Usomabhizinisi osebenzisa isitolo sokusebenza ngensimbi noma imboni kufanele atshale imali emishinini efanelekile ukuze aphumelele embonini yensimbi. Ngenxa yentuthuko yezobuchwepheshe, lawa mathuluzi ezimboni ashintshile, okwenza kube lula ukudala izingxenye zensimbi ezifiselekayo kunoma yisiphi isimo nosayizi.

Ukuvela kwala mathuluzi kube nomthelela ekusungulweni kwemishini eminingi engakhiqiza izimo eziyinkimbinkimbi zezingxenye zensimbi ngomzamo owenziwe umuntu oncishisiwe kanye nokusebenza kahle okukhulu. Futhi njengoba umuntu angakhetha ezinsimbi ezihlukahlukene imishini yokusebenza, kubalulekile ukuqonda izinhlobo ezahlukene zemishini laphaya kanye nemisebenzi yayo. Unalokhu engqondweni, lesi sihloko sizoxoxa ngemishini evamile engu-11 esetshenziswa embonini yensimbi, ukuze umthengi akwazi ukuthola ngokuzethemba imishini abayidingayo.

Imakethe yemishini yensimbi yomhlaba wonke

Usayizi wemakethe yomhlaba wonke yemishini yokwenza insimbi kulindeleke ukuthi ukhule ngesilinganiso sokukhula sonyaka esiyinhlanganisela (CAGR) ka-9.4%, isuka e-US $230,48 billion ngo-2021 iya e-US $364.92 billion ngo-2026.

Lokhu kukhula kugqugquzelwa izici eziningana, ezihlanganisa:

- Ukukhula komnotho okuzinzile emazweni amaningi asathuthuka nathuthukile, okugqugquzela ukutshalwa kwezimali ezimakethe zabasebenzisi bokugcina.

- Ukuthola izintengo zempahla kulandela imiphumela emibi ye-Covid-19.

- Imishini yokugaya ethuthukisiwe yekhompuyutha yokulawula izinombolo (6-axis CNC), esiza ukuguqulwa kwamabha ensimbi eluhlaza abe izingxenye zokugcina eziyinkimbinkimbi.

Uhlobo lwemishini yokwenza insimbi

Labo abasebenza efekthri esebenza ngensimbi bayazi ukuthi imikhiqizo yekhwalithi ephezulu ingavela kuphela emishinini efanele yezimboni. Ngezansi kunohlu lwemishini evamile yokwenza insimbi esetshenziselwa imisebenzi ethile, okuhlanganisa ukusika nokubumba insimbi.

1. Umshini we-lathe ovundlile

Lo mshini uvame ukusetshenziswa ekuphendukiseni ucezu lwento umuntu asebenza kuyo. ILathes ingasetshenziswa ukusika, ukuknulela, isihlabathi, ukubhola, intambo, ukubhoboza, ukujika, nobuso bepulasitiki, ukhuni, nezingxenye zensimbi. Ziza ngosayizi ohlukahlukene kanye nokuma kwazo nezisekeli ezimbalwa ezihambisanayo zokuthuthukisa imisebenzi yazo.

Iningi labasebenzi bensimbi abasebenza ngokunemba kwensimbi bayakujabulela ukusebenza nabo imishini yokugeza. Isibonelo, izimboni ezikhiqiza imishini ekhanyayo cishe zizosebenzisa imishini ye-lathe ukuthuthukisa imikhiqizo yazo.

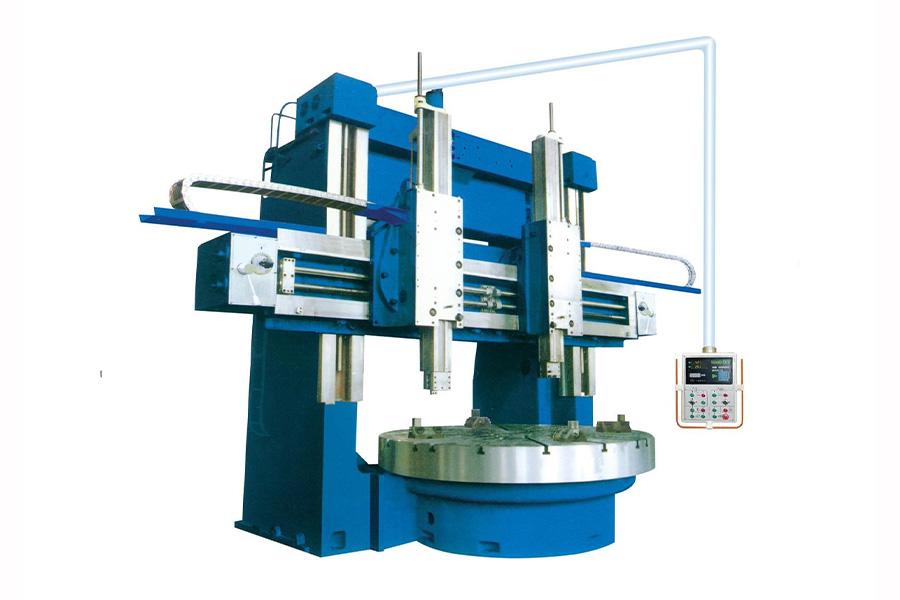

2. Imishini ye-lathe eqondile (VTLs)

Ama-VTL angelinye lamathuluzi anemisebenzi eminingi embonini yensimbi. Avame ukusetshenziselwa ukukhanda ama-alloys aqinile, amathuluzi ensimbi anesivinini esikhulu, amathuluzi e-ceramic, nezinsimbi ezisansimbi nezingezona ayoni.

Ngaphezu kwalokho, bangasebenza izingxenye ezinkulu zensimbi ezinobubanzi obusuka ku-1 kuye ku-20 wamamitha. Baletha imisebenzi esebenzayo yokusika insimbi ehlanganisa i-cylindrical boring, turning, surface, kanye ne-tapering.

3. Imishini yokugaya

Imishini yokugaya banemisebenzi eminingana lapho kucutshungulwa izinto ezahlukahlukene ezisetshenziswa zezimboni nezokukhiqiza. Basebenzisa amathuluzi okusika azungezayo ukuze bacwenge izingcezu zokusebenza ngokubhoboza, ukugaywa, ukuphinda kwenziwe kabusha, nokubhula.

Imishini yokugaya zihlukaniswa ngokuya ngesiqondiso sokujikeleza kwazo. Imishini emile inama-spindle ayo e-engeli elungile kuma-workpieces. Imishini yokugaya evundlile inesisiki esizungezayo esibheke ngokuvundlile futhi sisebenza ngokuhambisana nendawo yokusebenza. Ngokuphambene, umshini wokugaya jikelele ungaba ovundlile noma uqonde, kuye ngezidingo zezinhlelo zokusebenza ezithile.

4. Imishini yokuphehla

Umsebenzisi angasebenzisa a umshini wokugcwalisa ukwakha, ukusika, kanye nokubumba izinto ezihlukahlukene. Umshini usebenzisa i-broach noma ithuluzi elinamazinyo ukuze ukhiphe izinto futhi ucwenge ucezu lokusebenza. Inqubo ingaba yi-linear noma i-rotary, kuye ngokuthi umshini ubekwe kanjani ne-workpiece.

Isibonelo, lapho ususa izinto zokusebenza kucezu lokusebenza, umshini wokuphehla i-rotary broaching uzungezisa ithuluzi lawo elinamazinyo ukuze wakhe imikhiqizo yochwepheshe abaphatha amaphrojekthi ensimbi.

5. Umshini wokugaya

Imishini yokugaya angamathuluzi adumile embonini yensimbi ngoba asetshenziselwa ukubumba noma ukuqeda izindawo zensimbi. Ama-grinders asebenzisa i-abrasion ukuze asuse izinto ezingafuneki ku-workpiece. Njengoba inqubo yokugaya ikhiqiza ukushisa, imishini eminingi yesimanje yokugaya ifakwe amasistimu okupholisa amanzi, izinto zokupholisa ezisekelwe kuwoyela, noma amasistimu okupholisa umoya ukuze kugcinwe ucezu lokusebenza lupholile.

Uhlobo lomshini wokugaya umuntu okufanele awukhethe luncike kulokho okusetshenzwayo kanye nomphumela ohlosiwe. Isibonelo, izinto eziqinile zingadinga amapuleti okugaya ensimbi, kuyilapho izinto ezithambile zizokwenza kahle ngamapuleti e-aluminium.

Imishini yokugaya ingasetshenziswa futhi njengamathuluzi okusika lapho amanye amadivaysi engakwazi ukukhiqiza isimo esidingekayo.

Imboni yensimbi idinga izigayi ezahlukene ezifanelana nezinjongo ezihlukahlukene, njengokubamba kanye nokwenza umumo othile wocezu lokusebenza.

6. Imishini yokumba

Imboni yensimbi ihlanganisa ukubhoboza izimbobo ezinsimbi nezinye izinto ezifana nokhonkolo, ipulasitiki, nokhuni. Imishini yokumba ukusiza ukudala lezi zimbobo.

Zihlukaniswe ngezinhlobo ezimbili: imishini yokumba yeqembu lezigelekeqe kanye ne-radial. Imishini yokumba izigelekeqe inama-spindle amaningana abekwe phezu kwetafula elingashintshi. Ngakolunye uhlangothi, imishini yokumba ama-radial ine-spindle yayo ebekwe engalweni ejikelezayo.

Nakuba kunemishini yokumba esebenzisa amandla, abantu abaningi bakhetha imishini esebenza ngogesi ngenxa yokunemba nekhono layo lokusebenza ngomsebenzi obucayi. Noma kunjalo, imishini yokumba esebenza ngesandla isabalulekile, ikakhulukazi uma kudingeka ukuphatheka noma lapho isebenza ngezinto ezithambile ngendlela emangalisayo.

7. Umshini wokugunda

Ngicela ungawuphambanisi lomshini naleyo esetshenziselwa ukugunda izimvu! Lokhu umshini wokugunda isetshenziselwa ukusika amashidi ensimbi abe osayizi abafunwayo kanye nokuma ngaphandle kokwenza ama-chips noma izinsalela, ngaleyo ndlela kuncishiswe imfucumfucu eyingozi emoyeni naphansi. Lokhu umhlahlandlela wokuthenga wabaqalayo emishinini yokugunda iyindawo enhle yokuqala kulabo abangazi ukuthi umshini wenzani.

8. Imishini yokudoba

Izimboni ezihlukene zisebenzisa insimbi ukukhiqiza amagiya akhethekile, ama-splines, ama-shaft anembe kakhulu, nezinye izingxenye ezingamacylindrical zokusetshenziswa okuhlukahlukene. Imishini yokudoba zizosiza ekuxazululeni lezi zidingo. Ngenhlanhla, asebenzisa isabelomali futhi adinga abantu abambalwa ukuthi asebenze, kodwa asakhiqiza inqwaba yezingxenye zensimbi nsuku zonke.

9. Cindezela ibhuleki

Cindezela amabhuleki sekusetshenziswe amakhulu eminyaka embonini yensimbi ukucubungula izingxenye zensimbi. Nokho, ngobuchwepheshe obuphambili, cindezela amabhuleki ziye zaba ngamathuluzi ayinkimbinkimbi asebenzisa ubuchwepheshe bamakhompiyutha nezinhlelo ezisebenza ngamanzi ukuze agobe amashidi ensimbi. Bangajika noma insimbi esikiwe zibe amafomu nezimo ezihlukile kusetshenziswa isethi ye-die noma i-punch kuma-engeli athile.

10. Isikhungo somshini

Izikhungo zomshini bayindlovukazi namakhosi emishini embonini yensimbi. Ziyimishini enemisebenzi eminingi esiza ukwenza imisebenzi eminingana eyinkimbinkimbi, ehlanganisa okubuthuntu, ukugaya, ukubhoboza, nokufaka imicu ngoba iphatha amathuluzi amaningi kusishintshi.

Izikhungo zomshini ziyahlukahluka kuye ngemisebenzi yazo, ubukhulu bendawo yokusebenza, kanye nenani lezimbazo; nokho, ahlukaniswe kakhulu abe izikhungo zokukhanda eziqondile nezivundlile, kuye ngendawo ye-axis yokuphotha.

11. Ama-Sandblasters

A isandblaster ihambisa izinhlayiya zesihlabathi esihle noma imidiya ehubhukayo ngesivinini esikhulu ukwenza imisebenzi eminingana. Isetshenziswa embonini yensimbi ukuhlanza noma ukususa amapende opende, ukupeniwa, noma ukuthuthukisa ingaphezulu lezinto ezihlukene.

Abanikazi bezindawo, osonkontileka, amayadi kaloliwe, izindawo zemikhumbi, kanye nokusebenza okuhlukile kweselula kudinga imishini eqinile ye-sandblaster yokulawula ukugqwala nokuhlanza. Nakuba zidinga amakhono athile, indlela yomshini kulula ukuyiqonda.

Ama-sandblasters angasebenza ngesihlabathi, i-soda, noma ubuhlalu ukuhlanza izindawo. Umuntu angasebenzisa futhi umoya ocindezelweyo, uketshezi, noma umhwamuko ukuze akhiqize ukumunca okudonsa imidiya elumayo kubhobho yesibhamu ngaphambi kokushaya indawo yokusebenza.

Isici okufanele icatshangelwe lapho ukhetha imishini yokwenza insimbi

Nakuba eminye imishini yokwenza insimbi inemisebenzi eminingi, usengakhetha umshini ongalungile uma ungaqapheli. Unalokho engqondweni, lezi ezinye zezinto ezibalulekile okufanele zihlolwe ngaphambi kokutshala imali emshinini.

Izinto ezizocutshungulwa

Ukujiya, uhlobo, nokungaguquguquki kwezinto ezisetshenzwayo kunquma umshini wokusansimbi umuntu awukhethayo. Isibonelo, i-aluminium elula noma izinsimbi zegeji encane zidinga umshini wokugunda osebenza ngogesi noma osebenza ngomoya.

Ngaphandle kohlobo lwempahla, kubalulekile futhi ukubheka ukwakheka kwayo ukuze kunqunywe ukuthi yimuphi umshini ozoyilingana kangcono.

Uhlobo lomshini okufanele lwenziwe

Ngenkathi eminye imishini yokusebenza yensimbi iguquguquka, opharetha angase adinge imishini eqinile neyinkimbinkimbi yezinhlelo ezithile zokusebenza. Isibonelo, imishini yokubhoboza ingasetshenziselwa ukubhoboza, kodwa ayifanele ukugaya izingcezu zokusebenza.

Ukukhiqiza

Ibhizinisi ngalinye lifuna ukusebenza kahle futhi lithuthukise ukukhiqiza kwalo. Umshini osebenzayo wensimbi kufanele uthembeke futhi uhlale isikhathi eside ukuze ukhiqize okuqhubekayo. Kufanele futhi ikhiqize inani eliphakeme lezingxenye zensimbi nsuku zonke ukuze kuthuthukiswe inzuzo. Isibonelo, izimbobo ezisebenza ngogesi zingcono ukubhola ngobuningi kunemishini yokubhola eyenziwa ngesandla.

Ubukhulu bezinto zokusebenza

Izinto zokusebenza ezinkulu zidinga imishini emikhulu yensimbi, kuyilapho izinto ezincane zingadinga imishini ephathekayo nesebenza ngesandla. Umumo kanye nenombolo yezimbazo ze-workpiece kuzophinde kunqume uhlobo lombono womshini wensimbi okufanele umuntu awusebenzise.

Amazinga okunemba

Izinga lokunemba emkhakheni wokusebenza kwensimbi yikhono lomshini lokufanisa izilinganiso ezishiwo kumklamo. Ukunemba kanye namazinga okunemba komshini osebenza ngensimbi kubalulekile ekuqinisekiseni ukusebenza okufanele kwemishini kwezingxenye zensimbi nokwaneliseka kwamakhasimende. Ngaphezu kwalokho, ukunemba nokunemba kusiza ukuqinisekisa ukuthi izingxenye zensimbi ezikhiqiziwe ziyahambisana.

Isiphetho

Imboni yensimbi igcwele imishini, engadida abathengi abaningi. Kodwa-ke, umuntu angakhulisa amathuba abo okwenza isinqumo esihle ngocwaningo kanye nochwepheshe bezokubonisana. Inketho eyodwa esebenza ngokwezomnotho ukuthenga imishini ehlukahlukene eyenza imisebenzi eminingi. Qinisekisa ukuthi idivayisi inokukhiqiza okuphezulu namaleveli okunemba ukwanelisa izimfuno zamakhasimende. Futhi kulabo abafuna ukufunda okwengeziwe, hlola lo mhlahlandlela amathiphu okukhetha ifektri esebenza ngensimbi.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu