I-laser cladding, ebizwa nangokuthi i-laser overlay welding, isetshenziswa ekukhiqizeni ukugqoka izinto ezahlukahlukene. Ubuchwepheshe obuthole ukuduma eminyakeni edlule bufika nezinzuzo ezihlukahlukene. Kuyasiza ukuvikela izinto ezivela ku-oxidation kanye nokugqwala. Ukusebenzisa ubuchwepheshe be-laser cladding kuthuthukisa izakhiwo ezingaphezulu.

Lesi sihloko sizosebenza kukho konke odinga ukukwazi mayelana ne-laser cladding.

Okuqukethwe

Iyini i-laser cladding?

Inqubo yokuvala i-Laser

Izinzuzo ze-laser cladding

Izimpawu ze-laser cladding

Ingabe ukuvala nge-laser kuyabiza?

Izindlela ezintsha zakamuva zokuvala i-laser

Isiphetho

Iyini i-laser cladding?

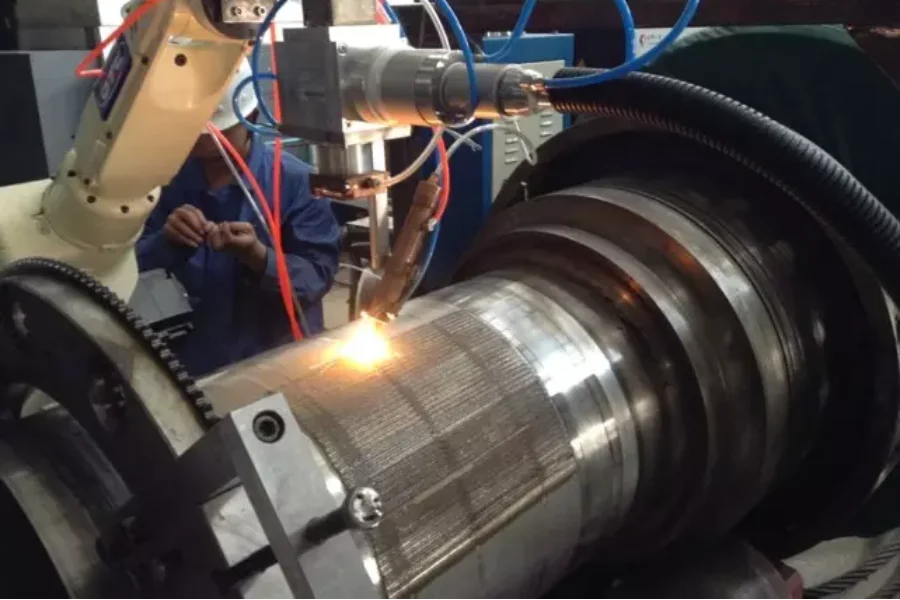

Ukufakwa kwe-laser kuyinqubo eyengeziwe ekukhiqizeni enikeza ukunamathela ezinhlotsheni ezihlukahlukene zezinto ezibonakalayo. Ngokuvamile, ithuthukisa izakhiwo ezingaphezulu, ezivikela izinto ezivela ku-oxidation kanye nokugqwala. Inqubo ibandakanya ichibi elincibilikayo elinqanyulwa endaweni yonke yezinto eziyisisekelo. Ngesikhathi esifanayo, i-powder noma i-wire feedstock isetshenziswa, okwenza ungqimba oluncane lwe-coating.

I-laser-induced cladding ihlinzeka ngezingubo ezisatshalaliswa ngokulinganayo. Ngokuphindaphinda okuphezulu, izendlalelo azikho ukuqhekeka kanye ne-porosity. Ziphinde zibonise ukunamathela okuhle, ukuhwalala okuphansi kwendawo, ukuhlanzwa okuphansi, kanye nokumoshakala okuncane kwezinto ezihilelekile. Inqubo ingathuthukiswa ngokulungisa ukuminyana, isivinini sohambo, kanye nobubanzi bemishayo ye-laser endaweni yento.

Inqubo yokuvala i-Laser

Inqubo i-directed energy deposition (DED), futhi ibizwa nangokuthi i-laser overlay welding. Uma isetshenziswa ekukhiqizeni okungeziwe, ibizwa ngokuthi i-laser metal deposition (LMD) noma i-directed laser metal deposition (DLMD).

I-laser beam iyancibilika futhi ibophe ama-alloys ensimbi endaweni engaphansi noma isendlalelo esifakwe ngaphambilini. Ungqimba oluminyene lwe-laser cladding luboshwe nge-metallurgically ngaphansi kokuhlanjululwa okuncane okuvela ezintweni zensimbi. Okokufaka kokushisa kufanele kube ngokwanele ukukhiqiza imbondela yekhwalithi ephezulu.

Ngezansi kunezinqubo ezahlukahlukene zokuvala i-laser:

Ukufakwa kwe-laser enesinyathelo esisodwa

Enqubweni yesinyathelo esisodwa, izinto zokumboza zethulwa echibini lokuncibilika lapho lishintsha libe yifomu elincibilikisiwe phezu kwendawo engaphansi. Lapho ugongolo lwe-laser olunyakazayo lushiya isikhala, into encibilikisiwe enamathelayo iyaqina. Ngenxa yalokho, ukunamathela okuhle kwenziwa ngamathrekhi agqagqene okunyakaza kwe-laser.

Izinyathelo ezimbili ze-laser cladding

Ukucutshungulwa kwezinyathelo ezimbili kuhilela ukubekwa kokuqala kwezinto zokumboza phezu kwe-substrate. Ngemuva kwalokho, ukwelashwa okungaphezulu kuthatha ugongolo lwe-laser olunyakazayo ukuze luncibilikise izinto zokumboza kanye ne-substrate ndawonye. I-coating iqina ngokuzenzakalelayo ngokushesha nje lapho ugongolo lwe-laser lushiya ukumbozwa kwesikhala.

Ukuvala ucingo

Ngesikhathi senqubo yokuhlanganisa ucingo, i- Ucingo idliswa ngqo kusuka ku-spool kuya kwithoshi yezembe. Kube sekushisisa ngaphansi kwezinga lokushisa elincibilikayo lapho ukuvala kwenzeka khona ngohlelo oluqondisayo lwezintambo.

Le nqubo inenzuzo ngenxa yokusebenza kahle okungu-100% ekusetshenzisweni kwezinto zokugcwalisa. Futhi kuyinqubo ehlanzekile enezinketho ezihlukahlukene zezinto zocingo. Nokho, ukumuncwa kwemisebe ezintanjeni kunikeza okukhiphayo okungahambisani.

I-powder cladding

Ku-powder cladding, i- powder idluliselwa kusuka ku-disc ejikelezayo kuya ku-nozzle feed. Idluliswa ngamagesi enkampani yenethiwekhi, isibonelo, i-Argon noma i-Helium, lapho kusetshenziswa isimiso sokumuncwa. Izinhlayiya zempushana zibe seziphoqwa amagesi othwala ngesivinini esikhulu.

Lokhu kubangela ukugqoka okuphezulu okulinganayo futhi okuphindaphindekayo. Inqubo inezindlela ezihlukahlukene zokudla nezinto zokwakha. Futhi kuyindlela engcono yokusethwa kwe-3D.

Izinzuzo ze-laser cladding

Ama-Lasers ayinketho ekhethwayo ye-micromachining kanye nokucutshungulwa kwezinto ezibonakalayo. Ngaphansi kwe-laser cladding, usebenzisa amapharamitha afana nemvamisa yokuphindaphinda ukushaya kwenhliziyo, amandla e-laser, ubude beza, nezinhlobo ezahlukahlukene zamaphrofayili e-beam.

Okulandelayo yizinzuzo ezishiwo ku-laser cladding:

- Iqinisekisa ukuhlangana kwe-metallurgical kwezindawo nezinto eziyisisekelo

- Inqubo idinga isikhathi esiphansi sokuchayeka nokujula kwe-laser beam

- I-Laser cladding ikhiqiza ukumbondelana okungazweli uma kuqhathaniswa nezingubo zokufafaza ezishisayo

- Ikhwalithi ephezulu ezuziwe kanye ne-warpage ephansi inciphisa isidingo sokucubungula ngemuva

- Isebenza kahle kakhulu ngenxa yezindleko ezincishisiwe, isikhathi esifushane sokuvala i-laser, kanye nokumoshakala okuncane

Izimpawu ze-laser cladding

Ukufakwa kwe-laser ikakhulukazi isebenzisa umthelela wokushisa ophansi kanye nezici ezinhle zokunemba. Iphinde ibe nezinye izici, ezihlanganisa:

- Izinga lokupholisa okusheshayo ngenxa yenqubo yokuqinisa ngokushesha; izinga likhuphukela cishe ku-106 K/s. Kulula ukuthola ama-crystalline ama-coatings asakazwa ngokulinganayo.

- Idinga okokufaka okuncane kokushisa kanye nokuhlanekezela lapho kusetshenziswa ukuhlanganisa ngokushesha okukhulu kokuqina kwamandla. Ukuhlanekezela kungancishiswa kube ngaphakathi kokubekezelelana komhlangano.

- Izinga lokuhlanjululwa kwentonga ephansi ngokuvamile elingaphansi kuka-5%. Ngokulungiswa kwepharamitha ye-laser, i-substrate iboshelwa ngokuqinile nge-metallurgically noma ngokuhlanganisa ubuso.

- Isendlalelo se-laser cladding sinohlu olukhulu logqinsi olunomshini wokuphakelayo oyimpushana wesiteshi esisodwa esingaba ngu-0.2 kuya ku-2.0 mm.

- Ayikho imingcele ekukhetheni impushana lapho ufaka izinto ezisezingeni eliphezulu zokuncibilika ebusweni bezinto ezincibilika eziphansi.

- Inqubo yokuvala i-laser kulula ukuzenzela.

- Inqubo ithuthukisa ukubekwa okukhethiwe okunokusetshenziswa kwempahla ephansi ngesilinganiso esihle kakhulu sokusebenza kuya kwentengo.

- Izendlalelo ze-beam ezihlose ukugqagqana futhi ngaleyo ndlela zingahlanganisa izindawo ezingafinyeleleki.

Ingabe ukuvala nge-laser kuyabiza?

Kwathuthukiswa eminyakeni engama-30 edlule, ukuvala nge-laser bekulokhu kuthathwa njengobuchwepheshe benketho yokugcina. Lokhu kungenxa yokutshalwa kwezimali okuphezulu kokuqala kanye nezindleko zokusebenza zemishini ye-laser. Kodwa-ke, kube nentuthuko enkulu kuma-laser wesimo esiqinile samanje.

Ukuhlanganiswa kwamarobhothi ngokulethwa kwe-fiber-coupled beam kwenze inqubo yasebenza kahle futhi yangabizi kakhulu. Uma kucatshangelwa ukuhlaziywa kwezindleko zenzuzo, ukuvala nge-laser kuyawina futhi kukhula kakhulu emikhakheni eyahlukene yezimboni.

Izindlela ezintsha zakamuva zokuvala i-laser

Izinto ezintsha zakamuva zokuvala i-laser zigxile kakhulu ekwandiseni umkhiqizo. Intuthuko isagcina izici eziyinhloko ze-laser cladding.

Okulandelayo yizibonelo zokuqanjwa okusha:

- Ukufakwa kwe-laser enesivinini esikhulu kuncibilikisa ngokuphelele impushana engezayo kugongolo lwe-laser ngaphambi kokufinyelela kusisekelo. Isisekelo esiqinile sihlanganiswa nempushana encibilikisiwe ngokudluliswa kokushisa.

- I-hot-wire laser cladding ihlinzeka ngocingo olushisiwe ngaphambili kunqubo; lokhu kuthola amandla e-laser engeziwe ukuze kuncibilike izinto eziyisisekelo ngezinga lokuphakela elikhuphukile.

- I-Laser cladding isebenzisa i-co-axial laser beam ephakela okungeziwe okuhambisana nendawo yokusebenza. I-laser i-coaxially iphrojekthi eduze kocingo. Lokhu kuthuthukisa ukucutshungulwa okungaguquki okuzimele ekuqondeni kohambo lwe-3D laser deposition deposition.

- Inqubo yokuvala i-laser yendawo enkulu inyusa usayizi wendawo ye-laser endaweni yokusebenza. Lokhu kuvumela ukusetshenziswa kwamandla e-laser engeziwe ngaphandle kokuncibilika ngokweqile kwesisekelo kanye nokwandisa ukuhlanjululwa.

Isiphetho

Ubuchwepheshe be-laser cladding muva nje buye benza intuthuko enkulu ekukhiqizeni kwesimanje. Izinkampani eziningi ezikhiqizayo zicabangela ubuchwepheshe be-laser ukulungisa kabusha imikhiqizo ye-OEM. Inqubo iphinde yathuthukisa ukugqwala kanye nezici zokugqoka zezinto.

Umhlahlandlela ongenhla uchaza inqubo ye-laser cladding kanye nezinzuzo zayo. Abathengi kufanele baqinisekise ukuthi ikhwalithi igcinwa ngesikhathi sokumbozwa kwe-laser. Ukuze uthole okokusebenza kwe-laser cladding ozikhethele yona, vakashela Chovm.com.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu