Ngenxa yenani elikhulu lamacandelo ekufuneka uwathathele ingqalelo kanye, ukulawula uluhlu lwakho lwezixhobo zeauto kunokuziva kunobunzima. Iworkshop yenkonzo yolawulo lwamalungu asetyenzisiweyo ngumsebenzi obaluleke kakhulu, kwaye ngenxa yobukhulu bawo obuncinci kunye nezithintelo zeendleko zokusebenza, ukulawula iintsimbi kunokuthatha ixesha.

Umthwalo onzima uya kuthetha ukuba abanini beendibano zocweyo bahlala bethandabuza ukwenza ixesha labo, imali, kunye namandla okuphatha izinto ezisetyenzisiweyo kwaye bayifumane ingumsebenzi oxabisa kakhulu.

Isiqulatho

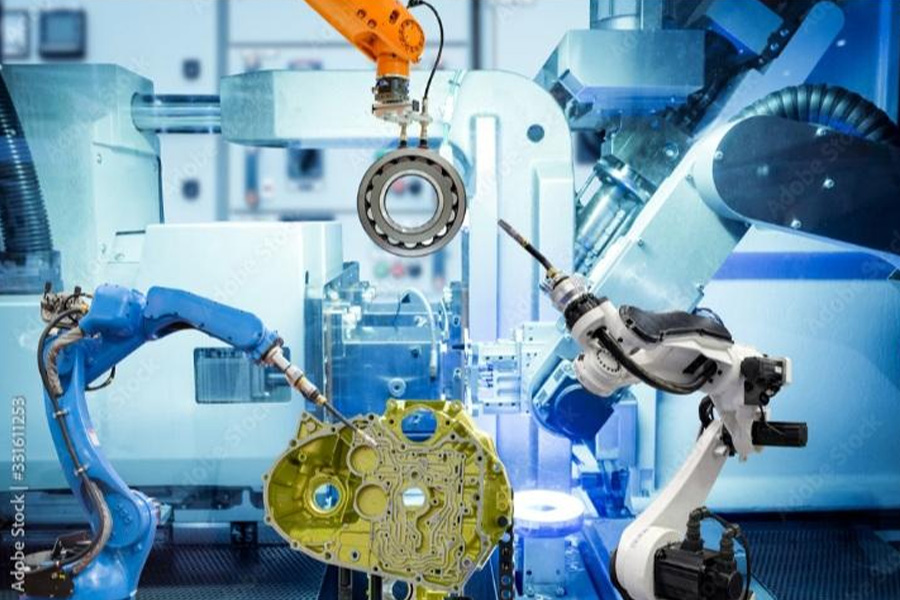

Inkqubo yokupholisa yeemoto zolawulo lwamalungu emoto

Ukulawula ngempumelelo iinxalenye ezizenzekelayo zenkqubo yokupholisa

isiphelo

Inkqubo yokupholisa yeemoto zolawulo lwamalungu emoto

ngaphandle izenzo zolawulo ezifanelekileyo, kuya kubakho imisebenzi engafanelekanga eya kuguqula imali kunye nokusebenza ngokubanzi kweshishini. Esi sesinye sezizathu ezingundoqo zokuba kutheni ulawulo lwamalungu emoto luyinto enkulu kubanini bamashishini eemoto abaneendawo zokugcina.

Ukugcina isixokelelwano sokupholisa semoto kufuna umyinge omninzi womzamo njengoko kuchaphazela ukusebenza kwe-injini kubungakanani obukhulu. Lulwazi ngokubanzi ukuba i injini yindlu yamandla yesithuthi. Ngoko ke, isixokelelwano sokupholisa kufuneka sijongwe rhoqo ukuqinisekisa ukuba zonke iindawo ezisecaleni zisebenza kumanqanaba obushushu aphakathi ngawo onke amaxesha ukuze isithuthi sisebenze ngokugqibeleleyo.

Iitshekhi zogcino lweenkqubo zokupholisa imoto

Iimvavanyo zokupholisa rhoqo ziyinxalenye ebalulekileyo yogcino lwesixokelelwano sokupholisa. Okukhona ifumana iitshekhi, kokukhona ubomi beshelufu iya kuba bude. Ngoko ke, okulungileyo uvavanyo lokupholisa ikhithi lutyalo-mali olufanelekileyo kwindawo yokugcina izinto ezisecaleni.

Ikhithi eqhelekileyo iya kuqulatha a Indawo yokubuyisela kuvavanyo lomkhenkce kunye nokuchasana nomkhenkce, imichilo yokulawula ukwakhiwa kokufuma ukuthintela ukubola kwesinyithi, imicu yovavanyo lokupholisa ukujonga i-liner pitting, kunye nokuxutywa kwesipholisi.

Ubusika lixesha lovavanyo lwazo zonke iintsimbi zentsimbi kwaye inkqubo yokupholisa ayinjalo. Ngeli xesha, imingcipheko yokubola kunye nokuguquka kombala idla ngokunyuka, ngoko ke uvavanyo lokupholisa rhoqo luya kuba luncedo.

Kubalulekile ukuqaphela ukuba isixokelelwano sokupholisa siyinxalenye yamalungu. La macandelo abandakanya, kodwa awaphelelanga apho, i iradiyetha, i-thermostat, impompo yamanzi egasket, amatanki aphuphumayo, friza iiplagi, kwaye imibhobho. Amacandelo ahlukeneyo anomsebenzi ngamnye kwaye ayizizo zonke ezenziwe ngezinto ezifanayo; kungoko iindlela zokugcinwa nokugcinwa kwazo zinokwahluka.

Izibonelelo zogcino (inkqubo yokupholisa) amalinge eenxalenye zemoto

Xa iitshekhi zolondolozo zilandelwa ngokufanelekileyo, zonke iinkqubo zeshishini ziya kuhlangabezana (kwaye zigqithe) imigangatho yemarike. Ingcono imeko yeenkqubo zokupholisa, ngakumbi abathengi bokugqibela baya kuba.

Ngaphaya koko, iinkqubo zokupholisa ezigcinwe ngokufanelekileyo zinokunciphisa iindleko zokusebenza kwaye zigcine ngokufanelekileyo umgangatho weemveliso. Zonke iimpazamo kunye neempazamo ezikhoyo kwii-spare parts ziya kulungiswa ngokufanelekileyo ukuqinisekisa ukusebenza kakuhle kwesithuthi sokugqibela.

Ukulawula ngempumelelo iinxalenye ezizenzekelayo zenkqubo yokupholisa

Kukho uthotho olungapheliyo lwabathengi abakhoyo kubathengisi bezixhobo zeauto zenkqubo yokupholisa. Nokuba kunjalo, imfuno yentengiso epheleleyo ayisosiqinisekiso sokuba zonke iinxalenye zemoto ziya kuphumelela.

Ngaphandle kwesicwangciso esiqinisekisiweyo, ukwandiswa kwenkqubo yokupholisa ishishini lamalungu emoto kunokunqunyanyiswa. Nazi ezinye iindlela eziqinisekisiweyo zokwandisa ishishini leendawo ezisecaleni njengomthengisi:

1. Yenza isicwangciso esifanelekileyo sokusebenza

Isicwangciso esifanelekileyo sokusebenza yenye yezi zinto. Oku kubandakanya zonke izibonelelo kunye neenkqubo ezibekelwe bucala ukuxhasa ngokufanelekileyo ulondolozo lwenkqubo. Isicwangciso sokusebenza sikwabonelela ngohlobo lwe-inshurensi yenkqubo yokupholisa kwimeko iingxaki ezingalindelekanga oko kunokuchaphazela ixabiso layo lemarike.

2. Chonga ababoneleli abathembekileyo

Abathengisi bezahlulo zemoto kufuneka baqinisekise ukuba banemfuno ephezulu yezixhobo zokupholisa ezikumgangatho ophezulu ngamaxesha onke. Ukubaluleka komboneleli othembekileyo obonelela ngokuthe ngcembe ngemveliso ephezulu ayinakuqikelelwa.

Ukukhetha oyena mboneleli weshishini, abathengisi kufuneka balungele ukwenza umzamo odibeneyo. Ngelixa udliwano-ndlebe nabaza kuba ngababoneleli, abanini bamashishini kufuneka babuze malunga namaxesha okutshintsha, iinkcukacha zokuthumela ngenqanawa, kunye neeodolo zokuthenga ezincinci. Kucetyiswa ukuba ukhethe kuphela umthengisi odibana kakhulu imfuno yeshishini.

3. Lawula uluhlu lwezinto ezisetyenzisiweyo

Ulawulo lwempahla ibalulekile kuye wonke umnini weshishini ozimisele ekwandiseni ixabiso lesitokhwe somsebenzi wabo. Iirekhodi zogcino lwenkqubo yokupholisa ziya kunika abanini bamashishini ingqiqo kuzo zonke iindidi ezibalulekileyo nezingabalulekanga zoomatshini. Ngaphezu koko, ngokuphononongwa ngokufanelekileyo kwe-inventri, zonke iziphelo ezivulekileyo ezibeka umngcipheko wokukhula kwesitokhwe zinokuphathwa ngokufanelekileyo.

4. Tyala imali kubasebenzi abasebenzayo

Ubungakanani bokusebenza kwendawo yokugcina impahla bumisela ukuba leliphi igosa elinoxanduva lokugcina nokugcina inkqubo yokupholisa. Abanini bamashishini banokugqiba ekubeni bawuphathe ngokwabo lo mba weshishini, njengoko uyinxalenye yemisebenzi yeshishini. Nangona kunjalo, kunconyelwa ukuba umsebenzi ushiywe kwizandla ezikhethekileyo ezikuxhobele ngokwaneleyo ukusingatha oku.

isiphelo

Ukhuphiswano kushishino lweemoto lunqanyulwe. Unale nto engqondweni, isicwangciso esifanelekileyo sokusebenza, izakhono ezifanelekileyo zolawulo lwe-inventri, abasebenzi abasebenzayo, kunye nomthengisi othembekileyo uqinisekisiwe ukukunceda uphumelele ukhuphiswano olunzima kwiimarike ze-spare parts kwaye uhlale uphezulu kwikhonkco lemarike. Ukulawula iinxalenye ezisecaleni ngaphandle kwamathandabuzo kufuna isixa esikhulu semali, umzamo, kunye nezicwangciso. Nangona kunjalo, zonke ezi zibophelelekile ukuba zihlawule ekugqibeleni.

Ukufumana i umboneleli onobuchule kunokubonakala ngathi yinkqubo entsonkothileyo, ngakumbi kumthengisi wokuqala. Kodwa le nkqubo inokwenziwa lula ngakumbi yivenkile yokumisa enye, Chovm.com. Yonke into enokufunwa ngumqali okanye inkqubo yokupholisa ephucukileyo inokufumaneka kwiqonga le-intanethi inkqubo yokupholisa icandelo lamalungu emoto.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu