Ngo-2025, isidingo sokulawula ukunyakaza okunembile ku-automation yezimboni siyaqhubeka nokukhuphuka, siqhutshwa intuthuko kwezobuchwepheshe nezinto zokwakha. Lesi sihloko sinikeza ukuhlaziya okujulile kwezinto ezibalulekile okufanele zicatshangelwe lapho kukhethwa ama-rack kanye ne-pinion, enikeza imininingwane ebalulekile kubathengi abangochwepheshe. Kusukela ekucacisweni kokusebenza kuya kwikhwalithi yezinto ezibonakalayo, lo mhlahlandlela uzosiza ekwenzeni izinqumo zokuthenga unolwazi.

Okuqukethwe:

-Market Uhlolojikelele of Rack kanye Pinion Mechanism

-Ukuhlaziywa Okujulile Kwemakethe Ye-Rack and Pinion

-Amathrendi Abalulekile Nezinto Ezintsha

-Izici Eziyinhloko Lapho Ukhetha I-Rack ne-Pinion Mechanisms

-Izicelo Ezithuthukisiwe Ze-Rack and Pinion Mechanisms

-Intuthuko Yezobuchwepheshe kuRack and Pinion Systems

-Amazinga okulawula nokuhambisana

-Imicabango yokugcina

Uhlolojikelele lwemakethe yeRack and Pinion Mechanism

Imakethe yomhlaba wonke yama-industrial rack and pinions yalinganiselwa cishe ku-USD 1.7 billion ngo-2023 futhi kulindeleke ukuthi ifinyelele ku-USD 2.7 billion ngo-2030, okubonisa izinga lokukhula elihlanganisiwe lonyaka (CAGR) lika-6.5% kusukela ngo-2023 kuya ku-2030. Lokhu kukhula kubangelwa ukwanda kwesidingo sokuzenzekelayo nokunemba ezinqubweni ezihlukahlukene zezimboni. Imakethe yaseMelika iyodwa yayilinganiselwa ku-USD 470.4 million ngo-2023, kanti iChina kulindeleke ukuthi ikhule ku-CAGR ehlaba umxhwele ka-10.4%, ifinyelele ku-USD 579.8 million ngo-2030.

Ukuhlukaniswa kwemakethe kukhombisa ukuthi i-alloy steel rack kanye namaphini kulindeleke ukuthi afinyelele ku-USD 1.1 billion ngo-2030, akhula ku-CAGR ka-6.5%. Ingxenye ye-carbon steel rack kanye ne-pinions isethwe ukuthi ikhule ku-CAGR ka-5.1% ngesikhathi esifanayo. Izifunda ezibalulekile ezinomthelela kulokhu kukhula zifaka iJapan, iCanada, iJalimane kanye nesifunda esibanzi sase-Asia-Pacific. Ukwamukelwa okwandayo kwezinto ezithuthukisiwe, njengama-alloys aphezulu kanye namapulasitiki anjiniyela, kukhulisa kakhulu ukuqina nokusebenza kwama-rack namaphinikhodi, ikakhulukazi ezindaweni ezinokhahlo.

Ukuhlaziywa Okujulile Kwemakethe Ye-Rack and Pinion

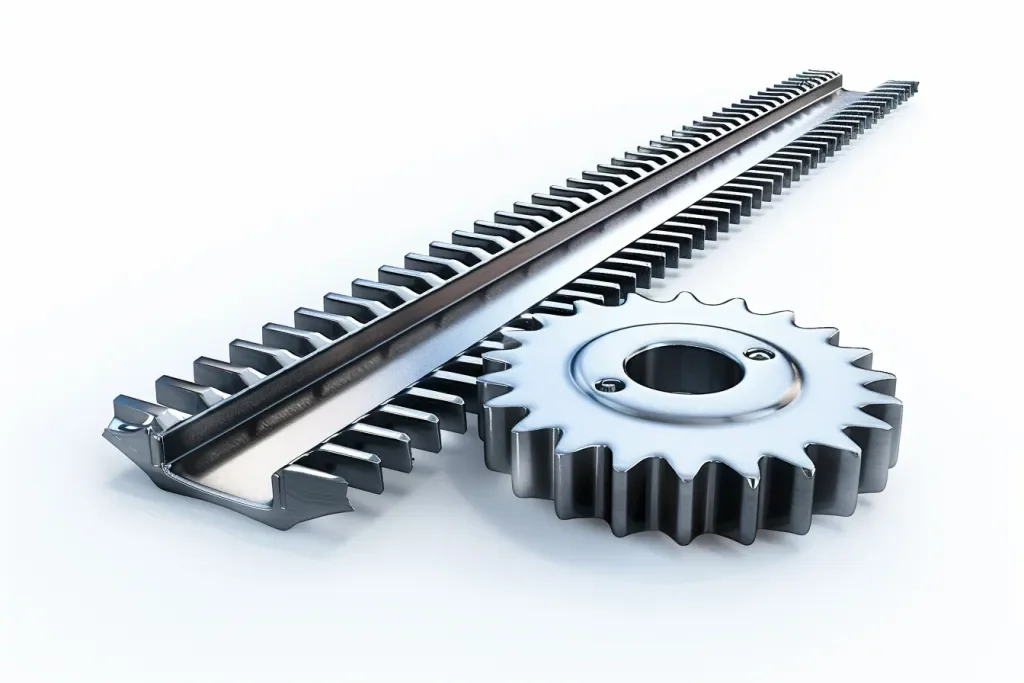

Imishini yokubeka iphini kanye nephinikhodi ibalulekile ekuguquleni ukunyakaza okuzungezayo kube ukunyakaza okuqondile futhi okuphambene nalokho. Zibalulekile emishinini, kumarobhothi, nasezinhlelweni ezizenzakalelayo zokulawula ukunyakaza okunembayo. Ekuqaleni zisetshenziswa emishinini eyisisekelo nokusebenza okwenziwa ngesandla, lezi zingxenye manje zisekela amasistimu asezingeni eliphezulu futhi asebenza kahle kakhulu.

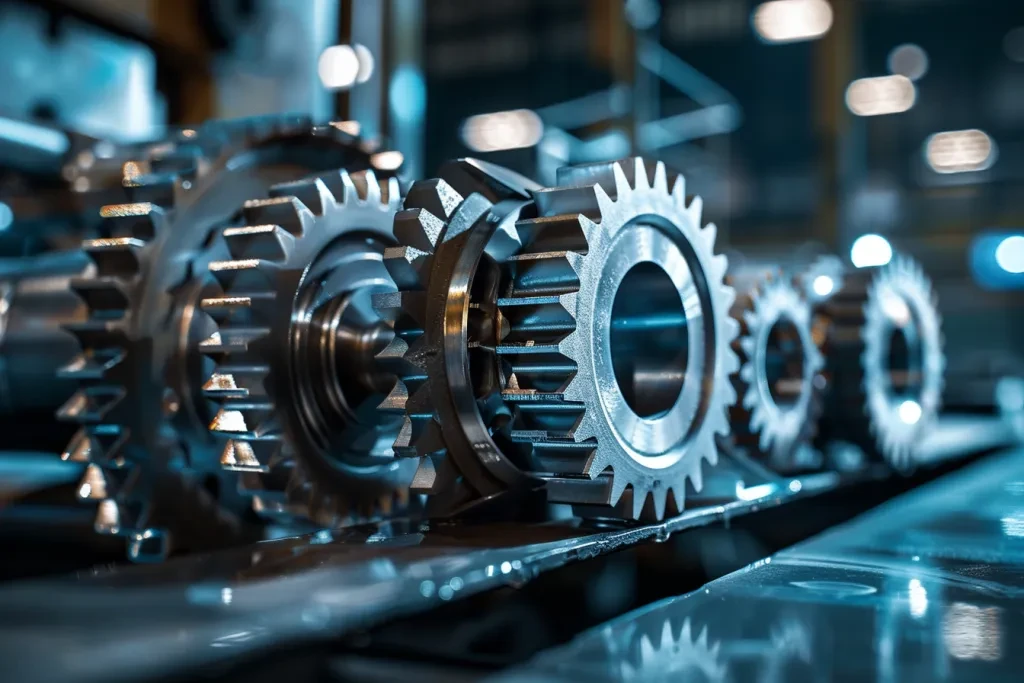

Amabhentshimakhi okusebenza angukhiye wama-rack namaphinikhodi ahlanganisa ukunemba, ukuqina, namandla okuphatha umthwalo. I-rack enembe kakhulu namaphinikhodi kunikeza ukunemba okuthuthukisiwe nokuphindaphinda, okubalulekile emishinini ye-CNC namarobhothi. Ukuhlanganiswa kwezinzwa ezithuthukisiwe nezinhlelo zokulawula kwenza ukuqapha kwesikhathi sangempela nokulungiswa kokunyakaza, kuthuthukise ukusebenza kwesistimu nokuthembeka.

Ukuziphatha kwabathengi kushintshela ezixazululweni ezisebenza kahle nezithembekile zokulawula ukunyakaza, ikakhulukazi emikhakheni yezimoto, ye-aerospace, neyokukhiqiza. Ukunyuka kwe-Industrial 4.0 kanye nokusetshenziswa okwandayo kwamarobhothi kanye ne-automation kuqhuba isidingo sama-rack kanye nezinhlelo ze-pinion eziphambili. Izinkampani zigxile emisha nasekuhlukaniseni, ikakhulukazi ezimakethe ze-niche ezidinga izixazululo ezenziwe ngokwezifiso.

Amathrendi Abalulekile Nezinto Ezintsha

Imakethe ibone amathrendi abalulekile kanye nokuqanjwa okusha, okuhlanganisa ukuthuthukiswa kwe-rack enembe kakhulu namaphinikhodi kanye nokusetshenziswa kwezinto ezithuthukisiwe ukuthuthukisa ukuqina. Ukuhlanganisa ama-rack kanye nama-pinion systems anezinzwa ezithuthukisiwe nezinhlelo zokulawula zenza ukuqapha kwesikhathi sangempela nokulungiswa kokunyakaza. Ama-actuator kagesi nama-servomotor ahlanganiswe nama-rack kanye nama-pinion systems andisa izinhlelo zawo zokusebenza, ikakhulukazi kumasistimu azenzakalelayo nawerobhothi.

Imithelela yezomnotho efana ne-global push towards automation kanye nesidingo sokunemba ezinqubweni zezimboni yizona ezihamba phambili zokukhula kwemakethe. Inguquko ebheke kudijithali kanye nokwamukelwa kobuchwepheshe be-Industrial 4.0 ihlela kabusha ukuguquguquka kwemakethe, kugcizelela ukukhiqizwa okuhlakaniphile. Izidingo zekhasimende zokunemba okuphezulu nokuthembeka ekulawuleni ukunyakaza zilungiswa ngokuqamba okusha okuqhubekayo nokuthuthukiswa kwemikhiqizo esebenza kahle kakhulu.

Izinto Ezibalulekile Lapho Ukhetha I-Rack ne-Pinion Mechanisms

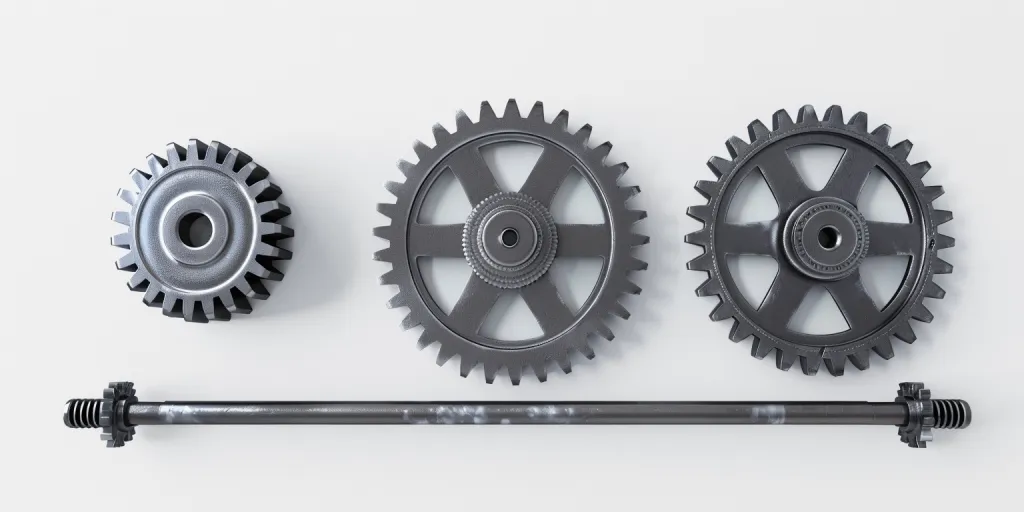

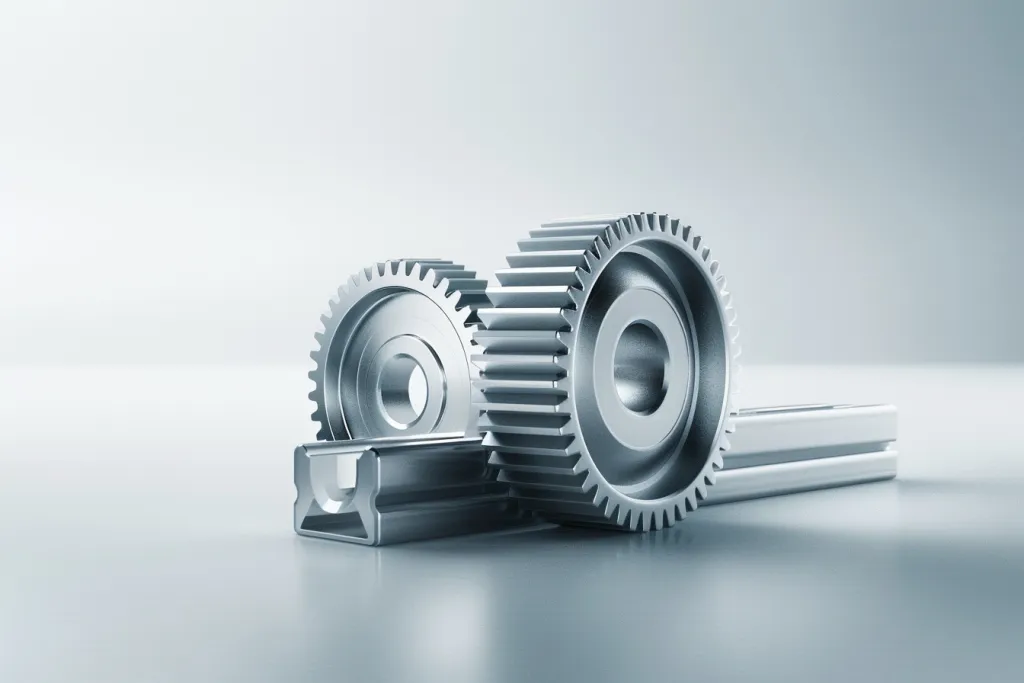

Izinhlobo zamaRakhi kanye nePinion Mechanisms

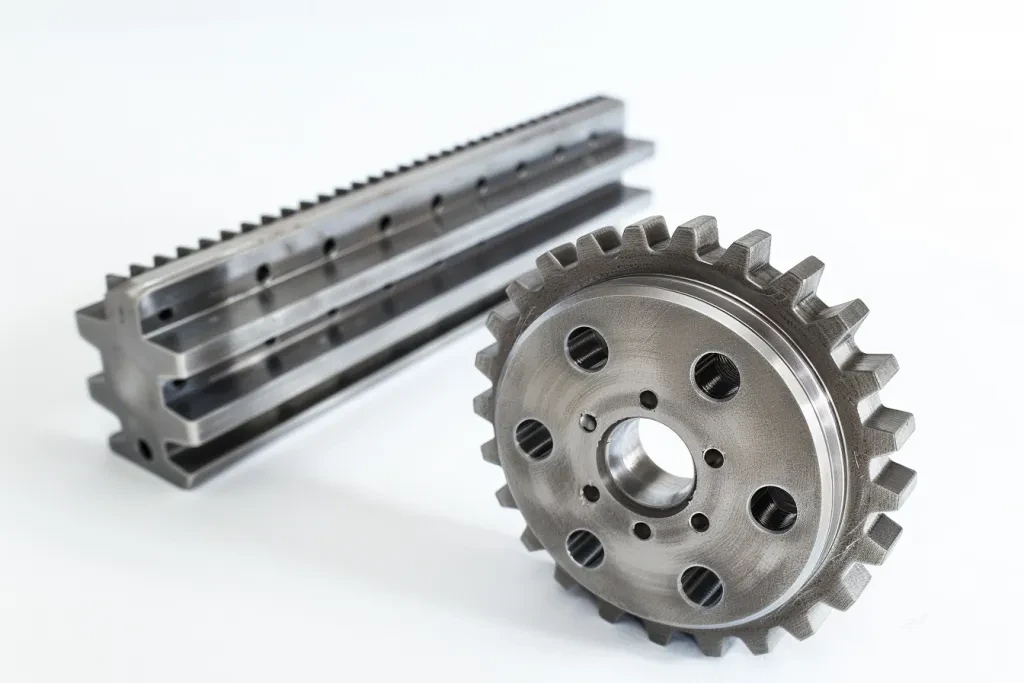

Imishini yokubeka kanye nephinikhodi iza ngezinhlobo ezimbalwa, ngayinye ifanele izinhlelo zokusebenza ezithile kanye nezidingo zokusebenza. Izinhlobo ezivame kakhulu zihlanganisa amazinyo aqondile, amazinyo e-helical, nama-roller pinion drives. Amarack amazinyo aqondile anamazinyo ahambisana ne-axis yegiya, alungele ukunyakaza okulula, okwenziwa ngesandla. Nokho, zingaba nomsindo futhi zingasebenzi kahle. Amarakhi amazinyo angama-Helical anamazinyo asontekile ahambisana nomzila we-helical, ahlinzeka ngokuhlanganyela okuqhubekayo ngobude bezinyo, okuholela ekusebenzeni okuthule futhi okuphumelelayo, okulungele ukusetshenziswa okunembayo okuphezulu kanye nesivinini esikhulu. Amadrayivu e-roller pinion asebenzisa ama-roller asekelayo ane-mesh ngamazinyo erack, ahlinzeka okuncane kokungabuyeli emuva, okubalulekile ekunembeni okuphezulu nokuphindaphinda.

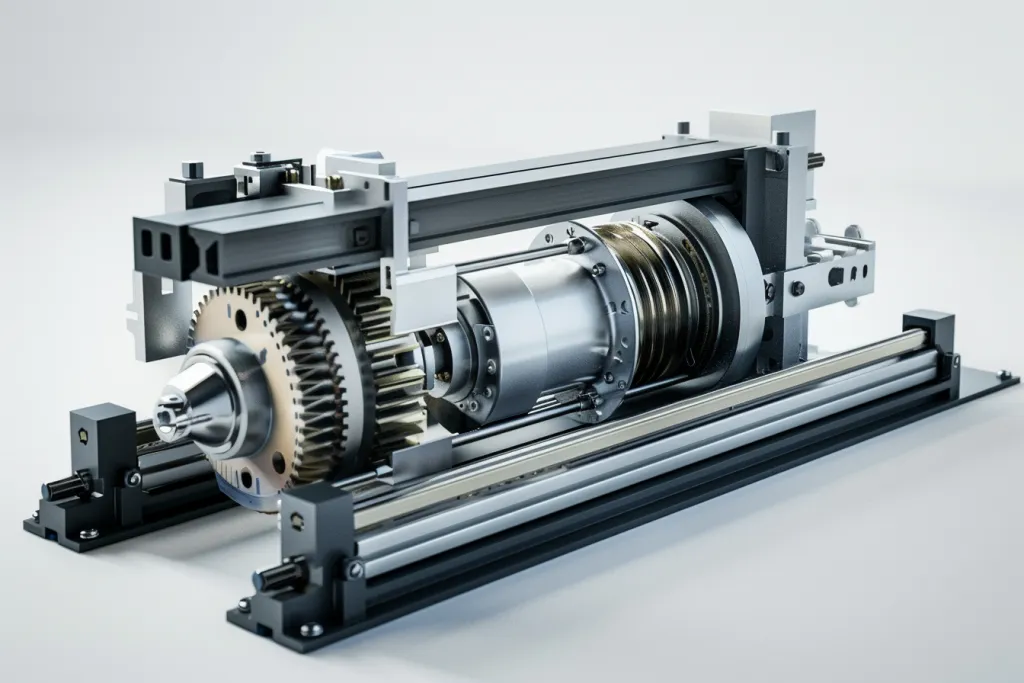

Ukusebenza kanye nokusebenza

Uma ukhetha i-rack kanye ne-pinion mechanism, cabangela ukucaciswa kokusebenza okufana namandla okushayela kwe-axis, isilinganiso sesisindo se-eksisi, ne-engeli yokucindezela. Amandla okushayela kwe-axis angamandla amakhulu umshini ongawaphatha, anqunywa ithoshi yemoto edluliswa ngephinikhodi iye endaweni yokubeka. Isilinganiso sesisindo se-eksisi sibonisa ubukhulu bomthwalo i-eksisi eshayelwayo engawusekela. I-engeli yokucindezela ichaza ukuma kwamazinyo kanye ne-engeli ayenza ngezikhala ku-rack, okuthinta indlela iphiniyoni elizogingqa ngayo ngokushelelayo. I-engeli yokucindezela ebanzi ngokuvamile iholela ekusebenzeni okushelelayo. Ukwengeza, isivinini lapho i-rack ihamba khona njengoba i-pinion iphenduka ithonywa ububanzi begiya, okwenza kubaluleke ukufanisa usayizi wegiya nesivinini esidingekayo kanye nokunemba kwesicelo.

Izinto kanye Nekhwalithi Yokwakha

Izinto ezibonakalayo nekhwalithi yokwakha yama-rack kanye ne-pinion ibalulekile ekuqinisekiseni ukuqina nokusebenza kwesikhathi eside. Izinto ezivamile zihlanganisa insimbi eqinile, insimbi engagqwali, nama-alloys ahlukahlukene. Insimbi eqinile ivame ukusetshenziselwa amandla ayo kanye nokumelana nokugqoka, okulungele izicelo zomthwalo ophezulu. Insimbi engagqwali inikeza ukumelana nokugqwala, okuzuzisayo ezindaweni ezichayeke kumswakama noma amakhemikhali. Ama-alloys anganikeza ibhalansi yamandla, ukuqina, nokumelana nokugqwala. Izinga lamazinyo, kungakhathaliseki ukuthi agayiwe, asikiwe ngokunemba, noma aphansi, nawo athinta ukusebenza. Amazinyo agayiwe asetshenziselwa izinhlelo zokusebenza ezijwayelekile, kuyilapho amazinyo anqunywe ngokunemba naphansi abekelwe izinhlelo zokusebenza ezinembayo nezisebenza kahle kakhulu.

Ukuhambisana Nokuhlanganiswa

Ukuhambisana nezinhlelo ezikhona kanye nokuthuthukiswa okuzayo kubalulekile. Imishini ye-Rack ne-pinion kumele ihambisane nezinjini kanye nezinhlelo zokulawula ezisetshenziswa ohlelweni. Lokhu kuhlanganisa nokuqinisekisa ukuthi i-pinion bore diameter yegiya ifana ne-motor shaft kanye nokuthi ukulungiselelwa kokukhwezwayo kuhambisana nezidingo zesistimu. Ukucabangela amandla okuthuthukisa, njengokushintshela ekunembeni okuphakeme noma umshini womthamo ophezulu, kungonga isikhathi nezindleko ngokuhamba kwesikhathi. Ukuqinisekisa ukuhlanganiswa okungenamthungo nezinye izingxenye, njengemihlahlandlela eqondile nama-actuator, kubalulekile ekusebenzeni okuhle nokuthembeka.

Izindleko Nesabelomali

Izindleko zama-rack kanye ne-pinion mechanisms zingahluka kakhulu ngokuya ngohlobo, impahla, kanye nokunemba okudingekayo. Amarack amazinyo aqondile ngokuvamile ayinketho engabizi kakhulu, kuyilapho amazinyo e-helical nama-roller pinion drives evame ukubiza kakhulu ngenxa yokusebenza kwawo okuphezulu nokunemba. Kubalulekile ukulinganisa izindleko zokuqala nezinzuzo zesikhathi eside, ezifana nokunciphisa ukulungiswa nesikhathi sokuphumula, ukusebenza kahle okuphezulu, nokuphila isikhathi eside. Ukucatshangelwa kwebhajethi kufanele futhi kubandakanye izindleko zokufakwa, isikhathi sokuncipha esingaba khona phakathi nokusetha, kanye nanoma yiziphi izingxenye ezengeziwe ezidingekayo ukuze kuhlanganiswe. Ukulinganisa izindleko eziphelele zobunikazi, kunenani lokuthenga lasekuqaleni nje, kungasiza ekwenzeni isinqumo esinolwazi.

Izicelo Ezithuthukisiwe Ze-Rack and Pinion Mechanisms

Imishini ye-Rack ne-pinion isetshenziswa kakhulu ezimbonini ezihlukahlukene ngenxa yekhono lazo lokuguqula kahle ukunyakaza okujikelezayo kube ukunyakaza okuqondile. Embonini yezimoto, zibalulekile ezinhlelweni zokuqondisa, zinikeza ukulawula okunembile kanye nempendulo kumshayeli, okubalulekile ekuphepheni kwemoto nokusebenza. Ku-automation yezimboni, ama-rack kanye nama-pinion drives asetshenziselwa ukubeka amatafula amathuluzi omshini, okuvumela ukunyakaza okunembile nokuphindaphindayo kubalulekile ezinqubweni zokukhiqiza ezinembayo. Baphinde baqashwe kumarobhothi okwenza i-linear actuation, banikeze ukulawula okuthembekile nokusebenzayo kokunyakaza ezingalweni zerobhothi kanye nezimoto eziqondiswayo ezizenzakalelayo.

Embonini yezokwakha, izindlela zokubeka ama-rack kanye ne-pinion zisetshenziswa kuma-elevator esikhashana kanye nezinhlelo zokuphakamisa, okwenza kube lula ukuhamba okuqondile kwezinto kanye nabasebenzi. Lezi zindlela zinikeza ukuqina nokuthembeka, okubalulekile ezimweni ezinzima zezindawo zokwakha. Ukwengeza, asetshenziswa ekugibeleni kwepaki yokuzijabulisa, lapho ukulawula ukunyakaza okunembe nokuphephile kubaluleke kakhulu. Ikhono lamadrayivu e-rack kanye ne-pinion ukuphatha imithwalo ephezulu nokuhlinzeka ngokuma okunembile kuwenza alungele izinhlelo ezinjalo.

Intuthuko Yezobuchwepheshe ku-Rack and Pinion Systems

Ukuthuthuka kwezobuchwepheshe kuthuthukise kakhulu ukusebenza kanye nokuguquguquka kwezinhlelo zama-rack kanye ne-pinion. Enye intuthuko ephawulekayo ukuhlanganiswa kwezinqubo zokulayisha kuqala ze-elekthronikhi, ezisebenzisa injini yesibili ukusebenzisa amandla aphikisayo, ukuqeda ukuhlehla emuva nokuthuthukisa ukunemba. Lobu buchwepheshe buzuzisa kakhulu ezinhlelweni ezidinga ukunemba okuphezulu, njengemishini ye-CNC nemishini yokukhiqiza i-semiconductor. Enye intuthuko ukusetshenziswa kwezinto ezithuthukisiwe, njengezinhlanganisela ze-carbon fibre, ezinciphisa isisindo ngenkathi zigcina amandla nokuqina, okuholela ekulawuleni ukunyakaza okushesha futhi okuphumelelayo, ikakhulukazi ekusetshenzisweni kwejubane eliphezulu.

Ukufakwa kwezinzwa ezihlakaniphile nokuxhumana kwe-IoT kuvumela ukuqapha kwesikhathi sangempela nokugcinwa kokubikezela. Lezi zinzwa zingathola ukuguga nokungahambi kahle, zinikeze izexwayiso zangaphambi kwesikhathi futhi zinciphise ubungozi bokuhluleka okungalindelekile. Idatha eqoqiwe ingahlaziywa ukuze kuthuthukiswe ukusebenza futhi kunwetshwe isikhathi sokuphila somshini. Ukwengeza, intuthuko kumasu okukhiqiza, njengokukhiqiza okungeziwe, inika amandla ukukhiqizwa kwezinto eziyinkimbinkimbi nezenziwe ngokwezifiso ze-rack kanye ne-pinion ngokunemba okuphezulu kanye nezikhathi zokuhola ezincishisiwe.

Amazinga Okulawula Nokuhambisana

Ukuhambisana nezindinganiso zokulawula kubalulekile ekuqinisekiseni ukuphepha nokuthembeka kwemishini yokubeka amaphinikhodi. I-American Gear Manufacturers Association (AGMA) ibeka izindinganiso zeleveli yekhwalithi yamagiya, okuhlanganisa ama-rack nama-pinion systems. Lawa mazinga amboza izici ezifana nokuhlukahluka kwephimbo, iphutha lephrofayela, nokunemba kokuqondanisa kwamazinyo. Amaleveli ekhwalithi ephezulu, njenge-AGMA 10 ne-AGMA 11, abonisa amagiya anamazinyo aqinile naphansi, afanele ukusetshenziswa okunemba okuphezulu. Ukuthobela la mazinga kuqinisekisa ukuthi izindlela ziyahlangabezana nenqubo edingekayo yokusebenza kanye nokuhlala isikhathi eside.

Ngokungeziwe kumazinga e-AGMA, ukuthobela imithetho ethile eqondene nomkhakha kuyadingeka. Isibonelo, embonini yezimoto, ama-rack kanye nama-pinion steering systems kumele ahlangabezane namazinga okuphepha aqinile asethwe izinhlangano ezilawulayo ezifana ne-National Highway Traffic Safety Administration (NHTSA) kanye Nohlelo Lwe-European New Car Assessment (Euro NCAP). Lawa mazinga aqinisekisa ukuthi amasistimu okuqondisa ahlinzeka ngokusebenza okuthembekile nokuphephile ngaphansi kwezimo ezihlukahlukene zokusebenza. Ngokufanayo, embonini yezokwakha, izinhlelo zokuphakamisa ezisebenzisa ama-rack kanye ne-pinion izindlela kufanele zihambisane nemithetho yokuphepha emsebenzini ukuze kuvikelwe abasebenzi futhi kuqinisekiswe ukusebenza okuphephile.

Imicabango Final

Kafushane, ukukhetha i-rack efanele kanye nendlela yephinikhodi kuhilela ukucabangela izici ezihlukahlukene, okuhlanganisa uhlobo lwemishini, ukucaciswa kokusebenza, impahla kanye nekhwalithi yokwakha, ukuhambisana, kanye nezindleko. Intuthuko yezobuchwepheshe iyaqhubeka nokuthuthukisa ukusebenza nokuguquguquka kwalezi zinhlelo, zizenze zifanelekele uhla olubanzi lwezinhlelo zokusebenza. Ukuhambisana nezindinganiso zokulawula kuqinisekisa ukuphepha nokwethembeka, okubalulekile ekusetshenzisweni kwezimboni. Ngokuhlola ngokucophelela lezi zici, amabhizinisi angakhetha indlela yokubeka efanelekile kanye nephinikhodi ngezidingo zabo ezithile, aqinisekise ukusebenza kahle, ukusebenza kahle, nokuphila isikhathi eside.