Ukusukela ngo-2024, imarike yomatshini wokuwelda umbane wehlabathi jikelele, kubandakanywa i-TIG welders, kuqikelelwa ukuba iya kukhula kwi-CAGR ye-7.81%, ifikelele kwi-USD 9.35 yezigidigidi ngo-2030. Kubathengi bamashishini, ukukhetha i-TIG welder efanelekileyo kubalulekile ukuhlangabezana neemfuno ezithile zabathengi babo kunye nokuqinisekisa iiwelds ezikumgangatho ophezulu.

Isiqulatho:

– Ukuqonda ukubaluleka kwe-TIG Welders kuShishino loomatshini

-Izinto eziphambili ekufuneka ziqwalaselwe xa ukhetha i-TIG Welder

-Iintlobo ze-TIG Welders kunye nezicelo zabo

-Iendlela ezisakhulayo kwi-TIG Welding Technology

– Ukuvavanya iNdleko epheleleyo yoBunini kwi-TIG Welders

– Ukusondezwa

Ukuqonda ukubaluleka kwe-TIG Welders kuShishino loomatshini

Izicelo eziphambili ze-TIG Welding kumacandelo ahlukeneyo

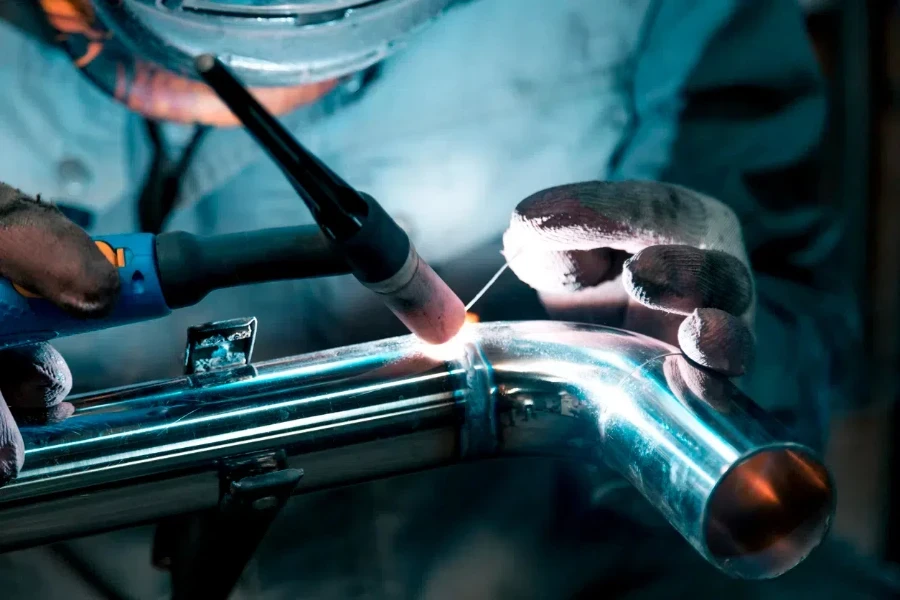

Ukuwelda kwe-TIG, okanye i-Tungsten Inert Gas welding, ibalulekile kumacandelo afuna ukuchaneka okuphezulu kunye ne-welds ecocekileyo. Kwishishini le-aerospace, i-TIG welding isetyenziswa kakhulu ngokukwazi kwayo ukuvelisa i-welds ekumgangatho ophezulu, engenaziphene kwizinto ezincinci. Oku kuchaneka kubalulekile kwimfezeko yesakhiwo samalungu eenqwelomoya. Ushishino lweemoto luxhomekeke kakhulu kwi-TIG ye-welding yokudibanisa iindawo ezibalulekileyo, ezifana neenkqubo zokukhupha kunye nezixhobo ze-chassis, apho amandla kunye nokuqina kubaluleke kakhulu.

Kushishino lwezixhobo zonyango, ukuwelda kwe-TIG kubaluleke kakhulu ngenxa yobuchule bayo bokudala i-welds ecocekileyo, engenalungcoliso. Oku kubalulekile ekuqinisekiseni ukhuseleko kunye nokusebenza kwezixhobo zonyango kunye nokufakelwa. Ukongeza, umzi-mveliso wokutya kunye nesiselo usebenzisa i-TIG welding ukwenza izixhobo zentsimbi engenasici, ekufuneka zihlangabezane nemigangatho engqongqo yococeko. Ukukwazi ukuvelisa i-welds egudileyo, engenaziqhekeza inceda ukukhusela ukukhula kwebhaktheriya, ukuqinisekisa ukuthotyelwa kwemimiselo yezempilo.

Icandelo lokwakha lixhamla kwi-TIG ye-welding's versatility ekudibaniseni iintsimbi ezahlukeneyo, kubandakanywa i-aluminiyam kunye nensimbi engenasici. Esi sikhundla siluncedo kakhulu kwizicelo zoyilo apho umgangatho wobuhle kunye nentembeko yesakhiwo zibaluleke kakhulu. Ngaphezu koko, i-TIG i-welding isetyenziswe ekuveliseni iinqanawa zoxinzelelo kunye nemibhobho, apho umgangatho we-welds uchaphazela ngokuthe ngqo ukhuseleko kunye nokusebenza.

Ukukhula kunye neMfuno ye-TIG Welders kwihlabathi jikelele

Imfuno yehlabathi ye-TIG welders iyanda, iqhutywa kukwandiswa kwamashishini abalulekileyo kunye neeprojekthi zeziseko. Ngokohlalutyo lwamva nje lwemarike, imakethi yomatshini wokuwelda umbane, equka i-TIG welders, ikhule ukusuka kwi-USD 5.52 yezigidigidi ngo-2023 ukuya kwi-USD 5.93 yezigidigidi ngo-2024. Oku kukhula kulindeleke ukuba kuqhubeke ngesantya sokukhula sonyaka esihlanganisiweyo (CAGR) se-7.81%, sifikelele kwi-USD 9.35 yezigidigidi ngo-2030.

Kwingingqi yeAsia-Pacific, amazwe anje ngeTshayina, iIndiya, kunye neJapan abona ukukhula okubonakalayo kwimakethi ye-TIG welder. Oku kuphenjelelwa ziiprojekthi ezinkulu zeziseko ezingundoqo, ishishini leemoto elikhulayo, kunye necandelo lemveliso elikhulayo. Ukwenziwa kwezinto ezintsha kwitekhnoloji ye-welding kunye nokwanda kotyalo-mali kuphando lwengingqi kunye nophuhliso kukhokelele ekuvelisweni komgangatho ophezulu kunye nezisombululo ze-welding ezinexabiso eliphantsi, ngakumbi ukuqhuba ukukhula kwemarike.

Amazwe aseMelika, ngakumbi i-United States, ikwamele imarike enkulu yabashiseli be-TIG. Amacandelo emizi-mveliso awomeleleyo, kubandakanywa iimoto, ulwakhiwo, kunye nokuvelisa, ngabaqhubi abaphambili bemfuno. Ukwamkelwa kobuchwephesha bokuwelda obukwinqanaba eliphezulu, olunje nge-automated kunye ne-semi-automated systems, iphucula impumelelo kunye nemveliso, inegalelo ekwandeni kwemarike. Ukongeza, iiprojekthi zeziseko zophuhliso kunye nophuhliso lwecandelo lamandla eCanada naseBrazil zenza imfuno yezixhobo zokuwelda ze-TIG.

Imiba ephambili ekufuneka iqwalaselwe xa ukhetha i-TIG Welder

IsiPhumo saMandla kunye noLuhlu lwe-Amperage

Xa ukhetha i-TIG welder, ukuphuma kwamandla kunye noluhlu lwe-amperage zizinto ezibalulekileyo ekufuneka ziqwalaselwe. Imveliso yamandla imisela isakhono somshiseli ukujongana nobukhulu obahlukeneyo bemathiriyeli. Umzekelo, i-welder enoluhlu oluphezulu lwe-amperage inokuwelda imathiriyeli engqindilili, iyenze ilungele usetyenziso olunzima. Ngokwahlukileyo, uluhlu olusezantsi lwe-amperage lufanelekile kwizinto ezincinci, eziqinisekisa ukuchaneka kunye nokulawula.

Uluhlu lwe-amperage lukwachaphazela ukuguquguquka kwe-welder. Uluhlu olubanzi lwe-amperage luvumela i-welder ukuba isetyenziswe kuluhlu olubanzi lwezicelo, ukusuka kwizinto ezithambileyo, ezibhityileyo ukuya kwintsimbi eyomeleleyo, engqindilili. Oku kubhetyebhetye kuluncedo ngakumbi kumashishini afana ne-aerospace kunye neenqwelomoya, apho amacandelo ahlukeneyo afuna ukucaciswa kwe-welding ezahlukeneyo. Ukongeza, ukukwazi ukulungelelanisa i-amperage ngokuchanekileyo kuqinisekisa ubulunga obuphezulu be-weld kwaye kunciphisa umngcipheko weziphene.

Ngaphaya koko, uhlobo lomthombo wamandla, nokuba yi-AC okanye i-DC, idlala indima ebalulekileyo ekusebenzeni komtshisi. Amandla e-AC aqhele ukusetyenziselwa ukuwelda ialuminiyam kunye nemagnesium, ngelixa amandla eDC akhethwa kwintsimbi yokuwelda kunye nentsimbi engatyiwayo. Ukuqonda iimfuno ezithile zezinto ezidityanisiweyo ziyimfuneko ekukhetheni ukukhutshwa kwamandla okufanelekileyo kunye noluhlu lwe-amperage, ukuqinisekisa i-welds esebenzayo kunye nekhwalithi ephezulu.

Ubunakho be-AC / DC kunye neeNzuzo zayo

Ubunakho be-AC/DC be-TIG welder luphawu olubalulekileyo oluphucula ukuguquguquka kunye nokusebenza kwayo. I-AC (Alternating Current) isetyenziselwa ukuwelda iintsimbi ezingenayo i-ferrous njenge-aluminiyam kunye ne-magnesium. Umsinga otshintshanayo unceda ukwaphula umaleko weoksidi kumphezulu wezi zinyithi, uqinisekisa i-weld ecocekileyo neyomeleleyo. Esi sixhobo siyimfuneko kwizicelo kwimizi-mveliso ye-aerospace kunye ne-automotive, apho i-aluminium isetyenziswa ngokuqhelekileyo.

I-DC (I-Direct Current), kwelinye icala, isetyenziselwa ukuwelda isinyithi esivuzayo njengentsimbi kunye nentsimbi engatyiwa. I-DC welding ibonelela nge-arc ezinzileyo kunye nokungena nzulu, iyenza ilungele izinto ezityebileyo. Ukukwazi ukutshintsha phakathi kweendlela ze-AC kunye ne-DC kuvumela abashiseli ukuba baphathe uluhlu olubanzi lwezixhobo kunye nokusetyenziswa, ukwandisa ukusetyenziswa kwabo kumashishini ahlukeneyo. Oku bhetyebhetye kunenzuzo ngakumbi kwimveliso kunye nokwakhiwa, apho iiprojekthi ezahlukeneyo zinokufuna ukuwelda iintlobo ezahlukeneyo zesinyithi.

Ngaphezu koko, isakhono se-AC/DC siphucula ukusebenza kakuhle kwe-welder kunye nemveliso. Ngokusebenzisa uhlobo lwangoku olufanelekileyo kwizinto ezidityanisiweyo, abaqhubi banokufikelela kwimigangatho ephezulu ye-welds kunye neziphene ezimbalwa. Oku kunciphisa isidingo sokuphinda kusetyenzwe kwaye kwandisa imveliso ngokubanzi. Ukongeza, ukukwazi ukutshintsha phakathi kweendlela ze-AC kunye ne-DC ngokukhawuleza kwaye kulula ukufezekisa inkqubo ye-welding, ukonga ixesha kunye nomgudu.

UMjikelo woMsebenzi kunye neMpembelelo yawo kwiMveliso

Umjikelo womsebenzi we-TIG welder yinto ebalulekileyo echaphazela ngokuthe ngqo imveliso. Umjikelo womsebenzi ubhekisa kwisixa sexesha umshiseli anokusebenza ngokuqhubekayo kwi-amperage enikiweyo ngaphambi kokuba afune ukupholisa. Ngokomzekelo, i-welder ene-60% yomjikelezo womsebenzi kwi-amps ye-200 inokuthi iqhube ngokuqhubekayo imizuzu engama-6 kwimizuzu eyi-10 ngaphambi kokuba ifune i-cooldown yemizuzu emi-4. Umjikelo ophezulu womsebenzi uvumela ixesha elide lokutshisa, ukwandisa ukusebenza kakuhle kunye nokunciphisa ixesha lokunciphisa.

Kwizicelo zoshishino, apho iiprojekthi ze-welding ezinkulu ziqhelekileyo, umjikelezo ophezulu womsebenzi uyimfuneko ekugcineni imveliso. I-Welders ezinomjikelezo ophezulu womsebenzi unokusingatha imisebenzi ebanzi kwaye enzima ngaphandle kokuphazamiseka rhoqo. Oku kubaluleke ngakumbi kumacandelo afana nokwakha kunye nokuvelisa, apho ukuwelda okuqhubekayo kudla ngokufuneka ukuhlangabezana nemihla ebekiweyo yeprojekthi kunye nokugcina iishedyuli zemveliso.

Ukongeza, umjikelo womsebenzi uchaphazela ukusebenza ngokubanzi kwe-welder kunye nokuphila ixesha elide. Ukusebenzisa i-welder ngaphaya komjikelo wayo womsebenzi kunokukhokelela ekugqithiseni kunye nomonakalo onokwenzeka kwisixhobo. Ngoko ke, ukukhetha i-welder kunye nomjikelezo ofanelekileyo womsebenzi kwizicelo ezijoliswe kuyo kuqinisekisa ukusebenza okuthembekileyo kunye nokwandisa ixesha lokuphila kwezixhobo. Olu qwalaselo lubalulekile kumashishini ajonge ukwandisa imbuyekezo yawo kutyalo-mali kunye nokunciphisa iindleko zokulondoloza.

Ukuphatheka kunye nokuQwalasela ubunzima

Ukuphatheka kunye nobunzima zizinto ezibalulekileyo ekufuneka ziqwalaselwe xa ukhetha i-TIG welder, ngakumbi kwizicelo ezifuna ukuhamba. I-welders ekhaphukhaphu kunye nephathwayo ilungele umsebenzi wasendle, ukulungisa imisebenzi, kunye neeprojekthi ezibandakanya ukuhamba phakathi kweendawo ezahlukeneyo. Ezi welding kulula ukuthutha kunye nokusetha, okwenza kube lula kwimisebenzi ye-welding kwi-site kumashishini afana nokwakha nokugcina.

Ubunzima be-welder buchaphazela ukusetyenziswa kwayo kunye ne-ergonomics. I-welders elula kulula ukuyiphatha kunye nokusebenza, ukunciphisa ukukhathala kwabaqhubi kunye nokuphucula ukusebenza kakuhle. Oku kuluncedo ngakumbi kwimisebenzi efuna ukuwelda ixesha elide okanye ukusebenza kwiindawo ezivaliweyo. Ukongeza, iiwelder eziphathwayo zihlala zineempawu ezifana nezibambo okanye amavili, ziphucula ngakumbi ukuhamba kwazo kunye nokusebenziseka ngokulula.

Nangona kunjalo, kubalulekile ukulinganisa ukuthwala kunye nokusebenza. Nangona i-welders lightweight ilungile, kufuneka ibonelele ngamandla aneleyo kunye nokusebenza kwezicelo ezijoliswe kuzo. Ukuqinisekisa ukuba i-welder ihlangabezana neenkcukacha ezifunekayo zokukhutshwa kwamandla, umjikelo womsebenzi, kunye nezinye izinto zokusebenza kubalulekile ekufezekiseni i-welds ephezulu kunye nokugcina imveliso. Ke ngoko, amashishini kufuneka avavanye ngononophelo iimfuno zabo ezithile kwaye akhethe i-welder enikezela ukudibanisa okufanelekileyo kokuphatheka kunye nokusebenza.

Iimpawu zoLawulo kunye neNdibaniselwano yomsebenzisi

Iimpawu zolawulo kunye nojongano lomsebenzisi we-TIG welder ichaphazela kakhulu ukusetyenziswa kwayo kunye nokuchaneka kwayo. Iimpawu zolawulo oluphezulu, ezifana ne-pulse welding, zivumela abaqhubi ukuba balawule igalelo lokushisa kunye nokunciphisa umngcipheko wokulwa okanye ukutshisa ngezinto ezincinci. Oku kuluncedo ngakumbi kwiinkqubo ezifuna ukuchaneka okuphezulu, okufana ne-aerospace kunye nokuveliswa kwezixhobo zonyango. Ukongezelela, iimpawu ezifana nokuhamba kwangaphambili kunye nokulawulwa kwegesi emva kokuhamba kunceda ukukhusela indawo ye-weld ekungcoleni, ukuqinisekisa i-welds ephezulu.

Ujongano olusebenziseka lula longeza ukukwazi komsebenzisi ukulungelelanisa useto ngokukhawuleza nangokuchanekileyo. Imiboniso yedijithali kunye nolawulo olucacileyo lwenza kube lula ukuseta kunye nokubeka iliso kwiiparamitha ezifana ne-amperage, i-voltage, kunye nokuhamba kwegesi. Oku kunciphisa ijika lokufunda kubaqhubi abatsha kwaye kwandisa ukusebenza kakuhle ngokubanzi. Kwiimeko zoshishino, apho ii-welders ezininzi zinokusetyenziswa, i-interface ehambelanayo kunye nelula ukuyisebenzisa iqinisekisa ukuba bonke abaqhubi banokufikelela kwiziphumo ezifunwayo ngoqeqesho oluncinci.

Ngapha koko, useto olucwangcisiweyo kunye nemisebenzi yememori ivumela abaqhubi ukuba bagcine kwaye bakhumbule iiparamitha ezithile ze-welding kwizicelo ezahlukeneyo. Olu phawu luluncedo ngakumbi kwiindawo zemveliso apho ukungaguquguquki kunye nokuphindaphinda kubalulekile. Ngokugcina izicwangciso ezikhethiweyo, abaqhubi banokutshintsha ngokukhawuleza phakathi kwemisebenzi ye-welding eyahlukeneyo ngaphandle kwesidingo sohlengahlengiso lwezandla, ukugcina ixesha kunye nokunciphisa umngcipheko weempazamo. Ngokubanzi, iimpawu zolawulo oluphezulu kunye nojongano olusebenziseka lula lunegalelo ekuphuculeni umgangatho we-weld, ukusebenza kakuhle, kunye nokwaneliseka komsebenzisi.

Iimpawu zoKhuseleko kunye neMigangatho yokuThobela

Iimpawu zokhuseleko kunye nemigangatho yokuthotyelwa zibaluleke kakhulu xa ukhetha i-TIG welder, njengoko iqinisekisa ukukhuselwa kwabaqhubi kunye nokuthotyelwa kwemimiselo yoshishino. Iimpawu eziphambili zokhuseleko ziquka ukukhuselwa kwe-thermal overload, okuthintela i-welder ekugqithiseni kunye nokunciphisa umngcipheko wokulimala kwezixhobo kunye nokulimala komsebenzisi. Ukongeza, iifitsha ezifana ne-high-frequency start kunye nozinzo lwe-arc lunceda ukunciphisa umngcipheko wogwayimbo lwe-arc ngengozi kunye nokuphucula ukhuseleko xa lusebenza.

Ukuthotyelwa kwemigangatho yoshishino kunye neziqinisekiso, ezifana ne-CE, UL, kunye ne-ISO, kubalulekile ekuqinisekiseni ukuba i-welder ihlangabezana neemfuno zokhuseleko kunye nokusebenza. Le migangatho inika isiqinisekiso sokuba izixhobo zivavanyiwe kwaye ziqinisekisiwe ukusebenza ngokukhuselekileyo phantsi kweemeko ezahlukeneyo. Kumashishini afana nokwakha kunye nokuvelisa, apho imigaqo yokhuseleko ingqongqo, ukusebenzisa izixhobo eziqinisekisiweyo kubalulekile ukugcina ukuthotyelwa kunye nokuphepha iziphumo ezinokuthi zibe khona zomthetho kunye nezemali.

Ngaphaya koko, izixhobo zokhuselo lomntu (i-PPE) kunye nezixhobo zokhuseleko, ezinje ngeehelmethi zokuwelda, iiglavu, kunye nempahla ekhuselayo, kufuneka zisetyenziswe ngokubambisana ne-welder ukomeleza ukhuseleko lomsebenzisi. Ukuqinisekisa ukuba i-welder iyahambelana nezi zincedisi kwaye ibonelela ngokhuseleko olwaneleyo kwiingozi ezifana nemitha ye-UV, iintlantsi, kunye nomsi kubalulekile ekudaleni indawo ekhuselekileyo yokusebenza. Ngokubeka phambili iimpawu zokhuseleko kunye nemigangatho yokuthotyelwa, amashishini anokukhusela abasebenzi bawo, anciphise umngcipheko weengozi, kwaye agcine indawo yokusebenza ekhuselekileyo nenemveliso.

Iintlobo ze-TIG Welders kunye nezicelo zabo

Inverter-Isekelwe TIG Welders

Iinverter-based TIG welders ziyaziwa ngokusebenza kwazo kunye nokuguquguquka. Ezi welder zisebenzisa izixhobo ze-elektroniki eziphucukileyo ukuguqula amandla ngokufanelekileyo, okukhokelela kuyilo oluhlangeneyo kunye nolukhaphukhaphu. Oku kubenza balungele izicelo ezifuna ukuphatheka, njengokusebenza ngaphandle kunye nokulungiswa kwendawo. Ukongeza, ii-welders ezisekwe kwi-inverter zibonelela ngolawulo oluchanekileyo kwiiparamitha ze-welding, ezivumela i-welds ezikumgangatho ophezulu kwizinto ezahlukeneyo, kubandakanya i-aluminium, insimbi engenasici, kunye ne-titanium.

Itekhnoloji ephuculweyo esetyenziswa kwi-inverter-based welders ibonelela ngeenzuzo ezininzi, kubandakanywa umjikelo ophezulu womsebenzi kunye nokuphuculwa kozinzo lwe-arc. Oku kuvumela ixesha elide le-welding kunye nokusebenza okungaguqukiyo, okubenza bafaneleke kwizicelo zoshishino apho imveliso kunye nokuthembeka kubaluleke kakhulu. Kumacandelo afana ne-aerospace kunye ne-automotive, apho ukuchaneka kunye nomgangatho kubaluleke kakhulu, ii-welders ze-TIG ezisekelwe kwi-inverter zikhethwa ngokukwazi ukuvelisa i-welds ezicocekileyo nezingenasiphako.

Ngaphezu koko, ii-welders ezisekelwe kwi-inverter zisebenza ngamandla, zinciphisa ukusetyenziswa kwamandla kunye neendleko zokusebenza. Oku kunenzuzo ngakumbi kwimisebenzi yokwenziwa komgangatho omkhulu apho ukongiwa kwamandla kunokuchaphazela kakhulu umgca osezantsi. Ukukwazi ukusebenza kwimithombo eyahlukeneyo yamandla, kubandakanywa iijenereyitha, kwandisa ngakumbi ukuguquguquka kwazo kwaye kubenze balungele ukusetyenziswa kwiindawo ezikude. Ngokubanzi, ii-welders ze-TIG ezisekwe kwi-inverter zibonelela ngokudityaniswa kokuphatheka, ukuchaneka, kunye nokusebenza kakuhle, kubenza babe yi-asethi yexabiso kumashishini ahlukeneyo.

Iiwelder zeTIG eziSekwe kwiTransformer

Iiwelder ze-TIG ezisekelwe kwi-transformer ziyaziwa ngokuhlala kwazo kunye nokomelela. Aba bashicileli basebenzisa itekhnoloji yesiguquli sokuguqula amandla ukuguqula amandla, okukhokelela kuyilo olukhulu nolunzima ngakumbi xa kuthelekiswa neewelder ezisekwe kwi-inverter. Nangona kunjalo, ukulula kwabo kunye nokuthembeka kwabo kubenza bafanelekele usetyenziso olunzima kunye neendawo ezisingqongileyo apho i-ruggedness ibalulekile. Amashishini afana nokwakhiwa kweenqanawa, ulwakhiwo, kunye nemveliso enzima ihlala ikhetha iiwelder ezisekwe kwi-transformer ukuze bakwazi ukusingatha imisebenzi enzima.

Enye yeenzuzo eziphambili ze-welders ezisekelwe kwi-transformer kukukwazi kwabo ukuhambisa ukusebenza okuhambelanayo phantsi kweemeko ezinzima. Abanovelwano kangako kukuguquguquka kwamandla kwaye banokusebenza ngokufanelekileyo kwiindawo ezinombane ongazinzanga. Oku kubenza balungele ukusetyenziswa kwiindawo ezikude kunye noseto lwefektri apho umgangatho wamandla unokuba ngumba. Ukongezelela, ukwakhiwa kwazo okuqinileyo kuqinisekisa ukuthembeka kwexesha elide kwaye kunciphisa imfuno yokugcinwa rhoqo kunye nokulungiswa.

Ngelixa i-welders esekelwe kwi-transformer inokuthi iswele ezinye zeempawu eziphambili zeemodeli ezisekwe kwi-inverter, zibonelela ngexabiso elihle kakhulu kwizicelo ezifuna ukuphuma kwamandla aphezulu kunye nokuqina. Ukukwazi kwabo ukuphatha izixhobo ezishinyeneyo kunye nokubonelela ngokungena okunzulu kubenza balungele ukuwelda izinto zesakhiwo kunye noomatshini abanzima. Ngokukhetha i-welder ye-TIG esekelwe kwi-transformer, amashishini anokuzuza ekusebenzeni okuthembekileyo kunye nokuphila ixesha elide, ukuqinisekisa ukuba iimfuno zabo ze-welding zidibene nakwiindawo ezifuna kakhulu.

IiWelders zenkqubo ezininzi

Iinkqubo ezininzi zokuwelda zibonelela ngobuchule bokwenza iindlela ezahlukeneyo zokuwelda, kubandakanya i-TIG, i-MIG, kunye ne-welding stick. Oku bhetyebhetye kubenza babe lolona khetho lubalaseleyo kumashishini afuna iinkqubo ezahlukeneyo zokuwelda kwizicelo ezahlukeneyo. Ii-welders zeenkqubo ezininzi zinenzuzo ngokukodwa kumashishini afana nokulungiswa kweemoto, ukuveliswa, kunye nokugcinwa, apho imisebenzi ye-welding eyahlukeneyo inokufuneka kwiprojekthi enye. Ukukwazi ukutshintsha phakathi kweenkqubo ngokukhawuleza kwaye kulula ukwandisa imveliso kunye nokunciphisa imfuno yoomatshini abaninzi.

Ukuhlanganiswa kweenkqubo ezininzi ze-welding kumatshini omnye kwakhona kunika ukugcinwa kweendleko kunye nokusebenza kakuhle kwendawo. Esikhundleni sotyalo-mali kwii-welders ezihlukeneyo kwinkqubo nganye, amashishini angasebenzisa i-multi-process welder ukusingatha uluhlu olubanzi lwemisebenzi. Oku kunciphisa utyalo-mali lokuqala kunye neendleko eziqhubekayo zokulondoloza, nto leyo eyenza ukuba ibe sisisombululo esingabizi kakhulu kumashishini amancinci ukuya kwaphakathi. Ukongeza, uyilo oludityanisiweyo lwee-welders zeenkqubo ezininzi lugcina indawo yokusebenzela exabisekileyo, eluncedo kakhulu kwiindibano zocweyo kunye nezixhobo zokuvelisa ezinendawo encinci.

Ngaphaya koko, iiwelder zeenkqubo ezininzi zihlala zineempawu eziphambili kunye nolawulo lwedijithali oluphucula ukusetyenziswa kunye nokusebenza kwabo. Iimpawu ezinje ngohlengahlengiso oluzenzekelayo lweparameter, useto lwememori, kunye ne-interfaces enembile yenza kube lula kubaqhubi ukuba bafezekise i-welds ezihambelanayo kunye neziphezulu. Oku kubaluleke ngakumbi kwiindawo zemveliso apho ukusebenza kunye nokuchaneka kubaluleke kakhulu. Ngokutyala imali kwi-welder eneenkqubo ezininzi, amashishini anokuxhamla kwizinto ezininzi, ukonga iindleko, kunye nobuchule obuphambili obunikezwa ngaba matshini.

Iindlela ezisakhulayo kwi-TIG Welding Technology

I-Automation kunye ne-Robotics Integration

Ukudityaniswa kwe-automation kunye nerobhothi kwi-TIG welding yindlela ebalulekileyo yokubumba ikamva loshishino. Iinkqubo ze-welding ezizenzekelayo kunye ne-robotic welders zibonelela ngokuchaneka okwandisiweyo, ukungaguquguquki, kunye nokusebenza kakuhle, okubenza ukuba balungele indawo yokuvelisa umthamo ophezulu. Ezi nkqubo zinokwenza imisebenzi ye-welding enzima kunye nokungenelela okuncinci komntu, ukunciphisa umngcipheko weempazamo kunye nokuphucula imveliso jikelele. Kumashishini afana neenqwelo-moya kunye ne-aerospace, apho ukuchaneka kunye nokuphindaphinda kubalulekile, ukwamkelwa kweenkqubo zokuwelda ezizenzekelayo ze-TIG kuyanda.

Iinkqubo zokuwelda iirobhothi zikwaphakamisa ukhuseleko ngokunciphisa imfuno yabaqhubi ukuba basebenze kwiindawo ezinobungozi. Ngokwenza imisebenzi ephindaphindwayo neyingozi, amashishini anokukhusela abasebenzi bawo kwaye athobele imithetho engqongqo yokhuseleko. Ukongeza, ukusetyenziswa kweerobhothi kwi-welding kuvumela ukuguquguquka okukhulu kwiinkqubo zemveliso, okwenza abavelisi baqhelane ngokukhawuleza neemfuno eziguqukayo kunye neemeko zentengiso. Lo mkhwa kulindeleke ukuba uqhubeke njengoko ukuqhubela phambili kwirobhothi kunye netekhnoloji ye-automation kuqhuba uphuculo olungakumbi ekusebenzeni kakuhle kunye nomgangatho.

Ukuqhubela phambili kwiMathiriyeli ye-Welding kunye ne-Consumables

Ukuqhubela phambili kwizixhobo ze-welding kunye nezinto ezisetyenziswayo ziqhuba ukuphuculwa kwe-TIG yokusebenza kwe-welding kunye nokusebenza kakuhle. Ukuphuhliswa kwezinto ezintsha zokuzalisa kunye nee-electrode ezinepropathi ezongeziweyo, ezifana nokonyuka kwamandla kunye nokumelana nokubola, kuvumela umgangatho ongcono we-weld kunye nokuqina. Olu phuculo lubaluleke kakhulu kumashishini afana ne-oyile negesi, apho iiwelds zivezwe kwindawo erhabaxa kwaye kufuneka zimelane neemeko ezinzima. Ukusetyenziswa kwezinto eziphambili kuqinisekisa ukuba ii-welds zigcina ingqibelelo kunye nokusebenza kwazo ngexesha.

Izinto ezintsha ezisetyenziswayo, ezifana nokuphuculwa kweegesi zokukhusela kunye nokuguquguquka, nazo zinegalelo kumgangatho ongcono we-weld kunye nokusebenza kakuhle. Ezi zinto zisetyenziswayo zinceda ukukhusela indawo ye-weld ekungcoleni kwaye iphucule ukuzinza kwe-arc, okukhokelela ekucoceni kunye ne-welds eqinile. Ukongeza, uphuhliso lwe-eco-friendly kunye ne-welding ezinzileyo ye-welding consumables ihambelana nogxininiso olukhulayo kuxanduva lokusingqongileyo kwimveliso. Ngokwamkela imathiriyeli ephucukileyo kunye nezinto ezisetyenziswayo, amashishini anokufikelela kwiiwelds ezikumgangatho ophezulu, anciphise inkunkuma, kwaye aphucule imizamo yawo yozinzo.

Iinkqubo eziChanekileyo neziLawulayo ezongeziweyo

Ukuchaneka okuphuculweyo kunye neenkqubo zokulawula ziguqula iteknoloji ye-TIG ye-welding, eyenza abaqhubi bafezekise amanqanaba aphezulu okuchaneka kunye nokuhambelana. Iinkqubo zolawulo oluphezulu, ezifana ne-digital interfaces kunye nezicwangciso ezicwangcisiweyo, zivumela ukulungiswa okuchanekileyo kweeparameters ze-welding, ukuqinisekisa ukusebenza kakuhle kwezinto ezahlukeneyo kunye nezicelo. Ezi nkqubo zibonelela ngengxelo yexesha langempela kunye nokubeka iliso, ukunceda abaqhubi bagcine umgangatho we-weld ongaguqukiyo kunye nokunciphisa umngcipheko weziphene. Kumashishini afana nokuveliswa kwezixhobo zonyango, apho ukuchaneka kubaluleke kakhulu, ezi nkqubela zibaluleke kakhulu.

Ukudityaniswa kobuchwepheshe be-smart, obufana nobukrelekrele bokwenziwa kunye nokufunda koomatshini, kuphucula ngakumbi amandla eenkqubo ze-TIG welding. Ezi teknoloji zenza ukuba i-welders ifunde kwii-welds zangaphambili kunye nokwandisa iiparitha ngokuzenzekelayo, ukuphucula ukusebenza kakuhle kunye nokunciphisa imfuno yokulungiswa kwezandla. Ukongezelela, ukusetyenziswa kweenzwa kunye nohlalutyo lwedatha kuvumela ukugcinwa kwangaphambili kunye nokubeka iliso ngexesha langempela lezixhobo ze-welding, ukuqinisekisa ukuba imiba enokuthi ibonwe kwaye iqwalaselwe ngaphambi kokuba ichaphazele imveliso. Ngokusebenzisa iinkqubo ezichanekileyo eziphuculweyo kunye nolawulo, amashishini anokufikelela kwiiwelds ezikumgangatho ophezulu, ukwandisa imveliso, kunye nokunciphisa iindleko zokusebenza.

Ukuvavanya iNdleko epheleleyo yoBunini kwi-TIG Welders

Iindleko zokuThenga zokuqala

Iindleko zokuqala zokuthengwa kwe-TIG welder yinto ebalulekileyo ekufuneka iqwalaselwe xa kuhlolwa ixabiso elipheleleyo lobunini. Eli xabiso libandakanya ixabiso le-welder ngokwayo, kunye nazo naziphi na izesekeli ezongezelelweyo kunye nezixhobo ezifunekayo ekusebenzeni. Iiwelder ze-TIG ezikumgangatho ophezulu ezineempawu eziphambili kunye nobuchule banokuba neendleko eziphezulu ngaphambili, kodwa zihlala zibonelela ngokusebenza okungcono kunye nokuqina. Utyalo-mali kwi-welder ethembekileyo kwaye esebenzayo kunokubangela ukonga ixesha elide ngokunciphisa imfuno yokulungiswa rhoqo kunye nokutshintshwa.

Xa uvavanya ixabiso lokuqala lokuthenga, kubalulekile ukuqwalasela iimfuno ezithile kunye neemfuno zezicelo ezijoliswe kuzo. Ngokomzekelo, i-welder enomjikelezo ophezulu womsebenzi kunye nokukhutshwa kwamandla kunokufuneka kwizicelo zoshishino, ngelixa imodeli esisiseko inokwanela imisebenzi elula. Ukongezelela, iindleko zezinto ezisetyenziswayo, ezifana ne-electrode kunye neegesi ezikhuselayo, kufuneka zifakwe kwibhajethi yonke. Ngokuhlola ngokucophelela iindleko zokuthengwa kokuqala kunye nokukhetha i-welder ehambelana neenkcukacha ezifunekayo, amashishini anokuqinisekisa utyalo-mali olunexabiso.

Iindleko zokuSebenza kunye noLondolozo

Iindleko zokusebenza kunye nokugcinwa ziindleko eziqhubekayo ezinegalelo kwixabiso elipheleleyo lobunini be-TIG welder. Ezi ndleko ziquka ukusetyenziswa kombane, izinto ezisetyenziswayo, kunye nokugcinwa nokulungiswa kwesiqhelo. Ii-welders ezisebenza ngamandla kunye neempawu zolawulo lwamandla aphezulu zinokunceda ukunciphisa iindleko zombane, zibenze ukhetho olunoqoqosho olungakumbi ekusebenziseni ixesha elide. Ukongezelela, ubukho kunye neendleko zezinto ezisetyenziswayo, ezifana nezixhobo zokuzalisa kunye neegesi ezikhuselayo, kufuneka ziqwalaselwe xa kuhlolwa iindleko zokusebenza.

Ukugcinwa rhoqo kubalulekile ekuqinisekiseni ixesha elide kunye nokusebenza kwe-TIG welder. Oku kuquka ukuhlolwa okuqhelekileyo, ukucocwa, kunye nokutshintshwa kwezinto ezigugileyo. Iindleko zokugcinwa ziyakwazi ukuhluka ngokuxhomekeka kubunzima kunye nokuqina kwe-welder. I-Welders ezinokwakhiwa okuqinileyo kunye namacandelo aphezulu angafuna ukulungiswa rhoqo, okubangelwa iindleko eziphantsi. Ukongeza, ubukho beendawo ezisecaleni kunye nenkxaso yobugcisa evela kumvelisi kunokuchaphazela iindleko zokulondolozwa. Ngokukhetha i-welder eneendleko eziphantsi zokusebenza kunye nokugcinwa, amashishini anokunciphisa ixesha lokunciphisa kunye nokwandisa imveliso.

Ukusebenza kakuhle kwamandla kunye noLondolozo lweXesha elide

Ukusebenza kakuhle kwamandla yinto ebalulekileyo ekuhloleni iindleko ezipheleleyo zobunini kwi-TIG welder. Ii-welders ezisebenza ngamandla zisebenzisa amandla amancinci, okukhokelela kumatyala aphantsi ombane kunye nokunciphisa impembelelo yokusingqongileyo. Ii-welders ezisekelwe kwi-inverter, umzekelo, ziyaziwa ngokusebenza kwazo okuphezulu kwamandla kwaye zinokubonelela ngolondolozo olubalulekileyo lwexesha elide xa kuthelekiswa neemodeli zemveli ezisekelwe kwi-transformer. Ukongeza, iiwelders ezisebenza ngamandla zihlala zinomjikelezo womsebenzi ophezulu, ovumela ixesha elide lokuwelda kunye nokwanda kwemveliso.

Ugcino lwexesha elide lunokufezekiswa ngokusetyenziswa kweempawu eziphambili kunye nobuchwepheshe obuphucula ukusebenza kunye nokunciphisa inkcitho. Ngokomzekelo, ii-welders ezinezicwangciso ezicwangcisiweyo kunye nolawulo lwedijithali lunokwandisa iiparamitha ze-welding kwizicelo ezahlukeneyo, okukhokelela kwi-welds ephezulu kunye nokunciphisa ukusebenza kwakhona. Ukusetyenziswa kwe-eco-friendly consumables kunye nemathiriyeli inokuphinda ibe negalelo ekongeni kweendleko.

Ukusondeza phezulu

Iiwelder ze-TIG zibalulekile kuwo wonke amashishini afuna ukuchaneka kunye nomgangatho. Ngokunyuka kwemfuno yehlabathi, izinto ezifana nokuphuma kwamandla, amandla e-AC/DC, kunye neempawu zokhuseleko zingundoqo ekukhetheni i-welder efanelekileyo. Ukwenziwa kwezinto ezintsha kwi-automation kunye nezixhobo zokwandisa ukusebenza, ukusebenza kakuhle, kunye nokugcinwa kweendleko, okwenza i-TIG welders ibe yi-smart investment kumashishini ajolise kwikhwalithi ephezulu, i-welding enemveliso.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu