- Uphuhliso lwakutsha nje kwi-wet-chemistry enxulumene ne-PERC kunye ne-HJT nayo ingasetyenziselwa ukuphucula i-TOPCon

- I-BSG kunye ne-single side emitter izixhobo zokususa zifuna i-TOPCon utshintsho oluthile phakathi kweebhentshi ezimanzi

- Itekhnoloji ye-atmospheric etching eyomileyo evela kwi-Nines photovoltaics ilungela ngokufanelekileyo kwiimfuno zokususa i-wraround kwiiseli ze-TOPCon

Ngelixa undoqo we TOPCon ilele kwindawo yokubeka i-tunneling oxide kunye ne-polysilicon layer, ivelisa ezi seli, ezifana ne-PERC, ifuna amanyathelo amaninzi okusebenza afanele ukukhankanywa, angagxeki nangona kunjalo. Ezinye zeenkqubo eziyinxalenye yokuhamba kwenkqubo ye-PERC ziyalungiswa okanye ziphuculwe, ngelixa onke amanyathelo amatsha ayafuneka. Njengayo nayiphi na enye itekhnoloji yeeseli, i-TOPCon nayo iqala ngokulungiswa komphezulu, nto leyo efuna ukwenziwa ngcono.

Unyango lwekhemikhali emanzi: Ngelixa ingajoliswanga kwi-TOPCon yodwa, uphuhliso oluphambili olwenzeka kwindawo yebhentshi emanzi ngokuqinisekileyo lunokuxhamla kuphuculo olwenzelwe ezinye iiseli zezakhiwo. Nangona izixhobo ezimbini zokuvelisa kufuneka zilungelelaniswe kwinkqubo ye-TOPCon - i-BSG kunye nezixhobo zokususa i-mitter-side-side-side-, ukuphuculwa kunye namanye amanyathelo onyango omanzi-amachiza nawo abalulekile kwisikimu esikhulu sezinto. Rena kwezinye iilwimi iye yaphucula amaqonga ayo isixhobo izixhobo ibhetshi ezisetyenziselwa isarha etching umonakalo kunye texturing. Ukwenza intetho kwiNkomfa ePhakamileyo yeTaiyangNews, uKuhnlein weRENA ukhankanye ukuba olona phuhliso lwamva nje olunxulunyaniswa nezi zixhobo zebhetshi kukukwazi ukwamkela iiwafers ezinkulu kunye nokusetyenzwa ngabathwali ngoxinaniso lokulayisha okuphezulu. Ngomgangatho ophuculweyo we-wafer ngokubanzi kunye nophuhliso kwintsimi yezongezo, kukho amandla okuphelisa inyathelo lokususwa komonakalo wesaw ukusuka kwi-PERC yokulandelelana ngokupheleleyo, enokuthi izuze i-TOPCon, ngokutsho kukaKuehnlein.

Olunye uphuhliso lwe-PERC olunokunceda kwakhona i-TOPCon bubungakanani obuphuculweyo bephiramidi kunye nokubonakala. Ubume bangoku bobugcisa bubukhulu be-1 ukuya kwi-3 µm yephiramidi kunye ne-9.9 ukuya kwi-10.1% yokubonakalisa nge-monoTEXH2.3. Ngelixa kukho iindlela ezinokunciphisa ubungakanani bephiramidi ukusuka kwi-0.5 ukuya kwi-3 µm kunye nokukhanya okuhambelanayo kwe-8.9 ukuya kwi-10%, le yokugqibela iphunyezwa kuphela kwinani eliqingqiweyo lemitsi emalunga ne-20. I-RENA isebenza kwinkqubo ezinzileyo enokuhlala ngaphezulu kwe-200 yemitsi, iqonda iphiramidi yobungakanani be-0.5 ebonisa ubungakanani be-2. 9.3%.

I-RENA yafunda kumava ayo kunye ne-HJT ukuba ukucocwa emva kokuthumela isicatshulwa kunokuphucula ukusebenza kakuhle - ukuya kuthi ga kwi-0.05% kunye ne-PERC -, enokuthi iphunyezwe kwi-TOPCon processing.

Ukuze ususe i-wravararound, i-RENA ikhuthaza iqonga lesixhobo se-etching elingaphakathi elibizwa ngokuba yi-InPolySide. Ngexesha le-alkaline yecala elinye lokuchopha inyathelo lokuhluba i-poly, i-BSG kwicala lokukhupha iseli ithintela ukufakwa kwe-emitter kunye nenkqubo ichanekile kwicala elinye, okuthetha ukuba umva ushiywe ungachaphazelekanga. Emva kwenyathelo lokuhluba, iglasi iyacinywa.

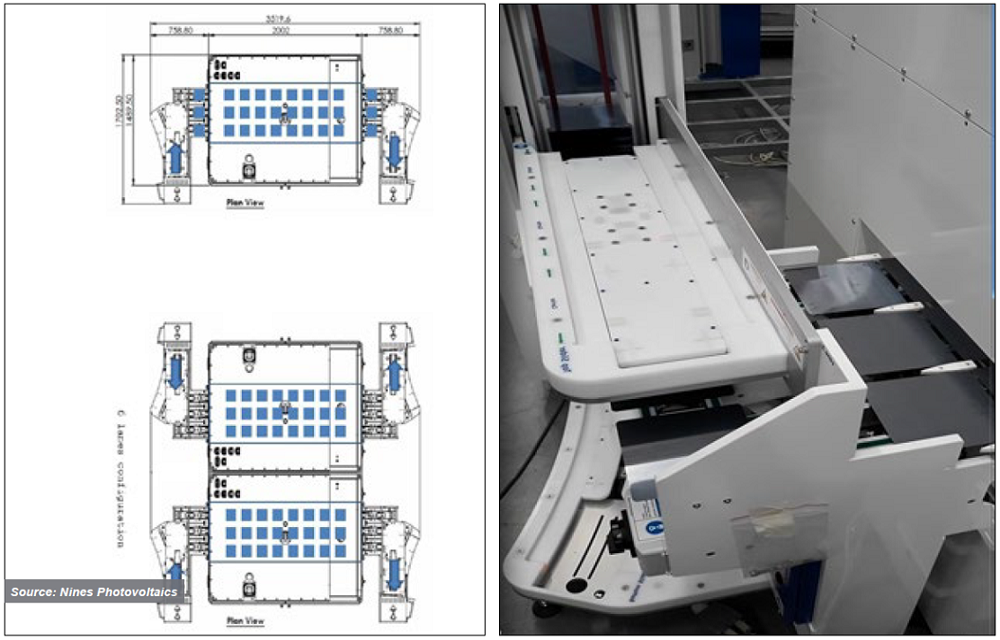

I-atmospheric dry etching: Njengenye indlela kwizisombululo zemichiza emanzi yokususa i-wraround, Nines Photovoltaics esekelwe ngaphandle kweDublin, eIreland, ikhuthaza isisombululo esitsha. Inkampani iphuhlise inkqubo yobunini ebizwa ngokuba yi-ADE, emele i-Atmospheric Dry Etching. Inkampani iye yaphuhlisa inkqubo eyomileyo yokuhombisa ukusukela ngo-2010 njengokutshintshwa kweenkqubo ezisetyenziswa ngokuqhelekileyo kwimichiza emanzi esetyenziswa kwimveliso yeeseli ze-PV. Yintoni eyenza le teknoloji ibe yodwa kukuba ifezekisa i-texturing eyomileyo kuxinzelelo lwe-atmospheric, isusa imfuno ye-vacuum kunye ne-plasma, ezo zombini izithako ezingundoqo kunye nabaqhubi beendleko kubuchwepheshe be-etching eyomileyo, igxininisa i-Nines Photovoltaics 'CTO Laurent Clochard.

Indawo yokusabela ye-reactor yodwa ukusuka kwabanye ngokusebenzisa amakhethini egesi. Inkqubo ifezekiswa ngendlela engaphakathi. Amaqhekezana afakwa koomatshini ngokusetyenziswa kwesiphatho se-wafer esishushu. Irhasi etshisayo, eyifluorine (F2), isebenze ngokushushu ukuze yahlukanise iimolekyuli. I-etchant ihanjiswa kwiiwafers ngesixhobo sosasazo esenziwe ngobunjineli ngokukodwa ukuze kudalwe ubunzulu obufunekayo, ukuthungwa kunye nokufana. UClochard ucacisa ukuba itekhnoloji ayinayo impembelelo engalunganga kwindalo. Ingcinga yefluorine njengerhasi etshisayo ngokwayo ikhalisa iintsimbi ezilumkisayo malunga neegesi zegreenhouse. Nangona kunjalo, ngokungafaniyo ne-SF esetyenziswa ngokuqhelekileyo6 ngamandla obushushu behlabathi obuphezulu bokuhombisa okomileyo, imolekyuli yefluorine esetyenziswa nguNines ayinakho ukufudumala kwehlabathi.

Isixhobo, xa saqaliswa kwi-2017, yayiyilwe ngokukodwa kwi-texturing, ukuba ibe yinto ethile, kwi-multicrystalline, apho ukuzuza ekuboniseni i-ADE kuphezulu kakhulu kunokuba kunokufezekiswa kunye nemeko yobugcisa bezisombululo zemichiza emanzi. Nangona kunjalo, ngokutshintshela kwimarike kwi-monocrystalline, i-Nines Photovoltaics nayo yajika ingqwalasela yayo kwi-PERC eqhelekileyo kunye nobunye ubuchwepheshe obuphambili. Ngelixa itekhnoloji isaqhubela phambili izibonelelo zayo ekuthumeleni imiyalezo, i-ADE ifumene isicelo esinomtsalane ngakumbi kwi-TOPCon kusetyenzwa kweeseli. Ukunikezelwa kwecala layo elilodwa lenkqubo, ingasetyenziselwa ngokufanelekileyo ukususwa kwe-wraround. "Yintoni egqithisile?" Utshilo uClochard, "Ungakhetha ukuchongwa komphezulu kunye / okanye ukususwa komphetho, njengoko itekhnoloji nayo ikhetha." Oko kuthetha ukuba inkqubo ye-Nines Photovoltaics ayifezekisi kuphela i-etching ngaphandle kokuphazamisa iprofayile ye-emitter engaphantsi, kodwa inokuthi yenziwe ngobunjineli ukususa i-polysilicon kwimiphetho ye-wafer, elona galelo liphambili kwii-shunts kunye nelahleko yesivuno. Isixhobo sinesicelo naxa iinkqubo zokubeka zicalanye.

I-Nines ngoku isebenza kumgca wokulingwa kwiziko layo eliseDublin kwaye ibambisene neFraunhofer ISE kuphuhliso lwenkqubo yeeseli ngelixa ikwabonelele ngenkqubo ye-R&D-scale. Inkampani ngoku ilungele iqonga lemveliso, elinikezelwa kwii-2 ezahlukeneyo - i-ADE-3000 kunye ne-ADE-6000. Iinkqubo zokugqibela zihamba ukuya kubukhulu be-M4 kwiindlela ezintandathu kunye ne-M6 ukuya kwi-G12 kwiindlela ezi-4. Isixhobo sinomthamo olinganisiweyo we-12,000 kunye ne-8,000 wafers ngeyure, ngokulandelanayo, kwinqanaba le-12 m.2. Inani lemizila lisisiqingatha kanye nge-ADE-3000, kunjalo ke ne-throughput. La manani okuphumelela, nangona kunjalo, ngawenkqubo yokubhala, okuthetha ukuba umthamo wesixhobo unokuba phezulu kakhulu kwi-etching-side etching kwi-TOPCon. UClochard uyachaza: “Isixa se-silicon ekufuneka sisuswe amaxesha ali-10 ngaphantsi kwento obuya kuyithumela. Inkampani ikwazimisele ukubonelela ngenkqubo yesikali ye-R&D ngendledlana enye yezothutho. Ngokumalunga neendleko, uClochard uthi iindleko ziphantsi kakhulu kuneenkqubo zemichiza emanzi kwaye izibonelelo zibonakala ngakumbi kwimveliso yesikali esikhulu. Oku kuququzelelwa yinyaniso yokuba irhasi ye-etching inokuveliswa kwindawo, ngokutsho kweClochard.

Umthombo ovela Iindaba zaseTaiyang

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu