Ukunyuka kwamva nje kwemfuno yeemveliso ezikhutshiweyo kuwo wonke amashishini kuye kwaqaqambisa ukubaluleka kokukhetha umatshini ochanekileyo we-extrusion. Eli nqaku lijonge kuhlalutyo olunzulu lwemiba ephambili, iintsingiselo zemarike, kunye neempawu eziphambili, ibonelela ngesikhokelo esixabisekileyo kubathengi abaziingcali ukuba benze izigqibo ezinolwazi kwaye baphucule amandla abo emveliso.

Isiqulatho:

-Extrusion Machine Market Overview

-Uhlalutyo olunzulu lweMarike yeeMishini zokuSebenza

-Izinto eziphambili xa ukhetha umatshini wokukhupha

-IiMpawu eziPhambili zoomatshini banamhlanje be-Extrusion

-Ukhuseleko kunye neMigangatho yokuThobela

-Ukuqwalaselwa kweendleko kunye ne-ROI

-Umgangatho kunye neeMetrikhi zokuSebenza

-UkuPakisha kunye nokuNqatshelwa kokuThumela

-Iingcinga zokugqibela

Isishwankathelo seMarike yoMatshini we-Extrusion

Imakethi yoomatshini bomhlaba jikelele ibona ukukhula okubalulekileyo, ikhula ukusuka kwi- $ 8.26 yeebhiliyoni ngo-2023 ukuya kwi-8.63 yeebhiliyoni zeedola ngo-2024. Uqikelelo lubonisa ukuba imakethi iya kuqhubeka ikhula ngesantya sokukhula sonyaka (CAGR) se-4.76%, sifikelele kwi-USD 11.45 yezigidigidi ngo-2030. ukwakhiwa, kunye nokupakishwa. Inkqubo ye-extrusion, eguqula izinto eziluhlaza zibe yifom egqityiweyo okanye ephakathi ngoxinzelelo oluphezulu kunye namaqondo okushisa alawulwayo, ibalulekile kwimveliso yokuvelisa kunye neeprofayili ezinqamlezayo ezihambelanayo njengemibhobho, i-tubing, kunye neefestile zefestile.

Uhlalutyo olunzulu lweMarike yeeMashini zokuSebenza

Iimpawu zeNdlela zokuSebenza eziPhambili

Oomatshini bokwandisa bavavanywa kwiibenchmarks zokusebenza ezininzi, kubandakanya izinga lemveliso, ukusebenza kakuhle kwamandla, kunye nokuchaneka ekugcineni imilinganiselo yemveliso. I-Twin-screw extruders iya isanda yamkelwa ngenxa yokuguquguquka okukhulu kwenkqubo kunye namazinga aphezulu emveliso xa kuthelekiswa ne-extruder-screw extruders. Aba matshini bathandwa kakhulu kumashishini afuna ukuqulunqwa kwezinto eziyinkimbinkimbi kunye nomthamo ophezulu.

ISabelo seMakethi Dynamics

Imarike yoomatshini be-extrusion ibonisa iinguqu ezibalulekileyo zengingqi. Amazwe aseMelika, ngakumbi i-United States, alawula ngenxa yeziseko zophuhliso ezomeleleyo kunye nenkqubela phambili yetekhnoloji. Ngeli xesha, ummandla we-Asia Pacific, okhokelwa yi-China kunye ne-Indiya, ujongene nokukhula okukhawulezayo kwamashishini kunye nokwandisa utyalo-mali kubuchwepheshe be-extrusion. IYurophu ihleli ingumdlali ophambili nogxininiso olumandla ekuzinzeni nasekusetyenzisweni ngokutsha, ukuqhuba imfuno yoomatshini be-extrusion abaphambili.

Iimpembelelo zezoQoqosho kunye neeShifts zokuziphatha kwaBathengi

Ukwandiswa kwecandelo lolwakhiwo kunye neleemoto kunyuse kakhulu imfuno yeemveliso ezikhutshiweyo. Ugxininiso olukhulayo kwizinto ezilula kunye nokusebenza okuphezulu kula mashishini ngumqhubi omkhulu. Ukongeza, izinto ezikhethwa ngabathengi zitshintshela kwiimveliso ezizinzileyo nezinokuphinda zisetyenziswe, ukukhuthaza ukwamkelwa koomatshini be-extrusion abaphezulu abaxhasa iindlela zokwenziwa kwe-eco-friendly.

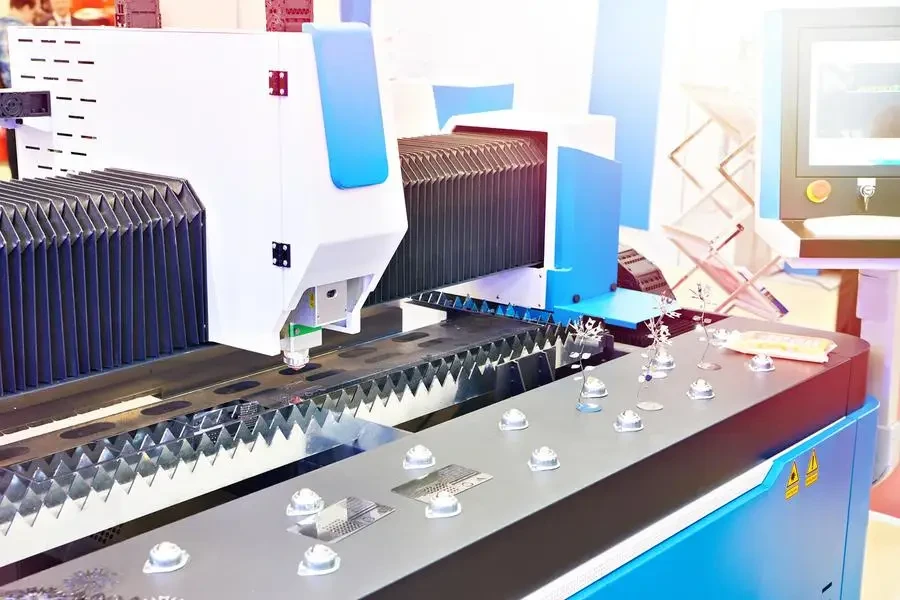

Izinto ezintsha zobuGcisa

Inkqubela phambili yetekhnoloji ibalulekile ekuveleni kwemarike yoomatshini be-extrusion. Ukudityaniswa kweetekhnoloji ze-Intanethi yeZinto (IoT) zogcino oluqikelelweyo kunye nokusebenza kakuhle kuya kuxhaphaka. Izinto ezintsha ezifana neemodyuli zesoftware ye-extruder ephezulu kunye noomatshini abaqhutywa ngokuchanekileyo baphucula amandla eenkqubo ze-extrusion, okuvumela ukuchaneka okuphezulu kunye nokusebenza kakuhle.

Product Lifecycle Stages

Oomatshini boKwenza ngokwesiqhelo badlula kwizigaba ezininzi kubomi babo bemveliso, ukusuka kwintshayelelo kunye nokukhula ukuya ekuvuthweni kunye nokwehla okunokwenzeka. Iindlela ezikhoyo ngoku zibonisa ugxininiso olomeleleyo kwinqanaba lokukhula, eliqhutywa bubuchule obuqhubekayo beteknoloji kunye nokwandisa izicelo kumashishini ahlukeneyo. Ukwaziswa koomatshini abasebenzayo nabaguquguqukayo kulindeleke ukuba kwandise isigaba sokukhula.

Amanqaku entlungu yabaThengi

Ngaphandle kwemikhwa emihle yokukhula, iindleko eziphezulu zoomatshini bokukhutshwa kunye nezithintelo zobugcisa zihlala ziyimiqobo ebalulekileyo. Le mingeni ichaphazela izinga lokwamkelwa kwabantwana, ingakumbi kumashishini amancinci naphakathi. Ukongeza, ukugcinwa kunye nemingeni yokusebenza ehambelana noomatshini abanzima kunokuthintela ukwanda kwemarike.

Ubume beBrand kunye noMahluko weQhinga

Iimpawu eziphambili kwimakethi yoomatshini bokukhupha, abanje ngeDavis-Standard kunye neHindalco, bagxile ekufumaneni okucwangcisiweyo kunye nentsebenziswano ukukhulisa amandla abo etekhnoloji kunye nobukho bentengiso. Iindlela zokwahlulahlula ziquka ukunika izisombululo ezilungelelanisiweyo, ukudibanisa itekhnoloji ephezulu, kunye nokugxininisa ukuzinza ukuhlangabezana neemfuno eziguquguqukayo zabathengi.

Iimarike zeNiche

Iimakethi ze-Niche ngaphakathi kwicandelo loomatshini be-extrusion zibandakanya usetyenziso olukhethekileyo olunje ngesantya esiphezulu somqeqeshi kaloliwe kunye nezixhobo zonyango ezichanekileyo. Iinkampani zisebenzisa ubuchule bazo kwiindawo ezithile ukulungiselela ezi marike ze-niche, zibonelela ngezisombululo ezilungelelanisiweyo ezihlangabezana neemfuno ezingqongqo zeshishini.

Imiba ephambili xa ukhetha umatshini wokukhupha

Ukukhetha umatshini ochanekileyo we-extrusion kwiimfuno zakho zemveliso kubandakanya ukuvavanya imiba eyahlukeneyo yobugcisa kunye nokusebenza. Aba matshini, babaluleke kakhulu kumashishini eplastiki, esinyithi, kunye namashishini adibeneyo, kufuneka akhethwe ngokuchanekileyo ukuqinisekisa ukusebenza kakuhle, umgangatho kunye nokusebenza kakuhle kweendleko. Ngezantsi yimiba ephambili ekufuneka iqwalaselwe:

Uhlobo loMtshini wokuKhulisa

Uhlobo lomatshini we-extrusion yingqwalasela ebalulekileyo. Oomatshini be-Extrusion bahlelwa ngokusekelwe kwizinto abazenzayo kunye nobuchwepheshe ababusebenzisayo. Ngokomzekelo, i-extruders yeplastiki yenzelwe ngokukodwa ukubumba izinto zeplastiki kwizicelo ezifana ne-extrusion yombhobho, i-profile extrusion, kunye ne-sheet extrusion. Oomatshini besinyithi kunye nerabha ye-extrusion nayo iyafumaneka, nganye ilungiselelwe ukuphatha izinto zabo. Ukhetho phakathi kwetekhnoloji ye-extrusion eshushu kunye nebandayo kufuneka yenziwe ngokusekelwe kwiimfuno zenkqubo yokuvelisa. Oomatshini abashushu be-extrusion bafanelekile kwizinto ezifuna ukushisa kwangaphambili, ngelixa oomatshini ababandayo be-extrusion basetyenziselwa izinto ezicutshungulwayo kwiqondo lokushisa.

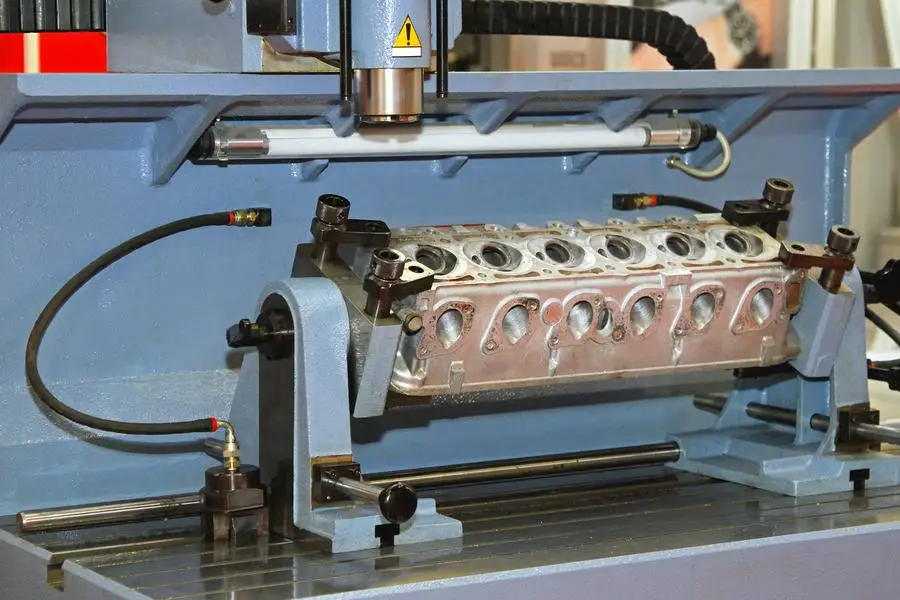

Izikhankanyi Technical

Iinkcukacha zobuchwephesha ezifana noyilo lwezikrufu, ukwakhiwa komphanda, kunye nolungelelwaniso lokufa ludlala indima ebalulekileyo ekusebenzeni komatshini wokukhupha. Isixhobo se-screw, esiqhele ukwenziwa ukusuka kwikhabhoni ephezulu, intsimbi ephezulu yechrome, kunye nonyango lomphezulu olufana ne-nitriding okanye i-chrome plating, imisela ukuqina nokusebenza komatshini. Ubungakanani bobude ukuya kububanzi be-screw, ubunzulu benqwelomoya, kunye nepitch yiparameters ezibalulekileyo eziphembelela isakhono somatshini sokubonelela ngesondlo esingaguqukiyo, ukunyibilika okufanayo, ukumpompa okuzinzile, kunye nokuxuba okulinganayo. Ezi nkcukacha kufuneka zihambelane neemfuno zenkqubo yokuvelisa ukuqinisekisa ukusebenza kakuhle.

Ukusebenza kwamandla

Ukusebenza kakuhle kwamandla yinto ebalulekileyo, ngakumbi kwimarike yanamhlanje ekhathalela indalo. Oomatshini banamhlanje be-extrusion benzelwe ukunciphisa ukusetyenziswa kwamandla ngelixa kunyuswa imveliso. Iimpawu ezinje ngeenjini eziwonga amandla, iinkqubo zokufudumeza ezikumgangatho ophezulu, kunye noyilo olulungisiweyo lwezikrufu negalelo ekunciphiseni unyawo olupheleleyo lwenkqubo ye-extrusion. Utyalo-mali kumatshini osebenza ngamandla kunciphisa iindleko zokusebenza kwaye kunceda ukufezekisa iinjongo zokuzinza.

Yakha umgangatho kunye nokuqina

Umgangatho wokwakha kunye nokuqina komatshini we-extrusion yeyona nto ibalulekileyo, kunikezwe ubume obufunwayo beenkqubo ze-extrusion. Oomatshini abakhiwe ngemathiriyeli ekumgangatho ophezulu kunye nobunjineli obomeleleyo banokumelana nokusebenza ngokuqhubekayo. Iilitha ezikwaziyo ukunxitywa kunye nezimelana nomhlwa kumbhobho, kunye nezixhobo ezomeleleyo ezisijiva, ziqinisekisa ubomi obude bomatshini. Ukugcinwa rhoqo kunye nokufumaneka kweendawo ezisecaleni kubalulekile ukugcina umatshini usebenza kakuhle kubomi bawo.

Ukuhambelana noPhuculo lwexesha elizayo

Njengoko itekhnoloji iguquguquka, ukukwazi ukuphucula oomatshini be-extrusion kuya kubaluleke kakhulu. Oomatshini abayilwe ngamacandelo eemodyuli kunye nojongano oluvulekileyo luvumela ukudityaniswa lula kobuchwepheshe obutsha kunye nezixhasi. Esi sixhobo sobungqina bexesha elizayo siqinisekisa ukuba umatshini unokulungelelanisa ukutshintsha iimfuno zemveliso kunye nokuqhubela phambili kwezobuchwepheshe, ukwandisa ubomi bawo obuncedo kunye nokwandisa imbuyekezo kutyalo-mali.

Imiba ekwinqanaba eliphezulu loomatshini banamhlanje be-Extrusion

Kwinkalo yetekhnoloji ye-extrusion eguquka ngokukhawuleza, oomatshini banamhlanje be-extrusion beza bexhotyiswe ngeempawu eziphucukileyo eziphucula kakhulu ukusebenza kwabo kunye nokuguquguquka.

Ukuzenzekelayo kunye neNkqubo yoLawulo

I-automation idlala indima ebalulekileyo koomatshini banamhlanje be-extrusion. Iinkqubo zolawulo eziphucukileyo, zihlala zisebenzisa ii-PLC (Abalawuli beeNkqubo eziLungisayo) okanye i-CNC (Ulawulo lweenombolo zeKhompyutha), vumela ulawulo oluchanekileyo kwiiparamitha ezahlukeneyo ezifana nobushushu, uxinzelelo kunye nesantya. Ezi nkqubo zenza umgangatho wemveliso ongaguqukiyo kwaye zinciphise imfuno yokungenelela ngesandla. Ukubeka iliso ngexesha langempela kunye nokukwazi ukungena kwedatha kunika ulwazi oluxabisekileyo kwinkqubo ye-extrusion, ukuququzelela ukugcinwa kwangaphambili kunye nokulungiswa kwenkqubo.

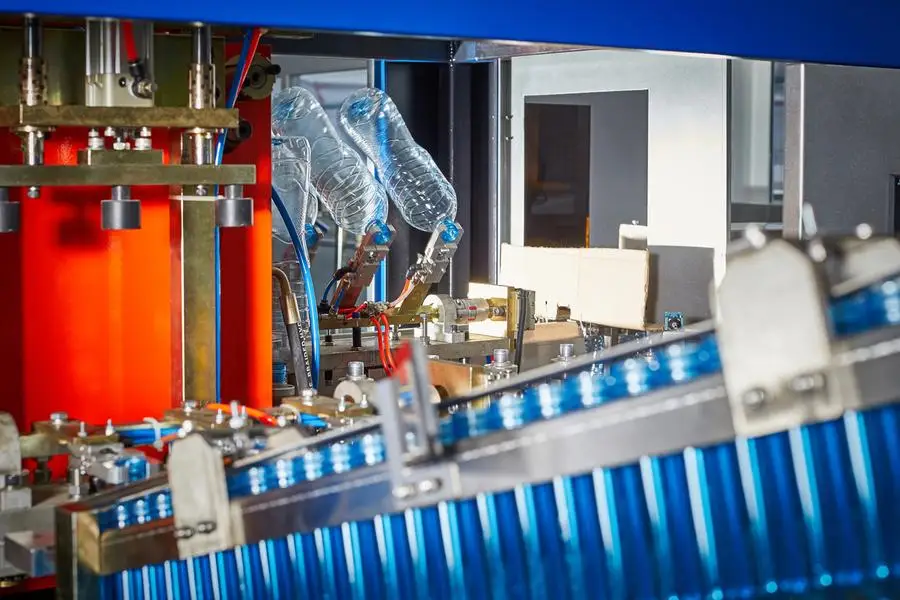

I-Multi-Layer Extrusion

Itekhnoloji ye-multi-layer extrusion iyanda kakhulu, ngakumbi kwimveliso yezinto zokupakisha kunye neeprofayili ezinzima. Le teknoloji ivumela ukukhutshwa kweeleyile ezininzi zezixhobo ezahlukeneyo ngaxeshanye, okukhokelela kwiimveliso ezineempawu eziphuculweyo ezifana nokusebenza komqobo ophuculweyo, amandla oomatshini, kunye nesibheno sobuhle. I-multi-layer extruders ixhotyiswe ngeentloko ezininzi ze-extruder kunye neenkqubo zokufa eziphucukileyo zokuqinisekisa ukuhanjiswa okuchanekileyo kunye nokubambelela.

IiNkqubo zokuBuyisa amandla

Iinkqubo zokubuyisela amandla ziyinto entsha kwiimatshini zanamhlanje zokukhupha. Ezi nkqubo zibamba kwaye ziphinde zisebenzise ubushushu benkunkuma obuveliswe ngexesha lenkqubo yokukhupha, ukuphucula ukusebenza kakuhle kwamandla. Ngokunciphisa imfuno yemithombo yokufudumala yangaphandle, iinkqubo zokubuyisela amandla zinceda iindleko zokusebenza eziphantsi kunye nokunciphisa impembelelo yokusingqongileyo yenkqubo ye-extrusion.

Ukhuseleko kunye neMigangatho yokuThobela

Ukuqinisekisa ukuthotyelwa kokhuseleko kunye nolawulo kubaluleke kakhulu xa ukhetha umatshini we-extrusion. Oomatshini kufuneka babambelele kwimigangatho yokhuseleko oluthe ngqo kwishishini kunye neziqinisekiso zokukhusela abaqhubi kunye nokuqinisekisa ukusebenza ngokukhuselekileyo.

Iimpawu zoKhuseleko

Oomatshini banamhlanje be-extrusion baxhotyiswe ngoluhlu lweempawu zokhuseleko ezifana namaqhosha okumisa ngexesha likaxakeka, oonogada kunye neenkqubo zokuvala. Ezi mpawu zenzelwe ukuthintela iingozi kunye nokuqinisekisa ukhuseleko lwabaqhubi. Iinkqubo zokubeka iliso eziphezulu ziyakwazi ukubona izinto ezingaqhelekanga kwaye zivale umatshini ngokuzenzekelayo ukukhusela umonakalo kunye nokuqinisekisa ukhuseleko.

Ukuthotyelwa koMthetho

Ukuthotyelwa kwemigangatho yolawulo kubalulekile ekuqinisekiseni ukuba umatshini we-extrusion uhlangabezana neemfuno zeshishini. Imigangatho efana ne-ISO, i-CE, kunye neziqinisekiso ze-UL zinika isiqinisekiso sokuba umatshini uthobela ukhuseleko olusekiweyo, umgangatho, kunye neendlela zokusebenza. Ukuphicothwa rhoqo kunye nokuhlolwa kunceda ukugcina ukuthotyelwa kunye nokuqinisekisa ukuba umatshini usebenza ngaphakathi kwezikhokelo ezifunekayo.

Imithetho yokusingqongileyo

Oomatshini bokukhutshwa kwamanzi kufuneka kwakhona bahambelane nemimiselo yokusingqongileyo, kuquka izikhokelo malunga nokukhutshwa, ulawulo lwenkunkuma, kunye nokusetyenziswa kwamandla. Oomatshini abayilwe ngeempawu ezihambelana ne-eco-friendly ezifana neenjini zokusebenzisa amandla, iinkqubo zokufudumeza ezikhupha kancinci, kunye nokukwazi ukuphinda kusetyenziswe inkunkuma kunceda ukuhlangabezana nale mimiselo kunye nokukhuthaza izenzo ezizinzileyo zokuvelisa.

Ukuqwalaselwa kweendleko kunye ne-ROI

Iindleko zomatshini we-extrusion yinto ebalulekileyo kwinkqubo yokwenza izigqibo. Kubalulekile ukuqwalasela kungekuphela nje ixabiso lokuqala lokuthenga kodwa kunye neendleko ezipheleleyo zobunini kunye nembuyekezo kutyalo-mali (ROI).

Ixabiso lokuThenga lokuqala

Ixabiso lokuqala lokuthenga umatshini we-extrusion linokwahluka ngokubanzi ngokuxhomekeke kwiinkcukacha, iimpawu, kunye ne-brand. Kubalulekile ukuvavanya amandla omatshini kunye nokuqinisekisa ukuba uyahlangabezana neemfuno zenkqubo yokuvelisa. Ngelixa oomatshini bexabiso eliphantsi banokubonakala benomtsalane, basenokungabi nazo iimpawu eziphambili kunye nokuqina okufunekayo ekusebenzeni ixesha elide.

Iindleko zokuSebenza

Iindleko zokusebenza, kubandakanywa ukusetyenziswa kwamandla, ukugcinwa, kunye nokusebenza, kufuneka zibalwe kwiindleko ezipheleleyo zobunini. Oomatshini abasebenzisa amandla, ngelixa banokubiza kakhulu ngaphambili, banokukhokelela kugcino olubalulekileyo ekuhambeni kwexesha. Oomatshini abaneemfuno zokugcinwa okuphantsi kunye ne-interfaces-friendly-friendly interfaces banokunciphisa iindleko zabasebenzi kunye nexesha lokuphumla.

Buyela kwi Investment

Ukubala i-ROI kubandakanya ukuhlola imveliso yomatshini, ukusebenza kakuhle, kunye nexesha lokuphila. Umatshini ovelisa iimveliso ezikumgangatho ophezulu ngokungaguqukiyo kwaye usebenza ngokufanelekileyo uya kubonelela nge-ROI engcono. Ukuthathela ingqalelo ukubanakho ukuphuculwa kwexesha elizayo kunye nexabiso lokuthengisa lomatshini kunokuphucula ngakumbi i-ROI.

Umgangatho kunye neeMetrics zokuSebenza

Umgangatho kunye nokusebenza komatshini we-extrusion zizinto ezibalulekileyo zokumisela ukufaneleka kwayo kwisicelo esinikezelweyo. Ukuvavanya ezi metrics kuqinisekisa ukuba umatshini unokuhlangabezana nemigangatho yokuvelisa efunwayo kwaye unike iziphumo ezihambelanayo.

Imveliso esemgangathweni

Ikhono lomatshini we-extrusion ukuvelisa iimveliso ezikumgangatho ophezulu yi-metric ephambili yokusebenza. Izinto ezinjengokuchaneka komgangatho, ukugqiba komphezulu, kunye neempawu zemathiriyeli kufuneka zivavanywe. Oomatshini abaneenkqubo zolawulo oluphezulu kunye nolungelelwaniso oluchanekileyo lokufa baxhotyiswe ngcono ukuhambisa umgangatho wemveliso ongaguqukiyo.

Ukuphumelela kunye nokuSebenza

Ukutyhutyha, okanye izinga apho umatshini unokuvelisa iimveliso ezigqityiweyo, yimetriki yokusebenza ebalulekileyo. Oomatshini abaphezulu bemveliso benza imijikelezo yokuvelisa ngokukhawuleza kunye nokwanda kwemveliso. Ucikizeko, olulinganiswa ngokwemigaqo yokusetyenziswa kwamandla kunye nokusetyenziswa kwemathiriyeli, kukwadlala indima ebalulekileyo ekumiseleni ukusebenza komatshini kukonke.

Ukuthembeka kunye nexesha elide

Ukuthembeka komatshini we-extrusion, kubandakanywa nokukwazi ukusebenza ngokuqhubekayo ngaphandle kokuphuka rhoqo, kubalulekile ukugcina iishedyuli zokuvelisa. Oomatshini abanolwakhiwo olomeleleyo, izinto ezikumgangatho ophezulu, kunye neeshedyuli zokulondolozwa rhoqo ziqinisekisa ixesha eliphezulu kunye nokunciphisa ukuphazamiseka.

Iingqwalasela zokuPakisha kunye nokuThumela

Ukupakishwa kunye nokuthunyelwa koomatshini be-extrusion bahlala bengahoywa kodwa zizinto ezibalulekileyo ezinokuchaphazela utyalo-mali lulonke.

Umgangatho wokupakisha

Ukupakishwa okufanelekileyo kuqinisekisa ukuba umatshini ukhuselwe ngexesha lokuhamba kwaye ufika kwimeko efanelekileyo. Izinto zokupakisha ezikumgangatho ophezulu, ezifana neekhreyithi eziqinisiweyo kunye nezigqubuthelo ezikhuselayo, zinceda ukuthintela umonakalo ngexesha lokuthumela.

ULungiselelo lokuThumela

Ukuhanjiswa kwempahla, kubandakanywa nokukhetha umthwali, indlela yokuthumela, kunye nexesha lokuhambisa, kufuneka kucwangciswe ngononophelo. Ukusebenza nabanikezeli bezothutho abahloniphekileyo kunye nokuqinisekisa amaxwebhu afanelekileyo kunokunceda ukuphepha ukulibaziseka kunye neendleko ezongezelelweyo.

Ukufakwa kunye nokuseta

Nje ukuba umatshini ufikile, ukufakwa kunye nenkqubo yokusetha kufuneka ilawulwe ngokufanelekileyo. Oku kuquka ukuqinisekisa ukuba umatshini ufakwe ngokuchanekileyo, ulungelelanisiwe, kwaye uvavanyiwe phambi kokuba uqalise ukuvelisa. Iinkonzo zofakelo lobuchwephesha kunye nenkxaso yobugcisa evela kumenzi inokuququzelela inkqubo yokuseta kakuhle.

Iingcinga Final

Ukukhetha umatshini ochanekileyo we-extrusion kubandakanya uvandlakanyo olubanzi lwezinto ezahlukeneyo, ukusuka kwiinkcukacha zobugcisa kunye neempawu eziphambili kwiingcamango zeendleko kunye neemetriki zomgangatho. Ngokuthatha indlela epheleleyo kunye nokuthathela ingqalelo iimfuno ezingxamisekileyo nezexesha elide, amashishini anokwenza izigqibo ezinolwazi ezandisa amandla awo emveliso kwaye aqinisekise imbuyekezo entle kutyalo-mali.

Ukuqukumbela, ukukhetha umatshini we-extrusion yinkqubo entsonkothileyo efuna ukuqwalaselwa ngononophelo kwizinto ezininzi. Ngokugxininisa kwiinkalo eziphambili ezifana nohlobo lomatshini, ukucaciswa kobugcisa, ukusebenza kakuhle kwamandla, umgangatho wokwakha, kunye nokuthotyelwa kokulawula, amashishini anokukhetha umatshini ohlangabezana neemfuno zabo ezithile kunye nokuhambisa ukusebenza kakuhle.