayo. Ulawulo oluchanekileyo kunye noluthembekileyo lokunyakaza kunye nezikrufu zebhola luncedisa kwimveliso kunye nokusebenza kakuhle kweenkqubo zokuvelisa zanamhlanje.

ULondolozo kunye noBomi obude beZikrufu zeBhola

Ukugcinwa okufanelekileyo kubalulekile kubomi obude kunye nokusebenza ngokufanelekileyo kwezikrufu zebhola. Ukuthambisa rhoqo kunciphisa ukungqubana kunye nokugqoka, ukuthintela ukungaphumeleli kwangaphambi kwexesha. Ukukhethwa kwe-lubricant kunye ne-lubrication intervals kufuneka kusekelwe kwiimeko zokusebenza kunye neengcebiso zomenzi. Ukuhlolwa rhoqo kunye nokucoca izikrufu zebhola kunceda ukuchonga kunye nokujongana nemiba enokubakho ngaphambi kokuba inyuke.

Ukubeka iliso kwi-backlash kunye nokunxiba kubalulekile ekugcineni ukuchaneka kunye nokusebenza. Ukugqithiswa kwe-backlash kungabonakalisa ukuguga okanye umonakalo, kufuna ukulungiswa okanye ukutshintshwa kwecandelo. Ukuphumeza inkqubo yokukhusela yokukhusela ebandakanya ukuhlolwa rhoqo, ukuthambisa, kunye nohlengahlengiso kunokwandisa kakhulu ubomi benkonzo yezikrufu zebhola, ukuqinisekisa ukusebenza okuthembekileyo kunye nokunciphisa ixesha lokuphumla.

Iingcinga Final

Ukukhetha isikrufu sebhola esifanelekileyo kubandakanya ukuthathela ingqalelo izinto ezahlukeneyo, kubandakanywa iimpawu zoyilo, iinkqubo zokuvelisa, iinkcukacha zomzimba, imigangatho, kunye neendleko. Iimathiriyeli ezikwinqanaba eliphezulu kunye nobuchwepheshe bonyuse ngakumbi ukusebenza kwe-screw yebhola kunye nokuqina, okwenza ukuba zilungele uluhlu olubanzi lwezicelo. Ukugcinwa okufanelekileyo kubalulekile ekuqinisekiseni ixesha elide kunye nokuthembeka kwezikrufu zebhola, ezinegalelo ekusebenzeni kakuhle kunye nokuveliswa koomatshini banamhlanje.