Ukuphrinta kwe-3D kungenye yobuchwepheshe obuguquguqukayo kakhulu be-21st ekhulwini leminyaka, futhi ishintsha kancane kancane indlela izinto ezidalwa ngayo, eziklanywe ngayo futhi zakhiwe ngayo. Ngakho-ke akumangazi ukuthi imboni yokuphrinta ye-3D ingenye yezimboni ezibaluleke kakhulu zokukhiqiza abathengisi okufanele bazibukele.

Kodwa-ke, abathengi abaningi bangase bazabalaze ukuhlala benolwazi lwakamuva mayelana nezinto ezintsha ezihlukahlukene kubuchwepheshe bokuphrinta be-3D. Lesi sihloko sizoxoxa ngobuchwepheshe obubalulekile obuyisikhombisa okufanele uzazi, futhi sinikeze amathiphu abalulekile okukhetha inqubo yokuphrinta efanele.

Okuqukethwe

Kuyini ukuphrinta kwe-3D?

Uhlolojikelele lwemboni yokuphrinta ye-3D

Izinhlobo ezingu-7 zobuchwepheshe bokuphrinta be-3D

Ungakhetha kanjani inqubo yokuphrinta ye-3D efanele

Isiphetho

Kuyini ukuphrinta kwe-3D?

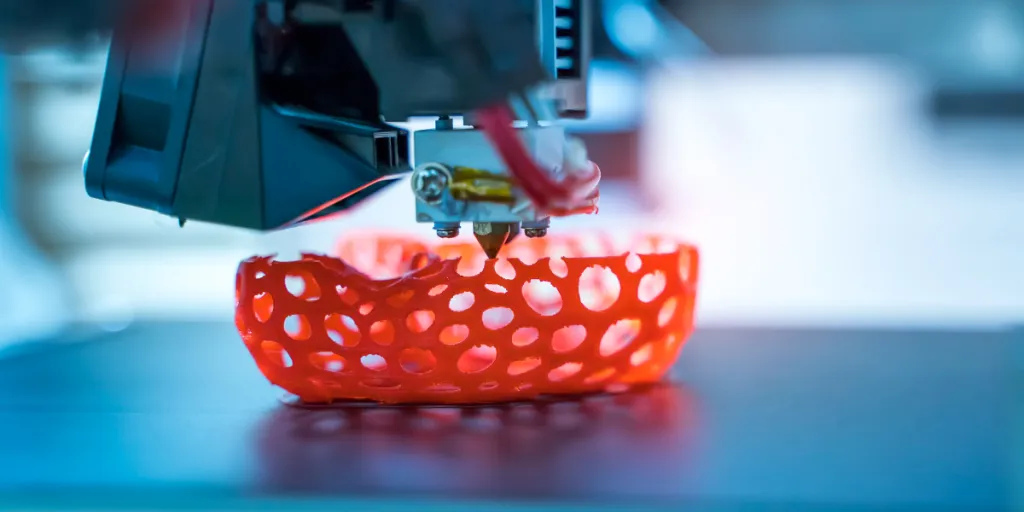

Ukuphrinta kwe-3D kuyingxenye yenqubo eyaziwa ngokuthi ukukhiqiza okungeziwe, lapho into idalwa ngokwengeza isendlalelo esibalulekile ngokwesendlalelo. Nakuba le nqubo isetshenziselwa ukukhiqiza okukhulu ukuze kwakhiwe izingxenye zezimoto noma izingxenye zenjini ye-jeet, ingasetshenziswa nasekhaya noma ukusetshenziswa kwebhizinisi kusetshenziswa abancane. Amaphrinta we-3D.

Isinyathelo sokuqala sokuphrinta kwe-3D sihlanganisa ukudala ipulani yento ezophrintwa. Uma umsebenzisi esenedizayini ye-3D, uyithumela kuphrinta ethola idatha, idonse okokusebenza ngeshubhu, iyincibilikise, futhi iyifake epuletini lapho iphola khona ngokushesha. Into ye-3D idalwe ngokwendlalelo, njengoba iphrinta izongeza ungqimba olulodwa lwento ngesikhathi kuze kuvele isakhiwo esiphelele.

Uhlolojikelele lwemboni yokuphrinta ye-3D

Imakethe yokuphrinta ye-3D ibilokhu ikhula kancane. Ngo-2023, imakethe yomhlaba wonke yafinyelela esilinganisweni sokuthi US $ 20.67 billion - isibalo okulindeleke ukuthi sikhuphuke sifike ku-US$ 91.8 billion ngo-2032. Abahlaziyi bezimakethe balindele ukuthi lokhu kukhula kwenzeke ngezinga lokukhula elihlanganisiwe lonyaka (CAGR) lika-18.92%.

Ukuqhuma kobuchwepheshe bedijithali kunomthelela ekukhuleni kwemboni yokunyathelisa ye-3D, elungele ukukhiqizwa kwesimanje. Amazwe amaningi asevele asebenzisa ukuphrinta kwe-3D, ne-United States evela njengabasebenzisa imali ephezulu ngokuphathelene nokuthenga amaphrinta e-3D ngo-2023, ebalwa ngaphezu kuka-34% wesabelo semakethe. Njengoba isidingo sobuchwepheshe bokuphrinta be-3D siqhubeka sikhula, amabhizinisi athola amathuluzi okuphrinta e-3D alungile asekulungele ukuzuza emakethe enkulu.

Izinhlobo ezingu-7 zobuchwepheshe bokuphrinta be-3D

Kunezinhlobo ezimbalwa zobuchwepheshe bokuphrinta be-3D obusetshenziswa emhlabeni jikelele. Ukuqonda lezi zinhlobo kungasiza abathengisi ukuthi benze izinqumo ezinolwazi lapho begcina imikhiqizo futhi bathuthukise ukukhetha kokukhiqiza okusekelwe esimisweni. Zihlanganisa okulandelayo:

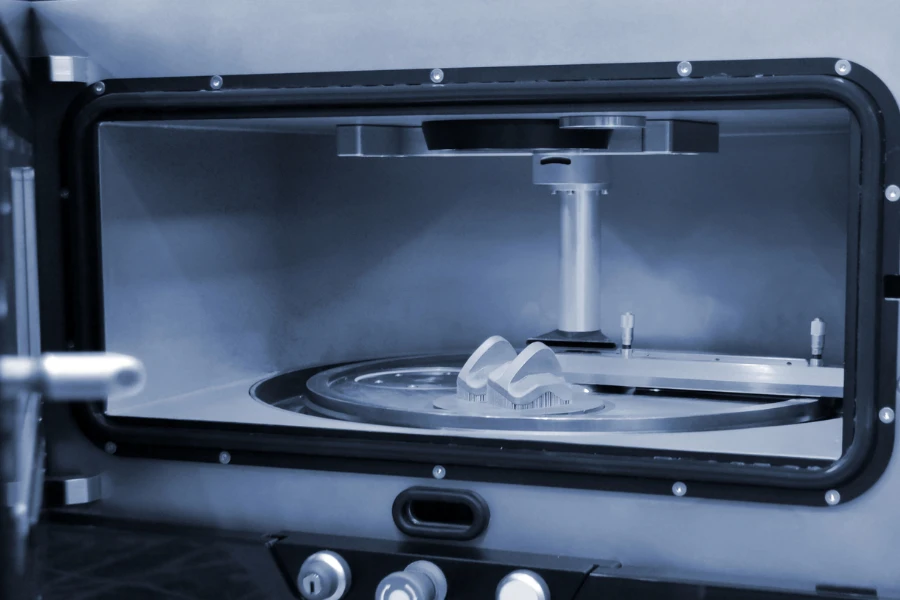

1. I-Stereolithography (SLA)

I-Stereolithography, noma i-SLA, inqubo yokuphrinta ye-3D esebenzisa i-laser ukwelapha inhlaka ewuketshezi ibe yipulasitiki eqinile. Isitiriyo esibheke phansi noma esihlanekezelwe wuhlelo oluvame kakhulu lwe-SLA.

Kuye ngomshini, i-resin ithululelwa ethangini ngumsebenzisi noma ikhishwe ngokuzenzakalelayo ku-cartridge.

Ekuqaleni kokuphrinta, isiteji esakhiwe sehliselwa ku-resin, kushiye ungqimba oluncane loketshezi phakathi kwendawo yokwakha kanye nangaphansi kwethangi.

Ingilazi ecacile ngaphansi kwethangi le-resin ivumela ama-galvanometers ukuthi aqondise i-UV laser, adwebe ingxenye enqamulayo yemodeli ye-3D futhi akhethe ukwenza lukhuni okokusebenza. Ukuphrinta kwakhiwe ngezingqimba ezilandelanayo, ngayinye inogqinsi olungaphansi kwama-microns ayi-100.

Uma ungqimba seluqediwe, isiteji siyehliswa futhi, bese ingxenye ehlutshiwe kusukela phansi ethangini ukuze kudedelwe inhlaka emisha ngaphansi.

Ithuthukiswe ekuqaleni ngeminyaka yama-80s, i-SLA yayivalelwe emishinini emikhulu yezimboni kuze kube muva nje. Namuhla, i-desktop lithography inikeza ukuphrinta kwe-3D okuthengekayo, okunokulungiswa okuphezulu okulingana kahle endaweni yokusebenza yomsebenzisi.

I-SLA ivumela ukusebenzisa inhlobonhlobo yezinto ezinezinto ezibonakalayo ezahlukahlukene. Noma ngabe unjiniyela, umklami womkhiqizo, umqophi, ubucwebe, noma udokotela wamazinyo, kukhona okubalulekile abazokusebenzisa.

2. I-Digital light processing (DLP)

In ukucubungula ukukhanya kwedijithali noma i-DLP, inqubo yangempela yokwelapha nokukhiqiza into ye-3D iyafana nokuphrinta kwe-SLA 3D, ngaphandle kokuchezuka okukodwa. I-Stereolithography isebenzisa i-laser ukuze iveze umfanekiso we-3D wento endaweni yethangi, idale isendlalelo phezu kwesinye.

Endabeni yokucubungula ukukhanya kwedijithali, i-laser ithathelwa indawo isibani se-arc noma umthombo wokukhanya. Ukukhanya kuvezwa ngesimo sesimo esifiswayo ebusweni be-polymer ewuketshezi, futhi i-polymer ethile ewuketshezi iba lukhuni kalula, ikwenze kudle isikhathi esincane kune-laser ukwenza umumo. Umphumela uba inqubo yokuphrinta ye-3D esheshayo kune-SLA.

Ukucutshungulwa kokukhanya kwedijithali kusebenzisa izinto ezahlukahlukene ezifana nenayiloni, i-ABS, ne-thermoplastics. Ngakho-ke, iguquguquka. Iphinde ikhiqize izimo ezihlukene isebenzisa ukuphrinta kwayo okusuka phansi kuya phezulu ngokulungiswa okuphezulu.

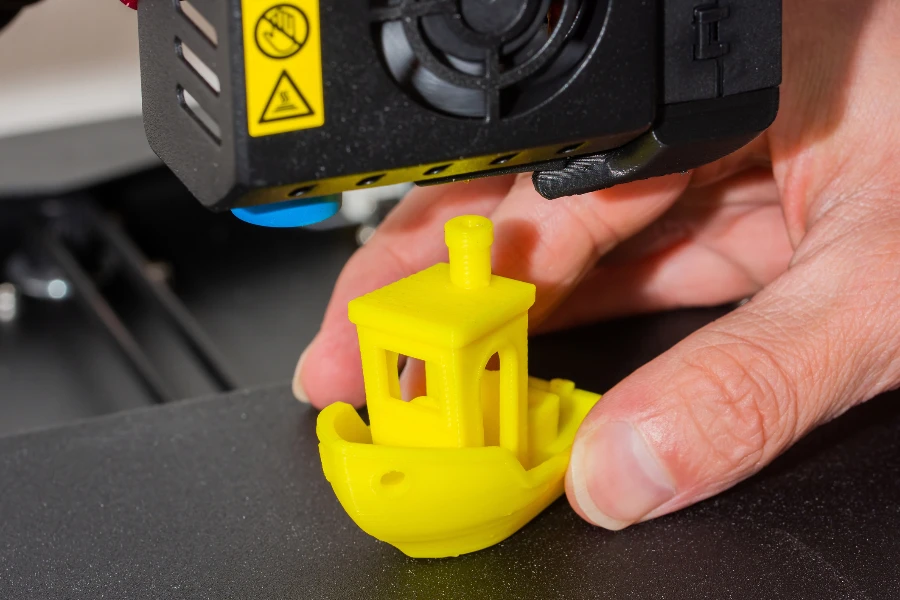

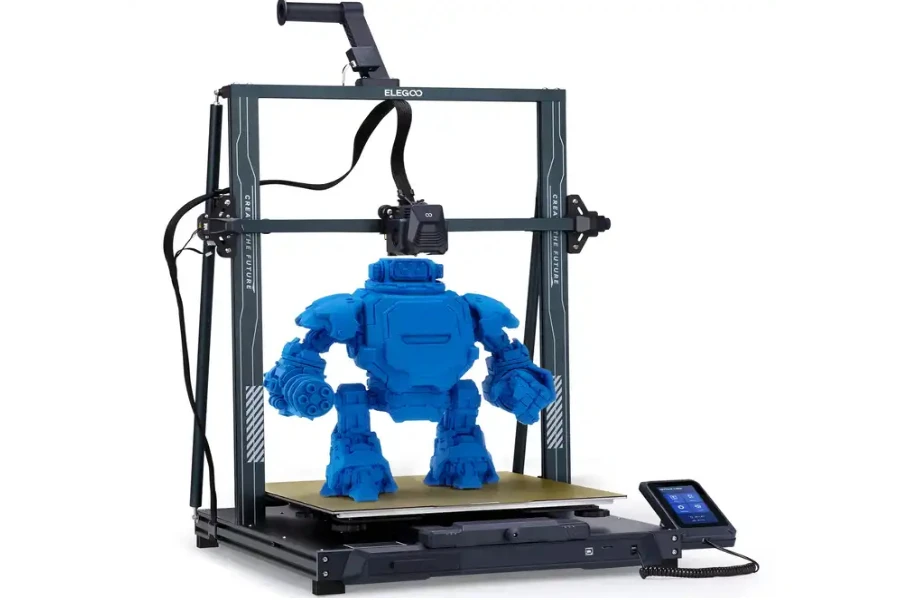

3. Imodeli ye-Fused Deposition (FDM)

Le nqubo yokuphrinta ye-3D engeza ungqimba isebenzisa izinto zokwakha ze-thermoplastic zebanga lokukhiqiza ukukhiqiza kokubili i-prototype nezingxenye ezisetshenziswa ekugcineni.

Ubuchwepheshe baziwa ngokukhiqiza imininingwane yesici ngokunembile futhi bunesilinganiso esihle kakhulu samandla nesisindo. Ilungele amamodeli womqondo, ama-prototypes asebenzayo, izinsiza zokukhiqiza, nezingxenye ezisetshenziswayo ezinevolumu ephansi.

The Inqubo ye-FDM iqala "ngokusika" idatha ye-3D CAD ibe izendlalelo. Idatha ibe isidluliselwa emshinini owakha ungqimba lwengxenye ngongqimba kuplathifomu yokwakha.

Ama-spools afana nentambo emincane ye-thermoplastic kanye nezinto ezisekelayo zisetshenziselwa ukudala ingxenye ngayinye ewela ingxenye. Njengesibhamu seglue esincibilikayo esishisayo, izinto ezingaboshiwe zikhishwa kancane kancane ngemibhobho eshiswa kabili. Ngokunemba, ama-nozzle abeka phansi kokubili usekelo kanye nezinto zokuphrinta ze-3D phezu kwezendlalelo ezandulele.

I-extrusion nozzle iyaqhubeka nokuhamba endizeni ye-XY evundlile ngenkathi iplathifomu yokwakha iyehla, yakha ingxenye yesendlalelo ngokwesendlalelo. Umsebenzisi ususa ingxenye eqediwe kuplathifomu yokwakha futhi ahlanze izinto zayo zokusekela.

Izingxenye ze-RAW FDM zinemigqa yesendlalelo esibonakalayo. Izinketho eziningi zokuqeda njengokusandwa kwesandla, ukuhlanganisa, noma upende wezimonyo ungasetshenziswa ukuze kwakheke izingcezu ezibushelelezi, ezivele phezulu.

Nakuba izingxenye ze-FDM zakhiwe nge-thermoplastics njenge-ABS, i-polycarbonate, ne-ultem, zombili ziyasebenza futhi zihlala isikhathi eside.

4.Lintering laser sintering (SLS)

Ukuphrinta kwe-SLS iwumshini wokunyathelisa osekelwe kumpushana we-laser osebenzisa impushana njengempahla eluhlaza esikhundleni se-filament noma inhlaka. Inqubo yokuphrinta iqala ngokwehlisa i-powder reservoir futhi igcwalise ngempushana ye-thermoplastic, ngokuvamile inayiloni.

Izinhlayiya ezakha impushana ziyindilinga, ezinobubanzi obungaphansi kwama-microns ayi-100 kanye nokuthungwa okubushelelezi. Lokhu kuvumela impushana ukuthi isatshalaliswe endaweni encane, eminyene, ebalulekile ekuphumeleleni kokuphrinta kwe-SLS.

Ngaphambi kokuqala ukuphrinta, impushana ishiswa ngaphansi nje kwezinga lokushisa elincibilikayo ngokusebenzisa amakhoyili okushisa futhi, kwezinye izimo, izibani ze-infrared. I-powder igcinwa kulokhu kushisa kulo lonke ukuphrinta ukuze kube lula nge-laser ukuncibilikisa impushana ngoba inani elincane lamandla lizodingeka. Iphinde ivimbele ingxenye ephrintiwe ukuthi ingaguquki ngenxa yezinga lokushisa.

I-powder spreader efana ne-blade noma i-roller yenza ungqimba oluncane lweyunifomu endaweni yesikhulumi sokwakha; bese, i-laser ishisa ngokukhetha izifunda zendawo yokwakha ukuze incibilikise impushana ku-geometry echaziwe. Le ngxenye iyaphindwa, ucezu ngalunye luba lude ngemva kongqimba ngalunye.

Kufanele kucace ukuthi uma kukhona amaphutha noma ama-artifacts ku-powder, lawa maphutha azohumusha ngokuqondile engxenyeni, okuholela ezenzweni ezimbi zemishini noma ukuhluleka kokuphrinta okungenzeka. Yingakho izingqimba ezibushelelezi, ezifanayo zibalulekile.

Lapho konke kuhamba kahle, impushana engafakiwe ihlanganisa ngokuphelele ingxenye ephrintiwe. Lokhu kusho ukuthi izinto zokusekela azidingeki ekuphrinteni kwe-SLS; noma iyiphi i-geometry ingaphrintwa. Okuwukuphela kwemikhawulo lapho kudingeka kube nesikhala esanele sokususa impushana exegayo ngemva kokuphrinta.

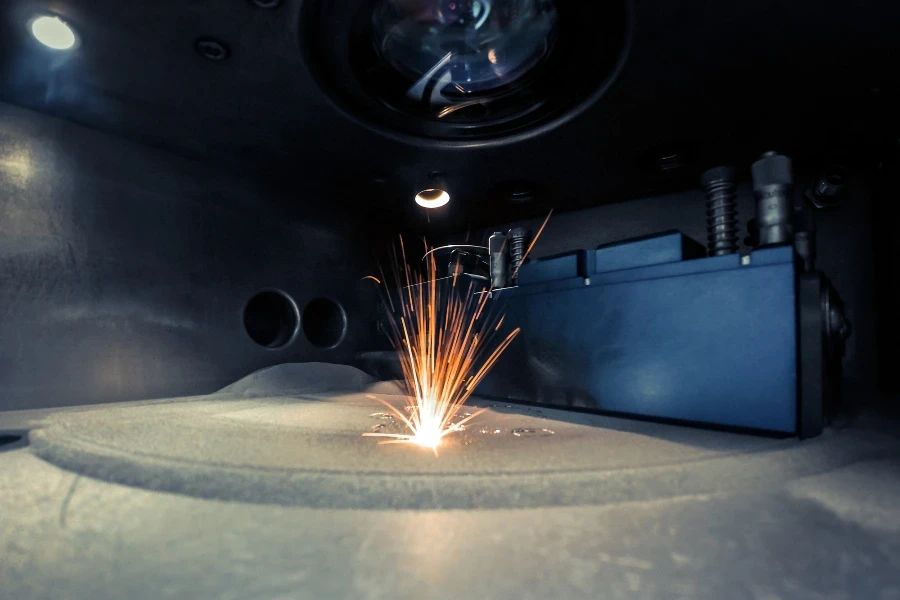

5. Ukuncibilika kwe-laser okukhethiwe (SLM)

The ukuncibilika kwe-laser okukhethiwe inqubo isebenzisa izinto eziyimpushana zensimbi ukwakha ungqimba lwento ngongqimba. Isetshenziselwa ukwakha izinto kusetshenziswa izinsimbi ezihlukahlukene, ezivame ukuba nokuminyana okuphezulu. Lobu buchwepheshe bokuphrinta be-3D busebenzisa i-laser ukuncibilikisa impushana yensimbi, eyipholisa futhi iyiqinise.

Umjikelezo we-laser ngamunye ukhiqiza ucezu olusha lwento edalwayo, bese iplatifomu yomsebenzi yehliswa ngokujiya ncamashi kohlangothi olulodwa njengoba i-scraper isabalalisa kabusha impushana. Insimbi encibilikisiwe iyaqina, futhi inqubo iyaphindwa.

I-laser ihlanganisa izingqimba ezindala nezintsha kuze kuqedwe i-prototype. Ingxenye ngayinye ishiselwe endaweni yokusebenza ngokusekelwa okuhlukanisiwe ngemva kokukhishwa kwengxenye.

Into eqediwe ikhishwa kumpushana engasetshenziswa kabusha futhi ikhululwe kwimpushana eyeqile, okuholela emikhiqizweni eqinile eqinile ekhiqiziwe.

Ukuncibilika kwe-laser okukhethiwe kufakazela ukubaluleka kwakho lapho izingxenye eziyinkimbinkimbi zidinga ukukhiqizwa ngokushesha. Iphinde inikeze amandla ukukhiqizwa kwemikhiqizo eyinkimbinkimbi enezici ezisebenzayo ezihlanganisiwe njengokupholisa okuhambisanayo.

6. I-Electronic beam melting (EBM)

Ukuncibilika kwe-electronic beam iyinqubo yokukhiqiza okunezengezo zensimbi lapho isiqalo siwumbhede wempuphu yensimbi ehlanganiswe ungqimba ngongqimba ukuze kwakhiwe ingxenye yensimbi eqinile kusetshenziswa ugongolo lwe-electron.

Uma kuqhathaniswa nezindlela ezijwayelekile zokuhlanganisa i-laser powder bed fusion njenge-SLS ne-SLM, kuyinqubo enamandla amakhulu, yingakho kusetshenziswa i-electron beam.

Ukuncibilika kwe-electronic beam ngokuvamile kwenzeka ngaphakathi komshini ngaphansi kwevacuum emazingeni okushisa aphezulu. Umsebenzisi uqala ngokusabalalisa ungqimba lwempushana yensimbi kuyo yonke indawo yokwakha futhi ashise kuqala yonke leyo mpushana. Khona-ke, i-electron beam iyayixuba ngokuncibilikisa izindawo ezidingekayo ukuze kwakhiwe into.

Inqubo iyaphindwa ukuze ekugcineni igcine nge-semi-solid block noma ikhekhe lempushana eliqukethe izinto ze-granular ezishisiwe. Isinyathelo esilandelayo sidinga ukwehlisa amandla ibhulokhi bese uqhubeka nokuhamba komsebenzi.

Enye yezinzuzo ze-EBM ukuthi umthombo wamandla ophezulu wenza kube nokwenzeka ukusebenzisa ububanzi obukhulu i-metal powder, okubuye kube lula ukusebenza ngakho. Futhi ayinayo ingozi yokuphefumula uma isebenza ngempushana ecolekile. Ngakho-ke, nge-EBM, ukusebenza nge-powder nokuba eduze kwayo ngaphandle kwemishini ekhethekile yokuphepha kungenzeka.

Enye inzuzo yokuncibilika kwe-electronic beam ukuthi kwenzeka emazingeni okushisa aphezulu kune-laser powder bed fusion. Lokhu kuhumusha ekulawuleni kangcono izingcindezi ezishisayo, ukugoqa okuncane nokuhlanekezela, kanye nokunemba okungcono kobukhulu.

Ukuncibilika kwemishayo ye-elekthronikhi kuvame ukusetshenziselwa ukwenza izimila zezokwelapha, nakuba sekuphinde kwasetshenziswa ku-aerospace kanye nobunjiniyela bezimoto.

7. Ukukhiqizwa kwento eyenziwe nge-laminated (LOM)

Obunye ubuchwepheshe bokuphrinta be-3D bu ukukhiqizwa kwezinto ezenziwe nge-laminated. Ukwenziwa kwento enziwe nge-laminated, noma i-LOM, kuyinqubo yokulinganisa esheshayo lapho amaphepha amboziwe, ipulasitiki, noma izendlalelo ezinalayini zensimbi zinamathiselwe ndawonye ngempumelelo futhi zisikwe ukuze zilolongeke ngethuluzi lokusika noma i-laser cutter.

Ingqimba ngayinye yenqubo yokwakha iqukethe izingxenye eziphambanayo zezingxenye eziningi. Ngaphambi kokuthi ukucubungula kuqale, isithombe esivela kufayela le-STL elithathwe ku-CAD sinikezwa iphrinta. Isofthiwe yesistimu ye-LOM ibala iphinde ilawule imisebenzi yokusika, kuyilapho i-lamination nokuma kwento kwenzeka mathupha.

Enqubweni yokwakha, isistimu idala isigaba esiphambene semodeli ye-3D, ikala ubude obuqondile bemodeli, futhi isike indiza evundlile ngokufanele. Isoftware ibe isithwebula ama-cross-hatches kanye nomjikelezo wemodeli.

Ugongolo olukhudlwana lusika ukujiya kongqimba olulodwa lwento ngesikhathi, futhi ngemva kokushiswa komjikelezo, umngcele wemodeli uyakhululwa eshidini elisele.

Iplatifomu enenqwaba yezendlalelo ezakheke ngaphambilini iyehla, kanye nesigaba esisha sokuthuthuka kwezinto.

Iplatifomu iyakhuphuka, futhi i-roller eshisayo ibeka izinto esitakini ngokunyakaza okukodwa okuhambisanayo, ibophe ungqimba lwangaphambilini. Bese, isishumeki sekhodi esiqondile sikala ubude benqwaba bese sidlulisela ubude obusha ukuze sisike. Lokhu kulandelana kuyaqhubeka kuze kube zonke izingqimba zakhiwe.

Ukucubungula izinto kulandela ngemuva kokuthi izinto zenziwe ngokugcwele, okubandakanya ukuhlukanisa ingxenye ye-laminated block ye-LOM. Ngemva kokuhlukaniswa, into ingafakwa esihlabathini, ipholishwe, noma ipendwe ngendlela efunwa ngayo.

Ungakhetha kanjani inqubo yokuphrinta ye-3D efanele

Amabhizinisi angakwazi ukukhetha okulungile 3D zokunyathelisa indlela kuphela uma becabangela izici ezithile ezibalulekile. Nazi izinto ezintathu ezibalulekile okufanele uzibeke phambili ngaphambi kokutshala imali kubuchwepheshe obuthile.

1. Ikhono lokukhiqiza noma lenqubo

Okokuqala, lapho ukhetha ubuchwepheshe bokuphrinta be-3D, kuza phansi ekusebenzeni kwenqubo yokwenza umkhiqizo. Izici ezibonakalayo zento ekhiqiziwe zingasiza abasebenzisi banciphise indlela yokuphrinta. Lokhu kufaka phakathi ugqinsi olufiselekayo lomkhiqizo ophelile, ukunemba, usayizi, noma isakhiwo sokusekela.

Isibonelo, ubukhulu obuncane bodonga ekuphrinteni kwe-SLA ngu-0.6mm, kuyilapho ukucutshungulwa kokukhanya kwedijithali kungamukela kufika ku-0.2mm. Umphumela wento ephrintiwe awunembile kancane ngokufakwa okuhlanganisiwe, kuyilapho i-SLA inembe kakhulu futhi inokulungiswa okuphezulu kakhulu.

Nakuba i-SLS noma i-SLA iyinhle kakhulu ezidingweni eziningi zokuphrinta ze-3D, imiklamo eyinkimbinkimbi edinga ukuphathwa kochwepheshe ingafinyelelwa ngokuphrinta kwe-FDM, EBM, noma i-LOM.

2. Izimpawu noma ukusebenza kwezingxenye zokugcina

Enye indlela yokukhetha inqubo efanelekile yokuphrinta ye-3D iwukucabangela ukusebenza komkhiqizo wokugcina. Lokhu kuhlanganisa ukubheka ukungathinteki ezimweni zemvelo, ukuguquguquka, ukuqina, nezinye izici ezibonakalayo ezifana nokumelana namakhemikhali nokushisa, ukuphepha kwemvelo, futhi uma kungadliwa.

Ukuchayeka kumswakama noma ukukhanya kwelanga kungathinta ikhwalithi yemikhiqizo; ngakho-ke, ukumelana nokushisa nomswakama akuqinisekisiwe i-resin-based izinqubo ezifana ne-SLA noma i-DLP. Ngakho-ke, abasebenzisi bangase bacabangele izindlela ezisekelwe kwi-powder infusion njenge-EBM, SLM, noma ubuchwepheshe bokuphrinta be-LOM. Ngaphezu kwalokho, izinto eziphrintiwe kusetshenziswa lobu buchwepheshe zinezakhiwo zamakhemikhali ezinamandla kakhulu.

Lokhu kusho ukuthi i-SLA ne-DLP zizofanelana nokuphrinta kwezinto ezingeke zivezwe ezintweni zangaphandle ezinokhahlo, kuyilapho izindlela zokukhetha ze-laser ezincibilika ze-elekthronikhi zisebenza kangcono kakhulu ekuphrinteni izinto ezisezingeni lezimboni.

3. Izinto kanye nokuqedwa

Okokugcina, amabhizinisi kufanele agcizelele uhlobo lwezinto azozisebenzisa ukuze akhiqize into kanye nesiphetho alilindele ekuphrintiwe. Izinto ezisetshenziswa kakhulu ukuphrinta 3D zihlanganisa umucu, powder, kanye ne-resin, lapho lezi zinto ziphinde zihlukaniswe zaba ama-polymer noma amapulasitiki, izinsimbi, izitsha zobumba, kanye izinhlanganisela.

Amapulastiki aphinde ahlukaniswe abe thermoplastic kanye thermosets. I-SLS ne-FDM zifaneleka kakhulu ku-thermoplastics, kuyilapho ubuchwepheshe bokuphrinta obungcono kakhulu be-thermosets i-stereolithography kanye ne-Digital Light Processing (DLP).

Izinto zensimbi zinezimfanelo eziqine kakhulu futhi zihambisana ne-aerospace, izimoto, kanye nezicelo zezokwelapha. Uhlobo lwento futhi lubalulekile lapho kwenziwa izingxenye eziqinile njengamahinge eminyango noma ezinye izingxenye zensimbi zokufaka ukukhanya. Izinqubo ze-SLM, LOM, ne-EBM zinikeza izixazululo zokuphrinta zezidingo ezinjalo.

Phakathi naleso sikhathi, lobu buchwepheshe bokuphrinta obuhlukene bubuye bube nokuqedwa okuhlukile. Isibonelo, labo abafuna isiphetho esicwebezelayo noma esicwebezelayo bangakhetha amasu e-SLA nawe-FDM. I-SLA ne-DLP zizokwenza isiphetho esicacile. Isiphetho esidayiwe noma se-matte singenzeka uma usebenzisa i-laser sintering ekhethiwe.

Isiphetho

Ekugcineni, kukhona ubuchwepheshe bokuphrinta be-3D obuhlukile, futhi ukukhetha okulungile kuvela ezidingweni zomsebenzisi. Ezinye izici, njengezinto ezibonakalayo nokusebenza kwazo, nazo zizonquma uhlobo lobuchwepheshe okufanele lusetshenziswe. Abasebenzisi abalungele ukuqalisa uhambo oluyimpumelelo lokuphrinta lwe-3D bangahlola uhla lwamaphrinta athembekile e-3D Chovm.com.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu