I-Laser cladding, ekwabizwa ngokuba yi-laser overlay welding, isetyenziselwa ukwenza ukwambathisa izinto ezahlukeneyo. Itekhnoloji ethe yafumana ukuthandwa kule minyaka idlulileyo iza neenzuzo ezahlukeneyo. Inceda ukukhusela izinto kwi-oxidation kunye ne-corrosion. Ukusebenzisa itekhnoloji yokugquma i-laser kuphucula iipropathi zomphezulu jikelele.

Eli nqaku liza kuhamba ngayo yonke into oyifunayo ukuyazi malunga ne-laser cladding.

Isiqulatho

Yintoni i-laser cladding?

Inkqubo yokufakwa kweLaser

Iinzuzo zokugquma kwelaser

Iimpawu ze-laser cladding

Ngaba ukugquma ngelaser kuyabiza?

Izinto ezintsha zamva nje kwi-laser cladding

isiphelo

Yintoni i-laser cladding?

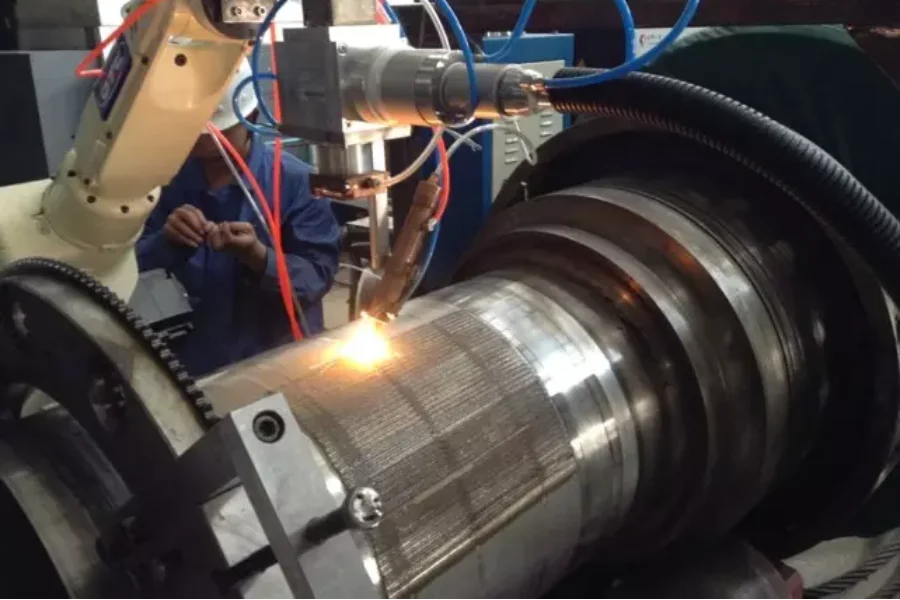

Ukufakwa kweLaser yinkqubo eyongeziweyo kwimveliso enikezela ngokugquma kwiintlobo ngeentlobo zemigangatho yezinto. Ngokubanzi, iphucula iipropati zomhlaba, ezikhusela izinto ezivela kwi-oxidation kunye nokubola. Inkqubo ibandakanya ichibi lokunyibilika linqunyulwa kumphezulu wemathiriyeli esisiseko. Ngexesha elifanayo, i-powder okanye i-wire feedstock isetyenzisiweyo, eyenza umgca omncinci wengubo.

I-laser-induced cladding inikeza iingubo ezisasazwa ngokulinganayo. Ngokuphindaphinda okuphezulu, iileya zikhululekile ekuqhekekeni kunye ne-porosity. Zikwabonisa ukuncamathela okulungileyo, uburhabaxa obuphantsi bomgangatho, ukuhlambuluka okuphantsi, kunye nenkcitho encinci yezinto ezibandakanyekayo. Inkqubo inokuphuculwa ngokuhlengahlengisa ukuxinana, isantya sokuhamba, kunye nobubanzi bemitha yelaser kumphezulu wento.

Inkqubo yokufakwa kweLaser

Inkqubo yi-directed energy deposition (DED), kwaye ikwabizwa ngokuba yi-laser overlay welding. Xa isetyenziswe kwimveliso eyongezelelweyo, ibizwa ngokuba yi-laser metal deposition (LMD) okanye i-laser metal deposition (DLMD).

I-laser beam iyanyibilika kwaye ibophe i-alloys zetsimbi kwindawo engaphantsi komhlaba okanye umaleko ofakwe ngaphambili. Umaleko oshinyeneyo we-laser cladding umaleko ubotshelelwe ngesinyithi phantsi kodilution oluncinci olusuka kwizinto zentsimbi. Igalelo lokushisa kufuneka libe lanele ukuvelisa ukugqithiswa komgangatho ophezulu.

Apha ngezantsi kukho iinkqubo ezahlukeneyo zokuvala i-laser:

Inyathelo elinye laser cladding

Kwinkqubo yenyathelo elinye, izinto zokugquma zingeniswa kwichibi elinyibilikayo apho litshintsha libe yimo etyhidiweyo ngaphezulu komphezulu we-substrate. Xa umqa welaser oshukumayo ushiya isithuba, into etyhidiweyo yokwambathisa iyaqina. Ngenxa yoko, i-coating ecolekileyo yenziwa yimizila edibeneyo yokunyakaza kwe-laser.

Inyathelo ezimbini zokuvala i-laser

Ukucutshungulwa kwamanyathelo amabini kubandakanya ukubekwa kokuqala kwezinto zokugquma phezu kwe-substrate surface. Emva koko, unyango lomphezulu luthatha i-laser beam ehambayo ukunyibilikisa izinto zokugquma kunye ne-substrate kunye. Ukwaleka kuqina ngokuzenzekelayo nje ukuba i-laser beam ishiya indawo yokwaleka.

Ukugquma ucingo

Ngexesha lenkqubo yokugquma ucingo, i wire iyondliwa ngokuthe ngqo ukusuka kwi-spool ukuya kwitotshi ecinyiweyo. Ithi ke ifudunyezwe ngaphantsi kweqondo lobushushu lokunyibilika apho ukugquma kwenzeka ngocingo olukhokelayo.

Le nkqubo inenzuzo ngenxa yokusebenza kakuhle kwe-100% ekusebenziseni izinto zokuzalisa. Kwakhona yinkqubo ecocekileyo eneendlela ezahlukeneyo zokukhethwa kwezinto zocingo. Nangona kunjalo, ukufunxa ngemitha kwiingcingo kunika imveliso engahambelaniyo.

Ukugquma umgubo

Kwi-powder cladding, i powder igqithiselwa ukusuka kwidiski ejikelezayo ukuya kumbhobho wesondlo. Igqithiswa ngeegesi ze-carrier carrier, umzekelo, i-Argon okanye i-Helium, apho umgaqo wokufunxa usetyenziswa. I-particle powder iphoqeleka ukuba ikhutshwe yi-carrier carriers ngesantya esiphezulu.

Oku kubangela ukugquma okokugqibela okulinganayo kwaye kuphindaphindeke. Inkqubo ineendlela ezahlukeneyo zokutyisa kunye nemathiriyeli. Ikwayindlela engcono yokuseta i-3D.

Iinzuzo zokugquma kwelaser

I-Lasers lukhetho olukhethiweyo lwe-micromachining kunye nokulungiswa kwezinto. Ngaphantsi kwe-laser cladding, usebenzisa iiparamitha ezinje ngokuphindaphinda i-pulse frequency, amandla e-laser, ubude be-wavelength, kunye neendidi ezahlukeneyo zeeprofayili zemiqadi.

Oku kulandelayo luncedo olubalelwa kwi-laser cladding:

- Iqinisekisa i-metallurgical bonding of surfaces kunye nezixhobo ezisisiseko

- Inkqubo idinga ixesha eliphantsi lokuvezwa kunye nobunzulu be-laser beam

- I-Laser cladding ivelisa ukugquma okuxhathisayo xa kuthelekiswa neengubo zokutshiza ezishushu

- Umgangatho ophezulu ophezulu ophunyeziweyo kunye ne-warpage ephantsi inciphisa imfuno yokulungiswa emva kokulungiswa

- Isebenza kakuhle kakhulu ngenxa yeendleko ezincitshisiweyo, ixesha elifutshane lokuvala i-laser, kunye nenkcitho encinci

Iimpawu ze-laser cladding

Ukufakwa kweLaser ikakhulu isebenzisa impembelelo yobushushu obuphantsi kunye neempawu ezichanekileyo ezichanekileyo. Ikwanazo nezinye iimpawu, eziquka:

- Isantya sokupholisa ngokukhawuleza ngenxa yenkqubo yokuqinisa ngokukhawuleza; izinga linyuka ukuya malunga ne-106 K / s. Kulula ukufumana i-crystalline ecolekileyo yokwaleka ngokulinganayo.

- Ifuna igalelo elincinci lobushushu kunye nokugqwetheka xa uxinaniso lwamandla aphezulu lusetyenziswa ngokukhawuleza. Ukugqwethwa kungancitshiswa ngaphakathi kokunyamezela kwendibano.

- Izinga lokuncibilika kokutyabeka okuphantsi okukholisa ukuba ngaphantsi kwe-5%. Ngokuhlengahlengiswa kweeparamitha ze-laser, i-substrate iboshwe ngokuqinileyo nge-metallurgically okanye ngokusasazwa kwe-interfacial diffusion.

- I-laser cladding layer inoluhlu olukhulu lokutyeba kunye ne-channel-powder feed feed coating malunga ne-0.2 ukuya kwi-2.0 mm.

- Akukho zithintelo kukhetho lomgubo xa ufaka izinto eziphezulu zokunyibilika kumphezulu wezinto ezisezantsi zokunyibilika.

- Inkqubo yokuvala i-laser kulula ukuzenzekelayo.

- Inkqubo yonyusa ideposition ekhethiweyo enosetyenziso oluphantsi lwemathiriyeli ngomlinganiselo ogqwesileyo wokusebenza ukuya kwixabiso.

- Imiqadi ejolise ekudibaneni kwaye ngaloo ndlela inokudibanisa iindawo ezingafikelelekiyo.

Ngaba ukugquma ngelaser kuyabiza?

Iphuhliswe ngaphezulu kweminyaka engama-30 eyadlulayo, i-laser cladding ibisoloko ithathwa njengetekhnoloji yokhetho lokugqibela. Oku kungenxa yotyalo-mali oluphezulu lokuqala kunye neendleko zokusebenza kwezixhobo ze-laser. Nangona kunjalo, kukho ukuqhubela phambili okukhulu kwiilaser zanamhlanje eziqinileyo.

Ukudityaniswa kweerobhothi ngokuhanjiswa kwe-fiber-coupled beam kuye kwenza inkqubo yasebenza ngakumbi kwaye ingabizi kakhulu. Ukuqwalasela uhlalutyo lweendleko-inzuzo, i-laser cladding iyaphumelela kwaye ikhula ngokukhawuleza kuwo wonke amacandelo oshishino.

Izinto ezintsha zamva nje kwi-laser cladding

Izinto ezitsha zamva nje kwi-laser cladding zigxile ikakhulu ekwandiseni imveliso. Ukuqhubela phambili kusazigcina iimpawu eziphambili zokugquma kwelaser.

Le ilandelayo yimizekelo yezinto ezintsha:

- Ukugquma kwe-laser enesantya esiphezulu kunyibilika ngokupheleleyo umgubo wokongeza kwi-laser beam ngaphambi kokufikelela kwizinto ezisisiseko. Isiseko esiluqilima sidityaniswe nomgubo otyhidiweyo ngokugqithiselwa kobushushu.

- I-laser-wire cladding inikezela ngocingo olushushu ngaphambili kwinkqubo; oku kufumaneka ngakumbi amandla e-laser ukunyibilikisa imathiriyeli esisiseko kunye nesantya esongeziweyo sokutya.

- I-Laser cladding isebenzisa umqadi we-laser we-co-axial ondla izinto ezongezelelweyo ngokuguquguqukayo kwi-workpiece. I-laser iqikelelwa nge-coaxially malunga nocingo. Oku kwandisa ukusetyenzwa okungaguqukiyo okuzimeleyo kwicala lohambo lwe-3D laser metal deposition.

- Inkqubo enkulu yokugquma ngelaser yonyusa ubungakanani bendawo yelaser kwindawo yokusebenza. Oku kuvumela ukusetyenziswa kwamandla e-laser ngakumbi ngaphandle kokunyibilika ngokugqithisileyo kwezinto ezisisiseko kunye nokunyusa ukuncipha.

isiphelo

Itekhnoloji yokugquma iLaser isandula ukwenza inkqubela phambili enkulu kwimveliso yanamhlanje. Iinkampani ezininzi zemveliso ziqwalasela iteknoloji yelaser ukubuyisela iimveliso ze-OEM. Inkqubo iye yaphucula i-corrosion kunye neempawu zokunxiba zezinto.

Esi sikhokelo singentla sichaza inkqubo ye-laser cladding kunye neenzuzo zayo. Abathengi kufuneka baqinisekise ukuba umgangatho ugcinwa ngexesha lokutyalwa kwe-laser. Ukufumana izixhobo zokuvala i-laser ozikhethayo, ndwendwela Chovm.com.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu