Izikhululo ze-Soldering zibonelela ngeemfuno ezininzi eziyimfuneko kwishishini lokwenziwa kombane. Ziye zavela ekuhambeni kweminyaka ngokuhambelana nenkqubela phambili yetekhnoloji. Ezinye izikhululo ze-soldering zinokusetyenziswa njengezixhobo zokulahla kwaye zinokubandakanya izandiso ezikhethekileyo ukwenza imisebenzi yonke ibe lula. Qhubeka ufunda ukuze ufumane ngakumbi malunga nezinto ezibalulekileyo zezikhululo ze-soldering.

Isiqulatho

Uhlalutyo lwemarike yezikhululo ze-soldering

Yintoni isikhululo sokuthengisela?

Iintlobo zezikhululo ze-soldering

Yintoni omele uyiqwalasele xa ukhetha izitishi ze-soldering

isiphelo

Uhlalutyo lwemarike yezikhululo ze-soldering

Imakethi yezixhobo zokuthengisa kulindeleke ukuba ikhule kwi-CAGR ye 9.56% ukufikelela kwi-USD 911.3 yezigidi nge-2030. I-Soldering isetyenziswa kumashishini ahlukeneyo, kuquka iimoto, ezonyango, izixhobo zomculo, ii-mobiles, kunye neekhompyutha. Ukukhula ngokukhawuleza kweshishini le-elektroniki kuye kwaququzelela uphuhliso lwezikhululo ze-soldering kunye ne-accessory market.

Ukukhula kusenokubalelwa kushishino olukhawulezayo kunye nokusetyenziswa kwezinto eziphambili i-soldering kwiindidi ezahlukeneyo zoomatshini. Abadlali abaphezulu kwintengiso zizixhobo zeWeller, iKurtz Holding, kunye neJameco Electronics, phakathi kwabanye, kwaye ummandla waseAsia Pacific kulindeleke ukuba ube yeyona ntengiso inkulu.

Yintoni isikhululo sokuthengisela?

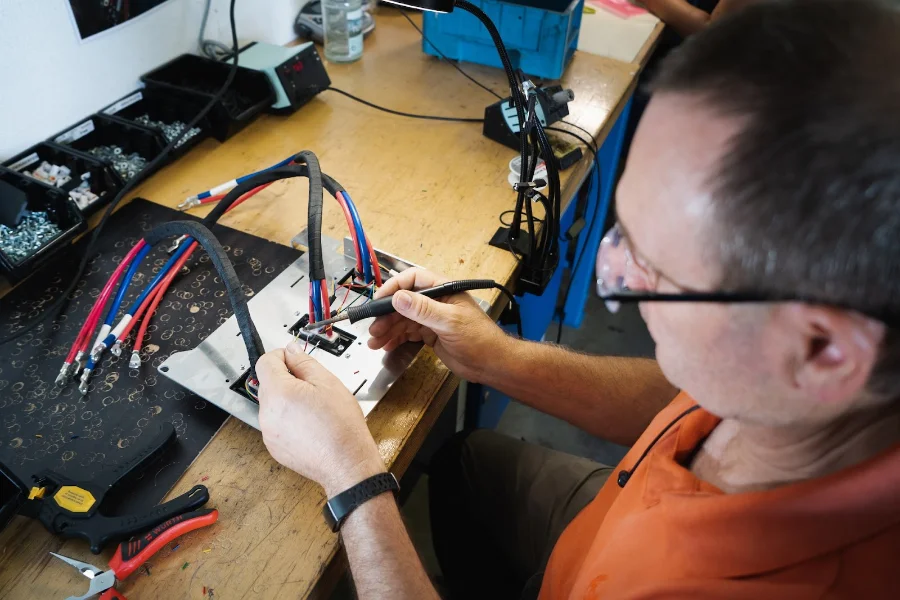

Isikhululo se-soldering sisixhobo sombane esisetyenziselwa ukuthengisa izinto ze-elektroniki kwibhodi yesekethe eprintiweyo (PCB). Iza kunye nokulawula ubushushu kunye nentsimbi ye-soldering. Uninzi lwesoldering Izitishi zineseto zokulawula ubushushu kwaye zisetyenziswa ikakhulu kwindibano ye-elektroniki yePCB kunye nezityalo. Zikwasetyenziselwa ukulungisa izixhobo zombane kunye nokuhlaziya iibhodi zeesekethe.

Phambi kokuba siye phambili, makhe sijonge kwizikhululo ezahlukeneyo zokuthengisela kwaye sixoxe ngeempawu kunye nokusetyenziswa kwazo.

Iintlobo zezikhululo ze-soldering

Qhagamshelana nezikhululo ze-soldering

Olu luhlobo oludumileyo lwe-soldering isitishi kwaye yahluke kancinane kwiinketho zemveli. Nangona kunjalo, ezinye iimpawu zinokuphuculwa-njengoko zingakwazi ukuhlengahlengisa ubushushu be-heater, zihlala zigqithisa into yokuva. Izikhululo ze-solder zoqhagamshelwano zineyunithi yokubonelela ngombane edibeneyo kwaye zinokufudumeza ukuya kuma-400 ° C.

Abasebenzisi banokutshintsha ubushushu bokufudumala ngokulungelelanisa i-voltage ye-heater element ngokusebenzisa iyunithi yokubonelela ngombane. Kwiimeko ezininzi, ubushushu obufanelekileyo bokuthengisa buphakathi kwama-250°C kunye nama-330°C.

Izikhululo zokuthambisa ezishushu

Isikhululo se-soldering somoya oshushu sixhotyiswe nge-compressor eyenza ukuhamba komoya, okufudumala kwiqondo lokushisa elithile. Lo moya owenziwe ngumpu wokushisa ujoliswe kwindawo ye-soldering. Ngamaphedi okufudumeza amaninzi akhoyo, esi sisisombululo esifanelekileyo sokuthengisa kwindawo encinci.

Zisetyenziswa kakhulu ukulungisa iiselfowuni kunye nezinye izinto zendlu. Le soldering isitishi iyahambelana zombini ilothe kunye nealloyi engenalothe. Ukusetyenziswa kwayo, nangona kunjalo, kunqongophele. Umzekelo, ayinakusetyenziswa ukuthengisa okanye ukuthengisa iitshiphusi ezinkulu zeBGA.

Izikhululo zedijithali kunye ne-analog soldering

Izikhululo zedijithali zokuthengisela zivumela abasebenzisi ukulawula ubushushu ngokusebenzisa useto lwedijithali. Banomboniso wedijithali obonisa ubushushu obumiselweyo kwaye unika ukuchaneka okukhulu kunye nokunyamezela. Zikwabiza ngaphantsi kunezikhululo zokuthengisela i-analog.

Kwelinye icala, analog i-soldering izikhululo zixhotyiswe ngeqhina lokulawula ubushushu. Ngokungafaniyo nabalingane babo bedijithali, abanalo isikrini sokubonisa ubushushu obumiselweyo. Ngaphezu koko, iisetingi zobushushu azichanekanga kakhulu. Zifanelekile kwimisebenzi emincinci efana nokulungiswa kweselula, phakathi kwezinye izinto.

Izikhululo ze-anti-static soldering

Izikhululo zokuthengisa zinokuba yi-ESD (i-electrostatic discharge) ekhuselekileyo okanye hayi. Intlawulo ye-static kwintsimbi ayiyi kuqokelela kwizikhululo ezikhuselekileyo ze-ESD, njengoko amandla ombane angaphezulu aya kukhutshwa ngokukhawuleza emhlabeni. Uninzi lwezixhobo zombane zanamhlanje, ezinjengee-smartphones, zifuna i-ESD-ekhuselekileyo yokuthengisa Izitishi kuba zineenxalenye ze-elektroniki ezibuthathaka kumbane ongashukumiyo kwaye zinokonakala ngokulula.

Izikhululo zokuthengisela ezikhokelayo kunye ne-load-free

Uninzi lweenkampani zokwenza izinto ziguqukela kwiinketho ezingenalo ilothe. I-lead-free soldering Izitishi sebenza ngokufanayo nabalingane bemveli kodwa bahluke kumandla wento yokufudumeza, ukusuka kwi-75-80 W ukuya kwi-150-160 W. Indawo yokunyibilika yocingo lwe-solder olungenayo i-load luyi-217 ° C ukuya ku-221 ° C, kwaye i-lead solder wire yi-183 ° C.

Ngoko ke, isikhululo sokuthengisa esinamandla ombane we-50 W ukuya kwi-60 W singaphezulu kokwaneleyo kwi-solder lead solder wire. Nangona kunjalo, isikhululo se-solder esinamandla siyafuneka kwi-lead-free soldering.

Yintoni omele uyiqwalasele xa ukhetha izitishi ze-soldering

Ulawulo lokushisa

I-solder eguquguqukayo isitishi kunye noluhlu olubanzi lobushushu luyafuneka ukusebenza kwiiprojekthi ezahlukeneyo. Imisebenzi ethile kuya kuba nzima ukuyigqiba ukuba iyunithi inobushushu obumiselweyo. Ke jonga iinketho eziguquguqukayo ngethermostat ezicima ngokuzenzekelayo isifudumezi xa sifikelela kubushushu obumiselwe ngumsebenzisi.

I-thermostat iluncedo kuba ivumela abasebenzisi ukuba bahlengahlengise ubushushu kwixabiso elichanekileyo elifunwa yiprojekthi. Ukuba olu phawu alukho, intsimbi iya kuqhubeka ishushu de i-PTC icitshiswe, enokuthi inganikezeli ubushushu obaneleyo kwiiprojekthi ezithile. Enye into ekufuneka uyiqwalasele xa kufikwa kwiqondo lobushushu kukuhambelana. Nje ukuba ifikelele kwiqondo lobushushu elifunekayo, isikhululo sokuthambisa esifanelekileyo kufuneka sikwazi ukugcina ubushushu ngokuqhubekayo.

ombane

Nangona i-wattage ihluka phakathi kweemodeli, ukukhetha isixhobo ekulula ukuyisebenzisa kwaye inoluhlu olubanzi lobushushu kubalulekile. Ezinye izixhobo zisebenzisa i-40 W, ngelixa ezinye zisebenzisa ukuya kuthi ga kwi-80 W. Xa uvavanya i-soldering isitishi, umgaqo wesithupha kukuba amanzi aphezulu enza imisebenzi enzima ibe lula ukuyigqiba.

Ukubuyiswa kwe-thermal

Kungcono ukhethe izitishi ze-soldering kunye nokubuyiswa kwe-thermal ephezulu, ngakumbi ukudibanisa rhoqo. Izikhululo ze-Soldering ezinokubuyiselwa kwe-thermal ephantsi zibangela imiba efana neendawo ezibandayo ze-solder. Ngokwahlukileyo, into yokubuyisela ubushushu iya kwazisa isikhululo sokuthengisa malunga nokuba kuthatha ixesha elingakanani ukuba i-solder tip ifikelele kwiqondo lokushisa elifunekayo.

Iingcebiso zentsimbi ye-soldering

Iintsimbi ze-soldering zineengcebiso ezitshintshileyo kwi-chisel kunye neemilo ezi-conical kwaye ubukhulu becala zenziwe nge-copper kunye ne-nickel solder. Zifumaneka ngokobukhulu obahlukeneyo kwaye zingasetyenziselwa ukugqiba imisebenzi eyahlukeneyo. Iingcebiso ze-solder zingachaphazela indlela othengisa ngayo kakuhle, kunye nesicatshulwa ngasinye sineenzuzo kunye nokungalunganga. Ngoko ke, ngaphambi kokuthenga ithiphu ye-solder, qwalasela ukuhambelana kwayo kunye ne-soldering isitishi.

Ngaphandle kokuhambelana, enye into ekufuneka iqwalaselwe sisimo sencam. Ingcebiso yetshisel ilungele abaqalayo kuba inomphezulu osicaba ekulula ukuwubamba nokusetyenziswa. Iingcebiso ngophuphu lolona khetho lubalaseleyo kubasebenzisi abaphambili kunye nokutsala-soldering iipads ezininzi zeentaba. Ziyinto enkulu kwiiprojekthi ze-soldering eziyinkimbinkimbi, ngakumbi xa zisetyenziswe kunye nesikhululo esifanelekileyo sokuthengisa. Phakathi kwazo zonke iintlobo zeengcebiso, iingcebiso ze-conical zezona zinzima kakhulu ukuzisebenzisa kodwa kunye nezona zichanekileyo.

Enye into ekufuneka iqwalaselwe yimpahla yeengcebiso ze-soldering. I-ayini inexabiso eliphantsi kwaye yomelele kodwa ayikwazi ukugcina okanye idlulise ubushushu ngokufanelekileyo njengeengcebiso zobhedu. Iingcebiso eziphakamileyo ze-soldering zinentsimbi yobhedu enentsimbi, enika eyona ndlela ifanelekileyo.

nokugcinwa

Xa usebenzisa i-soldering isitishi, kubalulekile ukuvavanya ukuba iindawo ezisecaleni zinokufumaneka ngokulula. Nangona i-iron soldering ingasetyenziselwa iminyaka emininzi, i-soldering iron bits inobomi obufutshane kwaye inokufuna ukutshintshwa ngezikhathi ezithile, kuxhomekeke ekusebenziseni.

isiphelo

Njengoko bekuxoxiwe ngaphambili, izikhululo zokuthengisa zinezo zonke izixhobo ezifunekayo ukusebenza kwiisekethe kunye nokulungiswa. Imarike igutyungelwe ziinketho ezahlukeneyo zesikhululo sokuthengisela, kwaye eli nqaku liqaqambisa kwiindidi eziphambili, iimpawu zabo zokusebenza, kunye nokusetyenziswa kwazo. Ndwendwela Chovm.com ukujonga izixhobo zokuthambisa zamva nje ezikhoyo namhlanje.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu