Ukuphendula kwiimfuno zoshishino lwamazwe ngamazwe, iteknoloji ye-laser iye yaqhubela phambili ukuze ibonelele ngokukrola okuphezulu kwe-laser kunye nokusika oomatshini abasika ixesha lokuvelisa kwisiqingatha. Aba matshini basebenzisa amandla amancinci, banomgangatho ochanekileyo wecala, kwaye banokusebenza ngezinto ezahlukeneyo. Qhubeka ufunda ukuze ufunde malunga neendlela zamva nje ze-laser kunye nendlela yokukhetha eyona mishini isebenzayo kwiimfuno zakho.

Isiqulatho

Imarike yeteknoloji yelaser yehlabathi

Iintsingiselo kushishino koomatshini laser

Uphuhliso lwetekhnoloji yelaser

Olunye uphuhliso lwesizukulwana esilandelayo koomatshini bokusika i-laser

Amazwi okugqibela

Imarike yeteknoloji yelaser yehlabathi

Ngo-2022, imakethi yetekhnoloji ye-laser yehlabathi yaxatyiswa nge-USD 16.7 ibhiliyoni, kwaye kulindeleke ukuba ikhule ngesantya sokukhula ngonyaka (CAGR) ye-8.9% ukuya kuthi ga kwi-USD 25.6 yezigidigidi ngo-2027. iteknoloji laser ibonelela ngokuchaneka okuphezulu, imveliso, kunye nokuguquguquka kwizicelo zokusetyenzwa kwamashishini ezifana nemveliso.

Ukunyuka kwemfuno kumacandelo e-oyile kunye negesi, iimoto, ezonyango kunye nelaphu kuqhuba ukukhula kwemarike. Ngaphezu koko, ukusebenza okuphezulu kwe laser-based ubuchule obungaphezulu kweendlela zokusetyenzwa kwemveli yinto ebalulekileyo eqhuba ukukhula kwemarike.

Eli nqaku liza kunceda abafundi ukuba bajonge iindlela zangoku zomatshini welaser olawula imarike.

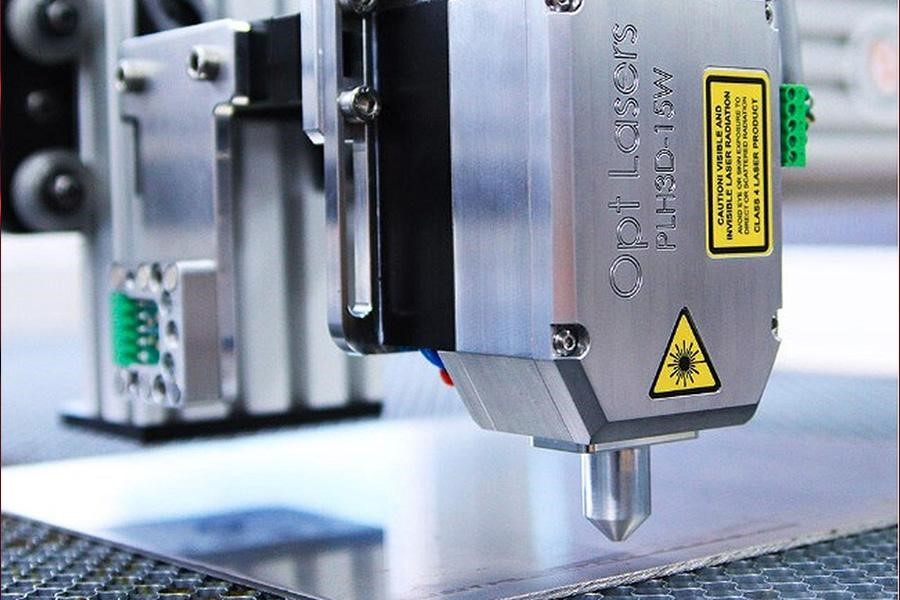

Ukuwelda kweLaser

The welding laser Imakethi yoomatshini kulindeleke ukuba ikhule kwi-CAGR ye-4.73% phakathi kuka-2021 no-2025 ukuya kuthi ga kwi-USD. 373.97 izigidi ekupheleni kwexesha. Ukuwelda kweLaser yindlela yokudibanisa iintsimbi ezahlukeneyo usebenzisa i-laser beam. Le welding yenziwa ngeendlela ezimbini: conduction welding limited and keyhole welding.

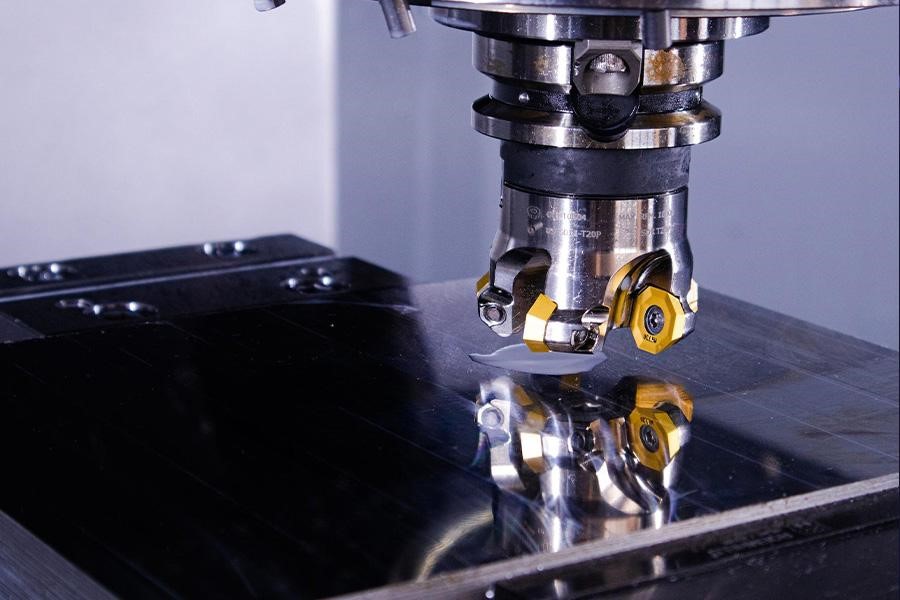

Ukusika iLaser

The ukusikwa kwelasi imakethi yomatshini kulindeleke ukuba ikhule nge-USD 1.02 ibhiliyoni phakathi kuka-2020 kunye no-2024. Aba matshini basebenzisa iilaser ukusika izinto ezahlukeneyo ukusuka kwiplastiki ukuya kwintsimbi ngokuchaneka ngokupheleleyo. Zizixhobo eziyimfuneko ezisetyenziswa ngokubanzi kumashishini amaninzi, kubandakanywa i-elektroniki kunye neemoto.

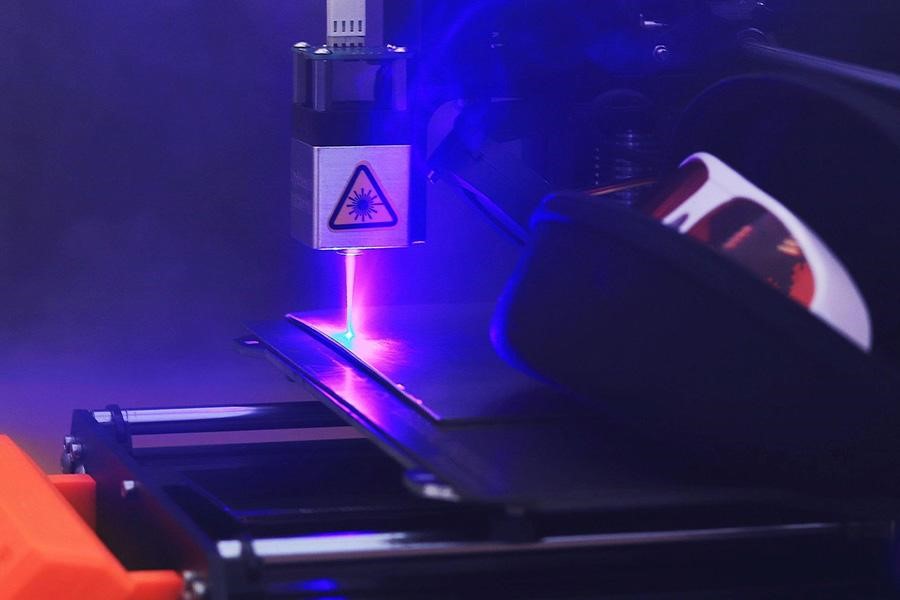

Ukuprinta iLasera

Oomatshini beLaser etching basetyenziselwa ukukrola amanqaku kwiindawo ezahlukeneyo. Phakathi kuka-2021 kunye no-2028, ihlabathi jikelele laser lokumakisha Imarike kulindeleke ukuba ikhule kwi-CAGR ye 8.0%. I-Asia Pacific iya kuba yeyona ntengiso inkulu kwaba matshini, ilandelwa nguMntla Merika kunye neYurophu.

Ukucocwa kweLaser

Ukucocwa kwelaser okanye ukukhutshwa kwelaser kubhekisa kubuchule apho imathiriyeli ephuma kumphezulu oqinileyo itsalwa ngomqadi welaser. Le marike yokucoca yayixabisa i-USD 587.18 Izigidi ngo-2021 kwaye kulindeleke ukuba ikhule kwi-CAGR ye-4.10% ukuya kuthi ga kwi-803.28 yezigidi zeedola ngo-2030.

Laser ukumakishwa

Okuchasene ne laser ngentlabo, ukumakishwa kwelaser kubeka ngokulula ulwazi kumphezulu kunye nokungena okuncinci. Xa kuthelekiswa nezinye iindlela zokumakisha, le nkqubo ibonelela ngokufundeka okuphezulu kunye nokuchaneka ngelixa ineendleko. Imarike yokumakisha i-laser yayixabisa i-USD 2.9 Ibhiliyoni ngo-2022 kwaye kulindeleke ukuba ikhule kwi-CAGR ye-7.2% ukuya kuthi ga kwi-4.1 yeebhiliyoni zeedola ngo-2027.

Iintsingiselo kushishino koomatshini laser

Yehlabathi umatshini laser imarike inokohlulwa ibe zezi ndidi zilandelayo: CO2 laser, ifayibha laser, kunye noomatshini laser diode.

Imarike yomatshini we-CO2 laser

Ukumakishwa kwe-CO2 laser ifanelekile kwizinto ezininzi ezingezizo ezentsimbi, kuquka iinkuni, iplastiki, i-acrylic, ilaphu kunye nelitye. Ngaphaya koko, itekhnoloji ye-CO2 laser isetyenziswa kakhulu kumayeza, ukupakishwa kokutya, kunye namashishini ombane. Oku kungenxa laser Lolona khetho lubalaseleyo lokusika imathiriyeli engqindilili kunye nexesha lokuqala lokugqobhoza elikhawulezayo kwaye libonelela ngokugqitywa komphezulu ogudileyo. Nangona kunjalo, iilaser zisebenzisa amandla amaninzi kunefiber, okukhokelela kwiindleko eziphezulu zokusebenza.

The I-laser ye-CO2 Imakethi yahlulwe yangamacandelo amathathu ngokusekwe kudidi lwelaser, ishishini lokusetyenziswa kokuphela, kunye nejografi. Phakathi kwamacandelo, icandelo le-CO2 yegesi yegesi ibonisa esona sithembiso, kunye ne I-laser ye-CO2 Imakethi iqhutywa ikakhulu licandelo leemoto, elemveliso, elokhuselo kunye nelezempilo. Ngokwejografi, uMntla kunye noMzantsi Melika, iAsia Pacific, iYurophu, kunye neAfrika zinokukhula kwemarike.

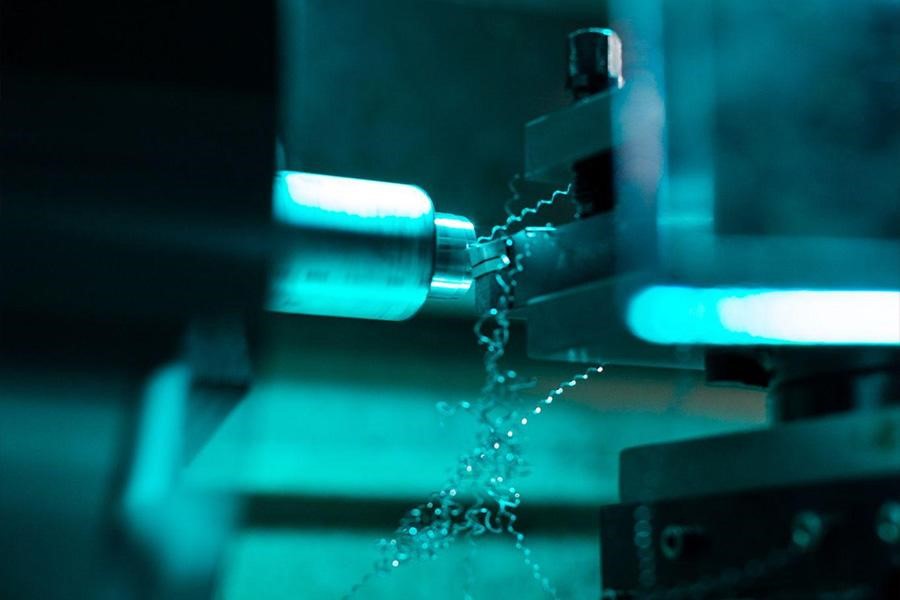

Ifayibha laser umatshini market

Ifayibha laser oomatshini banokwenza ukukrola, ukukrola, ukudibanisa, kunye nokuphawula okuphezulu. Ngenxa yedayamitha yefocal encinci, ezi lasers zifaneleke kakhulu ukuphawula idatha efana namanani kunye neebhakhowudi kwiintsimbi. Iifayibha lasers azinakugcinwa, zinobomi obude benkonzo, kwaye zineenyawo ezincinci kuneCO2 lasers.

Iifayibha lasers babona imfuno yokucoca izicelo. Amashishini amaninzi asebenzisa oomatshini bokucoca ngelaser ukunceda ukususa umhlwa, ipeyinti, iioksidi, kunye neengcoliseko kwiintsimbi. Oomatshini abanamandla amakhulu okusika i-laser ukusuka kwi-20 W ukuya kwi-6k W banamanqaku aphezulu exabiso.

The laser imakethi kulindeleke ukuba ikhule kwi-CAGR ye-10.9% phakathi kuka-2017 ukuya ku-2023. UMntla Melika kunye neYurophu banamathuba aphezulu okukhula kwemarike, kunye ne-Asia Pacific, uMbindi Mpuma, kunye ne-Afrika zonke zinendawo ebalulekileyo yokwandisa.

Imarike yomatshini weDiode laser

I-diode laser Itekhnoloji isetyenziswa kakhulu kwizikhombisi zelaser, kwaye ngokusisiseko iyafana neediode ezikhutshwa ngokukhanya. Nangona ekuqaleni kwakunzima kwii-laser diode ukusika isinyithi, ukuqhubela phambili kwetekhnoloji kwatshintsha ngonaphakade ishishini. Umatshini we-laser diode othe ngqo (i-DDL) udibanisa ukukhanya ukusuka kwiidiode ezininzi ukwenza umqadi omnye emva koko uqondiswe kumphezulu womdla.

Iilaser zeDiode zisebenza kakuhle kunefiber lasers kuba zinokusetyenziswa kwiindawo ezibengezelayo ezifana nobhedu kunye nealuminiyam. Ngenxa yokuba ubude be-laser ye-diode buthatyathwa lula yi-aluminium, isantya sokusika si-100% ngokukhawuleza. Ngaphaya koko, xa kuthelekiswa nefiber lasers, idiode enamandla kakhulu imishini inokusebenza i-10-20% ngokukhawuleza kwiintsimbi. Kwaye okokugqibela, babonelela ngomgangatho ongcono womphetho xa usebenzisana nezinto ezixineneyo.

Uphuhliso lwetekhnoloji yelaser

Rhoqo ngonyaka, iteknoloji yelaser enamandla kakhulu iqhubela phambili, kunye neelasesi ze 6kW okanye ngaphezulu ziye zaxhaphaka ngakumbi xa kuthelekiswa iinguqulelo ezindala 4kW oomatshini laser-ukusika. Inzuzo ebaluleke kakhulu kukuba ixesha lokuvelisa liyancipha ngesiqingatha.

La macandelo alandelayo axoxa ngophuhliso olubaluleke kakhulu kwimarike yokusika i-laser kunye nekamva labo kunye nokusetyenziswa.

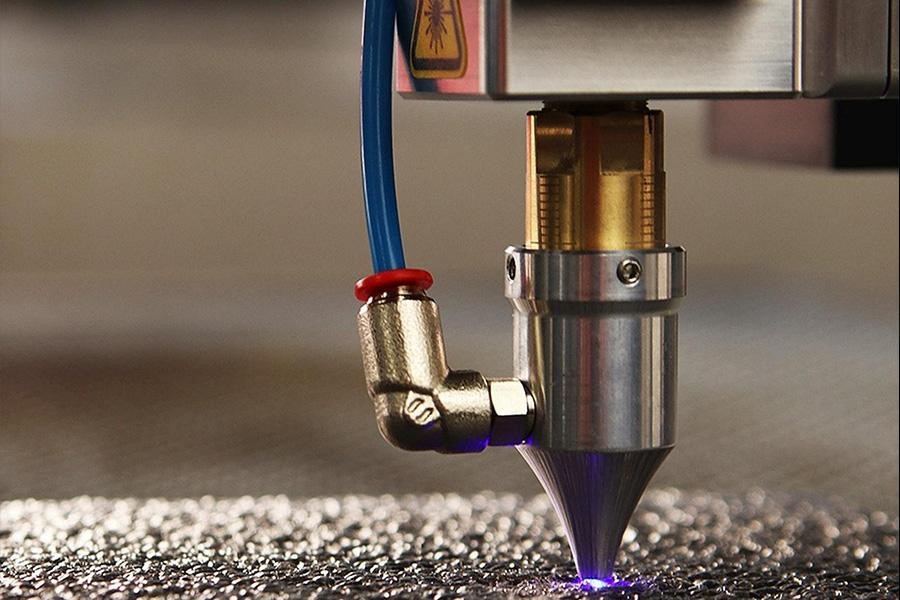

Ukwenza okuphezulu

Ukusika iLaser imishini babe nemilomo enye, kabini, okanye ukusetyenziswa kancinci. Imilomo enye yeyona ixhaphakileyo kwaye ixhotyiswe ngeendlela ezithembekileyo kodwa ezicothayo zokusika ngokucotha okuthintelweyo. Ngenxa yoko, imilomo enye idla igesi eninzi. Imilomo emibini inokonga ukuya kutsho kuma-50% kwirhasi xa kuthelekiswa nemilomo yodwa. Imilomo yokusetyenziswa kancinci iya kubonelela ngeyona ndlela ikhawulezayo nesebenzayo yokusika kumashishini asebenzisa ikota-intshi okanye izinto ezixineneyo.

Amandla aphezulu ngokubanzi aphucula ukusebenza kakuhle kunye nokusebenza kwenkqubo. Ngenxa yoko, amandla aphezulu oomatshini laser ingasila ngesantya esiphezulu ngelixa isongeza imida echanekileyo. Bakwaphucula ukusebenza kwelaser ngokuvumela izikali zokusika ezixineneyo. Uyilo ngalunye lombhobho lufanelekile kwizinto ezahlukeneyo kunye neeprojekthi.

Imveliso yokusika i-laser

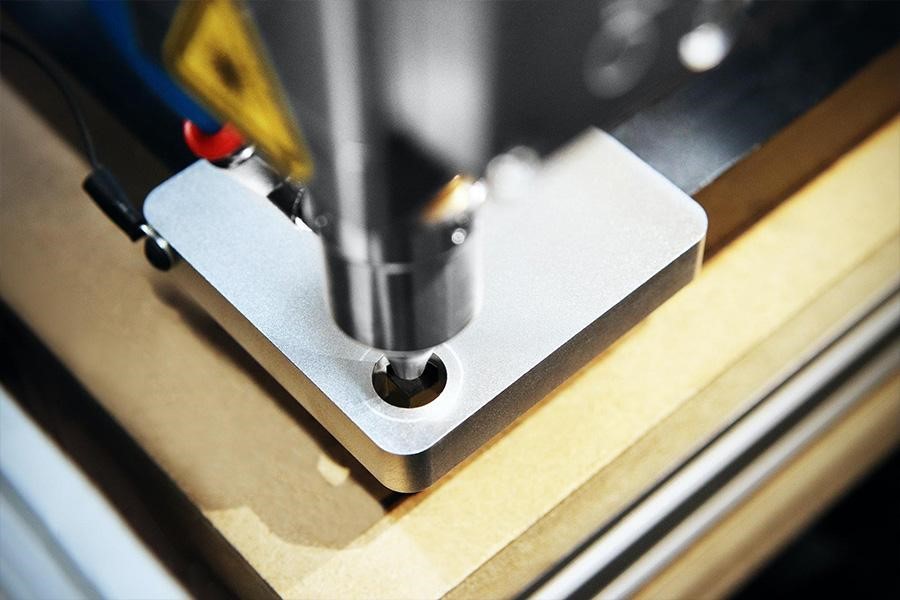

Ukusika iLaser, ukugrumba, ukumakisha, kunye nokuwelda zonke ziyimisebenzi yetekhnoloji yelaser, kwaye ezinye iimodeli zinokunika umzobo kumava omntu ngakumbi. Ezi imishini inokusebenza ngezinto ezahlukeneyo, kubandakanya umthi, ialloys, isinyithi, iiseramics, kunye neepolima.

Xa kuziwa ekwenzeni iimveliso zamashishini ahlukeneyo, ukusikwa kwelasi okanye ushicilelo yindlela yokuya, njengoko isebenza kakuhle ngezinto ezahlukeneyo. Ngenxa yokukwazi ukubonelela ngeemilo kunye nobukhulu obuhambelanayo kunye ne-2D kunye ne-3D echanekileyo, aba matshini banezicelo ezininzi kushishino lokwakha. Umzekelo, ukusikwa kwelasi lukhetho olusebenzayo lokwenza ngokwezifiso iphepha elenziwe ngesinyithi ukuze lisetyenziswe kwindawo yokuhlala kunye nokungahlali.

Ukuthembeka kwe-laser automation

Imisebenzi emininzi iye yazenzekela ngenxa yenkqubela phambili yetekhnoloji, ukunciphisa umzimba wezixhobo zokuvelisa kunye nokwandisa amathuba okwenza i-laser automation. Kukho iintlobo ezintathu zeenkqubo zokuphatha izinto eziphathekayo laser ukusika automation: umatshini ozimeleyo kunye netafile ye-shuttle, umatshini we-laser wokukhulula umthwalo, kunye nomatshini we-laser onenkqubo yokuvelisa i-flexible.

Ngaphaya koko, izinto ezinje ngeetafile zokusika, izikere, iileyibhile, okanye iinqwelo zinokusetyenziswa ngokwahlukeneyo kuyo nayiphi na inkqubo yokuzenzela. Le nkqubo ye-automation inokunyusa imveliso kunye nemveliso ngelixa inciphisa ukuthembela kubasebenzi. Imijikelo yovavanyo oluzenzekelayo nayo iya isiba mifutshane ukuhambisana nokunyuka kwemfuno ngelixa ikwabonelela ngenkuthazo kuphuhliso lwexesha elizayo.

As CO2 kwaye iilaser zefiber ziyaqhubeka nokulawula imarike, ishishini lijonge oomatshini ababukhali bokusika i-laser. Oomatshini abanoluhlu oluphezulu lwamandla 6kW kunye nemilomo enciphisa ukuthembela kwigesi kunye nexesha lokuvelisa ikhethwa namhlanje.

Olunye uphuhliso lwesizukulwana esilandelayo koomatshini bokusika i-laser

U ku lungiswa: Umatshini wokusika we-laser we-G wamva nje unokuxhonywa kwisiseko se-plasma yangaphambili koomatshini bokusika i-arc. Inokufakwa kwaye isetyenziswe kwisiseko sokuqala, ukugcina ixesha kunye neendleko. Abathengi abangenayo isiseko se-cement ekhoyo banokukhawuleza bafake kwaye bahambe kwindawo yokuvelisa ngokukhetha isiseko sombhede okhethiweyo.

Ukusika i-Wotho: Ukusetyenzwa kweBevel yinto ekhoyo kuthotho lwe-G umshini wokusika. Iibevel ezimile okwe-V, ezimilise ngo-C, ezimilise ngo-Y, nezimilise ngo-K zezona ntlobo zixhaphakileyo ezisetyenziswa ekuveliseni oomatshini bezolimo nokwakha.

Ukhuseleko olomeleziweyo: Oomatshini be-laser be-G bane-gratings yokhuseleko ngasemva nangaphambili kwi-beam. Xa into okanye umntu engena kumgama okhuselekileyo we-beam, inkqubo yongxamiseko isebenze ngokukhawuleza.

Umsebenzi wokuphepha umqobo osebenzayo: Oomatshini beLaser banokubona umqobo ozayo kwaye baphendule ngokukhawuleza ukuphepha ukungqubana. Oku kusabela ngokukhawuleza kusombulula ngokufanelekileyo imiba yokuqhawula ukuphazamiseka kunye nokungqubana kwentloko ye-laser ngexesha lokusika.

Amazwi okugqibela

Imarike yomatshini we-laser ihlala itshintsha ngenxa yenkqubela phambili eqhubekayo kubuchwepheshe. Ngokweendlela zamva nje, i-CO2 kunye ne-fiber lasers zilawula imarike ngenxa yokusebenza kakuhle, kodwa izinto zangaphandle zinegalelo kwimpumelelo yazo.

Iilaser diode ezithe ngqo ziya kuba neyona CAGR iphezulu kwixa elizayo ngenxa yolawulo lwazo oluphezulu, ukukhululeka kwenkonzo, kunye nokuthembeka okwandisiweyo ngelixa kuthoba iindleko zokusebenza. Ukusetyenziswa kwazo ngokubanzi kwi-ablation etching kunye ne-heat-affect zone etching nako kube negalelo ekukhuleni kwazo.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu