Oomatshini beLathe baluncedo kuyo nayiphi na iworkshop yentsimbi, benza imisebenzi ephuma ekubumbeni izixhobo zokusebenza ukuya kwi-chipling, i-knurling, kunye nezixhobo zokusika. Ngenxa yokubaluleka kwazo, ukugcinwa kwazo kubaluleke kakhulu ukuba iworkshop iza kusebenza ngaphandle komthungo ixesha elide. Esi sikhokelo sichaza indlela amashishini anokugcina ngayo oomatshini belathe ngokwabo.

Isiqulatho

Kutheni kubalulekile ukugcina umatshini we-lathe

Ubume bomatshini welathe

Uwugcina njani umatshini welathe

Iingcamango zokugqibela

Kutheni ukugcinwa komatshini we-lathe kubalulekile

Oomatshini beLathe bafuna ukulungiswa rhoqo kuba kulula ukuguga nokukrazuka xa besetyenziswa. Ugcino luqinisekisa ukuba oku kunxitywa kulawulwa kwaye umatshini ukwimeko entle yokusebenza. Ngaphandle koko, inciphisa iindleko zokuyilungisa xa kuthelekiswa naxa umatshini wonakala ngenxa yokungalungiswa kwaye inokunciphisa inani lolungiso olufunwa ngumatshini. Okokugqibela, ugcino lukwanceda ukwandisa ukhuseleko lomsebenzi wabaqhubi boomatshini. Ngelixa ukhuseleko lwabasebenzi luxhomekeke kubasebenzi, ulondolozo luthintela ukophuka ngequbuliso okunokwenzakalisa abasebenzi.

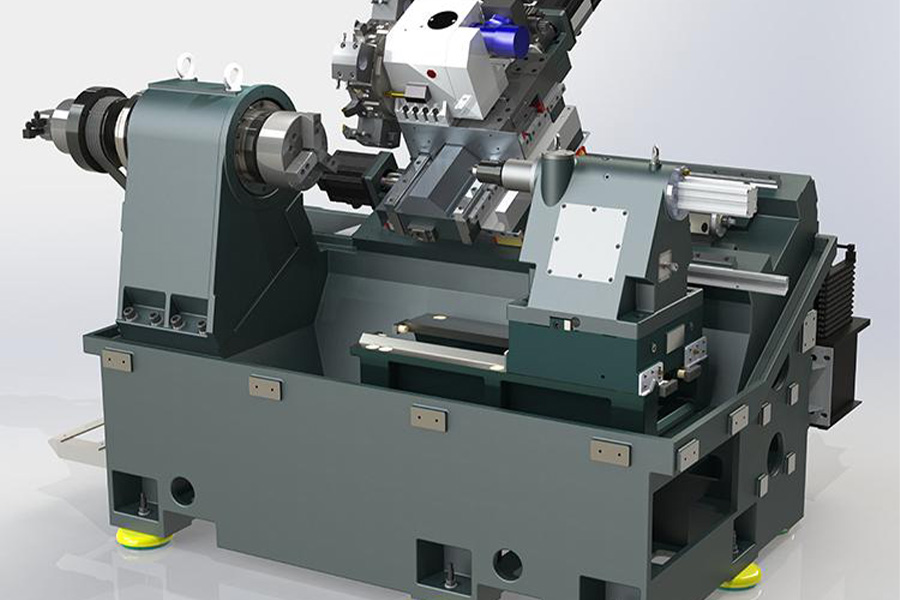

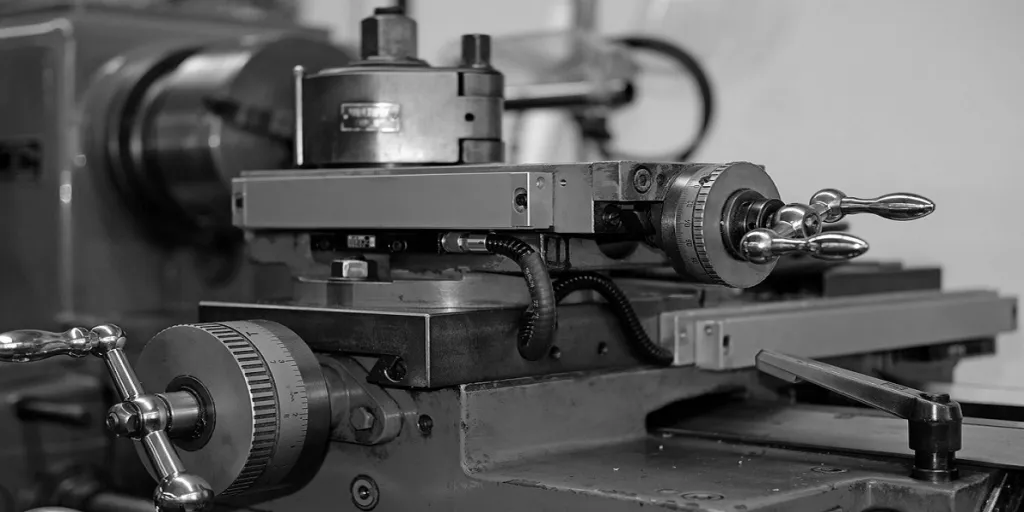

Ubume bomatshini welathe

Ibhedi: Iyinxalenye esisiseko yesikhokelo esichanekileyo kwaye ibambe zonke iinxalenye zomatshini we-lathe.

Ibhokisi yokusonta: Ihambisa amandla ukusuka kwinjini ukuya kwi-spindle ngokusebenzisa iindlela zothumelo.

Ibhokisi yesondlo: Isetyenziselwa ukutshintsha isantya semoto phambi kokuhambisa amandla kumphathi wesixhobo.

Umphathi wesixhobo: Isetyenziselwa ukufaka umsiki kunye nokuqhuba isixhobo. Iquka iipleyiti zezilayidi, isakhelo semela, kunye nesali yebhedi.

I-Tailstock: Ifakwe kumzila wesikhokelo sebhedi kwaye ijikeleze ukulungelelanisa indawo yokusebenza.

Isixhobo sokupholisa: Ikhupha i-fluid yokusika kwindawo yokusika ukunciphisa ubushushu bomsebenzi, ukuyicoca kwaye uyithambise.

Uwugcina njani umatshini welathe

Kukho izinto ezininzi ekufuneka ziqwalaselwe xa ugcina umatshini welathe. Ugcino kufuneka lwenzeke qho iiyure 40 ukuqinisekisa ukuba isebenza kakuhle.

Sebenzisa ibhodi yeleyile

Ibhodi yeleyile inceda ukubamba izinto ekuweni. Xa umqhubi etshintsha amacandelo omatshini welathe, afana neechucks, iicenterpieces, okanye iworkpiece, zize zityibilike, ibhodi yelathe iyayibamba. Ibathintela ukuba bawe phantsi, okuya kubangela umonakalo omkhulu kwiziqwenga.

Gcina izixhobo ngaphandle kwe-lathe way

Naziphi na izixhobo eziyimfuneko ngelixa usebenza kunye nomatshini we-lathe kufuneka zibekwe kwitafile eyahlukileyo kwaye kungekhona kwiindlela ze-lathe. Ngelixa kunokubonakala kukulungele ukubeka izixhobo kwiindlela ze-lathe, ukungcangcazela xa ubaleka kunokubangela ukuba ziwe kumatshini weleyile. Oku kuyingozi empilweni kubasebenzi kwaye kunokubangela umonakalo omkhulu kumatshini.

Thambisa

Umatshini we-lathe wenziwa ngokukodwa ngamacandelo esinyithi. Abaqhubi beLathe kufuneka bahlale beqinisekisa ukuba umatshini uthanjiswe kakuhle phambi kokuba usebenze. Ukungaphumeleli ukwenza oko kunokukhokelela ekuchaseni okukhulu ekuchanekeni kwezixhobo zokusika isinyithi. Umgangatho we-oyile kwiitanki zamadama kufuneka ujongwe rhoqo kwaye uphakanyiswe phezulu ukuba wehlile ngaphantsi kophawu lwesiqingatha sendlela. Izikrufu zefidi, amalungu ahambayo, kunye neebheringi kufuneka zithanjiswe ukuze zisebenze kakuhle phambi kwayo nayiphi na iprojekthi. Ukongeza kwi-lubrication, indawo yokupholisa kufuneka ihlolwe ngamaxesha athile. Ngelixa isisipholisi sisenokungasetyenziswa rhoqo njengeoyile, kuyacetyiswa ukuba kuqinisekiswe ukuba isigcinalwazi saso sigcwalisiwe.

Coca ii-spindle tapers

I-spindle tapers inokufumana i-axial okanye i-radial runout. Ukubaleka kwe-axial kwenzeka xa i-spindle ijikeleza ngaphandle kwe-axis yayo. I-Radial runout yimpazamo eyenzeka kwi-motion perpendicular to spindle axis. Iintambo zokusonta kufuneka zihlolwe kwaye zicocwe ngelaphu elithambileyo, elingenalusini xa kutshintshwa izixhobo. Idyasi yeoyile yenjongo zonke kufuneka isetyenziswe.

Uthuli olucocekileyo

Ukusebenza ngentsimbi, iplastiki okanye umthi kuya kuvelisa uthuli. Olu thuli lunokubambelela kwizinto zokusebenza kunye nakumatshini we-lathe. Uthuli olusuka kwintsimbi etyhidiweyo luyagqabhuka kwaye luyakwazi ukunamathela kumatshini wokuthambisa. Abaqhubi kufuneka bosule uthuli kumatshini, izixhobo zokusebenza, kunye neendlela zokusula. Indlela yokusula kufuneka itshintshwe xa sele igugile. Iichips zetsimbi ezintle zinokubangela umonakalo kwi-chuck ukuba azisuswanga. Imihlathi ye-lathe ke ngoko kufuneka ivaliwe phambi kokuhlola ii-chucks naziphi na iitshiphu zentsimbi ezintle ezifakwe apho ngexesha lokusebenza.

Khusela umatshini kumhlwa

Umhlwa usoloko uyinto enkulu ekufuneka uyiqwalasele xa usebenza ngoomatshini bentsimbi. Ukhuseleko olululo kufuneka lwenziwe koomatshini. Ibalulekile koomatshini abakufutshane nemizimba emikhulu yolwandle ngenxa yamanqanaba aphezulu okufuma. Umhlwa unokubangela ubuthathaka besakhiwo somatshini we-lathe, umhlwa, kunye neendawo ezonakalisiweyo. Ukugada umhlwa, oomatshini bokuleya bafanele bacocwe rhoqo baze baqatywe ngeoyile ethintela ukuhlwa. Umatshini nawo kufuneka ugqunywe xa ungasetyenziswa. Isigqubuthelo kufuneka sifakwe umoya ukuba umatshini welathe uya kuhlala kwindawo yokugcina ixesha elide.

Ukulinganisa inqanaba lokuchaneka emva kokugcinwa

Emva kokugcinwa komatshini we-lathe, ezinye iisetingi zinokuthi ziphazamisekile. Ukulungiswa kwakhona komatshini kucetyiswa emva kokugcinwa. Oku kuya kuvumela umqhubi ukuba aqonde imida yokuchaneka komatshini we-lathe. Ukugcinwa rhoqo kunye nokulinganisa kwakhona kubangela ukuveliswa kwezinto zokusebenza ezichanekileyo.

Iingcamango zokugqibela

Ukongeza ekuchazeni umatshini we-lathe kunye neempawu zawo, esi sikhokelo siye sajonga iingcebiso ezibalulekileyo ukuba ishishini lingasebenzisa ukuqinisekisa ukuba i-lathe yabo ikwimeko elungileyo yokusebenza kuyo yonke indawo. Ulwazi oluthe vetshe ngoomatshini belathe banokufumaneka Chovm.com.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu