Ngo-2025, imakethe yediski yokugaya ukhonkolo isethelwe ukuvela ngentuthuko entsha yezobuchwepheshe kanye namathrendi alungele imvelo. Lesi sihloko sihlinzeka ngokuhlaziywa okujulile kwemakethe, izinhlobo zamadiski, kanye nemibandela yokukhetha ebalulekile, enikeza imininingwane ebalulekile kubathengi abangochwepheshe ukuze benze izinqumo ezinolwazi.

Okuqukethwe:

- Ukuqonda imakethe ye-Concrete Grinder Disc

- Izinhlobo ezahlukene zama-Concrete Grinder Discs

- Izinto Okufanele Uzicabange Lapho Ukhetha Ama-Concrete Grinder Discs

- Ungawagcina Kanjani futhi Ufake esikhundleni Amadiski Okugaya Kakhonkolo

- Izinzuzo Zokusebenzisa Amadiski Okugaya Ukhonkolo Osezingeni Eliphezulu

- Imicabango yokugcina ekukhetheni ama-Concrete Grinder Discs

Ukuqonda imakethe ye-Concrete Grinder Disc

Abadlali Ababalulekile Embonini Ye-Concrete Grinder Disc

Imakethe ye-concrete grinder disc ilawulwa abadlali abambalwa ababalulekile abazisungulele ngokusungula izinto ezintsha kanye nekhwalithi. Izinkampani ezifana ne-3M Company, Carborundum Universal Ltd., kanye ne-NORITAKE Co., Ltd. zihola imakethe ngezixazululo zazo zokugaya ezithuthukile. Lezi zinkampani zinobukhona bemakethe obubalulekile kuzo zonke izindawo ezahlukahlukene, kufaka phakathi i-US, China, kanye ne-Europe. Isibonelo, i-3M Company ibihamba phambili ekuthuthukiseni amadiski okugaya asebenza kahle abhekelela izidingo zezimboni zokwakha nezokukhiqiza.

Ngaphezu kwalezi ziqhwaga, abanye abadlali abaphawulekayo bahlanganisa i-Camel Grinding Wheels Works Sarid Ltd. kanye ne-DEERFOS Co., Ltd. Lezi zinkampani bezigxile ekwandiseni amaphothifoliyo emikhiqizo yazo ukuze zifake inqwaba yamadiski okugaya afanele izinhlelo zokusebenza ezahlukene. Isimo sokuncintisana sibonakala ngokuqamba okusha okuqhubekayo, nezinkampani ezitshala imali eningi ocwaningweni nasekuthuthukisweni ukuze kuthuthukiswe ukusebenza nokuqina kwemikhiqizo yazo. Isibonelo, i-NORITAKE Co., Ltd. ibithuthukisa amasondo okugaya enziwe ngokwezifiso enzelwe izinhlelo zokusebenza ezithile, inika amandla imiphumela ephakeme ngokuhamba kancane kanye nokumosha izinto ezibonakalayo.

Imakethe futhi ibona ukungena kwabadlali abasha abasebenzisa ubuchwepheshe obuthuthukisiwe ukuze bathole umkhawulo wokuncintisana. Izinkampani ezifana ne-DSA Products Ltd. kanye ne-Kure Grinding Wheel zenza amagxathu abalulekile ngokwethula imikhiqizo emisha ehlangabezana nezidingo ezithuthukayo zomkhakha. Laba bangeneli abasha bagxile ezimakethe ze-niche kanye nezicelo ezikhethekile, ngaleyo ndlela bakhe indawo yemakethe ehlukahlukene futhi enokuncintisana.

Isidingo Semakethe namathrendi

Isidingo samadiski okugaya ukhonkolo siqhutshwa izitayela ezimbalwa ezibalulekile zemakethe, okuhlanganisa ukugxila okwandayo ekukhiqizeni okunembayo kanye nokukhula kwemboni yezokwakha. Imakethe yomhlaba wonke yamasondo okugaya, okubandakanya amadiski okugaya ukhonkolo, yayicishe ibe ngama-dollar ayizigidi eziyizinkulungwane ezingama-20.7 ngo-2023 futhi kulindeleke ukuthi ifinyelele ku-USD 25.0 billion ngo-2030, ikhula ku-CAGR ka-2.8%. Lokhu kukhula kudalwe ukwanda kwesidingo semikhiqizo esezingeni eliphezulu neqedwe kahle ezimbonini ezahlukahlukene, okuhlanganisa ezezimoto, i-aerospace, nezokwakha.

Intuthuko yezobuchwepheshe nayo idlala indima ebalulekile ekulolongeni imakethe. Ukwakhiwa kwezinto ezintsha ezihugayo, njengedayimane ne-cubic boron nitride (CBN), kuthuthukisa amandla okusika amadiski okugaya, okubavumela ukuthi basebenze ezintweni eziqinile ngokunemba okukhulu. Intuthuko yobuchwepheshe bokubopha inweba isikhathi sokuphila samadiski okugaya, ukunciphisa ukuguga, nokwandisa ukusebenza kahle kwawo emisebenzini yokugaya enesivinini esikhulu kanye nomsebenzi osindayo. Lokhu kuthuthuka kwezobuchwepheshe kuqhuba ukwamukelwa kwamadiski okugaya athuthukile kuzo zonke izimboni ezahlukahlukene, okusekela ukukhula kwemakethe.

Omunye umkhuba obalulekile ukwamukelwa okwandayo kwezixazululo zokugaya ezingasizungezile. Abakhiqizi bagxile ekuthuthukiseni amadiski okugaya akhiqiza uthuli oluncane nomsindo, ngaleyo ndlela ehlisa umthelela wemvelo futhi athuthukise ukuphepha kwendawo yokusebenza. Lo mkhuba ubonakala ikakhulukazi ezifundeni ezinemithetho eqinile yezemvelo, njengaseYurophu naseNyakatho Melika. Ukugxila okuqhubekayo ekusimameni nasekuvikeleni imvelo kulindeleke ukuthi kuqhubekisele phambili isidingo samadiski okugaya eco-friendly eminyakeni ezayo.

Izinhlobo ezihlukene zama-Concrete Grinder Discs

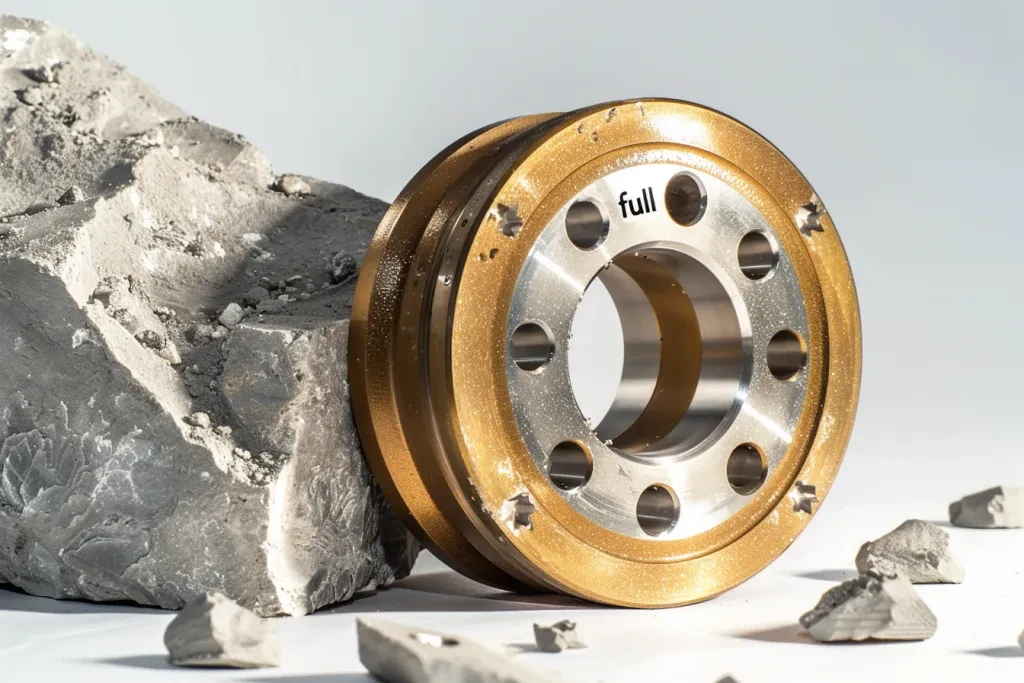

Amadiskhi Edayimane

Amadiski edayimane aphakathi kwezinhlobo ezidume kakhulu zamadiski okugaya ukhonkolo ngenxa yamakhono awo aphezulu okusika nokuqina. Lawa ma-disc ahlanganiswe nezinhlayiya zedayimane, ezihlinzeka ngobulukhuni obungavamile nokumelana nokugqoka. Amadiski edayimane alungele ukusika nokugaya izinto eziqinile ezifana nokhonkolo, igwadle, nemabula. Asetshenziswa kakhulu kumaphrojekthi wokwakha nokuvuselela lapho ukunemba nokusebenza kahle kubalulekile.

Imakethe yamadiski edayimane kulindeleke ukuthi ikhule kakhulu, iqhutshwa ukwanda kwesidingo sezixazululo zokugaya ezisebenza kahle kakhulu. Ngokombiko weGlobal Grinding Wheels Market, ukwamukelwa kwama-abrasives edayimane kanye ne-CBN kuyakhula, njengoba lezi zinto zinikeza amandla okusika athuthukisiwe nempilo ende. Lo mkhuba ubonakala ikakhulukazi embonini yezokwakha, lapho isidingo samathuluzi okugaya asebenzayo futhi anokwethenjelwa sibaluleke kakhulu.

Ngokungeziwe ekusebenzeni kwawo kokusika, ama-diamond discs ayaziwa nangokuguquguquka kwawo. Atholakala ngosayizi abahlukahlukene begrit nezinhlobo zamabhondi, okuwenza afanelekele uhla olubanzi lwezinhlelo zokusebenza. Isibonelo, ama-coarse-grit diamond discs asetshenziselwa ukususwa kwezinto ezinolaka, kuyilapho ama-fine-grit disc asetshenziselwa ukupholishwa nokuqedela. Lokhu kuguquguquka kwenza amadiski edayimane abe yinketho ekhethwayo kochwepheshe bemboni yokwakha neyokukhiqiza.

I-Silicon Carbide Discs

Ama-Silicon carbide discs angolunye uhlobo oludumile lwe-concrete grinder disc, eyaziwa ngobulukhuni nobukhali bawo. Lawa madiski enziwe nge-silicon carbide, into yokwenziwa ehlinzeka ngokusebenza okuhle kakhulu kokusika nokuqina. Amadiski e-silicon carbide avame ukusetshenziselwa ukugaya nokusika izinto ezithambile ezifana nokhonkolo, amatshe, namatshe. Zibuye zisetshenziselwe ukulungiswa kwendawo kanye nokuqeda izinhlelo zokusebenza.

Imakethe yamadiski e-silicon carbide iqhutshwa yisidingo esikhulayo sezixazululo zokugaya ezingabizi kakhulu. I-silicon carbide ayibizi kakhulu uma iqhathaniswa nedayimane, iyenza ibe inketho ekhangayo kubathengi abaqaphela ibhajethi. Ngokombiko weGlobal Grinding Wheels Market, isidingo samadiski e-silicon carbide kulindeleke ukuthi sikhule kancane kancane, sisekelwa imisebenzi ekhulayo yokwakha kanye namaphrojekthi okuthuthukiswa kwengqalasizinda emhlabeni jikelele.

Amadiski e-Silicon carbide ayatholakala ngamasayizi ahlukahlukene wegrit kanye nokucushwa, okuvumela abasebenzisi ukuthi bakhethe idiski elifanele ngezidingo zabo ezithile. Isibonelo, ama-coarse-grit silicon carbide discs asetshenziselwa ukususwa kwezinto ezisindayo, kuyilapho ama-fine-grit disc asetshenziselwa ukupholishwa nokuqeda. Ukutholakala kosayizi abahlukene begrit nokucushwa kwenza amadiski e-silicon carbide abe inketho eguquguqukayo neyongayo yezinhlelo zokusebenza ezihlukahlukene zokugaya.

I-Tungsten Carbide Diss

Amadiski e-Tungsten carbide aziwa ngobulukhuni bawo obukhethekile kanye nokungagugi, okuwenza alungele ukugaya umsebenzi osindayo. Lawa madiski enziwe nge-tungsten carbide, into eqinile kakhulu kunensimbi futhi inikeza ukusebenza okuhle kakhulu kokusika. Amadiski e-Tungsten carbide ajwayele ukusetshenziselwa ukugaya nokusika izinto eziqinile ezifana nokhonkolo, insimbi, nezitsha zobumba.

Imakethe yamadiski e-tungsten carbide kulindeleke ukuthi ikhule, iqhutshwa ukwanda kwesidingo samathuluzi okugaya asebenza kahle kakhulu ezimbonini ezahlukahlukene. Ngokombiko we-Global Grinding Wheels Market, ukwamukelwa kwezinto ezithuthukisiwe ezifana ne-tungsten carbide kuyakhula, njengoba lezi zinto zinikeza amandla okusika aphakeme nempilo ende. Lo mkhuba ubonakala ikakhulukazi ezimbonini ezisebenza ngensimbi nezokwakha, lapho isidingo samathuluzi okugaya ahlala isikhathi eside nasebenza kahle sibalulekile.

Amadiski e-Tungsten carbide atholakala ngosayizi abahlukahlukene begrit nezinhlobo zamabhondi, okuwenza afanelekele uhla olubanzi lwezinhlelo zokusebenza. Isibonelo, ama-coarse-grit tungsten carbide discs asetshenziselwa ukususwa kwezinto ezinolaka, kuyilapho ama-fine-grit discs asetshenziselwa ukupholishwa nokuqedela. Ukuguquguquka nokuqina kwamadiski e-tungsten carbide kuwenza abe yinketho ekhethwayo kochwepheshe bezokwakha, ezensimbi, nezimboni zokukhiqiza.

Izinto Okufanele Uzicabange Lapho Ukhetha Amadiski Okugaya Ukhonkolo

Ukuqina Kwezinto Ezibalulekile

Ukuqina kwezinto ezibonakalayo kuyisici esibalulekile okufanele sicatshangelwe lapho ukhetha amadiski okugaya ukhonkolo. Ukuqina kwento ephansi inquma uhlobo lwezinto ezilumayo okufanele zisetshenziswe. Isibonelo, amadiski edayimane alungele ukugaya izinto eziqinile ezifana nokhonkolo kanye negwadle, kuyilapho amadiski e-silicon carbide afanele izinto ezithambile ezifana ne-masonry netshe. Ngokombiko weGlobal Grinding Wheels Market, ukwamukelwa kwezinto ezithuthukisiwe ezifana nedayimane ne-CBN kuyakhula, kuqhutshwa isidingo sezisombululo zokugaya ezisebenza kahle nezithembekile.

Ukuqina kwe-grinder disc ngokwayo nakho kubalulekile, njengoba kuthinta ukuqina nokusebenza kwe-disc. Amadiski aqinile, njengalawo enziwe ngedayimane ne-tungsten carbide, anikezela ukumelana nokugqokwa okuphakeme nempilo ende, okuwenza afanelekele izinhlelo zokugaya ezisindayo. Ngakolunye uhlangothi, amadiski athambile, njengalawo enziwe nge-silicon carbide, abiza kakhulu futhi afanelekela imisebenzi yokugaya elula. Ukuqonda ukuqina kwakho kokubili okuphansi kanye nediski yokugaya kubalulekile ekukhetheni idiski elifanele lomsebenzi.

Ngaphezu kokuqina kwezinto ezibonakalayo, ezinye izici ezifana nohlobo lwebhondi nosayizi wegrit nazo kufanele zicatshangelwe. Uhlobo lwebhondi luthinta ukusebenza kokusika nokuqina kwediski, kuyilapho usayizi wegrit unquma izinga lokususwa kwezinto kanye nokuqedwa kwendawo. Ngokucabangela lezi zici, abasebenzisi bangakhetha idiski lokugaya elifanele elihlangabezana nezidingo zabo ezithile futhi liqinisekise ukusebenza kahle nokusebenza kahle.

Usayizi we-Disc Grit

Usayizi wegrit yediski ungenye into ebalulekile okufanele icatshangelwe lapho ukhetha amadiski okugaya ukhonkolo. Usayizi wegrit ubhekisela kusayizi wezinhlayiya ezilimazayo kudiski, onquma izinga lokususwa kwezinto kanye nokuqedwa kwendawo. Ama-coarse-grit discs, anezinhlayiya ezinkulu ezi-abrasive, asetshenziselwa ukususwa kwezinto ezinolaka nokugaya okumahhadla, kuyilapho ama-fine-grit disc, anezinhlayiya ezincane ezi-abrasive, asetshenziselwa ukupholisha nokuqeda.

Ukukhethwa kosayizi wegrit kuncike ekusetshenzisweni okukhethekile kanye nokuqedwa kwendawo oyifunayo. Isibonelo, ama-coarse-grit discs alungele ukususa izendlalelo eziwugqinsi zento, njengopende omdala noma ama-coatings, kuyilapho ama-fine-grit discs asetshenziselwa ukuthola indawo ebushelelezi futhi epholishiwe. Ngokombiko weGlobal Grinding Wheels Market, isidingo samadiski okugaya asebenza kahle kakhulu anosayizi abahlukahlukene begrit siyakhula, siqhutshwa isidingo sokunemba nokusebenza kahle ezimbonini ezahlukahlukene.

Ngokungeziwe kusayizi wegrit, uhlobo lwezinto eziqhumayo kanye nohlobo lwebhondi nakho kudlala indima ebalulekile ekunqumeni ukusebenza kwediski. Isibonelo, amadiski edayimane anosayizi abacolekile begrit asetshenziselwa ukupholisha izinto eziqinile ezifana negwadle netshe lemabula, kuyilapho amadiski e-silicon carbide anosayizi wamagrit amaholo asetshenziselwa ukugaya izinto ezithambile ezifana nokhonkolo nokwakha. Ngokucabangela usayizi wegrit, into elimazayo, kanye nohlobo lwebhondi, abasebenzisi bangakhetha idiski lokugaya elihlangabezana nezidingo zabo ezithile futhi liqinisekise ukusebenza kahle nokusebenza kahle.

Uhlobo lwe-Disc Bond

Uhlobo lwesibopho sediski lokugaya ukhonkolo luyisici esibalulekile esithinta ukusebenza nokuqina kwayo. Uhlobo lwebhondi lubhekisela ezintweni ezibamba izinhlayiya ezilumayo ndawonye kudiski. Izinhlobo zamabhondi ajwayelekile zifaka inhlaka, insimbi, namabhondi aqinisekisiwe, ngayinye inikezela ngamaleveli ahlukene okusebenza nokuqina. Isibonelo, amabhondi e-resin ahlinzeka ngokuguquguquka futhi afanele ukugaywa kwenjongo evamile, kuyilapho amabhondi ensimbi enikeza ukuqina okuphakeme futhi alungele ukugaya umsebenzi osindayo.

Ukukhethwa kohlobo lwebhondi kuncike ekusetshenzisweni okuqondile kanye nokokusebenza okugxiliwe. Isibonelo, ama-discs ahlanganiswe ne-resin avame ukusetshenziselwa ukugaya izinto ezithambile ezifana nokhonkolo nokwakhiwa kwamatshe, kuyilapho ama-discs ahlanganiswe nensimbi asetshenziselwa ukugaya izinto eziqinile ezifana ne-granite nensimbi. Ngokombiko we-Global Grinding Wheels Market, isidingo sobuchwepheshe obuthuthukisiwe bokubopha siyakhula, siqhutshwa isidingo sezisombululo zokugaya ezisebenza kahle neziqinile.

Ngokungeziwe ohlotsheni lwebhondi, ezinye izici ezifana nosayizi wegrit nezinto ezihuquzelayo nazo kufanele zicatshangelwe. Ukuhlanganiswa kwalezi zici kunquma ukusebenza kwe-disc, ukuqina, nokusebenza kahle. Ngokukhetha uhlobo olulungile lwebhondi, abasebenzisi bangaqinisekisa ukuthi idiski yokugaya ihlangabezana nezidingo zabo ezithile futhi inikeza ukusebenza okuhle nokuphila isikhathi eside.

Ukuhambisana ne-Grinder

Ukuhambisana ne-grinder kungenye into ebalulekile okufanele icatshangelwe lapho ukhetha amadiski okugaya ukhonkolo. I-grinder disc kufanele ihambisane nohlobo oluthile kanye nemodeli ye-grinder esetshenziswayo. Lokhu kufaka phakathi izici ezifana nosayizi wediski, usayizi we-arbor, nesivinini esikhulu sokusebenza. Ukusebenzisa i-disc engahambelani kungaholela ekusebenzeni kabi, ukulimala kumshini wokugaya, kanye nezingozi ezingase zibe khona zokuphepha.

Usayizi wediski ubhekisela kububanzi bediski lokugaya, okumele lifane nosayizi wesigada sesondo somshini wokugaya. Osayizi bediski abavamile bahlanganisa amayintshi angu-4.5, amayintshi angu-7, nama-intshi angu-9, anamadiski amakhulu asetshenziselwa izinhlelo zokusebenza zokugaya. Usayizi we-arbor ubhekisela kububanzi bembobo ephakathi nendawo yediski, okumele ifane nosayizi we-spindle ye-grinder. Osayizi abavamile be-arbor bahlanganisa i-intshi engu-5/8 no-7/8 intshi.

Isivinini esikhulu sokusebenza sediski yokugaya kufanele futhi sihambisane nesilinganiso sesivinini somshini wokugaya. Ukusebenzisa i-disc enezinga eliphansi lejubane kune-grinder kungaholela ekuhlulekeni kwediski kanye nezingozi zokuphepha ezingaba khona. Ngokuqinisekisa ukuhambisana ne-grinder, abasebenzisi bangaqinisekisa ukusebenza kahle, ukuphepha, nokusebenza kahle.

Izindleko Nesabelomali

Izindleko kanye nesabelomali yizinto ezibalulekile ezicatshangelwayo lapho ukhetha amadiski okugaya ukhonkolo. Izindleko zamadiski okugaya zingahluka kakhulu kuye ngezici ezifana nohlobo lwento eqhumayo, uhlobo lwebhondi, usayizi wegrit, nomkhiqizo. Isibonelo, amadiski edayimane ngokuvamile abiza kakhulu kunamadiski e-silicon carbide ngenxa yokusebenza kwawo okuphezulu nokuqina kwawo. Kodwa-ke, izindleko eziphakeme zamadiski edayimane zingathethelelwa ngokuphila kwawo okude kanye nesidingo esincishisiwe sokushintshwa njalo.

Uma ucabangela izindleko kanye nesabelomali, kubalulekile ukulinganisa izindleko zokuqala ze-grinder disc nokusebenza kwayo nokuphila isikhathi eside. Ukutshala imali kumadiski okugaya ekhwalithi ephezulu kungabangela ukonga izindleko ngokuhamba kwesikhathi ngokunciphisa isidingo sokushintshwa njalo kanye nokuthuthukisa ukusebenza kahle okuphelele. Ngokombiko we-Global Grinding Wheels Market, isidingo sezixazululo zokugaya ezisebenza kahle kakhulu nezingabizi siyanda, siqhutshwa isidingo sokukhiqiza okuthuthukisiwe kanye nokunciphisa izindleko zokusebenza.

Ngokungeziwe ezindlekweni zediski lokugaya, ezinye izici ezifana nokufakwa kwesicelo esithile, into ephansi, kanye nokuqedwa kwendawo okufiselekayo nakho kufanele kucatshangelwe. Ngokuhlola ngokucophelela lezi zici, abasebenzisi bangakhetha idiski lokugaya elifanele elihlangabezana nezidingo zabo ezithile futhi linikeze inani elingcono kakhulu lebhajethi yabo.

Ungawagcina Kanjani Futhi Umisele Amadiski Kakhonkolo Wokugaya

Amasu Okuhlanza Afanelekile

Ukuhlanzwa kahle kwamadiski okugaya ukhonkolo kubalulekile ekugcineni ukusebenza kwawo nokuphila isikhathi eside. Qala ngokunqamula i-grinder emthonjeni wamandla ukuze uqinisekise ukuphepha. Sebenzisa ibhulashi locingo noma ithuluzi lokuhlanza elikhethekile ukuze ususe noma iyiphi imfucumfucu noma i-buildup endaweni yediski. Ukuze uhlanzeke kahle, cabanga ukusebenzisa isisombululo sokuhlanza esithambile nendwangu ethambile ukuze usule idiski, uqinisekise ukuthi zonke izinsalela ziyasuswa.

Ngemuva kokuhlanza, kubalulekile ukomisa i-disc ngokuphelele ukuvimbela ukugqwala noma ukugqwala. Sebenzisa indwangu ehlanzekile, eyomile ukuze usule noma yimuphi umswakama, futhi uvumele i-disc ukuthi yome uma kunesidingo. Ukuhlanza okuvamile kufanele kwenziwe ngemuva kokusetshenziswa ngakunye ukuze kugcinwe ukusebenza kahle. Ukwengeza, hlola i-disc ukuze uthole noma yiziphi izimpawu zokulimala noma ukuguga ngesikhathi sokuhlanza.

Kumadiski angcoliswe kakhulu, cabanga ukusebenzisa isicoci samakhemikhali esidizayinelwe amathuluzi abrasive. Landela imiyalelo yomkhiqizi ngokucophelela ukuze ugweme ukulimaza idiski. Ukugcinwa ngendlela efanele kwamadiski ahlanziwe endaweni eyomile, engenalo uthuli kuzothuthukisa isikhathi sawo sokuphila futhi kuqinisekise ukuthi alungele ukusetshenziswa lapho edingeka.

Izimpawu Zokuguga

Ukuhlonza izimpawu zokuguga kanye nokudabuka kumadiski okugaya ukhonkolo kubalulekile ukuze kugcinwe ukusebenza okusebenzayo kokugaya. Olunye uphawu oluvamile ukwehla okuphawulekayo ekusebenzeni kahle kokugaya, okungabonisa ukuthi indawo eqhumayo isigugile. Ukwengeza, hlola i-disc ukuze uthole imifantu ebonakalayo, ama-chips, noma amaphethini okugqoka angalingani, angafaka engozini ubuqotho nokusebenza kwawo kwesakhiwo.

Enye inkomba yokugqoka ubukhona bokudlidliza okungajwayelekile noma imisindo ngesikhathi sokusebenza. Lezi zimpawu zingaphakamisa ukuthi i-disc ayisalingani noma ukuthi ithuthukise ukungahambi kahle. Ukuhlola njalo ubukhulu be-disc nakho kubalulekile, njengoba ukunciphisa ngokweqile kungaholela ekuqhekekeni ngaphansi kokucindezeleka.

Ukwengamela ukusebenza kwediski kanye nokwenza ukuhlola okujwayelekile okubonakalayo kungasiza ekutholeni ukuguga kusenesikhathi. Ukushintsha amadiski agugile noma alimele ngokushesha kuzovimbela izingozi ezingaba khona zokuphepha futhi kuqinisekise ikhwalithi engaguquki yokugaya. Ukugcina ilogi yokusetshenziswa kwediski kanye namaphethini okugqoka kungasiza futhi ekubikezeleni izikhawu zokushintshwa nokugcina ukunikezwa okuqhubekayo kwamadiski asebenzayo.

Izinkombandlela Zokumiselela

Ukushintsha amadiski okugaya ukhonkolo kuhilela izinyathelo ezimbalwa ezibalulekile zokuqinisekisa ukuphepha nokufakwa ngendlela efanele. Qala ngokunqamula umshini wokugaya emthonjeni wamandla ukuze uvimbele ukwenza kusebenze ngephutha. Sebenzisa ithuluzi elifanele, njengesikrufu noma isipanela, ukuze ususe inati lokukhiya noma i-flange evikela idiski endaweni. Susa ngokucophelela idiski endala, uqaphele ukuma kwayo nanoma imaphi amawasha noma ama-spacers asetshenzisiwe.

Ngaphambi kokufaka idiski entsha, hlola i-spindle ye-grinder kanye ne-hardware ekhwezwayo ukuze uthole noma yiziphi izimpawu zokulimala noma ukuguga. Hlanza lezi zingxenye ukuze ususe noma iyiphi imfucumfucu noma izinsalela ezingase zithinte ukuqondana kwediski. Beka idiski entsha ku-spindle, uqinisekise ukuthi ihlezi kahle futhi ivikelekile. Phinda unamathisele inadi elikhiyayo noma i-flange, uliqinise ngokuya ngemininingwane yomkhiqizi.

Ngemva kokufaka, yenza ukuhlola okufushane ukuze uqinisekise ukuthi idiski iqondaniswe kahle futhi ibhalansile. Lalela noma imiphi imisindo engajwayelekile futhi uhlole ukudlidliza okweqile, okungase kubonise ukufakwa okungafanele. Ukushintsha njalo amadiski agugile nokulandela lezi ziqondiso kuzosiza ukugcina ukusebenza kahle kokugaya futhi kunwebe impilo yezinto zakho zokusebenza.

Izinzuzo Zokusebenzisa Amadiski Okugaya Ukhonkolo Wekhwalithi Ephezulu

Ukusebenza Okuthuthukisiwe

Amadiski okugaya ukhonkolo ekhwalithi ephezulu athuthukisa kakhulu ukusebenza ngokuhlinzeka ngamakhono aphakeme okusika nokugaya. Lawa madiski ngokuvamile enziwa ngezinto zeprimiyamu, njengedayimane lezinga lezimboni noma izitsha zobumba ezithuthukisiwe, ezinikeza ubulukhuni nokuqina okukhethekile. Lokhu kubangela amazinga asheshayo okususwa kwezinto kanye nezinqubo zokugaya ezisebenza kahle.

Ukwenziwa ngokunemba kwamadiski ekhwalithi ephezulu kuqinisekisa ukusebenza okungaguquki kanye namaphethini okugqoka afanayo. Lokhu kuvumelana kuvumela ukusebenza kahle futhi kunciphisa amathuba okuhluleka kwediski ngesikhathi sokusetshenziswa. Ukwengeza, ama-discs ekhwalithi ephezulu avamise ukuba nobuchwepheshe bokubopha obuthuthukile obuthuthukisa ukusebenza kahle kwawo kokusika nempilo yawo.

Ukusebenzisa ama-disc ekhwalithi ephezulu futhi kunciphisa isikhathi sokuphumula esihambisana nezinguquko ezivamile zediski nokugcinwa. Ukusebenza okuthuthukisiwe nokuthembeka kwalawa madiski kunomthelela ekwandeni kokukhiqiza nokonga kwezindleko ngokuhamba kwesikhathi. Ukutshala imali kumadiski okugaya ukhonkolo wekhwalithi ephezulu kuyisinqumo samasu esingaletha izinzuzo ezibalulekile kukho kokubili ukusebenza nokusebenza kahle.

Ukuphila Isikhathi Eside

Ubude besikhathi eside bamadiski okugaya ukhonkolo buthuthukiswa kakhulu uma usebenzisa imikhiqizo yekhwalithi ephezulu. Lawa madiski adizayinelwe ukuthi amelane nobunzima bezinhlelo zokusebenza zokugaya ezisindayo, anikeza impilo yesevisi enwetshiwe uma kuqhathaniswa namadiski ajwayelekile. Ukusetshenziswa kwezinto ezi-abrasive eziphezulu kanye namasu okubopha okuthuthukile kuqinisekisa ukuthi ama-discs ekhwalithi ephezulu agcina umkhawulo wawo wokusika isikhathi eside.

Ukukhula kobude besikhathi kuhumushela ukushintshwa okumbalwa kanye nezindleko zokusebenza ezincishisiwe. Amadiski ekhwalithi ephezulu awajwayele ukuguga nokulimala ngaphambi kwesikhathi, okusho ukuthi angakwazi ukuphatha imijikelezo yokugaya ngaphambi kokudinga ukushintshwa. Lokhu kuqina kunenzuzo ikakhulukazi ezindaweni ezidinga kakhulu lapho ukusebenza okufanayo kubalulekile.

Ngaphezu kwalokho, isikhathi eside sokuphila samadiski ekhwalithi ephezulu sinomthelela ekusebenzeni kahle kwemishini yonke. Ama-opharetha angathembela kulawa madiski ukuze asebenze ngokungaguquki ngaphandle kwesidingo sokulungiswa njalo noma ukushintshwa. Lokhu kwethembeka kuthuthukisa ukuqhubeka komsebenzi futhi kunciphisa amathuba okuba nesikhathi sokuphumula esingalindelekile, ekugcineni kuthuthukisa izikhathi zephrojekthi kanye nemiphumela.

I-Surface Finish Engcono

Ukusebenzisa amadiski okugaya ukhonkolo wekhwalithi ephezulu kubangela isiphetho esisezingeni eliphezulu, esibalulekile kumaphrojekthi amaningi okwakha nokuvuselela. Lawa madiski enzelwe ukuhlinzeka ngokunemba ngisho nokugaya, ukunciphisa ukungapheleli kwendawo futhi afinyelele isiphetho esibushelelezi, esipholishiwe. Izinto ezigugulekayo zekhwalithi ephezulu ezisetshenziswa kulawa madiski ziqinisekisa isenzo sokusika esingaguquki, sinciphisa ubungozi bokugaya noma ukugaya okungalingani.

Ukuqedwa okungcono kwengaphezulu akugcini nje ngokuthuthukisa ukukhanga kobuhle bekhonkrithi kodwa futhi kuthuthukisa izici zayo zokusebenza. Izindawo ezibushelelezi kulula ukuzihlanza nokuzinakekela, futhi zinikeza ukunamathela okungcono kwezingubo zokumboza nezinsimbi. Ama-disc ekhwalithi ephezulu asebenza kahle kakhulu ekufezeni ukuqedwa okuhle okudingekayo ekuhlobiseni izicelo zekhonkrithi kanye nemisebenzi enembayo ephezulu.

Ukwengeza, ukuqedwa okuthuthukisiwe okutholakala ngamadiski ekhwalithi ephezulu kunganciphisa isidingo sezinyathelo zokuqedela ezengeziwe, ezifana nokufaka isihlabathi noma ukupholisha. Lokhu kusebenza kahle konga izindleko zesikhathi nezabasebenzi, okwenza inqubo yokugaya iyonke ingabizi kakhulu. Ukutshala imali kumadiski okugaya ukhonkolo wekhwalithi ephezulu kuyisinqumo esisebenzayo sokuthola imiphumela yezinga lochwepheshe ngomzamo omncane.

Imicabango yokugcina ekukhetheni ama-Concrete Grinder Discs

Ukukhetha amadiski okugaya ukhonkolo alungile kubalulekile ukuze kuzuzwe ukusebenza kahle nokuphila isikhathi eside. Amadiski ekhwalithi ephezulu anikeza ukusebenza kahle kokusika okuthuthukisiwe, ukuqina okukhuphukile, kanye nokuqedwa okuphezulu kwendawo, okuwenza abe utshalomali olubalulekile kunoma yiluphi uhlelo lokugaya. Ukubeka kuqala ikhwalithi nokugcinwa okufanele kuzoqinisekisa imiphumela engaguquki kanye nokonga kwezindleko zesikhathi eside.