Ngo-2025, ishishini lecrystallization libone izinto ezintsha eziphakamisa ukusebenza kakuhle kunye nokuzinza kokusingqongileyo. Eli nqaku linika uhlalutyo olunzulu lokukhetha i-crystallizer efanelekileyo, iintlobo zokugubungela, iinkcukacha zobugcisa, iimethrikhi zokusebenza, kunye nemigangatho yokhuseleko. Sisixhobo esixabisekileyo kubathengi abaziingcali abajonge ukwenza izigqibo zokuthenga benolwazi.

Isiqulatho:

-Umbono weMarike yeeCrystallizers

Izinto eziphambili xa ukhetha iCrystallizer

-Usetyenziso lweeCrystallizers

-Uphuculo lwetekhnoloji kwiiCrystallizers

-Iimodeli ezahlukeneyo zeCrystallizer kunye nobukhulu

– Iingcamango zokugqibela

Isishwankathelo seMarike yeeCrystallizers

Imakethi yehlabathi yeekristali zemveliso ibixabisa malunga ne-3.58 yeebhiliyoni zeedola ngo-2023 kwaye kuqikelelwa ukuba ifikelele kwi-6.11 yeebhiliyoni zeedola ngo-2032, imele inqanaba lokukhula lonyaka elihlanganisiweyo (CAGR) le-6.40% ukusuka ngo-2024 ukuya ku-2032. icrystallization elawulwayo. Amacandelo emarike angundoqo abandakanya ukuphunga, ukupholisa, kunye ne-vacuum crystallizers, nganye ifanele izicelo ezithile.

UMntla Merika, iYurophu, kunye neAsia-Pacific zikhokela le ntengiso ngenxa yeziseko zabo eziqinileyo zemizi-mveliso kunye notyalo-mali kwinkqubela phambili yetekhnoloji. Imfuno yeekhemikhali ezisulungekileyo kunye namayeza, kunye nezinto ezintsha kwitekhnoloji yecrystallization eyonyusa ukusebenza kakuhle kunye nokunciphisa impembelelo yokusingqongileyo, iqhube ukukhula kwemarike. Ukongeza, imfuno yokucocwa kwamanzi amdaka, ngakumbi kwimimandla enemigaqo engqongqo yokusingqongileyo, iyayixhasa imakethi.

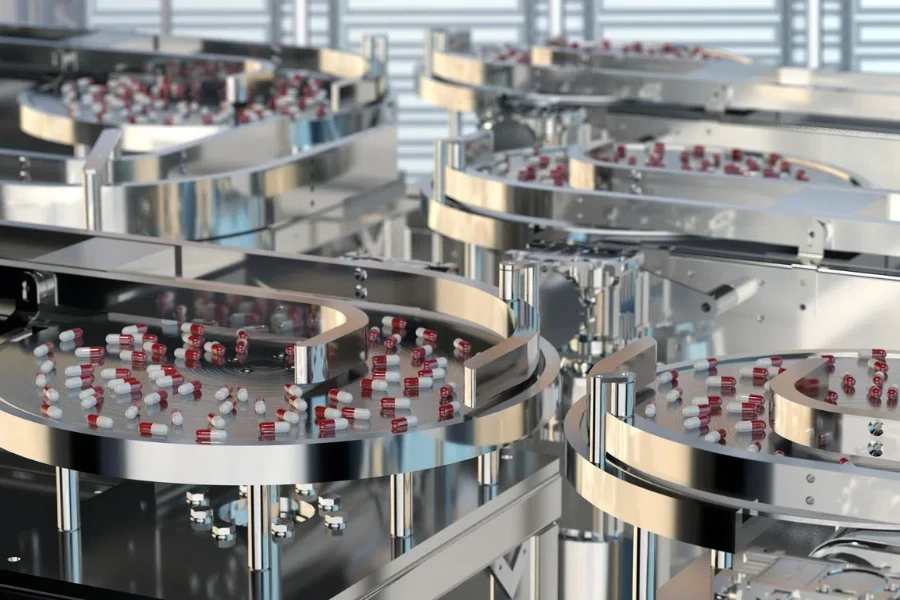

Uhlalutyo oluneenkcukacha lweMarike

Imarike yeekristali zemizi-mveliso iyaguquguquka, iphenjelelwa zizinto ezahlukeneyo. Ubunyulu kunye nobukhulu beenkqubo zecrystallization ziyimpawu eziphambili. Iindidi zekristali eziqhelekileyo zibandakanya ukujikeleza okunyanzeliswayo, idrafti ye-tube baffle (DTB), kunye ne-vacuum crystallizers, nganye ikhonza iimfuno ezithile zoshishino. Iikristali ze-DTB zibamba esona sabelo sikhulu semarike ngenxa yokuguquguquka kwazo kunye nokusebenza kakuhle, okubenza badume kumacandelo amachiza kunye namayeza.

Imiba yezoqoqosho inefuthe elibonakalayo kutshintsho lwemarike. Iindleko eziphezulu zokuvelisa kunye nokusebenza kunokuthintela ukungena kwemveliso. Nangona kunjalo, ukwamkelwa kweendlela ezisebenzayo kunye nezizinzileyo zecrystallization kuqhuba izinto ezintsha. Iinkampani zidibanisa ii-automation kunye neenkqubo zokulawula ukuphucula ukusebenza kunye nokuthobela imimiselo yokusingqongileyo. Ngokucacileyo, iinkqubo eziqhubekayo zecrystallization zibonelela ngokuphuma okuphezulu kunye nomgangatho wemveliso ongaguqukiyo, ubenza bakhethelwe imveliso enkulu.

Indlela yokuziphatha yabathengi itshintshela ekuzinzeni kwendalo kunye nokusebenza kakuhle. Lo mkhwa ubonakala ekwamkelweni kweenkqubo ze-Zero Liquid Discharge (ZLD) kumashishini afana neempahla ezilukiweyo kunye namayeza, apho iikristali zinceda ukubuyisela nokubuyisela amanzi kunye neekhemikhali. Ishishini lokutya kunye nesiselo likwaxhomekeke kwiikristali kwiinkqubo ezifana nokucocwa kweswekile kunye nokuveliswa kwetyuwa. Iinkampani ezifana neRaízen eBrazil kunye neFonterra eNew Zealand ngumzekelo wokusetyenziswa kweekristali zokufezekisa ukucoceka okuphezulu kunye nomgangatho.

Izimvo zeNgingqi kunye neMeko yoKhuphiswano

UMntla Merika ulawula imakethi yeekristali zemizi-mveliso, kunye ne-United States neCanada ekhokelayo ngenxa yesiseko esomeleleyo semizi-mveliso kunye nobuchule bobuchwepheshe. Imigangatho yolawulo engqongqo kunye notyalo-mali olubalulekileyo lwe-R&D luqhuba ukusetyenziswa kobuchwephesha becrystallization ephucukileyo. Ummandla waseAsia-Pacific yeyona ndawo ikhula ngokukhawuleza kwimarike, ikhuthazwa kukukhula kwemizi-mveliso ngokukhawuleza eTshayina, eIndiya, nakuMzantsi-mpuma weAsia. Inkxaso karhulumente yokwenziwa kwemveliso kunye nokunyusa ukukhula kwabantu ezidolophini ngakumbi yonyusa imfuno yobugcisa obusebenzayo becrystallization.

Ubume bokhuphiswano bubonisa abadlali abaphambili abanje ngeGEA Group, Sulzer Ltd., kunye neSumitomo Heavy Industries, abanezabelo ezibalulekileyo zemarike ngenxa yeenzame zabo zeR&D kunye nobuhlakani obucwangcisiweyo. Imiba ekhuphisanayo ibandakanya amaxabiso, umgangatho wemveliso, kunye nokwenziwa kwezinto ezintsha zobuchwepheshe. Njengoko imakethi ikhula, ukhuphiswano luya kunyuka, kunye neenkampani ezigxile kubuchule obutsha kunye nobuchule bokukhula obucwangcisiweyo ukufumana umda.

Izinto eziphambili xa ukhetha iCrystallizer

Iintlobo zeekristali

Ukukhetha i-crystallizer kuqala ngokuqonda iintlobo ezikhoyo kunye nezicelo zabo ezithile. Kukho iintlobo ezintathu eziphambili: ukugxininiswa, ukupholisa, kunye nokusabela okanye ukufuduswa okulinganayo. Iikristali zoxinaniso zenza amanzi amdaka, zivelise iikristale eziqinileyo kunye namanzi acocekileyo. Iikristali zokupholisa, zihlala zisebenza phantsi kwevacuum okanye zisebenzisa isitshintshi sobushushu, zezezinto ezifuna ukupholisa ukuze zibengezelelekileyo. I-reaction okanye i-equilibrium displacement crystallizers isetyenziswa xa i-crystallization iphuma kwi-chemical reaction okanye i-shift in equilibrium.

Khetha uhlobo lwe-crystallizer esekelwe kwizinto ezicutshungulwayo, ukucoceka okufunekayo kwemveliso yokugqibela, kunye neemeko zokusebenza. Umzekelo, ikristali yokupholisa ethe nkqo eqhubekayo (VCCC) ifanelekile kwizinto ezibonakala ziphezulu, zikhazimla kancinci kancinci, ngelixa icrystallizer yetyuwa ilungiselelwe amanzi amdaka anetyuwa.

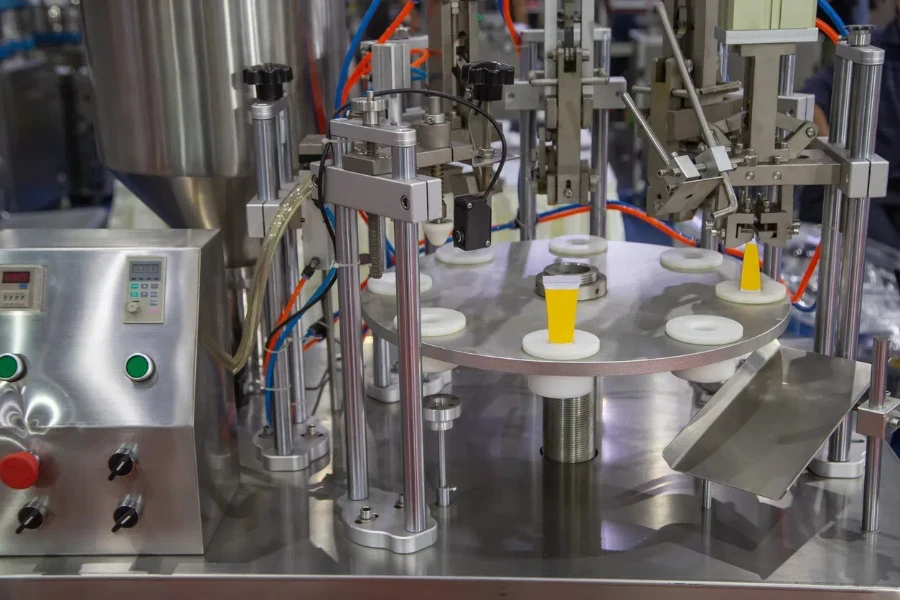

Izikhankanyi Technical

Iimpawu zobugcisa be-crystallizer kufuneka zihambelane neemfuno zesicelo. Iimpawu eziphambili ziquka amandla, ukuhambelana kwezinto eziphathekayo, kunye nokusebenza kakuhle. Ngokomzekelo, i-resin crystallizer yenzelwe i-crystallizing flake okanye i-amorphous resin pellets, idinga ukuhambelana kwezinto ezithile kunye neeparitha zokusebenza.

Uyilo kufuneka kwakhona luhambiselene neempawu zenyama kunye neekhemikhali zemathiriyeli. Izinto ezinje nge-viscosity, isantya secrystallization, kunye nobuntununtunu bobushushu buchaphazela ukhetho lwesixhobo. Ukusebenza ngokufanelekileyo kusetyenziso lwamandla, ukugqithisa, kunye nesantya sokubuyisela kubalulekile ekukhetheni i-crystallizer.

Ukusebenza kunye nokusebenza

Ukusebenza kwe-crystallizer kunye nokusebenza kugqitywa ngokukwazi kwayo ukuvelisa iikristale eziphezulu zokucoceka ngelixa kuncitshiswa ukusetyenziswa kwamandla kunye neendleko zokusebenza. Iimethrikhi eziphambili zokusebenza ziquka izinga le-crystallization, imveliso yemveliso, kunye namanqanaba okucoceka.

Umzekelo, i-concentrator ye-brine, ehlala isetyenziswa kunye ne-crystallizers, inokubuyisela i-95% ukuya kwi-99% yamanzi amdaka, iyenze isebenze kakuhle kumashishini ajolise ekukhupheni ulwelo oluyi-zero (ZLD). Ukukwazi ukudibanisa nezinye iiteknoloji, ezifana ne-evaporators, kwandisa ukusebenza kunye nokusebenza kakuhle.

Izinto eziphathekayo kunye noMgangatho woKwakha

Izinto eziphathekayo kunye nomgangatho wokwakha zichaphazela kakhulu ukuqina kwekristali, iimfuno zokugcinwa, kunye nobomi. Iikristali zenziwa ngokwesiqhelo kwizixhobo ezimelana nendalo eyonakalisayo yezinto ezicutshungulwayo. Izinto eziqhelekileyo ziquka insimbi engenasici kunye ne-alloys ezikhethekileyo ezichasene nokugqwala kunye nokugqoka.

Ukwakhiwa komgangatho ophezulu kuqinisekisa ukusebenza okuqhubekayo phantsi kweemeko ezinzima, ukunciphisa imfuno yokulungiswa rhoqo kunye nokutshintshwa. Oku kuthembeka kubalulekile kumashishini aneemfuno eziphezulu zemveliso kunye nemigangatho engqongqo yobulunga.

Imigangatho yoKhuseleko kunye neziQinisekiso

Ukuthotyelwa kwemigangatho yokhuseleko kunye neziqinisekiso kubalulekile xa ukhetha i-crystallizer. Ukuqinisekisa ukuba isixhobo siyahlangabezana nemigaqo yokhuseleko ethe ngqo kushishino lukhusela abasebenzi kwaye lugcina imfezeko yokusebenza. Izatifikethi ezifana ne-ISO kunye namanqaku e-CE zibonisa uvavanyo olungqongqo kunye nokuthotyelwa kwemigangatho yokhuseleko kunye nokusebenza kwamazwe ngamazwe.

Iimpawu zokhuseleko ezifana neendlela zokuvala ngokuzenzekelayo, iivalve zokunciphisa uxinzelelo, kunye neenkqubo zokulawula ezinamandla zikhusela iingozi kunye nokuqinisekisa ukusebenza okukhuselekileyo. Ukuthotyelwa kwemimiselo yokusingqongileyo kuqinisekisa ukuba i-crystallizer isebenza ngaphakathi kwemida evumelekileyo yokukhutshwa, igalelo kwiinkqubo ezizinzileyo zoshishino.

Ukusetyenziswa kweCrystallizers

Iikristali zisetyenziswa kuwo wonke amashishini ahlukeneyo, kubandakanya ukwenza, ukusetyenzwa kweekhemikhali, imigodi, ukucokisa i-petrochemical, kunye ne-elektroniki. Kwimveliso, bafumana iityuwa ezixabisekileyo kumanzi amdaka, nokwenza ngcono ukusetyenziswa kobutyebi kunye nokuhlangabezana neemfuno ze-ZLD.

Ekusetyenzweni kweekhemikhali, iikristali zivelisa iikhemikhali ezicocekileyo kunye neziphakathi eziyimfuneko kumayeza kunye neekhemikhali ezikhethekileyo. Ishishini lezimayini lisebenzisa iikristali zokukhupha kunye nokucoca izimbiwa kwi-ore slurry, ukuphucula ukusebenza kakuhle kokubuyisela izimbiwa.

I-Petrochemical refineries isebenzisa i-crystallizers ukwahlula kunye nokucoca i-hydrocarbons, ukuphucula i-fuel kunye ne-petrochemical product quality. Kwezobuchwephesha, iikristali zibalulekile ekwenzeni izinto ezicocekileyo ezifunekayo kwizixhobo zombane eziphambili.

Ukuqhubela phambili kweTekhnoloji kwiiCrystallizers

Ukuqhubela phambili kwitekhnoloji yecrystallizer iphucula ukusebenza kakuhle, ukuzenzekelayo, kunye nokuqina. Iikristali zanamhlanje zibonakalisa iinkqubo zolawulo oluphezulu zokubeka iliso oluchanekileyo kunye nohlengahlengiso lweeparamitha zokusebenza, ukuqinisekisa ukusebenza kakuhle.

Izinto ezintsha ezifana neenkqubo zecrystallization eziqhubekayo zivelisa iikristale ezifanayo kunye nomgangatho ohambelanayo, ukunciphisa ukuhluka kwebhetshi. Ukudityaniswa kweenzwa zedijithali kunye nobuchwepheshe be-IoT buvumela ukuqokelela idatha kunye nohlalutyo lwexesha langempela, ukuququzelela ukugcinwa kwangaphambili kunye nokunciphisa ixesha lokunciphisa.

Uyilo olusebenzisa amandla, njengeenkqubo zokubuyisela ubushushu, ziya zixhaphaka, zinciphisa ukusetyenziswa kwamandla ngokubanzi. Ezi nkqubela phambili zenza iikristali zilungele ngakumbi kwiimfuno eziguqukayo zemizi-mveliso, ukukhuthaza ukusebenza okuzinzileyo kunye neendleko ezifanelekileyo.

Iimodeli ezahlukeneyo zeCrystallizer kunye nobukhulu

Iikristali ziza ngobukhulu obahlukeneyo kunye neemodeli ukuhlangabezana neemfuno ezahlukeneyo zamashishini. Ukusuka kwiikristali ezincinci zaselabhoratri zophando kunye nophuhliso ukuya kwiikristali zemveliso ezinkulu zokuvelisa ngobuninzi, kukho ukhetho olufanelekileyo kwisicelo ngasinye.

Iikristali zeLabhoratri zivumela abaphandi ukuba bafunde iinkqubo zecrystallization kunye nokwandisa iiparamitha kwinqanaba elincinci. I-pilot-scale crystallizers ibhuloho umsantsa phakathi kovavanyo lwaselabhoratri kunye nemveliso epheleleyo, eyenza uvavanyo lwemeko ekufutshane noshishino.

Iikristali zemizi-mveliso zenzelwe ukusebenza okuphezulu, ukusetyenzwa ngokufanelekileyo umthamo omkhulu wezinto. Ezi modeli zihlala zibonakalisa uyilo lwemodyuli ukuze kube lula ukulinganisa kunye nokudityaniswa kunye nemigca yemveliso ekhoyo, ibonelela ngokuguquguquka kwiimfuno ezikhulayo zemizi-mveliso.

Iingcinga Final

Ukukhetha i-crystallizer efanelekileyo kubandakanya ukuvavanya izinto ezifana nohlobo lwekristali, iinkcukacha zobugcisa, ukusebenza, umgangatho wezinto eziphathekayo, kunye nemigangatho yokhuseleko. Ukuqonda iimfuno ezithile zesicelo kunye nokuhambisana nenkqubela phambili yetekhnoloji kunokunyusa kakhulu ukusebenza kakuhle kweenkqubo zecrystallization.

Ngokuthathela ingqalelo le miba ibalulekileyo kunye nokuxhasa izinto ezintsha zamva nje, amashishini anokuphucula imisebenzi yawo yecrystallization, afezekise umgangatho wemveliso ephezulu, kwaye abe negalelo kwimisebenzi ezinzileyo yemizi-mveliso.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu