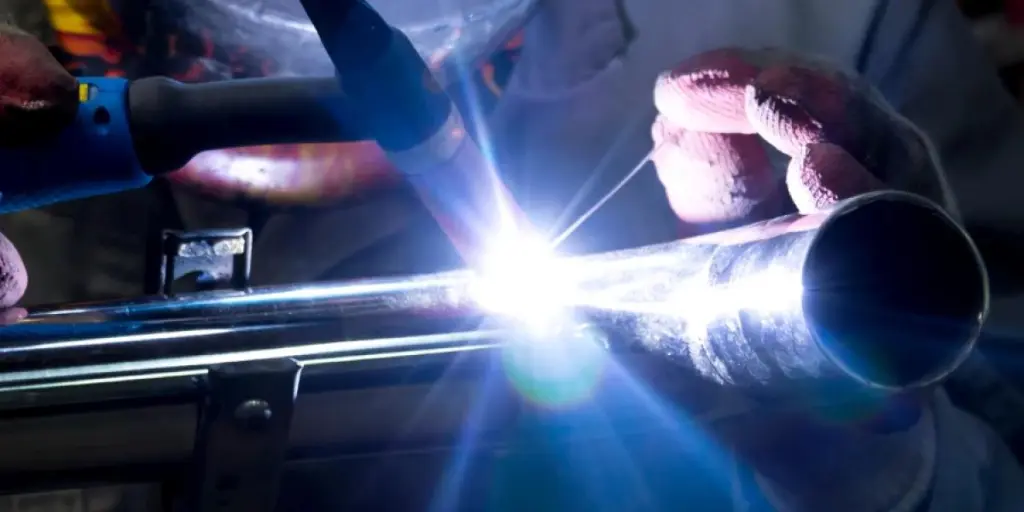

Abashiseli be-TIG, ababizwa nangokuthi ama-tungsten anert gas welders, basebenzisa ama-electrode e-tungsten angasebenziseki ukuze akhiqize i-weld ensimbi. Lawa mashisela ahlukahlukene njengoba ehambisana nokushisela izinhlobonhlobo zezinsimbi, okuhlanganisa i-aluminium, ithusi, ithusi, i-magnesium, insimbi engagqwali, negolide, phakathi kwezinye izinsimbi. Njengoba abashiseli be-TIG sebevamile, le mishini itholakala kalula.

Ukwazi ukuthi yikuphi phakathi kwezinketho ezifanele izinhlelo zokusebenza ezahlukene zokushisela kungaba inselele. Ngakho-ke, lesi sihloko sizohlola izici ezibalulekile okufanele uzicabangele ngenkathi ukhetha i-TIG welder. Izophinde ibheke izinhlobo ezahlukene zamashiseli e-TIG atholakalayo ukuze asize abathengi ukuthi bathole okufanelana nezidingo zabo kangcono.

Okuqukethwe

Uhlolojikelele lwemakethe yomhlaba wonke ye-TIG welders

Amathiphu okukhetha abashiseli be-TIG

Izinhlobo zokushisela ze-TIG

Isiphetho

Uhlolojikelele lwemakethe yomhlaba wonke ye-TIG welders

Imakethe yokushisela ye-TIG yomhlaba wonke ifanelekile US $ 13 billion futhi kulindeleke ukuthi ifinyelele ku-US$ 25 billion ngo-2032, ikhula ngezinga lokukhula elihlanganisiwe lonyaka (CAGR) lika-6.7%. Ukukhula kwemakethe kugqugquzelwa yisidingo semishini yokushisela evela emikhakheni eyahlukene yezimboni, okuhlanganisa izimboni zezimoto, i-aerospace, ezokuthutha, nezimboni zikawoyela negesi.

Isidingo somthengi sokushisela izinsimbi ezingavamile ezinobukhulu obuhlukene siholele ekukhuleni kosayizi wemakethe yama-welders we-TIG. Njengoba bekhiqiza ukushisela okunembe kakhudlwana nasezingeni eliphezulu, abaningi bakhetha ukushisela igesi ye-tungsten inert kunemishini yokushisela izinti.

Amathiphu okukhetha abashiseli be-TIG

Izinga le-amperage

Lapho uthenga i- TIG welder, cabangela izinga le-amperage. Kungamandla kagesi asuka emshinini wokushisela okalwa ngama-ampere. Imishini enamazinga aphansi e-amperage inikeza ukuzinza okuhle kwe-arc ekuqaleni nokuqedela ama-welds.

Amashisela e-TIG asezingeni eliphansi afanele izinsimbi ezincane ngoba angakhiqiza amashisela aqinile ngaphandle kokuwashisa. Ngakolunye uhlangothi, abashiseli bezinga eliphakeme le-amperage bafanele ochwepheshe abasebenza ngezinsimbi eziwugqinsi.

I-AC ne-DC welding

Ngaphambi kokutshala imali ku-welder ye-TIG, kubalulekile ukucabangela izinketho zayo zamanje. Amashisela atholakalayo ahlinzeka ngenketho ye-DC noma enye i-DC/AC. Lezi zinketho zincike ohlotsheni lwensimbi ezingashisela ngalo kahle.

Isibonelo, ukushisela i-DC TIG kufanelekile uma kushiselwa izinsimbi ezivamile njengensimbi. Lapho usebenza ngezinsimbi ezilula neziqinile njenge-aluminium, a Umshini we-DC/AC ifanela inhloso ngendlela efanele.

Izilawuli ezifanele

Ukuhlola izilawuli ze-welder nakho kubalulekile ngenkathi uthenga isishiseli esithembekile se-TIG. Le mishini yakhelwe nge-foot pedal esiza ukulungisa izinga le-amperage. Kuba lula ukulawula ukunemba kwe-welding kanye nekhwalithi yokugcina ngokulawula izinga le-amperage.

Ngakho-ke, abathengi kufanele bahlole izilawuli futhi baqinisekise ukuthi ziqinile futhi zivikelekile ngomshini. Ukuhlola kahle i-welder kugwema ukulimaza i-weld lapho uthinta isilawuli esingalungile. Ukuhlola imininingwane ebalulekile njengezilawuli eziqinile nezilungile kuqinisekisa inqubo yokushisela ebushelelezi ngaphandle kokuyekethisa ikhwalithi yomphumela wokugcina.

Ukusebenza kwe-welding ephansi

Ukuhlola ukusebenza komshiseli ku-amperage ephansi kubalulekile ngaphambi kokuthenga. Imishini ene-amperage ephansi inganikeza ama-arcs azinze kakhulu. Futhi, banikeza isiqalo se-weld esilula, ukulawula ikhwalithi engcono ye-weld, kanye nomthamo omuhle kakhulu wokugcwalisa i-crater.

Ama-welders ane-amperage ephansi zinokwethenjelwa lapho usebenza ngezinsimbi ezincane. Ngokuphambene, ama-welders aphezulu asebenza kabi ezinsimbi ezincane. Akhiqiza ama-weld arcs aqinile angathungela futhi alimaze insimbi.

Ukuzinza kwe-arc ku-amperage ephansi nakho kuyadingeka ukuze kuqedelwe ukushisela. Isibonelo, i-concave enkulu ingase yakheke lapho kushiselwa i-aluminium, engase iqhekeke ngemva kokuphola kwe-weld. I-low amperage welding yakha i-concave encane ukunciphisa amathuba okuqhekeka lapho i-welding iphola.

Izinketho ze-Plasma cutter kanye ne-stick welding

Abathengi kufanele futhi bacabangele ukufuna i-tungsten inert gas welder enezici ezengeziwe. Ukuba nezici ezengeziwe kumshini wokushisela kuvumela ukufezwa kwemisebenzi eminingi emshinini owodwa. Ngokwesibonelo, a umshini wokufaka insimbi enikeza izici zokusika i-plasma nezici zokushisela izinduku kwenza insimbi isebenze umsebenzi ongenazihibe.

I-TIG welder ingasebenzisa i-electrode ye-tungsten ukuze inikeze kokubili izinzuzo zokusika i-plasma kanye nokushisela izingcezu zensimbi ezisikiwe ndawonye. I-stick welder iba enye indlela yokushisela i-TIG uma kudingeka inketho yokusekelayo. Ukwengeza, ukuba ne-a I-welder ehlukahlukene yonga ezindlekweni zokuthenga imishini ehlukene kanye namandla azowasebenzisa ngokuphelele.

Power

Kubalulekile ukucabangela inani lamandla i-welder edinga ukusebenza. Kuya ohlotsheni lwensimbi olushiselwayo. Isibonelo, i-aluminium, i-magnesium, nama-alloys amaningi ensimbi zisebenzisa ama-welders anamandla aphezulu. Insimbi emaphakathi nensimbi engagqwali zidinga ukusebenzisa imishini yokushisela enamandla aphansi.

Inani lamandla ongakhetha nalo lincike kusayizi wesitolo. Izitolo ezincane ezenza i-welding encane zingase zifune ukusebenzisa i-welder edla amandla amancane. Izitolo ezinkulu zokushisela zingakhetha umshini osebenzisa amandla aphezulu.

Ukuqina kwensimbi nakho kunquma ukuthi yimuphi umshini wokushisela ongawuthola. Ezinsimbi eziwugqinsi, i-TIG welder enamandla amakhulu ifanelekile. Izinsimbi ezizacile zilungile ukusebenza ngemishini edla amandla amancane.

Izinhlobo zokushisela ze-TIG

AC/DC TIG welder

Amashisela e-AC/DC TIG ayimishini eguquguqukayo engashintsha yamanje kuye ngensimbi esebenza kuyo. Ziletha ukusebenza okuthembekile nokungaguquguquki futhi zingasetshenziselwa izinhlelo zokusebenza ezihlukahlukene, okuhlanganisa umsebenzi wamapayipi, umsebenzi ohlanganyelwe, nokulungiswa kwezimoto.

Ukushisela i-AC kusetshenziselwa ukushisela i-aluminium ne-magnesium kuyilapho i-DC isetshenziselwa insimbi emnene nensimbi engagqwali. Ama-welders e-AC/DC anikeza izilungiselelo zamanje eziguquguqukayo, izilungiselelo zemithambeka phezulu/phansi, i-pedal yonyawo, nezilawuli zesikhathi eziningana, okuvumela abashiseli ukuba benze ama-welds ahlukahlukene futhi basebenze ezinhlotsheni ezahlukene zezinsimbi.

buhle

- Bangakwazi ukushisela izinsimbi ezihlukahlukene, okuhlanganisa insimbi, i-aluminium, nezinsimbi ezingavamile.

- Ukushintsha phakathi kwe-AC ne-DC kunikeza umuntu ukuzethemba ekusebenzeni nomshini.

bawo

- Angabiza kakhulu kunamashisela e-DC.

DC TIG welder

I-DC TIG welder ingumshini wokushisela osebenzisa i-DC ukushisela izinsimbi njengensimbi ethambile, insimbi engagqwali, ne-carbon steel. Lokhu kusho ukuthi i-current igeleza kuphela ohlangothini olulodwa ukuze idale ama-welds ekhwalithi ephezulu.

buhle

- Bangakwazi ukukhiqiza amashisela ensimbi ekhwalithi enhle.

– Akhiqiza intuthu encane kanye nentuthu lapho eshisela.

bawo

- Ukushisa ngokweqile kuyinkinga enkulu ngemishini ye-DC.

- Ukwakheka kwama-crater amaningi kakhulu kuholela ekuqhekekeni kokushisela lapho kuphola.

I-Pulse TIG welder

Lezi zithuthuke kakhulu kwezobuchwepheshe Imishini yokushisela ye-TIG kushintshana phakathi kwamandla aphezulu naphansi, okunikeza abashisela ukulawula okwengeziwe nokunemba ngenkathi beshisela izinsimbi.

buhle

- Angakwazi ukukhiqiza ama-welds ahlanzekile futhi anembile ngisho nasezindaweni okunzima ukufinyelela kuzo.

- Bakhiqiza ama-welds ngokushesha ngenxa yekhono labo lokulawula ngokunembile ubude nokwakheka kwe-arc yokushisela.

– Awonga kakhulu amandla.

bawo

- Abiza kakhulu kunezindlela zendabuko zokushisela.

- Kudinga ikhono eliphezulu lokuzisebenzisa ngendlela efanele.

- Akhiqiza ukushisa okunamandla futhi akhiqize amagesi amaningi angaba yingozi kanye nentuthu. Ngakho-ke, badinga izinyathelo ezifanele zokuphepha okufanele zithathwe lapho bezisebenzisa.

Isiphetho

Abashiseli be-TIG bahlinzeka ngokushisela okunembile nokunembile uma kuqhathaniswa nabashiseli bendabuko. Uma ukukhetha i-welder efanelekile kuyinselele, amabhizinisi angalandela amathiphu angenhla okwenza isinqumo esifundisiwe. Ngakho-ke kufanele babe nesikhathi esilula sokukhetha i-welder ye-TIG enikeza ama-welds ekhwalithi futhi aqinile.

Futhi funda: Umehluko Phakathi kwe-MIG ne-TIG Welding