Imarike yehlabathi yezixhobo zokwenziwa kwenyama, kubandakanywa nezilayi zenyama, yayixabisa i-USD 8.84 yezigidigidi ngo-2023, kwaye kuqikelelwa ukuba iya kukhula kwi-CAGR ye-10.29% ifikelele kwi-USD 17.55 yezigidigidi ngo-2030. Njengoko amashishini ejonge ukomeleza ukusebenza kakuhle kunye nokugcina imigangatho ephezulu yokhuseleko lokutya, ukukhetha isiceli senyama esifanelekileyo kubalulekile.

Isiqulatho:

– Indima yeMeat Slicers kuShishino

-IiNzuzo eziphambili zokuSebenzisa izilayidi zenyama

– Iindidi zeMeat Slicers ezikhoyo

-Iimpawu eziphambili ekufuneka uziqwalasele xa ukhetha i-Meat Slicer

-Ukuvavanywa kweNdleko kunye ne-ROI ye-Meat Slicers

–Iintsingiselo kwiTekhnoloji yeSicebi seNyama

-Ukwenza iSigqibo sokugqibela ngokuThenga iMeat Slicer yakho

Indima yeMeat Slicers kumashishini

Izisiki zenyama zizixhobo eziyimfuneko kwishishini lokutya, ngakumbi kumashishini abandakanyekayo ekusetyenzweni kwenyama kunye nokuthengisa. Baphucula ukusebenza kakuhle ngokuvumela ukunqunyulwa okuthe ngqo nokungatshintshiyo kweemveliso zenyama, okubalulekileyo ekugcineni umgangatho wemveliso kunye nokuhlangabezana nokulindelweyo kubathengi. Ngokwengxelo yeMarike yeZixhobo zokuxhela iGlobal, imarike yezixhobo zokwenziwa kwenyama, kubandakanywa nezilayi, yayixabisa i-USD 8.84 yezigidigidi ngo-2023 kwaye kuqikelelwa ukuba iya kukhula kwi-CAGR ye-10.29% ukuya kuthi ga kwi-17.55 yeebhiliyoni zeedola ngo-2030.

Ukusetyenziswa kwezisiki zenyama nako kunegalelo ekongeni kweendleko zabasebenzi. Izilayi ezizenzekelayo kunye ne-semi-automated zinciphisa imfuno yomsebenzi wezandla, ukuvumela amashishini ukuba abele izibonelelo ngokufanelekileyo. Ukudityaniswa kwe-automation kunye ne-robotics kwisixhobo sokwenza inyama, njengoko kugxininiswe kwingxelo, kuguqula ishishini ngokuphucula ukusebenza kakuhle kunye nokuchaneka. Lo mkhwa kulindeleke ukuba uqhubeke, kunye necandelo lezixhobo ze-semi-automated ekucingelwa ukuba lifikelele kwi-USD 6.1 yezigidigidi ngo-2030, likhula kwi-CAGR ye-3.9%.

Ngapha koko, abasiki benyama badlala indima ebalulekileyo ekuqinisekiseni ukhuseleko lokutya kunye nococeko. Ukunqunyulwa okuhambelanayo kunciphisa umngcipheko wokungcola kwaye kuqinisekisa ukuba iimveliso zenyama ziphathwa ngendlela ecocekileyo. Ugxininiso kukhuseleko lokutya kunye nococeko ngumqhubi ophambili wokukhula kwimarike yezixhobo zokuxhela, njengoko amashishini ezama ukuthobela imigangatho yolawulo engqongqo. Imakethi yase-US, umzekelo, yaqikelelwa kwi-USD 2.0 yeebhiliyoni ngo-2023, ebonisa imfuno ephezulu yezixhobo zokulungisa inyama kwimimandla enemithetho engqongqo yokhuseleko lokutya.

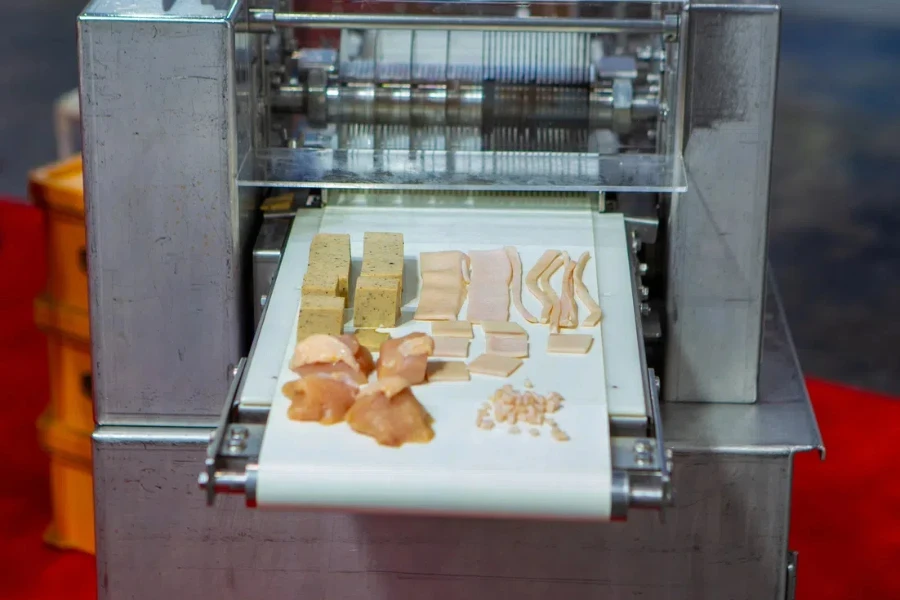

IiNzuzo eziphambili zokuSebenzisa iziqwenga zenyama

Enye yeenzuzo eziphambili zokusebenzisa i-slicers yenyama kukukwazi ukufezekisa iziqwenga ezifanayo, eziyimfuneko ekulungelelaniseni imveliso kunye nokwaneliseka kwabathengi. Ukunqunyulwa okufanayo kuqinisekisa ukuba iqhekeza ngalinye lenyama linobukhulu obufanayo, nto leyo ibaluleke kakhulu kwiimveliso ezifana nenyama emnandi kunye ne-steaks. Oku kuhambelana akuphuculi nje ukubukeka kwembonakalo yemveliso kodwa kuqinisekisa nokuba ukupheka kunye nokusabalalisa incasa. Imarike yehlabathi yezixhobo zokulungisa inyama kunye neenkukhu, ezibandakanya izilayi, kulindeleke ukuba zikhule kakhulu, ziqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu.

Enye inzuzo ebalulekileyo ye-slicers yenyama kukunciphisa ukuchithwa kwenyama. Ukusika ngesandla kudla ngokukhokelela ekusikekeni okungalinganiyo kunye nenkcitho ephezulu, ngelixa izisiki ezizenzekelayo zinokucwangciswa ukunciphisa inkunkuma ngokwenza amanxeba achanekileyo. Oku kusebenza kakuhle kuguqulela kugcino lweendleko kumashishini, njengoko anokwandisa isivuno kwisiqwenga ngasinye senyama. Ingxelo igxininisa ukuba ukwamkelwa kwezixhobo eziphambili zokulungisa inyama, kubandakanywa nezilayi, kuqhutywa yimfuneko yokunciphisa inkcitho kunye nokuphucula isivuno, ngokukodwa kwiindawo zokulungisa umthamo ophezulu.

Ukongeza, abasiki benyama baphucula ukusebenza kakuhle ngokukhawulezisa inkqubo yokusika. Ukunqunyulwa kwezandla kudla ixesha kwaye kufuna umsebenzi omkhulu, ngelixa izilayi ezizisebenzelayo zinokucubungula izixa ezikhulu zenyama ngokukhawuleza kunye nokungenelela okuncinci komntu. Oku kwanda kokusebenza ngokufanelekileyo kubalulekile kumashishini ajonge ukukhulisa imisebenzi yawo kunye nokuhlangabezana nemfuno ekhulayo. Ukudityaniswa kwe-IoT kunye nohlalutyo lwedatha kwizixhobo zokusebenza zenyama kwandisa ngakumbi ukusebenza ngokuvumela ukubeka iliso ngexesha langempela kunye nokuphucula inkqubo, ukunciphisa ixesha lokunciphisa kunye neendleko zokusebenza.

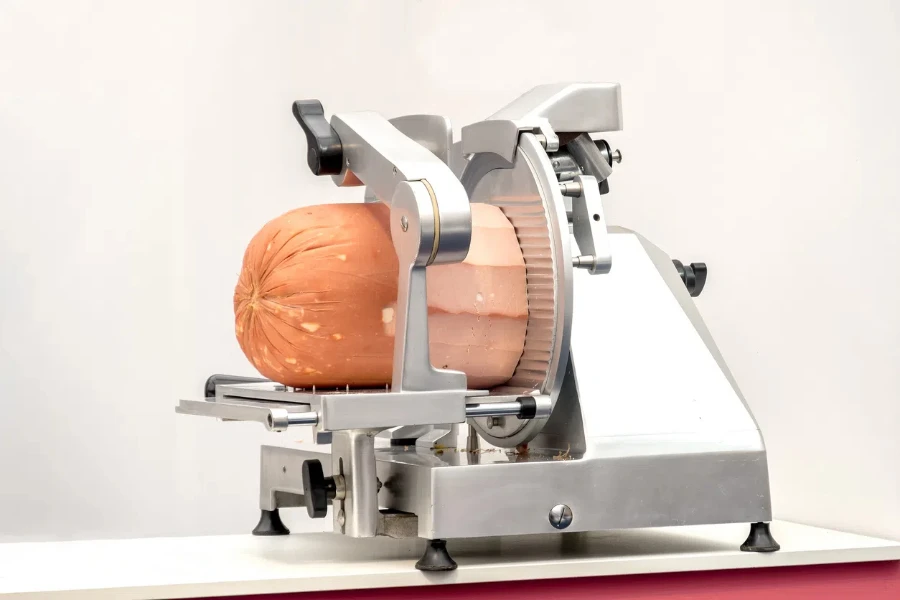

Iindidi zeMeat Slicers ezifumanekayo

Iziqwenga zeMeat Manual

Izisiki zenyama zezandla zolona hlobo lusisiseko lwezisiki, eziqhutywa ngokupheleleyo ngesandla. Ngokuqhelekileyo zisetyenziswa kwiindawo ezincinci apho umthamo wokulungiswa kwenyama uphantsi. Ezi zisiki zithandwa ngenxa yobulula bazo, ukusetyenziswa ngokulula, kunye neendleko eziphantsi xa kuthelekiswa neemodeli ezizenzekelayo. Ngaphandle komsebenzi wabo wezandla, basenokubonelela ngokusikeka okuchanekileyo, okubenza bafanelekele amashishini abeka phambili ulawulo oluzenzekelayo. Imarike yezicengce zenyama ihleli izinzile, ngakumbi kwimimandla apho ukucutshungulwa kwenyama kuxhaphakile.

Enye yeempawu eziphambili ze-manual slicers zenyama kukuhlala kwazo kunye neemfuno zokugcinwa okuphantsi. Ekubeni bengathembeli kumacandelo ombane, abancinci kakhulu kwiintsilelo zoomatshini kwaye banokugcinwa lula ngokucoca rhoqo kunye nokulola i-blade. Oku kubenza babe yinketho engabizi kakhulu kumashishini anohlahlo lwabiwo-mali olulinganiselwe. Ingxelo ibonisa ukuba ngelixa imarike itshintshela kwi-automation, kusekho imfuno ebalulekileyo yezixhobo zezandla kumacandelo athile oshishino lokulungisa inyama.

Nangona kunjalo, abasiki benyama bezandla banemida malunga nesantya kunye nokusebenza kakuhle. Bafuna umgudu obalulekileyo womzimba kunye nexesha lokusebenza, elinokuba ngumqobo kumashishini anemiqulu ephezulu yokusetyenzwa. Ngenxa yoko, amashishini amaninzi atshintshela kwi-semi-automated okanye i-automated slicers ngokupheleleyo ukunyusa imveliso. Umkhwa wehlabathi obhekiselele kwi-automation ekusetyenzweni kwenyama kulindeleke ukuba uqhubeke, kunye necandelo lezixhobo ezizenzekelayo ekucingelwa ukuba likhule kwi-CAGR ye-2.5% ngexesha lohlalutyo.

Iziqwenga zenyama ezizenzekelayo

Izilayi zenyama ezizenzekelayo ziyilelwe ukuphatha umthamo ophezulu wenyama kunye nokungenelela okuncinci komntu. Ezi zisiki zixhotyiswe ngeempawu eziphambili ezifana nesetingi enokucwangciswa, ukulolwa kwencakuba okuzenzekelayo, kunye neendlela zokhuseleko zokuqinisekisa ukusebenza ngokufanelekileyo nangokukhuselekileyo. Zilungele iindawo ezinkulu zokulungisa inyama ezifuna ukunqunyulwa okufanayo kunye nesantya esiphezulu. Ukwamkelwa kweziceli zenyama ezizenzekelayo kuqhutywa yimfuneko yokunyuswa kwemveliso kunye nokuchaneka kokulungiswa kwenyama.

Enye yeenzuzo eziphambili ze-autoslicers zenyama kukukwazi ukuvelisa izilayi zeyunifomu ngesantya esikhawuleza kakhulu xa kuthelekiswa nezilayi zezandla. Oku akuphuculi nje ukusebenza kakuhle kodwa kuqinisekisa ukuba iimveliso zenyama ziyahlangabezana nemigangatho yomgangatho ofunekayo. Le ngxelo igxininisa ukuba ukudityaniswa kwe-automation kunye ne-robotics kwisixhobo sokulungisa inyama kuguqula ishishini ngokuphucula ukusebenza kakuhle kunye nokuchaneka. Imakethi yezixhobo zokulungisa inyama ezenzekelayo kulindeleke ukuba ikhule kakhulu, iqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu.

Ukongeza kwisantya kunye nokuchaneka, izilayi zenyama ezizenzekelayo zikwabonelela ngeempawu zokhuseleko ezongeziweyo. Ezi zisiki zixhotyiswe ngeenzwa kunye nabalindi bokhuseleko ukukhusela iingozi kunye nokuqinisekisa ukusebenza ngokukhuselekileyo. Ugxininiso kukhuseleko ngumqhubi ophambili wohlumo kwimarike yezixhobo zokwenziwa kwenyama, njengoko amashishini ezama ukuthobela imigangatho yolawulo engqongqo. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kuqukwa nezisika ezizenzekelayo, kuqhutywa yimfuneko yokuqinisekisa ukhuseleko lokutya kunye nococeko kwiindawo zokulungisa inyama.

I-Semi-Automatic Meat Slicers

I-Semi-automatic meat slicers inikezela ngolungelelwaniso phakathi kokusebenza ngesandla kunye nokusebenza ngokuzenzekelayo, ukubonelela zombini ulawulo kunye nokusebenza kakuhle. Ezi zisiki zixhotyiswe ngeencakuba zemoto ezinciphisa umgudu womzimba ofunekayo wokusikwa, ngelixa zivumela umqhubi ukuba alawule inkqubo yokusika. Zilungele amashishini aphakathi afuna umthamo ophezulu wokucutshungulwa kwenyama kunokuba izilayi zezandla zinokuphathwa, kodwa azidingi i-automation epheleleyo yezilayi ezizenzekelayo. Imakethi ye-semi-automatic slicers kulindeleke ukuba ikhule, iqhutywa kukunyuka kwemfuno yezisombululo ezisebenzayo neziguquguqukayo zokwenziwa kwenyama.

Enye yezinto eziphambili ze-semi-automatic meat slicers kukuguquguquka kwazo. Zingasetyenziselwa uluhlu olubanzi lweemveliso zenyama, ukusuka kwi-deli meats ukuya kwi-steaks, kwaye zinokuhlengahlengiswa ngokulula ukufezekisa ubukhulu obufunwayo. Oku kuguquguquka kubenza babe lukhetho oludumileyo kumashishini aqhuba iintlobo ngeentlobo zeemveliso zenyama. Ingxelo ibonisa ukuba icandelo lezixhobo ezizenzekelayo kulindeleke ukuba lifikelele kwi-USD 6.1 yezigidigidi ngo-2030, likhula kwi-CAGR ye-3.9%, ebonisa imfuno ekhulayo yezisombululo eziguquguqukayo nezisebenzayo zokulungisa inyama.

Ukongeza kwizinto ezininzi, izisiki zenyama ezizenzekelayo zikwabonelela ngeempawu zokhuseleko ezomeleziweyo xa kuthelekiswa nezisiki zezandla. Baxhotyiswe ngoonogada bokhuseleko kunye neenzwa zokuthintela iingozi kunye nokuqinisekisa ukusebenza ngokukhuselekileyo. Ugxininiso kukhuseleko ngumqhubi ophambili wohlumo kwimarike yezixhobo zokwenziwa kwenyama, njengoko amashishini ezama ukuthobela imigangatho yolawulo engqongqo. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kuqukwa ne-semi-automatic slicers, kuqhutywa yimfuneko yokuqinisekisa ukhuseleko lokutya kunye nococeko kwiindawo zokulungisa inyama.

Iimpawu eziphambili zokuqwalasela xa ukhetha i-Meat Slicer

Ubungakanani beBlade kunye neMathiriyeli

Ubungakanani be-blade kunye nezinto eziphathekayo zizinto ezibalulekileyo ekufuneka ziqwalaselwe xa ukhetha isilayi senyama. Ubungakanani be-blade bumisela ubukhulu kunye nobukhulu beesilayi zenyama, kunye namaqabunga amakhulu afaneleka ukusika okuthe tye kunye namacangci amancinci kwiincinci ezincinci. Ubukhulu be-blade obuqhelekileyo buqala kwi-9 ukuya kwi-intshi ye-14, kunye ne-12-intshi iibhleyidi zithandwa kakhulu kusetyenziso lwezorhwebo. Izinto eziphathekayo ze-blade nazo zichaphazela ukuqina kwayo kunye nokusebenza kwayo, kunye nensimbi engenasici iyona nto ikhethiweyo ngenxa yokumelana nokubola kunye nokulula kokucoca.

Iintsimbi zensimbi ezingenasici ziyaziwa ngokuba bukhali kunye nokukwazi ukugcina umda, oyimfuneko ekufezekiseni ukusika okuchanekileyo. Kananjalo azifane zifane nomhlwa kunye nomhlwa, nto leyo ezenza ukuba zilungele ukusetyenziswa kwindawo zokwenziwa kwenyama apho ucoceko lubalulekile. Ingxelo ibonisa ukuba ugxininiso kukhuseleko lokutya kunye nococeko ngumqhubi ophambili wokukhula kwimarike yezixhobo zokwenziwa kwenyama, kunye namashishini anyukayo akhetha i-high-quality steel stainless blades ukuqinisekisa ukuthotyelwa kwemigangatho yokulawula.

Ukongeza kubukhulu kunye nezinto eziphathekayo, uyilo lwe-blade nalo ludlala indima ekusebenzeni kwayo. I-Serrated blades ikulungele ukusika inyama eqinile, ngelixa iiblades ezigudileyo zifaneleka ngcono kwinyama ethambileyo kunye neemveliso ezidliwayo. Ukukhethwa koyilo lwe-blade kuxhomekeke kuhlobo lwenyama ecutshungulwayo kunye nobukhulu obufunwayo bamacwecwe. Ingxelo ibonisa ukuba imakethi yezixhobo zokwenziwa kwenyama, kubandakanywa nezilayi, kulindeleke ukuba ikhule kakhulu, iqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu kunye nesidingo sezisombululo ezichanekileyo nezisebenzayo zokusika.

Amandla eMotor kunye nesantya

Amandla eemoto kunye nesantya yimiba ebalulekileyo emisela ukusebenza kakuhle kunye nokusebenza komceli wenyama. Amandla emoto, alinganiswa ngeewatts, achaphazela amandla omntu oqhekezayo ukuphatha iintlobo ezahlukeneyo zenyama kunye nomthamo wenyama enokuyiqhuba. Amandla emoto aphezulu avumela isilayi ukuba sinqumle inyama eyomeleleyo kwaye iphathe izixa ezikhulu, iyenze ilungele indawo yokusetyenzwa kwevolumu ephezulu. Umlinganiselo wamandla eemoto oqhelekileyo kubasiki benyama abarhwebayo usukela kuma-200 ukuya kuma-500 eewatts, kwaye umlinganiselo wamandla uphezulu okhethwayo xa usetyenziswa umsebenzi onzima.

Isantya se-slicer, esilinganiswe kwi-revolutions ngomzuzu (RPM), nayo ichaphazela ukusebenza kwayo kunye nokusebenza kwayo. Izantya eziphakamileyo zivumela ukunqunyulwa ngokukhawuleza, okuyimfuneko kumashishini afuna ukucubungula umthamo omkhulu wenyama ngokukhawuleza. Le ngxelo igxininisa ukuba ukudityaniswa kwe-automation kunye ne-robotics kwisixhobo sokulungisa inyama kuguqula ishishini ngokuphucula ukusebenza kakuhle kunye nokuchaneka. Imakethi yezixhobo zokulungisa inyama ezizenzekelayo, ezibandakanya izilayi ezinesantya esiphezulu, kulindeleke ukuba zikhule kakhulu, ziqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu.

Ukongeza kumandla eemoto kunye nesantya, uyilo lwe-slicer ikwachaphazela ukusebenza kwayo. Iziqwenga ezineesethingi zesantya ezilungelelanisiweyo zivumela umqhubi ukuba alawule inkqubo yokuqhawula kwaye afezekise ubuninzi obufunwayo kunye nokuhambelana. Oku kuguquguquka kubaluleke ngakumbi kumashishini aqhuba iintlobo ngeentlobo zeemveliso zenyama. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kuqukwa nezilayi zesantya esiphezulu, kuqhutywa yimfuneko yokuphucula imveliso kunye nokuhlangabezana nemfuno ekhulayo yeemveliso zenyama egayiweyo.

Iimpawu zoKhuseleko

Iimpawu zokhuseleko ziyingqwalasela ebalulekileyo xa ukhetha i-slicer yenyama, njengoko zinceda ukukhusela iingozi kunye nokuqinisekisa ukusebenza ngokukhuselekileyo. Iimpawu zokhuseleko eziqhelekileyo zibandakanya abalindi be-blade, utshintsho lokhuseleko, kunye neenyawo ezingatyibiliki. Abalindi beblade bakhusela umqhubi ekudibaneni ngengozi nencakuba, ngelixa iiswitshi zokhuseleko zithintela isilayi ukuba sisebenze xa i-blade guard ingekho. Iinyawo ezingabonakaliyo zibonelela ngokuzinza kwaye zithintele i-slicer ekuhambeni ngexesha lokusebenza, ukunciphisa umngcipheko weengozi.

Ukongeza kwezi zinto zisisiseko zokhuseleko, izilayi zenyama eziphucukileyo zixhotyiswe ngezixhobo zoluvo kunye neendlela zokuzivalela ngokuzenzekelayo ezonyusa ukhuseleko. Ezi mpawu zifumanisa naziphi na izitenxo kwinkqubo yokunqunqa kwaye zicime ngokuzenzekelayo isilayi ukunqanda iingozi. Le ngxelo iqaqambisa ukuba ugxininiso kukhuseleko ngoyena ndoqo wokukhula kwimarike yezixhobo zokwenziwa kwenyama, njengoko amashishini ezamela ukuthobela imigangatho yolawulo engqongqo. Ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kubandakanywa nezisiki ezineempawu zokhuseleko ezongeziweyo, kuqhutywa yimfuneko yokuqinisekisa ukhuseleko lokutya kunye nococeko kwiindawo zokulungisa inyama.

Ngaphezu koko, uqeqesho kunye nokusetyenziswa ngokufanelekileyo kubalulekile ukuqinisekisa ukusebenza ngokukhuselekileyo kwezisiki zenyama. Abanini-zithuthi kufuneka baqeqeshwe ngendlela yokusebenzisa isisiki ngokuchanekileyo kwaye balandele imigaqo yokhuseleko ukuthintela iingozi. Ukugcinwa rhoqo kunye nokucocwa kwe-slicer kukwanceda ukuqinisekisa ukusebenza kwayo ngokukhuselekileyo kunye nokwandisa ubomi bayo. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kubandakanywa nezisiki ezineempawu zokhuseleko ezomeleziweyo, kuqhutywa yimfuno yokuqinisekisa ukhuseleko lokutya kunye nococeko kwiindawo zokulungisa inyama.

UkuLula kokuCoca kunye noLondolozo

Ukulula ukucoca kunye nokugcinwa yinto ebalulekileyo ekufuneka uyiqwalasele xa ukhetha i-slicer yenyama, njengoko ichaphazela ukucoceka kwe-slicer kunye nokuphila ixesha elide. Izilayi zenyama kufuneka kube lula ukuzichitha kwaye zicoceke ukuthintela ukwakhiwa kweentsalela zenyama kunye neebhaktheriya. Amacandelo ensimbi engenasici akhethwa ngenxa yokuchasana nokubola kunye nokulula kokucoca. Ingxelo igxininisa ukuba ugxininiso kukhuseleko lokutya kunye nococeko ngumqhubi ophambili wokukhula kwimarike yezixhobo zokwenziwa kwenyama, kunye namashishini akhulayo akhetha izilayi ekulula ukuzicoca nokuzigcina.

Ukongeza kokucocwa lula, ukugcinwa rhoqo kubalulekile ukuze kuqinisekiswe ukusebenza kakuhle kwe-slicer kunye nobomi obude. Oku kubandakanya ukulola i-blade, ukuthambisa iindawo ezihambayo, kunye nokujonga nayiphi na into egugileyo kunye nokukrazula. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kuqukwa nezilayi, kuqhutywa yimfuneko yokuqinisekisa ukhuseleko lokutya kunye nococeko kwiindawo zokulungisa inyama. Amashishini kufuneka alandele izikhokelo zokugcinwa komenzi kwaye acwangcise uhlolo rhoqo ukuze agcine isisiki sikwimeko entle yokusebenza.

Ngaphezu koko, ezinye izilayi zenyama eziphambili zixhotyiswe ngezinto zokuzicoca kunye nokuzilola ezinciphisa imfuno yokucoca kunye nokugcinwa ngesandla. Ezi mpawu ziphucula ukusebenza kakuhle komceli kwaye zinciphise ixesha lokuphumla, zizenza zilungele iimeko zokusetyenzwa kwevolyum ephezulu. Le ngxelo igxininisa ukuba ukudityaniswa kwe-automation kunye ne-robotics kwisixhobo sokulungisa inyama kuguqula ishishini ngokuphucula ukusebenza kakuhle kunye nokuchaneka. Imakethi yezixhobo zokwenziwa kwenyama ezizisebenzelayo ngokupheleleyo, eziquka izilayi ezineempawu zokuzicoca kunye nokuzilola, kulindeleke ukuba zikhule kakhulu, ziqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu.

Ubungakanani kunye neemfuno zesithuba

Ubungakanani kunye neemfuno zesithuba somceli wenyama yingqwalasela ebalulekileyo, ngakumbi kumashishini anendawo encinci. Izisiki zenyama ziza ngobukhulu obahlukeneyo, ukusuka kwiimodeli ezihlangeneyo ezifanelekileyo kwiikhikhini ezincinci ukuya kwiimodeli ezinkulu ezilungiselelwe ukusetyenzwa kwevolumu ephezulu. Ubungakanani be-slicer kufuneka bukhethwe ngokusekelwe kwindawo ekhoyo kunye nomthamo wokulungiswa kwenyama efunekayo. Ingxelo ibonisa ukuba imarike yezixhobo zokulungisa inyama, kubandakanywa ne-slicers, kulindeleke ukuba ikhule kakhulu, iqhutywe yimfuno ekhulayo yeemveliso zenyama eziphezulu kunye nesidingo sezisombululo ezisebenzayo kunye nezonga indawo.

Ukongeza kubukhulu bomzimba, ubunzima be-slicer bukwayingqwalasela ebalulekileyo. Izilayi ezinobunzima ziqhele ukuzinza kwaye zomelele, kodwa kunokuba nzima ukuhamba kwaye zifuna indawo ezinikeleyo. Izilayi ezikhaphukhaphu ziyaphatheka ngakumbi kwaye zinokushukunyiswa lula, kodwa zisenokungazinzi kwaye zomelele. Ukukhethwa kwe-slicer kuxhomekeke kwiimfuno ezithile kunye nemiqobo yeshishini. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kubandakanywa nezisiki, kuqhutywa yimfuneko yokuphucula imveliso kunye nokuhlangabezana nemfuno ekhulayo yeemveliso zenyama egayiweyo.

Ngaphaya koko, ezinye izilayi zenyama eziphucukileyo ziyilwe zineempawu zokugcina indawo ezinje ngezinto ezisongekayo kunye noyilo oludityanisiweyo. Ezi mpawu zibenza balungele amashishini anendawo encinci kwaye ancede ukwandisa ukusetyenziswa kwendawo ekhoyo. Le ngxelo igxininisa ukuba ukudityaniswa kwe-automation kunye ne-robotics kwisixhobo sokulungisa inyama kuguqula ishishini ngokuphucula ukusebenza kakuhle kunye nokuchaneka. Imakethi yezixhobo zokulungisa inyama ezizenzekelayo, ezibandakanya izilayi ezigcina indawo, kulindeleke ukuba zikhule kakhulu, ziqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu.

Isidima seBrand kunye neWaranti

Udumo lwebrendi kunye newaranti yimiba ebalulekileyo ekufuneka iqwalaselwe xa ukhetha isisiki senyama, njengoko zibonelela ngengqiniseko yomgangatho kunye nokuthembeka kwalowo usika inyama. Iibrendi ezihloniphekileyo ziyaziwa ngeemveliso zazo ezikumgangatho ophezulu kunye nenkonzo egqwesileyo yabathengi, nto leyo ezenza zibe lolona khetho lukhethwayo kumashishini. Ingxelo ibonisa ukuba imarike yezixhobo zokulungisa inyama, kuquka i-slicers, kulindeleke ukuba ikhule kakhulu, iqhutywe kukunyuka kweemfuno zemveliso yenyama ephezulu kunye nesidingo sezixhobo ezithembekileyo nezizinzileyo.

Ukongeza kwigama le-brand, iwaranti enikezelwa ngumenzi nayo yinto ebalulekileyo yokuqwalaselwa. Iwaranti elungileyo ibonelela ngokhuseleko kwiziphene kwaye iqinisekisa ukuba isilayi sinokulungiswa okanye sitshintshwe xa singasebenzi kakuhle. Ubude kunye nokhuseleko lwewaranti iyahluka ngokomenzi, abanye banikezela ngeziqinisekiso ezongeziweyo zoxolo lwengqondo. Ingxelo ibonisa ukuba ukwamkelwa kwezixhobo eziphucukileyo zokwenziwa kwenyama, kuqukwa nezilayi, kuqhutywa yimfuneko yokuqinisekisa ukhuseleko lokutya kunye nococeko kwiindawo zokulungisa inyama. Amashishini kufuneka akhethe abasiki kwiibrendi ezithembekileyo ezinikezela ngewaranti ezibanzi ukuqinisekisa ukuthembeka komsiki kunye nokuphila ixesha elide.

Ngaphezu koko, ukuphononongwa kwabathengi kunye nobungqina bunokubonelela ngengqiqo ebalulekileyo ekusebenzeni kunye nokuthembeka kwe-slicer. Amashishini kufuneka aphande kwaye athelekise iibrendi ezahlukeneyo kunye neemodeli ukufumana esona sisiki sifanelekileyo esihlangabezana neemfuno kunye neemfuno zabo. Le ngxelo igxininisa ukuba ukudityaniswa kwe-automation kunye ne-robotics kwisixhobo sokulungisa inyama kuguqula ishishini ngokuphucula ukusebenza kakuhle kunye nokuchaneka. Imakethi yezixhobo zokulungisa inyama ezizenzekelayo, ezibandakanya abasiki abasuka kwiimpawu ezithembekileyo, kulindeleke ukuba zikhule kakhulu, ziqhutywa kukunyuka kwemfuno yeemveliso zenyama ezikumgangatho ophezulu.

Ukuvavanya iNdleko kunye ne-ROI ye-Meat Slicers

Iindleko zokuThenga zokuqala

Iindleko zokuqala zokuthengwa kweenyama zenyama zihluka kakhulu ngokusekelwe kuhlobo kunye neempawu zomatshini. Iimodeli zomgangatho wokungena wemisebenzi emincinci ingaqala malunga ne-500 yeedola, ngelixa i-slicer yentengiso ephezulu eneempawu eziphambili zinokudlula i-5,000 yeedola. Izinto eziphembelela iindleko ziquka ubungakanani beblade, amandla emoto, kunye nemisebenzi eyongezelelweyo efana nokusika okuzenzekelayo kunye neempawu zokhuseleko.

Xa uvavanya ixabiso lokuqala, kubalulekile ukuqwalasela iimfuno ezithile zomsebenzi wakho. Umzekelo, i-deli efuna ukunqunyulwa kwevolyum ephezulu iya kuxhamla kutyalo-mali kwi-slicing eyomeleleyo, enomthamo ophezulu. Ngokuchaseneyo, ivenkile ethengisa inyama encinci inokufumana imodeli yoluhlu oluphakathi olwaneleyo, ibhalansi yeendleko kunye neempawu eziyimfuneko.

Ukongeza, uphawu kunye newaranti enikezelwayo inokuchaphazela utyalo-mali lokuqala. Iimpawu ezihloniphekileyo zihlala zibonelela ngeewaranti ezinde kunye nenkxaso engcono yabathengi, enokuthi ithethelele iindleko eziphezulu zangaphambili. Kubalulekile ukuvavanya ezi zinto ukuze uqinisekise ukuba umceli uyahlangabezana neemfuno zakho zokusebenza kunye nemiqobo yohlahlo lwabiwo-mali.

Iindleko zokuSebenza kunye noLondolozo

Iindleko zokusebenza kwizisiki zenyama ziquka ukusetyenziswa kombane, ukulola iblade, kunye nokugcinwa kwesiqhelo. I-slicers ezinamandla aphezulu zisebenzisa umbane ongaphezulu, onokunyusa iindleko zokusebenza, ngakumbi kwiindawo ezisetyenziswa kakhulu. Ukulolwa kweencakuba rhoqo kuyimfuneko ukugcina ukusebenza kakuhle kwe-slicing kwaye kunokubiza phakathi kwe-$ 50 ukuya kwi-100 yeedola ngeseshoni.

Iindleko zogcino zikwaquka ukutshintshwa kwamalungu kunye nolungiso olunokubakho. Izinto ezinje ngamabhanti, iibheringi, kunye neenjini zinokufuna ukutshintshwa ngamaxesha athile, ngeendleko eziyohluka ngokusekwe kwimodeli yesilayi kunye nobunzulu bokusebenzisa. Umzekelo, isisiki sodidi lwentengiso olusetyenziswa ngokuqhubekayo kwideli exakekileyo uya kuba neendleko eziphezulu zogcino xa kuthelekiswa nomsiki osetyenziswa manqaphanqapha kwivenkile ethengisa inyama encinci.

Ukunciphisa ixesha lokuphumla kunye nokwandisa ubomi bomsiki, kuyacetyiswa ukuba ulandele ishedyuli yogcino lomenzi. Ukwenza utyalo-mali kwikhontrakthi yolondolozo kunokubonelela ngoxolo lwengqondo kwaye kunokuthoba iindleko zexesha elide ngokuqinisekisa isevisi ngexesha kunye nokutshintshwa kweengxenye.

Ukonga ixesha elide kunye nokusebenza kakuhle

Utyalo-mali kwi-slicer yenyama ekumgangatho ophezulu kunokukhokelela ekongeni kwexesha elide kunye nokusebenza kakuhle. Izisiki ezisebenzayo zinciphisa inkunkuma yemveliso ngokuqinisekisa ukutyeba okungaguquguqukiyo kwesilayi, okubalulekileyo kulawulo lwezahlulo kunye nolawulo lweendleko. Umzekelo, isilayi esinciphisa inkunkuma yenyama nge-1% kuphela inokugcina ishishini amawaka eedola ngonyaka.

Izisiki eziphucukileyo ezineempawu ezizisebenzelayo zisenokuphucula imveliso ngokunciphisa umsebenzi wezandla. Izilayi ezizisebenzelayo zinokuphatha imiqulu ephezulu ngolawulo oluncinci, ukuvumela abasebenzi ukuba bagxile kweminye imisebenzi, ngaloo ndlela bephucula ukuhamba komsebenzi ngokubanzi. Oku kusebenza kakuhle kuguqulela ukongiwa kweendleko zabasebenzi kunye nokwanda kwesiphumo.

Ngapha koko, izilayi zale mihla ezineemotor ezonga amandla kunye neempawu ezintle zinokuthoba usetyenziso lombane. Ngokuhamba kwexesha, olu londolozo lunokuhlawula iindleko zokuthenga zokuqala eziphezulu, nto leyo eyenza ibe lutyalo-mali olungabizi kakhulu. Ukuphonononga zonke iindleko zobunini, kubandakanywa ukonga okunokubakho, kubalulekile ekwenzeni isigqibo sokuthenga unolwazi.

IiNdlela zeTekhnoloji yeMeat Slicer

Izinto ezintsha kwiTekhnoloji yeBlade

Inkqubela phambili yamva nje kwitekhnoloji yeblade iphucule kakhulu ukusebenza kunye nobomi obude bezisiki zenyama. Iintsimbi zentsimbi eziphakamileyo ezinekhabhoni ezikumgangatho ophezulu ngoku zisemgangathweni, zinika ubukhali obuphezulu kunye nokuqina xa kuthelekiswa nentsimbi yesiko. Ezi blades zigcina umda wazo ixesha elide, zinciphisa ukuphindaphinda kokulola kunye nexesha lokuphumla elihambelanayo.

Iincakuba ezigqunywe ngeCeramic yenye into entsha, ebonelela ngokuxhathisa umhlwa kunye neempawu ezingabambekiyo. Oku kugquma kunciphisa ukukhuhlana ngexesha lokusikwa, okukhokelela ekusikeni okugudileyo kunye nokwakhiwa okuncinci kwentsalela. Ngokomzekelo, ii-ceramic-coated blades ziluncedo ngokukodwa kwiindawo apho ucoceko kunye nokulula kokucoca kubaluleke kakhulu.

Ukongeza, abanye abavelisi babandakanya iindlela zokuzilola kwizisiki zabo. Ezi nkqubo zilola ngokuzenzekelayo i-blade ngexesha lokusebenza, ziqinisekisa ukusebenza ngokulinganayo kunye nokwandisa ubomi be-blade. Olu phawu luluncedo ngakumbi kwiisetingi zomthamo ophezulu apho ukugcina ukusebenza kakuhle kwencopho kubalulekile.

Ukuqhubela phambili kwi-Automation kunye noKhuseleko

I-automation kwi-slicing yenyama iye yaliguqula ishishini, inikezela ngeempawu ezinjengokunqunyulwa okuzenzekelayo, ulawulo lwezahlulo, kunye noseto olucwangcisiweyo. Ezi nkqubela zinciphisa imfuno yongenelelo ngesandla, ukwandisa imveliso kunye nokuqinisekisa ukutyeba okufanayo kwesilayi. Umzekelo, izilayi ezizisebenzelayo zinokucwangciswa ukuba zivelise izilayi ezichanekileyo zeemveliso ezahlukeneyo, ukuqinisa ukungaguquguquki kunye nokwaneliseka kwabathengi.

Iimpawu zokhuseleko zikwabone ukuphucuka okubalulekileyo, kunye nezisiki zala maxesha ezibandakanya izixhobo zoluvo eziphucukileyo kunye noonogada bokhuseleko. Ezi mpawu zithintela ukulimala ngengozi ngokumisa ngokuzenzekelayo i-blade xa kufunyenwe imiqobo. Umzekelo, izisiki ezinezivamvo zokugada izandla ziqinisekisa ukuba umatshini uyayeka ukusebenza ukuba isandla somsebenzisi sisondela kakhulu kwincakuba.

Amaqhosha okumisa okungxamisekileyo kunye neenyawo ezingatyibiliki zizongezelelo ezongezelelweyo zokhuseleko ezibonelela abaqhubi ngokulawula okukhulu nokuzinza. Ezi mpawu zibalulekile kwiikhitshi ezixakekileyo zorhwebo apho ukhuseleko nokusebenza zizinto eziphambili ngokubaluleka. Utyalo-mali kwiisila ezineempawu zokhuseleko oluphezulu kunokunciphisa iingozi zasemsebenzini kunye neendleko ezinxulumene noko.

I-Smart kunye ne-IoT-Enabled Meat Slicers

Ukudityaniswa kwetekhnoloji ye-smart kunye ne-Intanethi yeZinto (IoT) kwizilayi zenyama yindlela evelayo ebonelela ngeenzuzo ezininzi. I-IoT-enabled slicers inokudibanisa kwinkqubo yokulawula ephakathi, ivumela ukubeka iliso ngexesha langempela kunye nohlalutyo lwedatha. Olu qhagamshelo luvumela abaqhubi ukuba balandele iipatheni zokusetyenziswa, iishedyuli zogcino, kunye neemetrics zokusebenza bekude.

Abasiki be-Smart banokubonelela ngezilumkiso zolondolozo oluqikelelweyo, ukwazisa abaqhubi ngemiba enokubakho ngaphambi kokuba bakhokele kwixesha lokuphumla. Umzekelo, abenzi boluvo banokubona ukuguga kweblade kwaye bathumele izilumkiso xa kulola okanye kufunwa ukutshintshwa. Le ndlela isebenzayo inciphisa ukonakaliswa okungalindelekanga kwaye yandise ubomi besixhobo.

Ngaphaya koko, ii-slicing ze-IoT-enabled-enabled zinokudibanisa kunye neenkqubo zolawulo lwe-inventri, ukwandisa amanqanaba esitokhwe ngokusekwe kumsebenzi wokusika. Oku kudityaniswa kuqinisekisa ukuba amashishini agcina amanqanaba aphezulu e-inventri, ukunciphisa inkcitho kunye nokuphucula ukusebenza kakuhle kweendleko. Njengoko itekhnoloji iqhubeka nokuvela, ukwamkelwa kwezisiki ezihlakaniphile kulindeleke ukuba kunyuke, kunikeze ulawulo oluphuculweyo lokusebenza kunye nokusebenza kakuhle.

Ukwenza iSigqibo sokugqibela ekuThengweni kwakho kweMeat Slicer

Xa usenza isigqibo sokugqibela ekuthengeni isixhobo sokusika inyama, kubalulekile ukuqwalasela iindleko zokuqala nezexesha elide. Vavanya iimpawu zesisiki, kubandakanya itekhnoloji yeblade, i-automation, kunye nezixhasi zokhuseleko, ukuqinisekisa ukuba iyahlangabezana neemfuno zakho zokusebenza. Ukongeza, qwalasela ukonga okunokubakho kunye neenzuzo ezisebenzayo kutyalo-mali oluphambili, izilayi ezinikwe i-IoT.