Oomatshini bokuvuthela ngeplastiki banceda ukuvelisa iimveliso ze-thermoplastic ngokubumba. Ekubumbeni ukuvuthela, abavelisi basebenzisa iindlela ezahlukeneyo zokubumba iimveliso zeplastiki kwiimo ezahlukeneyo kunye nobukhulu. Iindidi ezahlukeneyo zokubumba ziquka i-extrusion, ucinezelo, inaliti, kunye ne-injection stretch blow blowing.

Kubuchule ngabunye, abavelisi banokufuna uncedo ekukhetheni umatshini wokuvuthela weplastiki osebenza kakuhle. Ukukhetha umatshini ongcono kufuneka kube lula. Ke ngoko, eli nqaku liza kuphonononga iingcebiso zokukhetha umatshini ofanelekileyo wenkqubo esebenzayo yokubumba.

Isiqulatho

Isishwankathelo semarike yehlabathi yoomatshini bokuvuthela ngeplastiki

Iingcebiso ezi-8 zokukhetha oomatshini bokuvuthela ngeplastiki

Iindidi zoomatshini bokuvuthela ngeplastiki

isiphelo

Isishwankathelo semarike yehlabathi yoomatshini bokuvuthela ngeplastiki

Imarike yoomatshini bokuvuthuza yehlabathi ibixatyiswa I-13.08 yeebhiliyoni zeedola zaseMelika ngo-2022. Ijonge ukufikelela kwixabiso le-17.33 yeebhiliyoni zeedola zaseMelika ngo-2030, ikhula ngenqanaba le-CAGR ye-3.5%. Ubukhulu bemarike ubukhulu buvela kwimfuno yezikhongozeli zeplastiki kushishino lwezonyango. Abavelisi bePlastiki baxhomekeke kwizixhobo zokubumba ukuvuthela ukuvelisa izitya ezinjengeebhotile kunye nesirinji zokugcina amayeza.

Imfuneko yokuphinda isetyenziswe iplastiki ukuhlangabezana nemfuno ephezulu evela ukutya nesiselo ukwandise imfuneko yezixhobo zokubumba izivuthelo. Izityalo ezivelisa ukutya zityala imali eninzi kwiplastiki esetyenzisiweyo ukupakisha ukutya kunye neemveliso zesiselo.

Iingcebiso ezi-8 zokukhetha oomatshini bokuvuthela ngeplastiki

amandla yemveliso

Amashishini atyala imali koomatshini bokuvuthela iplastiki kufuneka abe nomdla wokuqwalasela umda abanokuvelisa oomatshini. Izixhobo zokubumba zivuthela zinomda wokuba zingaphi iimveliso ze-thermoplastic ezinokuthi zivelise ngexesha elithile. Ke ngoko, kubalulekile ukuphanda kwaye ufunde ngakumbi malunga neemodeli zoomatshini bokuvuthela eplastiki kunye nokuba bangavelisa kangakanani.

Kufuneka kwakhona baqwalasele ukuba ingakanani na iplastiki ekufuneka beyivelise phambi kokuba bathathe isigqibo ngomatshini wokuvuthela weplastiki onesakhono esifanelekileyo sokuvelisa. Abavelisi abakhulu banokufuna oomatshini abanomthamo ophezulu wemveliso, ngelixa abavelisi abancinci banokufumana ii-molders zokuvuthela kunye nemveliso ephantsi.

uhlobo Product

Ukuqwalasela uhlobo lwemveliso yeplastiki kubalulekile kumashishini athengela oomatshini bokuvuthela iplastiki. Oomatshini basebenzisa ubushushu ukuvelisa iindidi ezahlukeneyo zeplastiki. Ngokomzekelo, isixhobo sokubumba i-extrusion blowing sifanelekile xa usenza iibhotile zeplastiki ze-HDPE okanye i-LDPE enentamo ebanzi. Oomatshini bokubumba i-compression blowout baya kunceda ukwenza iibhotile ezinomzimba obanzi kunye nentamo encinci.

Ukusebenza kwamandla

Xa uthenga umatshini wokuvuthela ngeplastiki, qwalasela amandla owasebenzisayo. Abathengi kufuneka bahlale begxile ekufumaneni izixhobo eziphantsi kusetyenziso lwamandla. Oomatshini baya kunceda ukonga kungekuphela nje kwiindleko zamandla okusebenzisa izixhobo kodwa nakwixabiso elipheleleyo lemveliso.

Auto-deflashing

Ekubumbeni, i-residu engafunwayo inokubumba kwimveliso yeplastiki. Abasebenzi babedla ngokusika inyama eyongezelelweyo ngesixhobo esibukhali, njengemela, kwiibhotile okanye izikhongozeli ngendlela ebizwa ngokuba yi-deflashing.

Kuba ukudenyezwa kwezandla kusetyenziswa kakhulu, kuyadinisa, kwaye kudla ixesha, amashishini kufuneka acinge ngokufumana umatshini onophawu lokuzidengezela ngokuzenzekelayo.

Imishini yokucima i-auto-deflashing iqinisekisa ukuchaneka kunye nokuchaneka kwimveliso yebhotile. Kwakhona, bandisa ukusebenza kakuhle kwemigca yokuvelisa.

Uyilo lomatshini oluphezulu

Uyilo loomatshini bokuvuthela ngeplastiki luya kwahluka, olunokuthi luchaphazele imveliso yomatshini kunye nemveliso yokugqibela yenkqubo yokubumba. Umzekelo, uyilo lomatshini lwakudala alukwazi ukusebenza ngokufanelekileyo njengoyilo olutsha oluneempawu eziphambili. Iimodeli zokuvuthela ngeplastiki ezisebenzisa itekhnoloji endala zineziphene. Zicotha, zidla amandla amaninzi, kwaye kunokuba yindleko ukuzigcina.

Amashishini kufuneka athathele ingqalelo ukuthenga oomatshini abane uyilo oluhlaziyiweyo. Aba matshini bayakhawuleza, bayonga amandla, kwaye baxabisa imali eninzi ukubagcina. Oku kuqinisekisa ukusebenza okungenangxaki ngelixa uvelisa iimveliso ezisemgangathweni ngesantya esiphezulu kunye nokuchaneka.

Umlawuli weParison

Abathengi abafuna oomatshini bokuvuthela beplastiki abanokwethenjelwa kufuneka bathathele ingqalelo into yolawulo lwecawe. Umlawuli we-parison unceda ukulawula ubukhulu beemveliso zeplastiki kwiinkqubo zokubumba, ukuvumela ukuveliswa kweemveliso ezichanekileyo.

Ngaphezu koko, umlawuli wecawe unceda kulawulo lomgangatho kunye nokuthotyelwa kwemigangatho yoshishino ye-axial kunye nemveliso yeradial efunekayo.

Ubuninzi bomthamo wokusebenza

Xa ukhetha umatshini wokuvuthela iplastiki, ubuninzi bokusebenza buyimfuneko. Umthamo wokusebenza komatshini uxhomekeke kwiimfuno zokuvelisa. Oomatshini bokubumba bahlulahlulwe ngokwe-auto ngokupheleleyo, i-semi-auto, kunye noomatshini beemoto.

Kumashishini akhangela umatshini onokuzisa ngokukhawuleza, okuchanekileyo, kunye nesantya esiphezulu semveliso, anokukhetha iimodeli zokuvuthela zeplastiki ngokupheleleyo.

Semi-auto kunye noomatshini bokubumba iplastiki yokuvuthela ngokuyinxenye babonelela ngesantya kunye namathuba okwenza ngokwezifiso ixesha lokuveliswa kokungunda. Inzuzo yabo kukuba baquka ubungakanani obudibeneyo kwaye banokuhambisa amanqanaba emveliso ngokusekelwe kwiimfuno ezithile. Aba matshini, ke ngoko, balungele abavelisi abancinci.

Amandla okuqhawula

Amandla okubamba abalulekile xa uthenga umatshini wokuvuthela weplastiki. Ngamandla afunekayo ukucinezela kunye nokugcina ukubumba kunye. Abathengi kufuneka bathenge umatshini okwaziyo ukumelana noxinzelelo oluphezulu olufunekayo.

Ukuba isixhobo sokuvuthela iplastiki sinamandla okubamba amancinane kuneeponti okanye iikhilogram ezifunekayo, sinokuvelisa ukungunda okukumgangatho ophantsi. Kwakhona, ukuba umatshini uvelisa amandla amaninzi, amandla amaninzi okusebenza aya konakala ngelixa usebenzisa amandla amaninzi.

Iindidi zoomatshini bokuvuthela ngeplastiki

Umatshini wokubumba wokubumba wokutofa

Aba matshini bokuvuthela beplastiki basebenzisa isikrufu eside ukutofa intlaka eshushu kwaye bayicinezele ibe ngundo. Njengoko i-resin inyibilika, iba yi-preform. Emva koko igalela umoya kwi-preform ukwenza ubume obufunwayo.

eziluncedo

– Banesantya esiphezulu sokuvelisa kunye nokusebenza kakuhle.

– Bagcina umgangatho wemveliso engaguqukiyo kunye nemilinganiselo.

– Banokuvelisa uluhlu olubanzi lweebhotile kunye nemilo.

-Banokuvelisa iibhotile ezinodonga olungqingqwa, ezifanelekileyo ukupakisha iimveliso ezahlukeneyo.

neengozi

-Amaxesha amade okuvelisa ukungunda kuthoba imveliso.

-Amaxabiso e-Scrap anokuba phezulu xa usenza iinxalenye ezinzima okanye iimolds eziyilwe kakubi.

Oomatshini bokubumba i-Extrusion blow

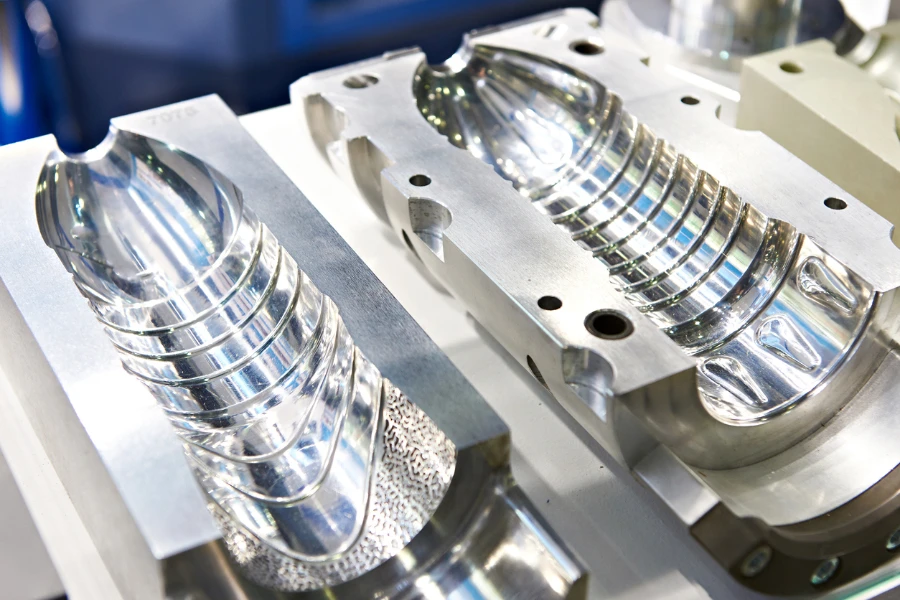

An umatshini wokubumba i-extrusion blow ivelisa iindawo zeplastiki ezingenanto isebenzisa inkqubo eqhubekayo. Inkqubo ibandakanya ukunyanzeliswa kwezinto zeplastiki ezinyibilikisiweyo ngokuqhubekayo kwityhubhu engenanto (i-parison), ethi emva koko idluliselwe kwi-mold apho ifakwe khona kwaye yenziwe ibe yimo efunwayo.

eziluncedo

– Baxhasa isantya esiphezulu semveliso.

– Zinokuvelisa iimilo ezintsonkothileyo.

– Bavumela ukusetyenziswa ngokufanelekileyo kwemathiriyeli ekrwada.

– Zinokuzenzekela.

neengozi

– Bavelisa iinxalenye zeplastiki ezinobungakanani obulinganiselweyo.

-Kunokubakho amaxesha okuseta amade okutshintsha izixhobo.

– Zinezinga eliphezulu le-scrap xa kuthelekiswa nokubumba inaliti.

Oomatshini bokubumba bolula

A wolula ukubetha kokubumba Umatshini usebenza ngokufanayo kwisixovulelo sokuvuthela inaliti, kodwa umahluko kukuba usebenzisa umoya ukolula i-preform phezu komngundo ukwenza imilo yokugqibela yemveliso.

eziluncedo

-Banokuvelisa amanani amakhulu eenxalenye ngexesha elifutshane.

– Zinokuvelisa iinxalenye ezinobunzima bodonga oluhambelanayo kunye nokucaca okuphezulu.

- Abavelisi banokusebenzisa izinto ezininzi ezahlukeneyo kunye ne-stretch blow molding, kuquka i-PET (i-polyethylene terephthalate), i-PVC (i-polyvinyl chloride), kunye ne-PP (i-polypropylene).

– Ukubetha oomatshini bokubumba sebenzisa amandla amancinci xa kuthelekiswa nezinye iinkqubo zokubumba.

neengozi

– Oomatshini kunye nezixhobo zinokubiza ukuthenga nokufaka.

- Inkqubo ngokuqhelekileyo inqunyelwe ukuvelisa iinxalenye ze-cylindrical, kwaye kunokuba nzima ukuvelisa iimilo eziyinkimbinkimbi okanye iinkcukacha eziyinkimbinkimbi.

– Ukubunjwa kwe-Stretch blow kufuna ukuveliswa kwe-preforms, eyongeza inyathelo kwinkqubo yokuvelisa kunye nokwandisa iindleko zokuvelisa.

isiphelo

Oomatshini bokuvuthela ngeplastiki babalulekile kwimveliso echanekileyo yeplastiki yokusetyenziswa kwezinto ezahlukeneyo zokupakisha. Amashishini anemingeni ekufumaneni oomatshini angasebenzisa la macebiso angasentla ukukhetha izixhobo zokubumba ezinokuthenjwa.