Iigranulator zeplastiki ngoomatshini abasetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki. Oku bakwenza ngokusika iiplastiki zibe ziiflakes okanye iiregrind ezithi kamva zisetyenziswe ukwenza iimveliso ezahlukeneyo. Zibonwa njenge zibalulekile ekuthinteleni ukungcoliseka kwendalo kuba zinciphisa ubungakanani beplastiki kokusingqongileyo. Esi sikhokelo sibonisa ukuba amashishini kufuneka ayazi malunga neegranulator zeplastiki.

Isiqulatho

Iigranulator zePlastiki: isabelo semarike kunye nemfuno

Iingcebiso eziBalulekileyo ekufuneka ziqwalaselwe xa kuthengwa igranulator yeplastiki

Iintlobo zegranulator zeplastiki

Imarike ekujoliswe kuyo kwiigranulator zeplastiki

Iigranulator zePlastiki: Isabelo semarike kunye nemfuno

Iigranulator zePlastiki zisetyenziselwa ukwenza ukuba iplastiki ekulahliweyo iphinde isetyenziswe xa kusenziwa iplastiki. Isabelo semarike yeegranulator zeplastiki yi-3.4 yeebhiliyoni zeedola. Imikhwa yangoku kwimarike yegranulator yeplastiki ibandakanya ukudibanisa ezinye izongezo ukunceda ukuthambisa okanye ukwenza lukhuni iplastiki, ngokuxhomekeke apho iya kuphinda isetyenziswe khona, kunye nokuxuba iigranules kunye nemathiriyeli enyulu kwiresin iyonke ukugcina umgangatho othile.

Iingcebiso ezibalulekileyo ekufuneka ziqwalaselwe xa kuthengwa igranulator yeplastiki

Ukufumana igranulator yeplastiki kuxhomekeke kwiingcebiso ezimbalwa ekufuneka umnini-shishini ngamnye aziqwalasele.

Ukujikeleza

Kukho iintlobo ezine zerotors ngokuxhomekeke kwinto eqhutyelwayo. Ivuliwe, ivaliwe / iqinile, igxadazile, kwaye yahlulahlulwe. I-rotor evulekileyo ifanelekile kwii-resin ezithintekayo ukushisa.

I-rotor evaliweyo ayinayo indawo phakathi kwemela kunye ne-shaft. Ngenxa yoko, ivumela ukunqunyulwa kwe-feedstocks eshinyeneyo. I-rotor edibeneyo ifanelekile ukusika kwizinto ezinzima, ngelixa i-rotor edibeneyo inqumla kwizinto ezinzima kwaye yandisa inani lokusikeka kwi-revolution nganye.

Uyilo lwemela

Iimela zifakwe kwibhedi emileyo okanye ngokuthe ngqo kwi-rotor. Isithuba phakathi kweemela siya kugqiba uhlobo lwegranule. Isithuba esincinci semela siya kubangela imathiriyeli ethambileyo, ngelixa isithuba esikhulu phakathi kweemela siphumela kwiigranule eziqinileyo.

nokugcinwa

Ukugcinwa okufanelekileyo kubalulekile kumatshini ukuvelisa i-granules ephezulu ixesha elide. Ukugcinwa kwakhona kuya kunciphisa uthuli kwiigranules. Njengoko iigranulators zingayilwanga kujongwa ulondolozo, ulondolozo lobungcali yinto ekufuneka amashishini ayithathele ingqalelo phambi kokuthenga.

Ukusetyenziswa okusetyenzisiweyo

Amashishini kufuneka ayazi indlela abaza kuyenza ngayo igranulator yeplastiki. Ezinye iigranulator zeplastiki zinomthamo we I-1000 kg / hr, ngelixa abanye banokuqhubeka I-3000 kg / hr. Indlela yegranulation nayo ibalulekile. Oomatshini banokusebenzisa nokuba yi-extrusion, Ukubetha ukubumba, ukubumba inaliti, okanye ukugaywa ngokutsha. Imveliso eyenziwayo yenye into eqwalaselwayo, nokuba ziibhotile okanye amashiti.

Iintlobo zegranulator zeplastiki

Kukho iintlobo ezininzi zeegranulator zeplastiki njengoko zidweliswe ngezantsi.

Ngaphandle-kwe-press-press granulator yeplastiki

Ngaphandle kweegranulator ze-press inokudibanisa kuyo nayiphi na into yokubumba okanye i-extrusion yokuqokelela i-resin.

Iimbonakalo:

- Iza kunye nokugquma kwesandi.

- Inamagumbi okusika apholile ngamanzi.

- Ibonisa izikrini zokujonga ukujonga ukucola njengoko kusenzeka.

eziluncedo:

- Inokuqwalaselwa ukusetyenziswa ngesandla okanye ngokuzenzekelayo.

- Ilungele imveliso emifutshane.

bendlela:

- Kubiza imali eninzi ukuyifumana nokuyilondoloza.

Thermoforming granulators

Ukunyanga umzimba iigranulators ziyilelwe ukusetyenzwa kwe-inline kunye ne-offline yezixhobo ezisicaba.

Iimbonakalo:

- Inodayi kunye nomphetho apho imathiriyeli ishukunyiswa kwaye iqhutywe.

- Izinto ezicandiweyo ke zibalwa ngeerola ngaphambi kokuba ziye kwigranulator.

eziluncedo:

- Ibonelela ngeegranule ezikumgangatho ophezulu.

bendlela:

- Inokwenza kuphela izinto ezisicaba.

Iigranulator ezidityanisiweyo

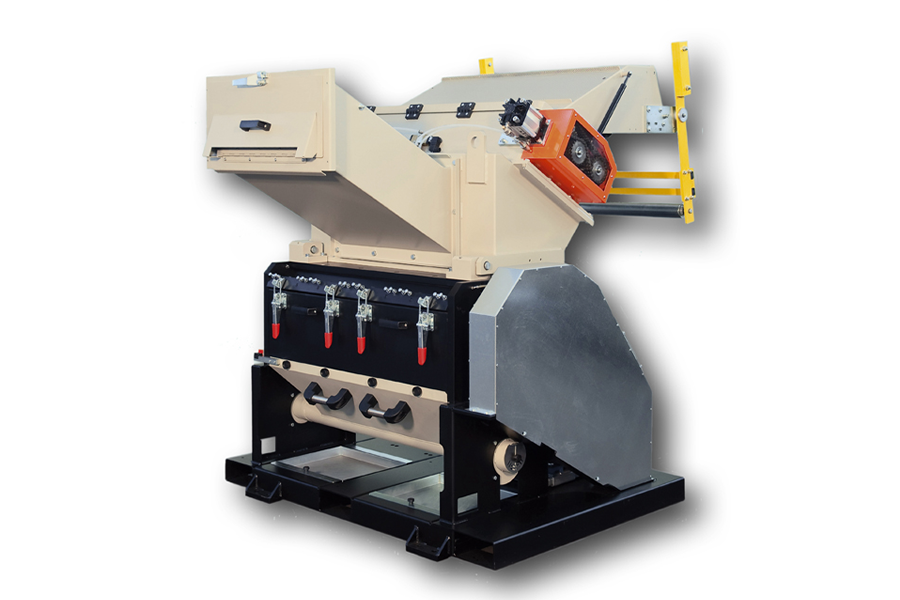

Iigranulator ezidityanisiweyo ube neshredder kunye negranulator kumatshini omnye.

Iimbonakalo:

- Izinto ezinzima, ezixineneyo ziqala zicutshungulwe kwi-shredder ngaphambi kokuba zisiwe kwigranulator.

- I-shredder ibonelela ngobungakanani bezinto eziphathekayo kunye nomthamo kwigranulator.

eziluncedo:

- Ibonelela ngeegranules ezikumgangatho ophezulu ngenxa yokulungiswa kwangaphambili.

- Inomgangatho ophezulu wokugqiba.

- Imagnethi inokudityaniswa kuyo ukuze yahlule imathiriyeli ye-ferrous kwiplastiki.

bendlela:

- Kuntsonkothe ngakumbi ngoomatshini ukusebenza.

Iigranulator eziphambili

Iigranulator eziphambili sebenza ngokomgaqo wokusikwa kwesikere esisikwe kabini.

Iimbonakalo:

- Inika i-tangential okanye i-offset geometries kwizinto zokusika.

- Igumbi lokusika linokucwangciswa ukusika iindawo ezinoxinano oluphezulu.

eziluncedo:

- Iyaguquguquka ukwenza iinxalenye ezinkulu nezincinci ezinomthamo.

- Iyasebenza kusetyenziso olususela kwiinxalenye zezixhobo ukuya kwiinaliti ezinkulu kunye nezixhobo zefenitshala.

- I-tangential offset inika amandla okwenza iintlobo ezininzi ze-scrap ngamandla aphantsi.

bendlela:

- Inokukhawuleza ivaleke xa ilayishwe ngokungalunganga.

- Kubiza imali eninzi ukuyifumana.

Imarike ekujoliswe kuyo kwiigranulator zeplastiki

Iigranulator zePlastiki kulindeleke ukuba zikhule kwi-CAGR ye 5.6% ngo 2027 ukuba $ 5.1 billion. Oku kukhula kubalelwa kwizinto ezininzi, kubandakanywa ukonyuka koshishino kwihlabathi liphela kunye nokunciphisa iindleko zemveliso ngenxa yokusetyenziswa kweegranules. Ummandla weAsia Pacific kulindeleke ukuba ulawule imakethi, ulandelwa nguMntla Merika.

isiphelo

Kweli xesha apho ungcoliseko lokusingqongileyo luxhaphakile, iigranulator zeplastiki zibaluleke kakhulu ekuhlaziyeni iiplastiki. Eli nqaku liqaqambisa izinto ezibalulekileyo ekufuneka zithathelwe ingqalelo kunye neentlobo zeegranulator zeplastiki ezikhoyo. Ke ngoko, kuluncedo kumashishini afuna ukungena ekusetyenzisweni ngokutsha kwenkunkuma yeplastiki.