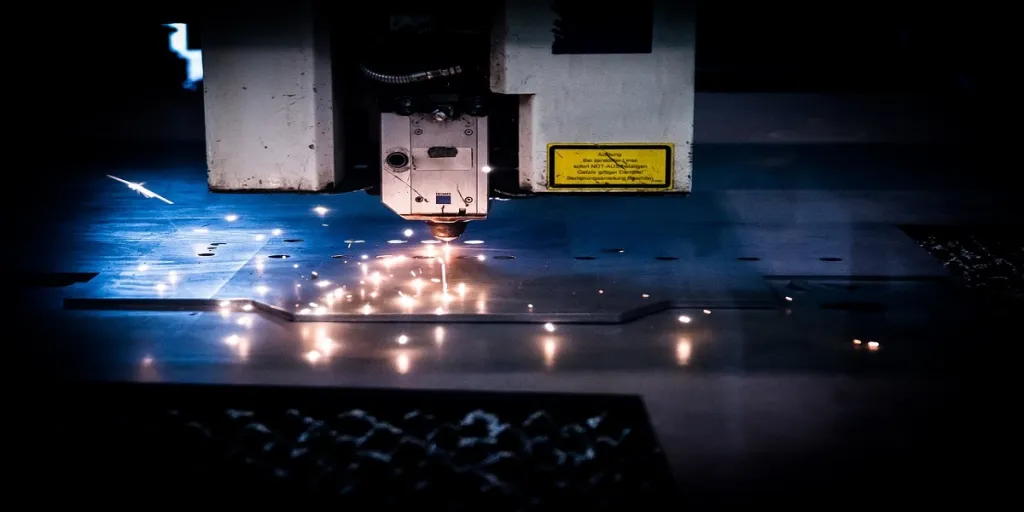

Imishini yokusika i-laser yaziwa ngokusika izinsimbi isebenzisa imishayo ye-laser-amafomu agxilile wamandla aqondiswe endaweni eyodwa. Lobu buchwepheshe busebenza kahle, bushesha, futhi buthembekile kakhulu. Kodwa-ke, ukuze kuqinisekiswe imiphumela efanayo ngaso sonke isikhathi lapho umshini usetshenziswa, ukunakekelwa okufanele kwe-laser cutter kuyodingeka kwenziwe. Lo mhlahlandlela ugqamisa izinqubo ezingcono kakhulu zokunakekela imishini yokusika laser.

Okuqukethwe

Kungani kubalulekile ukugcina umshini wokusika we-laser

Isakhiwo somshini wokusika we-laser

Ungawugcina kanjani umshini wokusika we-laser

Imicabango yokugcina

Kungani kubalulekile ukugcina umshini wokusika we-laser

Ukugcinwa kwe-a umshini wokwehlisa laser kufanele kuthathwe ngokungathi sína uma umshini uzosebenza kahle futhi isikhathi eside. Lapho ukusika izinto ezifana ne-MDF ne-acrylic, imfucumfucu eminingi ikhishwa ngenkathi uthuli nemfucumfucu kuhlangana emshinini wokusika. Uma lezi zinhlayiya zinganakekelwa, zingaholela ezinkingeni ezinzima ezifana nokushisa ngokweqile kanye nokwehluleka kwesistimu, okungabangela ukungasebenzi kwedivayisi. Ukugcina i-laser cutter njalo kuzonciphisa ukuphuka komshini okungalindelekile.

Isakhiwo somshini wokusika we-laser

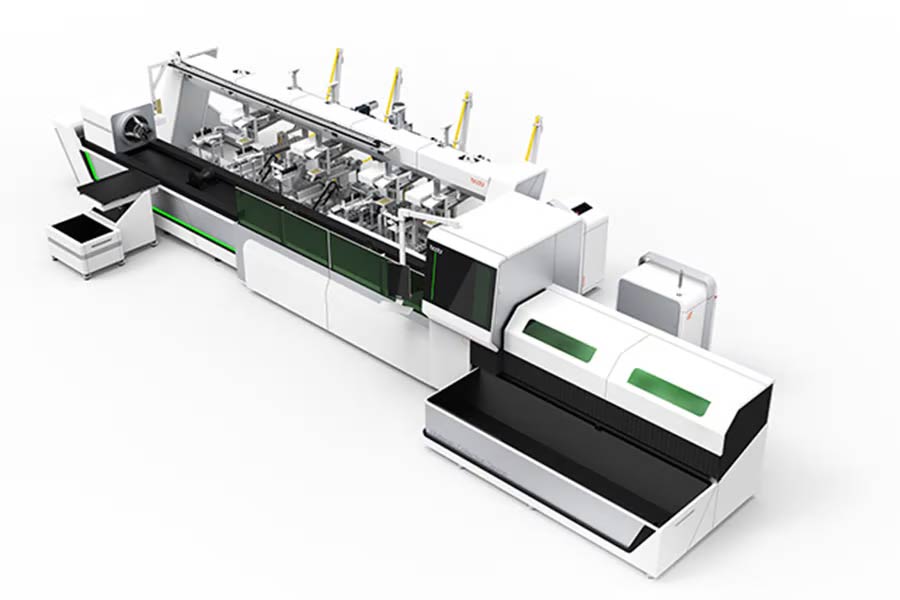

Njengoba kushiwo ngezansi, imishini yokusika laser abe nezingxenye eziningana.

I-Laser oscillator: Iqukethwe ekhanda le-laser, elikhiqiza i-laser beam.

Izibuko ezibonisayo: Baqondisa ugongolo lwe-laser ngendlela efanele futhi banesembozo sokuvikela ukuvimbela ugongolo ukuthi lungasebenzi kahle.

Ithoshi yokusika: Ihlanganisa ilensi yokugxilisa ingqondo, umzimba wesibhamu se-laser, kanye nombhobho wegesi osizayo.

Idivayisi yokusika ithoshi: Isetshenziselwa ukuphatha ithoshi lokusika lihambisana nezimbazo ze-X kanye ne-Z njengoba kuqondiswa uhlelo lwekhompyutha. Ihlanganisa isikulufu se-motor kanye ne-lead.

Amasilinda egesi: Bahlinzeka ngegesi ye-laser oscillation kanye negesi elisizayo lokusika.

Iphaneli yokulawula: Iqukethe izilawuli ezisetshenziselwa ukuqondisa yonke inqubo yokusika yomshini.

Iphampu yomoya: Isetshenziselwa ukunikeza umoya ohlanzekile nowomile kumashubhu e-laser kanye nendlela yomgodi ukuze kuqinisekiswe ukuthi asebenza ngendlela evamile.

Ukunikezwa kwamandla nge-laser: Inikeza amandla kumashubhu e-laser ukuze enze i-laser beam, ebonakala ngezibuko endaweni yokusebenza edingekayo.

Ungawugcina kanjani umshini wokusika we-laser

Isibuko nelensi

I-Optics yomshini wokusika we-laser ihlanganisa ilensi nesibuko. Uma uthuli nezinye izinto zihlala isikhathi eside, zingavutha phezu kwe-optics, okuholela emigqeni efiphele. I-laser beam nayo ingaba buthakathaka, okuholela ekusikeni kwe-laser okubi. Ngakho-ke ukuhlanzwa kwama-optics kubalulekile ukuze kuvinjwe ukulimala kwawo unomphela. Kunconywa ukuwahlanza ngokucophelela njalo 10-40 amahora ngesisombululo se-acetone noma se-IPA kanye nama-cotton buds.

Qeda abalandeli

Uthuli lungabangela umonakalo omkhulu kubalandeli bomshini wokusika i-laser. Isixazululo esikahle ukufaka isihlungi somusi esihlanza umoya ngaphambi kokuba siqondiswe kufeni yedivayisi. Nokho, abalandeli basengahlanzwa ngempumelelo ngisho noma isihlungi singakafakwa. Noma yikuphi ukunqwabelana kothuli nemfucumfucu ku-impeller kubalandeli be-extractor kufanele kususwe. Izinto ezifana ne-MDF ne-acrylic zikhipha intuthu eminingi lapho zisikwa, futhi zingaba yingozi yomlilo uma zinganakwa kahle. Ukuhlanza kungenziwa ngokunqamula i-fan ekunikezeni amandla kanye nokukhipha amapayipi epayipi lokukhipha ngaphambi kokuhlanza i-impeller fan. Ukudonsa kufanele kwenziwe kumapayipi okungenisa kanye nokukhipha umoya ngebhulashi lokupenda elithambile njalo 40 amahora.

Isihlungi se-tube

Isihlungi seshubhu, naso, kufanele sihlanzwe kunoma yikuphi ukungcola okungenzeka sibe nakho. Amanzi ku-tube kufanele akhishwe futhi akhishwe ngaphambi kokuhlanza. A 50-50 ingxube wamanzi noviniga kufanele kusetshenziselwe ukugeza ishubhu ngaphambi kokuba lixhunywe endaweni yokungena amanzi futhi libuyiselwe emshinini.

Isipholile samanzi

Imishini yokusika i-laser ikhiqiza ukushisa okuningi lapho isebenza. Afika nama-water coolers, abuye aziwe ngokuthi ama-water chiller. Izinga lokushisa le-cooler yamanzi kufanele liqashwe ngesibonisi. Njalo emavikini ambalwa, izihlungi ku-cooler kufanele zihlolelwe ukwakheka kwempahla. Noma iyiphi impahla kufanele isuswe. Ukungcoliswa kwamanzi kufanele futhi kuhlolwe ukuze kuqinisekiswe ukuthi amanzi awaholeli ekugqwaleni kwezingxenye ze-cooler. Amanzi asetshenzisiwe kufanele enziwe i-deion ngoba amanzi ajwayelekile aqukethe ukungcola okungavala amapayipi nezihlungi noma kukhuthaze ukukhula kwamagciwane. Kubalulekile futhi ukuthi i-chlorine ingasetshenziswa ngesikhathi sokulungiswa ngoba i-ion ye-chloride ihlasela ungqimba lwensimbi engagqwali noma izingxenye zethusi okungenzeka zibe endaweni epholile.

Ikhanda le-laser/umthombo

Umthombo we-laser head/laser yilapho ugongolo luqala khona, futhi nawo udinga ukulungiswa. Ukuhlanza ikhanda le-laser kufanele kuqale ngokukhipha uthuli ne-lint kusetshenziswa umoya ocindezelwe. Izinto zokuhlanza/uketshezi lokuhlanza kanye nezinto zokuhlanza kuyanconywa ukuze kuhlanzwe. Ikhanda kufanele liqale ligezwe kusetshenziswa uketshezi lokuhlanza. Khona-ke, ukwehla koketshezi lokuhlanza kufanele kubekwe ekhanda futhi kushiywe umzuzu. Ikhanda kufanele lisulwe ngezinto zokuhlanza futhi ligcinwe lilungele ukusetshenziswa.

Umhlahlandlela rail

Izinsimbi zomhlahlandlela zibalulekile emshinini wokusika we-laser ngoba zinikeza isiqondiso nokuzinza. Ngakho-ke, zithinta ukunemba kokucubungula komshini. Ukwehluleka ukuwagcina kungaholela emazingeni okugqwala, kuphazamise ukunyakaza komsiki we-laser. Umsebenzisi kufanele ahambise i-laser cutter ohlangothini olulodwa lwesitimela futhi asule lonke uthuli ngendwangu kakotini eyomile. Amafutha amancane okuthunga kufanele athululwe kumzila wesitimela, futhi ikhanda le-laser kufanele liphushwe ngaphesheya komzila wesitimela ukuze usakaze amafutha ngokulinganayo.

Imicabango yokugcina

Ukugcinwa okuhle kubalulekile ekugcineni ukusebenza kwemishini yokusika i-laser. Yingakho lo mhlahlandlela uye wazama ukuchaza izingxenye ezibucayi ezidinga ukubhekwa ngokucophelela ekunakekeleni. Vakashela Chovm.com ngokukhethwa kwemishini engcono kakhulu yokusika i-laser etholakalayo.