Ngo-2025, isidingo samathuluzi okusika ngokunemba siyakhula, siqhutshwa izimboni ezidinga ukusikeka kwe-acrylic kwekhwalithi ephezulu. Lesi sihloko sinikeza ukuhlaziya okujulile kwezinto ezibalulekile okufanele uzicabangele lapho ukhetha i-acrylic sheet cutter, ehlanganisa izici ezifana nezinhlobo, ukusebenza, izici zobuchwepheshe, namathrendi emakethe. Inikeza imininingwane ebalulekile yabathengi abangochwepheshe abahlose ukwenza izinqumo zokuthenga benolwazi.

Okuqukethwe:

-Acrylic Sheet Cutter Market Uhlolojikelele

-Ukuhlaziywa Okuningiliziwe Kwemakethe Ye-Acrylic Sheet Cutter

-Izici Eziyinhloko Okufanele Zicabangele Lapho Ukhetha I-Acrylic Sheet Cutter

Izici Zezobuchwepheshe Zakamuva kuma-Acrylic Sheet Cutters

-Ukucatshangelwa kwesabelomali sabasiki be-Acrylic Sheet

-Ukuqonda Imakethe kanye Nezitayela Zesikhathi esizayo

- Ukugoqa

Uhlolojikelele lwemakethe ye-Acrylic Sheet Cutter

Imakethe yomhlaba wonke yamathuluzi okusaha nokusika ibibiza cishe i-USD 7 billion ngo-2023 futhi kulindeleke ukuthi ifinyelele ku-USD 9.4 billion ngo-2030, ikhula ku-CAGR ka-4.4% ukusuka ngo-2023 kuya ku-2030. Kule makethe, ingxenye yokusika amashidi e-acrylic izuza kakhulu ngenxa yesidingo esikhulayo samathuluzi wokusika ama-industries ahlukahlukene. Ingxenye yezicelo zezimboni kulindeleke ukuthi ifinyelele ku-USD 6.6 billion ngo-2030, ikhule ku-CAGR ka-4.7%, kanti ingxenye yesicelo se-DIY kulindeleke ukuthi ikhule ku-CAGR ka-3.7% ngesikhathi esifanayo.

Ngokwesifunda, imakethe yase-US ibibiza cishe i-USD 1.9 billion ngo-2023, kanti iChina yabikezela ukuthi izokhula ku-CAGR ehlaba umxhwele ka-7.4%, ifinyelele ku-USD 2 billion ngo-2030.

Ukuhlaziywa Okuningiliziwe Kwemakethe Ye-Acrylic Sheet Cutter

Amabhentshimakhi Okusebenza Okubalulekile kanye Nezimakethe Zokwabelana Ngezimakethe

Imakethe yokusika amashidi e-acrylic idinga ukunemba okuphezulu nokusebenza kahle ekusikeni izinto ze-acrylic. Abadlali abamqoka abafana ne-Apex Tool Group, i-Atlas Copco, i-Hilti Corporation, kanye ne-Makita Corporation balawula imakethe ngokusungula izinto ezintsha eziqhubekayo nokusebenzisana kwamasu. Imakethe inokuncintisana kakhulu, igxile kubuchwepheshe bokusika obusezingeni eliphezulu bezimboni ezifana nezezimoto, ezokwakha kanye ne-electronics.

Imithelela Yezomnotho kanye Nokushintsha Kokuziphatha Kwabathengi

Isimo somnotho sithinta kakhulu imakethe yokusika amashidi e-acrylic. Isidingo sihlobene eduze nokukhula kwezimboni zokwakha nezezimoto, abathengi abakhulu bezinto ze-acrylic. Ukushintshela ezinqubweni zokukhiqiza ezisimeme futhi ezonga amandla kuholele ekuthandeni amathuluzi okusika anembayo anciphisa ukumoshwa kwempahla.

Izintandokazi Zesiteshi Sokusabalalisa kanye Nezinto Ezintsha Zakamuva

Iziteshi zokusabalalisa zabasiki beshidi le-acrylic zihlanganisa kokubili izinkundla eziku-inthanethi nezingaxhunyiwe ku-inthanethi. Ingxenye eku-inthanethi ithola ukuduma ngenxa yokusebenziseka kalula kanye nohlu olubanzi lwezinketho. Izinqubo ezintsha zakamuva zihlanganisa imishini yokusika i-laser kanye nezinhlelo ze-CNC (Computer Numerical Control), enikeza ukunemba okuthuthukisiwe nokusebenza kahle. Lobu buchwepheshe kulindeleke ukuthi buqhubekise ukukhula kwemakethe, buhlinzeke ngamathuba amasha kubakhiqizi nabasabalalisi.

Izigaba Zokuphila Komkhiqizo kanye Nedijithali

Umjikelezo wokuphila womkhiqizo wabasiki beshidi le-acrylic ubandakanya izigaba ukusuka ekwakhiweni kuya ekusatshalalisweni. Ukwenziwa kwedijithali ekukhiqizeni kuye kwahlela lezi zigaba, kwathuthukisa ukusebenza kahle nokunciphisa izindleko zokukhiqiza. Ukuhlanganiswa kwe-IoT (i-Inthanethi Yezinto) kanye ne-AI (Artificial Intelligence) emishinini yokusika kuthuthukisa ukusebenza, kunika amandla ukuqapha kwesikhathi sangempela nokugcinwa kokubikezela.

Amaphuzu Obuhlungu Bekhasimende kanye Namasu Okubeka uphawu lomkhiqizo

Naphezu kwentuthuko, amakhasimende abhekana nezinselele ezifana nezindleko eziphezulu zokutshala izimali kanye nesidingo sabasebenzi abanamakhono. Abakhiqizi bagxile ekuthuthukiseni izixazululo ezisebenziseka kalula nezingabizi kakhulu. Amasu okubeka uphawu lomkhiqizo agqamisa izici ezihlukile nezinzuzo ezifana nokunemba, ukuqina, kanye nokusebenziseka kalula ukuze kuhlukaniswe izimbangi.

Amasu Okuhlukanisa kanye Nezimakethe Ze-Niche

Amasu okuhlukanisa ahlanganisa ukunikeza izixazululo ezenziwe ngezifiso zezidingo ezithile zemboni kanye nezinsiza eziphelele zangemuva kokuthengisa. Izimakethe ze-Niche, ezifana nabathandi be-DIY nabakhiqizi abancane, banikeza amathuba okukhula ezinkampanini ezinikeza amathuluzi okusika angabizi futhi asebenzayo ahambisana nezidingo zabo.

Izinto Ezibalulekile Okufanele Uzicabange Lapho Ukhetha I-Acrylic Sheet Cutter

Ukukhetha i-acrylic sheet cutter efanele kubalulekile ekusebenzeni kahle kanye nekhwalithi yokusebenza kwakho. Ngezansi, sihlola ukucatshangelwa okubalulekile ngokuningiliziwe.

Izinhlobo Nezitayela Ze-Acrylic Sheet Cutters

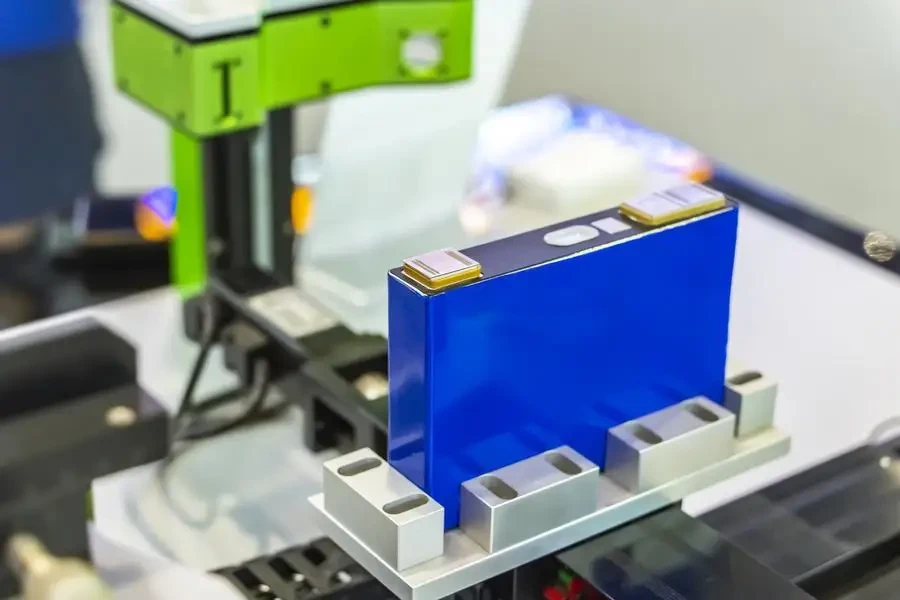

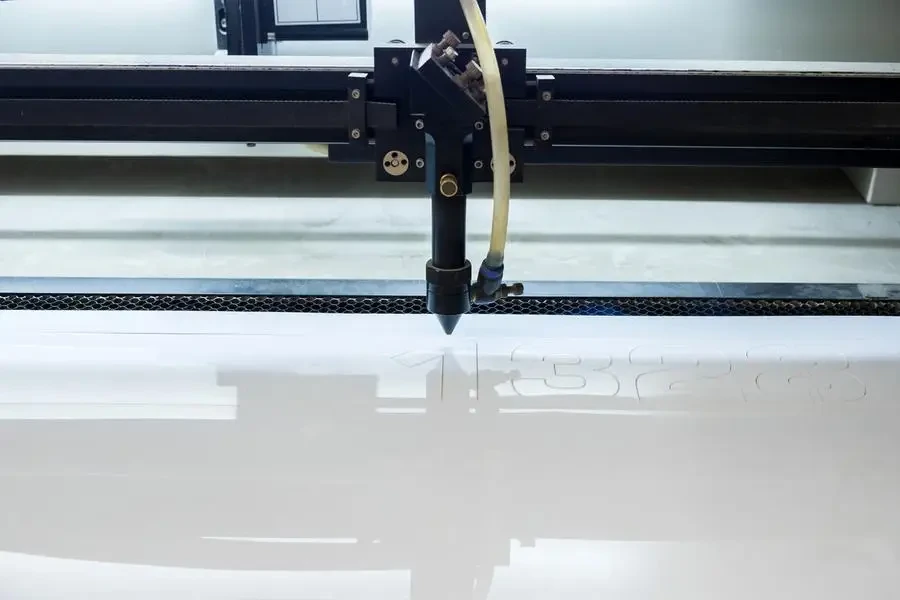

Abasiki beshidi le-Acrylic bafika ngezinhlobo nezitayela ezahlukahlukene, ngasinye silungele imisebenzi ehlukene nezikali zokusebenza. Izinhlobo ezivame kakhulu zihlanganisa abasiki bezandla, abasiki belaser, kanye namarutha e-CNC (Computer Numerical Control).

Abasiki bezandla ngokuvamile basetshenziselwa amaphrojekthi amancane noma ngabathanda ukuzilibazisa. Ayabiza kakhulu kodwa adinga umzamo owengeziwe kanye nekhono lokusikeka okunembile. Abasiki be-laser banikeza ukunemba okuphezulu futhi balungele imiklamo eyinkimbinkimbi, besebenzisa i-laser enamandla amakhulu ukusika i-acrylic, banikeze imiphetho ehlanzekile futhi banciphise isidingo sokucutshungulwa ngemuva. Amarutha e-CNC ahlukahlukene kakhulu futhi angakwazi ukuphatha ukukhiqizwa kwenani elikhulu. Zilawulwa isofthiwe yekhompuyutha, okuvumela ukuthi izimo eziyinkimbinkimbi nemiklamo isikwe ngokunemba okuphezulu nokuphindaphinda.

Ukusebenza kanye nokusebenza

Ukusebenza komsiki weshidi le-acrylic kunqunywa ijubane layo lokusika, ukunemba, kanye nekhwalithi yamaphethelo asikiwe. Abasiki bezinga eliphezulu banganciphisa isikhathi sokukhiqiza futhi bathuthukise ikhwalithi yomkhiqizo wokugcina.

Isibonelo, abasiki be-laser bangakwazi ukufinyelela isivinini sokusika esingafika ku-120 amayintshi ngomzuzu (IPM) futhi bangasika amashidi e-acrylic aze afike ku-intshi engu-1 ngokunemba okuphezulu. Amarutha e-CNC, kuyilapho ehamba kancane, anganqamula izinto eziwugqinsi futhi aphathe amashidi amakhulu. Ukusebenza komsiki kuhlanganisa nekhono layo lokuphatha izinhlobo ezahlukene ze-acrylic, njenge-cast noma i-acrylic extruded, ngaphandle kokuyekethisa ikhwalithi yokusika.

Imininingwane Technical

Lapho ukhetha umsiki weshidi le-acrylic, cabangela imininingwane yayo yobuchwepheshe. Lokhu kufaka phakathi indawo yokusika, ukujula kokusika, izidingo zamandla, nokuhambisana nesoftware ehlukahlukene kanye nezinsiza.

Indawo yokusika ichaza ubukhulu obukhulu beshidi le-acrylic umsiki angakwazi ukuphatha. Ngemisebenzi emikhulu, i-cutter enendawo enkulu yokusika ingcono. Ukujula kokusika kubalulekile kumashidi e-acrylic aminyene. Izidingo zamandla ziyahlukahluka kuye ngohlobo lomsiki; abasiki be-laser ngokuvamile badinga okokufaka kwamandla aphezulu uma kuqhathaniswa nabasiki bezandla noma be-CNC. Ukuhambisana nesofthiwe yokuklama efana ne-AutoCAD noma i-Adobe Illustrator nayo ibalulekile ekuhlanganiseni okungenamthungo ekuhambeni komsebenzi wakho wokukhiqiza.

Amazinga Okuphepha kanye Nezitifiketi

Ukuphepha kuyinkinga enkulu lapho usebenza nabasiki beshidi le-acrylic, ikakhulukazi labo abasebenzisa ama-laser anamandla amakhulu noma ama-blade ajikelezayo. Khetha abasiki abathobela amazinga okuphepha embonini kanye nezitifiketi.

Abasiki be-laser kufanele bahambisane nemithetho ye-FDA yemikhiqizo ye-laser futhi babe nezici zokuphepha njengezindawo zokusika ezivalekile kanye nezinhlelo zokukhiya ukuvikela ukuchayeka ngengozi ku-laser beam. Amarutha e-CNC kufanele abe nezinkinobho zokumisa izimo eziphuthumayo kanye nonogada abavikelayo ukuze bavikele opharetha ezingxenyeni ezihambayo. Ukwengeza, khetha abasiki abathole izitifiketi ezinhlakeni ezaziwayo ezifana ne-International Organization for Standardization (ISO) noma i-Occupational Safety and Health Administration (OSHA).

Ukuqina kanye Nokwakha Ikhwalithi

Ukuqina kanye nekhwalithi yokwakha ye-acrylic sheet cutter ithinta ubude bayo bempilo kanye nezidingo zokunakekelwa. Izisiki zekhwalithi ephezulu zivame ukwakhiwa ngezinto eziqinile njengensimbi noma i-aluminium, engamelana nokusetshenziswa okuqhubekayo.

Izisiki ze-laser zivame ukufaka amashubhu e-laser avaliwe anweba impilo yomthombo we-laser, ehlisa imvamisa yokushintshwa. Amarutha e-CNC anamafreyimu esindayo kanye nama-spindles ekhwalithi ephezulu aqinisekisa ukusika okuzinzile nokunemba ngesikhathi eside. Ukunakekelwa okuvamile, okufana nokuhlanza nokugcoba izingxenye ezihambayo, kubalulekile ukuze kugcinwe ukusebenza komsiki futhi kwandiswe ukuphila kwayo. Ukutshala imali kusisiki esinekhwalithi yokwakha eqinile kungase kuhilele izindleko eziphezulu zangaphambili kodwa kungaholela ezindlekweni eziphansi zokunakekela kanye nempilo ende yokusebenza.

Izici Zobuchwepheshe Zamuva Ku-Acrylic Sheet Cutters

Imboni yemishini ilokhu ithuthuka ngokuthuthuka kwezobuchwepheshe, futhi abasiki beshidi le-acrylic banjalo.

Ukuhlanganiswa kwe-AI kanye nokufunda komshini

Abasiki bamashidi besimanje be-acrylic baya ngokuya behlanganisa ubuhlakani bokwenziwa (AI) nokufunda komshini ukuze kuthuthukiswe ukunemba nokusebenza kahle. Lobu buchwepheshe buvumela abasiki bengqephu ukuthi bafunde emisebenzini yokusika yangaphambilini, bathuthukise amapharamitha afana nesivinini sokusika namandla e-laser ukuze enze imisebenzi yesikhathi esizayo. Lokhu kuthuthukisa izinga lokusikeka futhi kunciphisa ukumoshwa kwempahla kanye nezindleko zokusebenza.

Amakhono Esoftware Athuthukile

Amakhono esoftware esezingeni eliphezulu angenye intuthuko ebalulekile kubasiki beshidi le-acrylic. Abasiki abaningi besimanje beza nesofthiwe yobunikazi enikeza izici ezifana nokuqapha kwesikhathi sangempela, ukutholwa kwamaphutha okuzenzakalelayo, namandla okusebenza okude. Lezi zixazululo zesofthiwe ngokuvamile zihlanganisa amathuluzi okuklama athuthukile avumela amaphethini ayinkimbinkimbi futhi ayinkimbinkimbi ukuthi asikwe kalula. Ukuhlanganiswa nezinkundla ezisekelwe emafini kuphinde kwenze ukubambisana okungenazihibe nokwabelana ngedatha kuyo yonke iminyango nezindawo.

I-Automation ethuthukisiwe kanye namarobhothi

Ama-automation namarobhothi aguqule inqubo yokusika amashidi e-acrylic, ikakhulukazi ezindaweni zokukhiqiza ezinkulu. Abasiki beshidi le-acrylic abazenzakalelayo bangakwazi ukuphatha amashidi amaningi ngesikhathi esisodwa, bakhulise kakhulu ukukhiqizwa kokukhiqiza. Izingalo zamarobhothi zingahlanganiswa namarutha e-CNC noma izinqamuli ze-laser ukuze kufakwe ngokuzenzakalelayo ukulayisha nokuthulula amashidi, kuthuthukiswe ukusebenza kahle nokunciphisa umsebenzi wezandla. Leli zinga le-automation lisheshisa inqubo yokukhiqiza futhi linciphisa ubungozi bephutha lomuntu.

Ukucatshangelwa kwesabelomali sabasiki be-Acrylic Sheet

Uma utshala imali kumsiki weshidi le-acrylic, cabanga ngesabelomali sakho kanye nenani eliphelele lobunikazi.

Izindleko Zokuthenga Zokuqala

Izindleko zokuthenga zokuqala ze-acrylic sheet cutter zingahluka kakhulu kuye ngohlobo, izici, nomkhiqizo. Abasiki bezandla ngokuvamile yibo abathengeka kakhulu, ngamanani asukela ku-$50 kuya ku-$500. Ama-Laser cutter namarutha e-CNC abiza kakhulu, amanani asukela ku-$5,000 kuya ku-$50,000 noma ngaphezulu, kuye ngamakhono azo kanye nezici zawo. Linganisa isabelomali sakho nokusebenza komsiki nezici ukuze uqinisekise ukuthi uthola inani elingcono kakhulu lemali oyitshalile.

Izindleko Zokusebenza Nokunakekela

Izindleko zokusebenza nezokulungisa ziyizindleko eziqhubekayo okufanele zifakwe kubhajethi yakho. Abasiki be-laser, ngokwesibonelo, badinga ukushintshwa njalo kwamashubhu namalensi, okungabiza kakhulu. Amarutha e-CNC angase adinge ukushintshwa kwe-spindle ngezikhathi ezithile kanye nezibuyekezo zesofthiwe. Ukwengeza, ukusetshenziswa kwamandla kuyindleko enkulu yokusebenza, ikakhulukazi kubasiki be-laser abanamandla amakhulu. Khetha amamodeli awonga amandla ukusiza ukunciphisa lezi zindleko ngokuhamba kwesikhathi.

Buyisela ku-Investment (ROI)

Ukuhlola imbuyiselo ekutshalweni kwezimali (ROI) kubalulekile uma ucabangela ukuthengwa komsiki weshidi le-acrylic. Isisiki sekhwalithi ephezulu esinikeza ukusebenza kahle kokukhiqiza okukhulisiwe, ukumoshwa kwempahla okuncishisiwe, kanye nezindleko zokulungisa eziphansi zinganikeza i-ROI ephakeme ngaphezu kwesikhathi sayo sokuphila. Yenza ukuhlaziya kwezindleko zenzuzo ukuze unqume ukonga okungaba khona kanye nokwenza imali umsiki angakunikeza. Lokhu kuhlaziya kufanele kucabangele izici ezifana nokwanda komthamo wokukhiqiza, ikhwalithi yomkhiqizo ethuthukisiwe, kanye nesikhathi esincishisiwe sokwehlisa.

Ukuqonda Imakethe Namathrendi Azayo

Imakethe yokusika amashidi e-acrylic ithonywa izici ezihlukahlukene, futhi ukuhlala unolwazi ngamathrendi esikhathi esizayo kungasiza ukwenza izinqumo zokuthenga unolwazi.

Isidingo Semakethe Nokukhula

Isidingo sabasiki beshidi le-acrylic siqhutshwa izimboni ezahlukahlukene, kufaka phakathi izimpawu, ezezimoto, ezokwakha, kanye nokwakhiwa kwangaphakathi. Njengoba lezi zimboni ziqhubeka nokukhula, isidingo sabasiki bephepha be-acrylic bekhwalithi ephezulu kulindeleke ukuthi sikhuphuke. Ukuthandwa okukhulayo kwe-acrylic njengento eguquguqukayo futhi ehlala isikhathi eside yezinhlelo zokusebenza ezihlukahlukene kuqhubezela phambili lesi sidingo. Ukuqonda ukuguquguquka kwemakethe nokukhula kungasiza ekukhetheni i-cutter ehambisana nezidingo zemboni kanye nezidingo zesikhathi esizayo.

Ukuthuthukiswa kwezobuchwepheshe

Intuthuko yezobuchwepheshe idlala indima ebalulekile ekulolongeni ikusasa labasiki beshidi le-acrylic. Ukuqamba okusha okufana ne-AI, ukufunda ngomshini, kanye ne-automation kulindeleke ukuthi kwande kakhulu, kuthuthukise amakhono nokusebenza kahle kwalaba basiki. Ukwengeza, ukuthuthuka kubuchwepheshe be-laser kanye ne-CNC cishe kuzoholela ezinqubweni zokusika ezinembayo nezisheshayo. Ukuhlala unolwazi lwalezi zindlela zobuchwepheshe kungasiza ekukhetheni isisiki esinobufakazi besikhathi esizayo futhi esikwazi ukuzivumelanisa nezimo zemboni ezithuthukayo.

Ukucatshangelwa Kwezemvelo Nezokulawula

Ukusimama kwemvelo kanye nokuhambisana nokulawula kuya ngokuya kubaluleke kakhulu embonini yemishini. Abasiki beshidi be-Acrylic abahlanganisa izici ezivumelana nemvelo, ezifana nokusebenza okonga amandla kanye nokukhishwa okuncishisiwe, bazuza ukuduma. Ukuhambisana nemithethonqubo yezemvelo kanye nezitifiketi, ezifana ne-ISO 14001, nakho kubalulekile ekuqinisekiseni ukusebenza okuphephile nokuqhubekayo. Ukucabangela lezi zici kungasiza ekukhetheni umsiki ohlangabezana nezidingo zokulawula zamanje nezesikhathi esizayo.

Ukufaka phezulu

Ukukhetha umsiki weshidi le-acrylic ofanele kuhilela ukucatshangelwa ngokucophelela kwezici ezihlukahlukene, okuhlanganisa uhlobo nesitayela somsiki, ukusebenza kwawo nokusebenza kwawo, imininingwane yobuchwepheshe, izindinganiso zokuphepha, ukuqina, kanye nesabelomali. Ukwengeza, ukuhlala unolwazi mayelana nezici zakamuva zobuchwepheshe, izitayela zemakethe, nokucatshangelwa kwemvelo kungasiza ukwenza isinqumo esinolwazi. Ngomshini wokusika amashidi we-acrylic ofanele, amabhizinisi angafinyelela ukusebenza kahle okuphezulu, ikhwalithi yomkhiqizo ethuthukisiwe, nomkhawulo wokuncintisana emakethe.