Ngeli xesha loShishino 4.0, ukwenziwa kwedijithali kwinguqulelo yesithathu yeshishini kudibana neenkqubo ezikrelekrele nezizimeleyo kunye neenkcukacha kunye nokufunda koomatshini ukuzisa iminyaka engazange ibonwe kumatshini wokwenza izinto.

Kweli nqaku, siza kuhamba ngaphezulu kwe-7 yeendlela eziphambili eziya kubumba i-automation ye-industrial. Ezi ndlela ziza kunika abathengi ukuqonda ukuba ishishini lisingise phi kwaye abathengi baya kujonge ntoni ukuze baphucule imisebenzi yabo.

Isiqulatho:

Amagqabantshintshi emarike yemizi-mveliso

Iindlela eziphambili zokubumba i-automation ye-industrial

Ixesha elitsha kwi-industrial automation

Amagqabantshintshi emarike yemizi-mveliso

Ubungakanani bemakethi ye-automation ye-automation yehlabathi ibonise amathemba amahle kwixesha le-2020-2025. Ngoku ka Statist, imakethi kulindeleke ukuba ibe nokukhula kwexabiso ukusuka kwi-175 yeebhiliyoni zeedola zaseMelika ngo-2020 ukuya kwi-265 yeebhiliyoni zeedola zaseMelika ngo-2025.

Ikhula ngesantya sokukhula sonyaka esihlanganisiweyo (CAGR) se-9%, imakethi ibonisa iimpawu ezinamandla zokukhula okuzinzileyo. Nangaphandle kwengxaki yezempilo yehlabathi kunye nokuphazamiseka kwekhonkco lokubonelela, kukho iimpawu zokubuyela umva kwemarike.

I-Fortune Business Insights yafumanisa ukuba abaqhubi abaphambili emva kokukhula kwemarike kukuvela kwetekhnoloji ye-5G edityaniswe nolwamkelo olwandisiweyo lweShishini 4.0 phakathi kwamashishini.

Iindlela eziphambili zokubumba i-automation ye-industrial

Ngoku ekubeni sinombono wemarike ye-automation yehlabathi jikelele, sinokungena kwiindlela eziphambili eziza kuba nefuthe kwicala leshishini lemveliso ngokubanzi.

1. I-Intanethi ye-Intanethi yeZinto

Umzi-mveliso we-4.0 uya kubona ukudibana kobuchwepheshe bolwazi kunye nobuchwepheshe bokusebenza (ukudibana kwe-IoT) kwinqanaba eliya kubangela inguqu yedijithali engazange ibonwe ngaphambili. I-IoT ye-Industrial iya kunceda ukudibanisa ii-asethi zemizi-mveliso yamashishini ngendlela ecacileyo, elula, kunye nokwandisa imveliso. Amashishini aya kuba nakho ukwenza lula isoftware yawo yomgangatho wevenkile kuwo wonke umjikelo wobomi kwaye andise ukusebenzisana kunye nokuguquguquka kwemisebenzi yawo.

Umzi mveliso wehlabathi kulindeleke ukuba wonge i-US$500 yeebhiliyoni zeedola minyaka le ngenxa ye-automation eqhutywa yi-IoT. I-IoT iyakwazi ukunceda amashishini achonge ukungasebenzi kakuhle kwenkunkuma, ukuthintela ukusilela kwezixhobo, kunye nokuqinisekisa umgangatho wemveliso. Ukuphendula kwi Uphando lwe-RT Insight, izibonelelo ezicatshulwe kakhulu ngabamkeli be-IoT yamashishini ziquka:

- Ukucuthwa kweendleko zokusebenza (53%)

- Ukuphucula ukuqokelelwa kwedatha (48%)

- Ukunyusa ingeniso kwimithombo ekhoyo (42%)

I-Artificial Intelligence (AI) iya kuba yinxalenye ebalulekileyo ye-Industrial IoT njengoko inani lezisombululo zemizi-mveliso liya kusebenzisa uhlalutyo oluphambili ngakumbi kunye nomphetho kunye ne-computing yamafu kuhlalutyo lwedatha yomatshini.

Ukuqonda kweNtengiso yexesha elizayo iiprojekthi ukuba imakethi yehlabathi ye-AI kwi-IoT, okwangoku ixabisa i-US$ 78 yebhiliyoni, iya kufikelela kwi-US $ 142.4 yezigidigidi ngo-2032. Oku kukhula kuyaqondakala kuthathelwa ingqalelo ukuba ukufunda koomatshini (okuyi-subset ye-AI) kunye ne-IoT zenza ukuba amashishini enze uqikelelo olusebenzayo. Amaxesha angama-20 ngokukhawuleza kunetekhnoloji yemveli kunye nokubonelela ngokuchaneka okuphakamileyo.

2. Shift ukusuka kumatshini ukuya kukuzimela

Inkqubela phambili eyenzekileyo ngaphakathi kwidijithali edityaniswe nemigangatho emitsha yokuzenzela inkqubo evulekileyo inike abavelisi ithuba lokutshintsha imisebenzi yabo isuke “kokuzenzekelayo” ukuya “kokuzimelayo.”

Nge-AI kunye nedatha yoomatshini, ukuhlangana okukhankanywe ngasentla kwe-IoT ye-IoT kunye nokuguqulwa kwedijithali kwenza abavelisi benze iinkqubo ezizimeleyo ezikwaziyo ukwenza izigqibo eziphambili zemveliso okanye zokusebenza ngelixa abantu besebenza nje njengabaveleli.

Iinkqubo ezizimelayo kwishishini leemoto lase-US ziqikelelwa ukuba zibonelele ngolondolozo olupheleleyo lonyaka ukuya kuthi ga US$ 1 yetriliyoni, eya kuba nefuthe elibonakalayo kuqoqosho. Izityalo ezisebenzayo ziya kukwazi ukuphucula kakhulu ukuthembeka kunye nokuqikelelwa kwemisebenzi yazo. Oomatshini baya kuba nako ukuqeqeshwa ngeenkcukacha eziphambili zembali ezidityaniswe nedatha yexesha langempela kunye nezicelo ezinikwe amandla yi-AI ukuze ekugqibeleni kwandiswe ukusebenza kakuhle.

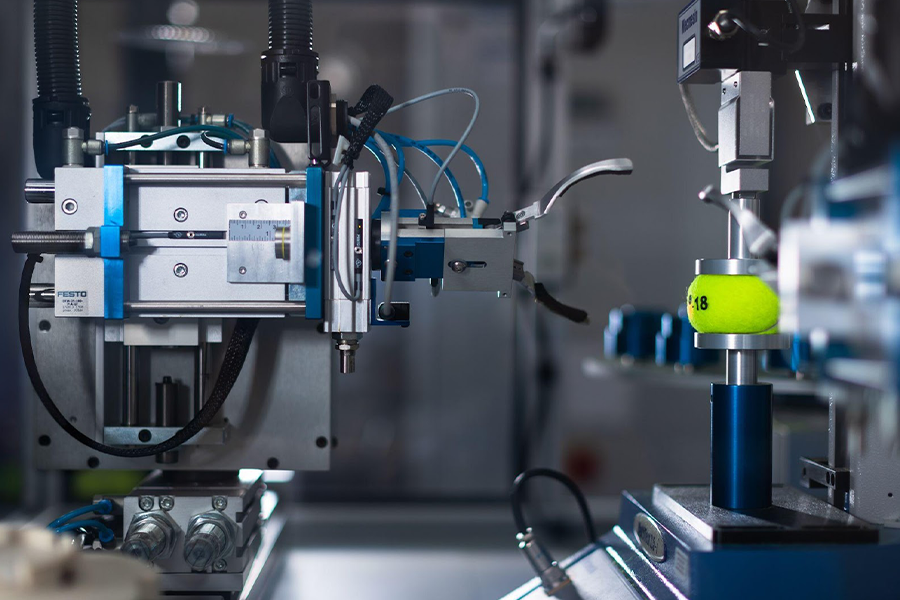

3. Iindleko eziphantsi zeengalo zerobhothi

Ubunjineli be-360 babika ukuba iindleko zeerobhothi ziye zehla ngaphezu kwe-25% ukususela ngo-2014, kwaye kulindeleke ukuba zehle ngakumbi nge-22% eyongezelelweyo ngo-2025. Imarike yerobhothi yoshishino yayixabisa kwi-US $ 24.35 yebhiliyoni ngo-2020 kwaye kuqikelelwa ukuba ifike kwi-US $ 52.85 yezigidigidi, ikhula kwi-CAGR ye-2026% kwi-14.1% ye-2021%. 2026–XNUMX ixesha lengqikelelo.

Ngelixa imfuno yeerobhothi zoshishino iye yanda, ukuhla kweendleko iingalo zerobhothi zoshishino ngokukodwa yenze ukuba ukusetyenziswa kwe iingalo zerobhothi ukuba isasazeke ngakumbi kushishino lwemveliso.

Ukusebenzisa umbono womatshini kunye nobuchwepheshe benethiwekhi, iingalo zerobhothi zoshishino ukunceda amashishini ukuba azenzele iinkqubo eziphambili ezithi ekugqibeleni zibe negalelo ekwandeni kokhuseleko lwabasebenzi, imveliso ekhawulezayo, kunye nokwanda kwemveliso. Kumanani okwenyani, i-Boston Consulting Group uqikelelo ukuba iingalo zerobhothi zoshishino inokunikezela nge-avareji yogcino lweendleko zelizwe jikelele malunga ne-16% ngo-2025.

Abavelisi banako ukuthenga iingalo zerobhothi ezinexabiso eliphantsi kwinani lezicelo, ukusuka ukulayisha iingalo ukuba iiwelder ezichanekileyo. Ekuhambeni kwexesha, oku kuya kunceda amashishini omeleze inzuzo yawo yokukhuphisana njengoko aya kukwazi ukugcina iindleko zawo ziphantsi kwaye adlulisele le nzuzo yeendleko kubathengi.

4. Ukwamkelwa okwandisiweyo kweerobhothi ezisebenzisanayo

Iirobhothi ezisebenzisanayo (ekwabizwa ngokuba “zii-cobots”) babona ukonyuka ukwamkelwa kumatshini wokwenza izinto. Njengoomatshini abajonge ukwenza intsebenziswano ngokuthe ngqo yomntu-irobhothi ngaphakathi kwendawo yokusebenza ekwabelwana ngayo, iicobots benza inguqulelo kwi-automated okanye imisebenzi yokuzimela lula kumashishini kwihlabathi liphela.

IiCobots Ziyindlela entsha yokwenza iirobhothi kodwa ziya zisanda kakhulu kwizicelo zokwenziwa kwemizi-mveliso. Ziya kuthunyelwa kwimisebenzi eyahlukeneyo kwinani lamashishini kuquka Automotive, i-electronics, imveliso jikelele, metal kungamampunge, ukupakisha kunye nokupakishwa ngokubambisana, iiplastiki, kunye nokutya kunye nezolimo.

Kwishishini lemveliso, zisetyenziselwa kukhetha kunye nokubeka, kwishishini lokutya zisetyenziselwa ukusika kunye ukusika, kwaye kushishino lwezempilo, zisetyenziselwa utyando. Xa isicelo sifakwe yokuvelisa, umatshini oxabisa i-US$50,000 unokuzisa ukuya kutsho kwi-US$ 150,000 ekulondolozweni kwiindleko zokupakisha.

Esinye sezizathu zokuthandwa kwazo kukuba ii-cobots ziyilwe kucingwa ngabaqhubi babantu, kwaye zinceda ekuqinisekiseni indima yabasebenzi ngelixa zikwancedisa ekusebenzeni, ukuchaneka, kunye nokhuseleko lokusebenza.

5. Ukuqhubela phambili kumbono womatshini

Inkqubela phambili ebalulekileyo kumbono womatshini ivumela oomatshini abazenzekelayo ukuba benze imisebenzi ngokuchanekileyo kunye nemisebenzi enzima ngakumbi.

Umbono womatshini (MV) ubhekiselele kubuchwephesha kunye neendlela ezisetyenziswa kwi-automation ye-industrial ukubonelela ngokuhlolwa kwe-imaging-based based inspection kunye nohlalutyo lwezicelo ezibandakanya ulawulo lwenkqubo, ukuhlolwa okuzenzekelayo, ukulandelela inxalenye, kunye nesikhokelo serobhothi.

Ngenxa yeenzuzo zesantya esiphezulu, ukusebenza kakuhle, kunye nokuchaneka okukuvumelayo, iminyaka embalwa ezayo iya kubona iteknoloji yombono womatshini isasazwa kwaye idityaniswe neenkqubo ezizenzekelayo.

6. Ukwenyuka kokuthembela kushicilelo lwe-3D

Enye yetekhnoloji eyothusayo eya kuba nefuthe kwimizi-mveliso ye-automation yi-3D yoshicilelo. Ihlabathi le-Automation iqaphela ukuba ushicilelo lwe-3D luya kuba lutshintsho-mdlalo ngaphakathi kwimarike ye-automation yehlabathi njengoko iya kunciphisa kakhulu iindleko zemveliso.

I-automation ye-Industrial automation iyatshintsha ngokukhawuleza kwaye ukubanakho ukwenza iprototype ngokukhawuleza ye-R&D evumela ushicilelo lwe-3D luvumela amashishini ukuba alungelelanise ngokukhawuleza kwiimfuno eziguqukayo zeshishini. Ushicilelo lwe-3D luyasetyenziswa ngoku ukupakisha, imfundo, iyeza, yaye ukwakhiwa.

Ngenxa yeprototyping ekhawulezayo, abavelisi bayakwazi ukuvavanya iikhonsepthi zabo ngokungqongqo ngaphambi kokuba baye kwinqanaba lokuphunyezwa kunye nemveliso epheleleyo. Izibonelelo zoku kukuba uyilo olutsha luziswa kwintengiso ngokukhawuleza, iindleko ze-R&D ziyancitshiswa, 40–70% imathiriyeli engaphantsi isetyenziselwa ukwenziwa kweemveliso xa kuthelekiswa neendlela zemveli, kwaye abathengi bayakwazi ukuba neenxalenye koomatshini babo abazenzekelayo endaweni yabo ngokukhawuleza.

7. Ukwamkelwa okuqhubekayo kweenkqubo zokwenziwa kwezinto eziguquguqukayo

Ukwamkelwa kweenkqubo zokuvelisa eziguquguqukayo (FMS) kuqhubekile phakathi kwamashishini emveliso kwihlabathi liphela. I-FMS yindlela yokuvelisa eyandisa ukulungelelaniswa kokutshintsha kobuninzi okanye uhlobo lwemveliso eyenziwayo.

Ii-FMS zibonelela ngokuguquguquka komatshini, okubhekiselele kwindlela inkqubo ekwazi ngayo ukutshintsha ukudala iintlobo zemveliso entsha okanye ukuguqula umyalelo wokusebenza kwenxalenye ethile. IiFMS zikwabonelela ngokuguquguquka kwendlela, okubhekiselele kubuchule benkqubo bokusebenzisa oomatshini abaninzi ukwenza imisebenzi efanayo kwindawo enye.

Ngelixa ezi nkqubo zinokugqalwa njengexabiso eliphezulu, zisebenza ukwandisa imveliso nokunciphisa iindleko zokusebenza. Ukukwazi kwabo ukuziqhelanisa notshintsho kukwanceda amashishini athintele iimveliso ezineziphene kunye nokuchitha ixesha kunye nezixhobo.

BrainKart Iingxelo ukuba iiFMS zihambisa ukusetyenziswa koomatshini okwandisiweyo xa kuthelekiswa noomatshini abakwimveliso yebhetshi eqhelekileyo, evumela amashishini ukuba afikelele 80-90% kusetyenziso lwempahla. Amazinga aphezulu okuvelisa kunye nokunciphisa ukuthembela ekusebenzeni ngokuthe ngqo ukuba iiFMS zivumela ukuba amashishini enze ukugcinwa kwabasebenzi abanokufikelela. 30-50%.

Ixesha elitsha kwi-industrial automation

Ngeendlela ezininzi, sibona kuphela ukuqala kwe-Industrial 4.0 kunye nefuthe eliya kuba nalo kumashishini, ishishini lemveliso, kunye noluntu ngokubanzi. Into eqinisekisiweyo kukuba eli xesha litsha lokwenziwa kwemizi-mveliso liya kwenza inani elingazange libonwe ngaphambili lesantya kunye nokuchaneka kwemveliso.

Kwangaxeshanye, ishishini lokuvelisa lilungiswa ngokutsha, lenze indlela yokusebenza edityaniswe ngakumbi kwaye inenqanaba eliphezulu lokuchaneka kunye nokhuseleko.

Iindlela eziphambili zokuzisebenzela kwimizi-mveliso ekufuneka uzijonge ziya kuba:

- Umzi mveliso we-Intanethi wezinto

- Shift ukusuka kumatshini ukuya kwimisebenzi yokuzimela

- Iindleko eziphantsi zeengalo zerobhothi

- Ukwandiswa kokwamkelwa kweerobhothi ezisebenzisanayo

- Ukuqhubela phambili kumbono womatshini

- Ukwenyuka kokuthembela kushicilelo lwe-3D

- Ukwamkelwa okuqhubekayo kweenkqubo zemveliso eziguquguqukayo

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu