Ukufika komshini ozishintshayo ngobuchwepheshe bokulawula izinombolo (NC) ngeminyaka yawo-1940 kanye nokushintshashintsha okuthuthukile okwalandela okwanikwa amandla amakhompyutha ngeminyaka yawo-1970 kusho ukuthi ukukhiqiza kwesimanje kugcizelela ekukhiqizeni okunembayo nokungashintshi. Elinye lamathuluzi elihlala lilethwa futhi elihlala lidingeka kakhulu i-CNC lathe.

Qhubeka ufunde ukuze uthole isingeniso sezintambo ze-CNC, kanye nokwahlukaniswa kwezinhlobo eziyinhloko zamalebula emakethe kanye nezinhlelo zokusebenza zawo ezibalulekile, ukuze uqiniseke ukuthi unikeza abathengi bakho izinketho ezinhle kakhulu ngo-2025.

Okuqukethwe

Iyini i-CNC lathe?

Izingxenye ze-CNC lathe

Izinhlobo ze-CNC lathes

CNC lathe izicelo

Izinzuzo zokusebenzisa i-CNC lathe

Izinkinga zokusebenzisa i-CNC lathe

Amathrendi wesikhathi esizayo kubuchwepheshe be-lathe ye-CNC

Isiphetho

Iyini i-CNC lathe?

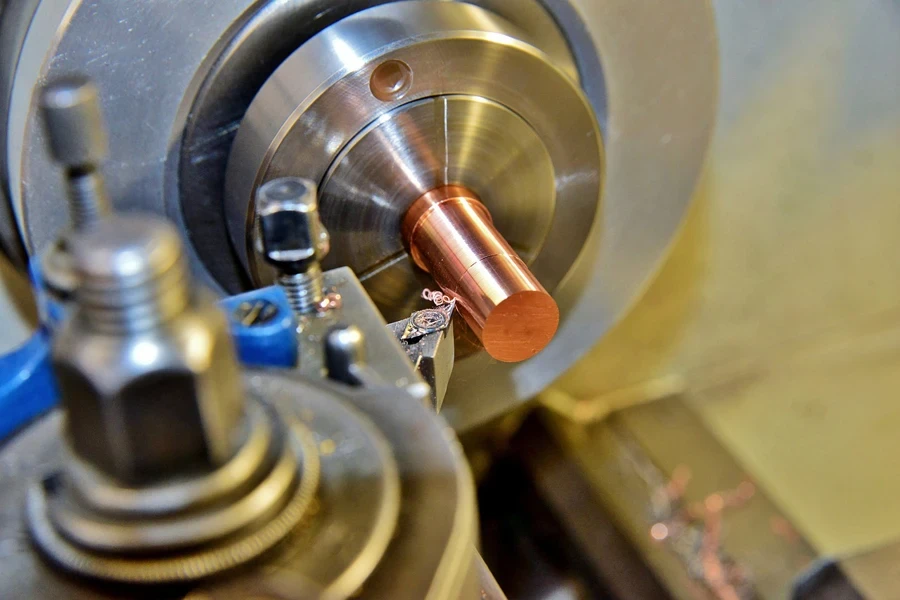

I-Computer Numerical Control, noma i-CNC, amalebula ayimishini enembayo ezungezisa izinto, njengepulasitiki, ukhuni, noma insimbi, ngokumelene nethuluzi lokusika ukuze lizilolonge. Izinhlobo ze-CNC zihluke emigqeni evamile ngoba zilawulwa izinhlelo zekhompiyutha, zisusa isidingo sokungenelela komuntu kanye namaphutha abantu okungenzeka. Lokhu kuzenzakalela kusho ukuthi i-lathe ye-CNC iyakwazi ukudala imiklamo enemininingwane, enembile, futhi ephindaphindwayo ngendlela efanele futhi engaguquki.

Izingxenye ze-CNC lathe

I-CNC lathes yakhiwe izingxenye ezimbalwa ezibalulekile.

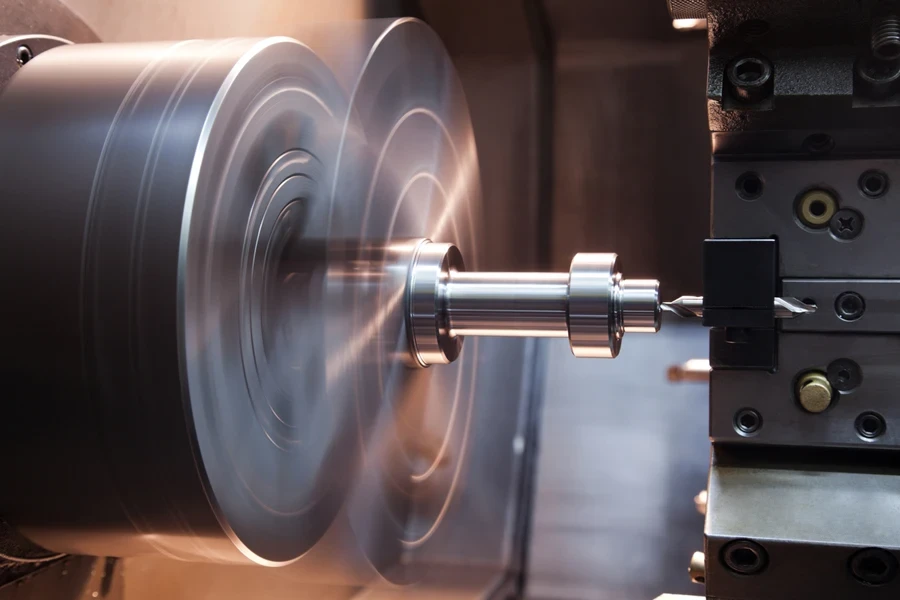

I-Headstock

I-headstock ye-CNC lathe iyingxenye ebalulekile ekufinyeleleni ukusika okunembile kocezu lokusebenza. Iphethe inaliti yokuphotha eyinhloko, esekela futhi izungezisa ucezu lokusebenza, kanye nomshini wokuphotha kanye nomshini wokugiya, oshayela i-spindle futhi ulawule isivinini sokuphotha, ngokulandelana.

Umsila womsila

Ngasohlangothini oluphikisayo lwe-CNC lathe esihlokweni, i-tailstock yingxenye esekela enye ingxenye yesiqeshana sokusebenza enalithi yokuphotha. Uma kwenziwa umsebenzi oyisicefe, i-tailstock yilapho ama-drill azoba khona.

Chuck

I-Chuck iza ngamajamo nobukhulu obuhlukene, kuye ngokuthi i-workpiece, futhi isetshenziselwa ukubamba lesi sakamuva endaweni ngesikhathi sokusika.

Bed

Lesi ucezu oluyisisekelo lwe-CNC lathe, esebenza njengesizinzisi esiyinhloko ukuze kuqinisekiswe ukusika okubushelelezi nokunembe kwesiqeshana sokusebenza ngaphandle kokuphazamiseka kokudlidliza.

Ukuthutha

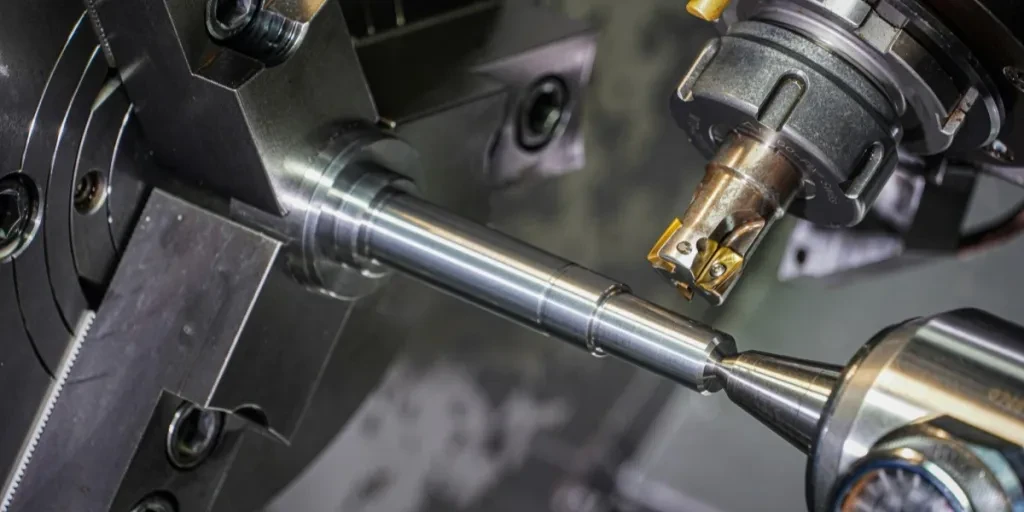

Ikalishi liyingxenye egcina ithuluzi lokusika futhi ilinyusa liye phansi endaweni yokusebenza. Ukwengeza, inqola kwesinye isikhathi izobamba ezinye izindlela ezisiza ukuphatha ithuluzi lokusika, okuhlanganisa isilayidi esiphambanayo, iphinifa, nokuthunyelwe kwamathuluzi.

I-Turret

I-turret iyingxenye ejikelezayo esebenza njengesibambi samathuluzi, okuvumela izinguquko ezisheshayo zamathuluzi anesikhathi esincane sokuphumula.

Iphaneli yokulawula

Njengoba igama libonisa, iphaneli yokulawula ivumela u-opharetha ukuthi afake yonke imiyalo yokuqala, njengejubane lokusika, indlela yamathuluzi, nohlobo lomshini womsebenzi wokusebenza. Iphaneli yokulawula isetshenziswa kusetshenziswa isofthiwe efana ne-G-code noma isofthiwe ye-Computer-Aided Manufacturing (CAM) ukuze isho izidingo zomshini we-CNC lathe.

Izinhlobo ze-CNC lathes

Kunezinhlobo ezahlukene zezintambo ze-CNC ezivumela ukubunjwa kwe-workpiece ehlukene nezinhlobo zezinto ezibonakalayo, amaphethini ahlukene kanye nezidingo zokusika, kanye nokusebenza kwemishini ehlukene. Ngokuvamile, i-CNC lathes ingahlukaniswa ngezigaba ezimbili:

Izintambo ze-CNC ezisuselwe kwinani lezimbazo

Ama-lathe e-CNC anezinhlangothi ezimbili

Lezi yizinhlobo ezivame kakhulu ze-CNC lathe futhi zingabalwa njengobubanzi bezinga lokungena, kubalwa nge-X-eksisi elula ne-Z-eksisi ukulawula ukunyakaza kwethuluzi lokusika. Lokhu kusetha kubenza babe olunye lwezinhlobo ze-lathe ze-CNC ezithengekayo futhi kusho ukuthi zilungele imisebenzi elula.

Multi-axis CNC lathes

Uhlobo lwe-lathe oluyinkimbinkimbi kancane lwe-CNC kune- ama-axis amabili we-CNC lathe, lo multi-eksisi CNC lathe isebenzisa izimbazo zika-X kanye no-Z kanye nezimbazo ezengeziwe, ezifana ne-Y-eksisi noma i-C-eksisi. Lokhu kuvumela imiklamo eyinkimbinkimbi yokusika namaphethini futhi kunciphisa isikhathi sonke uma wenza imisebenzi eyinkimbinkimbi njengoba kugwema isidingo sokudlula okuningi noma ukusetha.

I-CNC lathes esekelwe ekuqondaneni kwe-workpiece

Izintambo ze-CNC eziqondile

Izintambo ze-CNC eziqondile bamba i-workpiece iqonde phezulu futhi, kanjalo, ivame ukutholakala ezimbonini ezidinga ukusika izingxenye ezinkulu nezisindayo, njengasezimbonini ze-aerospace kanye nezamandla.

Ama-lathe e-CNC avundlile

Ama-lathe e-CNC avundlile bamba i-workpiece ngokuvundlile futhi ziwuhlobo oluvame kakhulu lwe-CNC lathe emakethe. Lolu hlobo lwe-CNC lathe alufaneleki kuma-workpieces asindayo noma amakhulu ngenxa yokuntuleka kokusekelwa okuphakathi kanye nokwenzeka okulandelayo kokugoba phakathi nendawo yokusebenza.

CNC lathe izicelo

Ngenxa yokusebenzisa kwabo okuzenzakalelayo nokusebenza kahle kwabo, izinsimbi ze-CNC zisetshenziswa ezimbonini eziningi zenani eliphezulu.

Imboni ye-Aerospace

I-Aerospace idinga ukusikeka okunembayo okuphezulu, okwenza i-CNC lathe ibe ithuluzi elibalulekile laleyo mboni. Lapha, izintambo ze-CNC zisetshenziselwa ukusika izingxenye ezihlanganisa ama-turbine blades, amagiya okufika, nezingxenye zenjini.

Imbonini yezimoto

Imboni yezimoto inezinhlobonhlobo zemishini esindayo edinga ukusika okuphezulu nokunembayo. Ukwengeza, izidingo zokukhiqiza umthamo ophezulu womkhakha zisho isidingo sejubane nokungaguquguquki - konke okwenza i-CNC lathe ibe ithuluzi elibalulekile. Lapha, i-CNC lathe isetshenziselwa ukukhiqiza izingxenye zenjini, ama-gearbox, nezinto zokumiswa.

Ukukhiqizwa kwedivayisi yezokwelapha

Imishini yezokwelapha kufanele inembe ngokwedlulele, futhi ngenxa yalokho, i-CNC lathe isetshenziswa enqubweni yokukhiqiza, ikakhulukazi kugxilwe ekufakweni, amathuluzi okuhlinza, nama-prosthetics.

Ukukhiqiza okujwayelekile

Amalebula e-CNC angamathuluzi abalulekile kuzo zonke izimboni eziningi zokukhiqiza ngenxa yokuguquguquka kwawo ezintweni zokwakha nosayizi abangasebenza ngawo. Eminye yeminye imikhakha yokukhiqiza lapho kusetshenziswa izinsimbi ze-CNC ihlanganisa izimpahla zabathengi nemishini yezimboni.

Izinzuzo zokusebenzisa i-CNC lathe

Ngenxa yezinzuzo zayo eziningi phezu kwamathuluzi afanayo, imishini ye-CNC lathe ilungele uhla olubanzi lwezinhlelo zokusebenza ezimbonini ezahlukahlukene.

Ukunemba nokunemba

Ngenxa yesakhiwo sazo esivikelekile, ukusebenza okuzenzakalelayo kokusika, namakhono okunyakaza kwamathuluzi, ama-CNC lathes ayakwazi ukusika ama-workpieces ngokunemba okuphezulu futhi akhe izingcezu zekhwalithi ephezulu ngokungaguquki. Lokhu futhi kunciphisa amathuba okuba neziphambeko nokumosha izinto ezibonakalayo, kuzenze zisebenze kahle kakhulu.

yizinhlobonhlobo

I-CNC lathes ingasika izinto ezihlukahlukene, okuhlanganisa izinsimbi, izinhlanganisela, namapulasitiki, ngamaphethini amaningi ahlukene. Amathuluzi atholakala kumalebula e-CNC avumela ukugxilisa, ukubheka, ukujika, ukugoba, ukugoqa, ukusika intambo, ukubhoboza, ukubhora, ukuphinda, ukuphotha, ukucofa, nokuhlukana, kanye nokusebenza okwengeziwe.

Isivinini sokukhiqiza

Ukuzenzakalela kanye nezinketho eziningi ze-eksisi kusho ukuthi ama-lathe e-CNC ayakwazi ukusebenza ngokushesha nangempumelelo, ngaphandle kwesidingo sokuphumula. Lokhu kusho izikhathi zokukhiqiza ezisheshayo.

Ukwehliswa kwezindleko zabasebenzi

Esinye isici esithinta i-automation izindleko zabasebenzi. Njengoba ama-lathe e-CNC adinga kuphela ukungenelela komuntu ukusetha izidingo zokuqala zokusika kanye nezilungiselelo ze-lathe kuphaneli yokulawula, kunesidingo esincishisiwe sabasebenzi abakhokhelwayo.

Izinkinga zokusebenzisa i-CNC lathe

Naphezu kwezinzuzo eziningi ze-CNC lathes, kukhona nezinkinga ezithile. Nokho, lezi zinganqotshwa kalula.

Ukutshalwa kwezimali kokuqala okuphezulu

Izintambo ze-CNC ziyi-investimenti ebizayo, futhi okungenzeka kube nzima kumabhizinisi amancane ukuphatha. Kodwa-ke, imali elondolozwe ezindlekweni zabasebenzi kanye nokumoshwa kwempahla ngokusebenzisa i-CNC lathe izovala ukutshalwa kwezimali kokuqala, ikakhulukazi uma isetshenziswa endaweni yokukhiqiza umthamo omkhulu. Kufanele kuqashelwe ukuthi lokhu kutshalwa kwezimali kungase kungakhokhi uma amaphrojekthi adingekayo enevolumu ephansi noma ama-workpieces angokwezifiso.

Ukusethwa okuyinkimbinkimbi nokuhlela

Kungaba nzima ukufunda ukuthi ungasetha kanjani kahle futhi uhlele i-CNC lathe ukuze isebenze kahle futhi inembile. Nokho, uma lezi zici sezifundiwe, lezi zinyathelo zingenziwa ngokushesha, okusho ukuthi u-opharetha oyedwa angasetshenziselwa amalebula amaningi e-CNC. Ngaphezu kwalokho, ama-lathe e-CNC angathengwa ngezindlela zokusebenzelana ezilula eziguqula ngokuqondile izilungiselelo ezifinyelelekayo zibe ikhodi ye-G yomshini.

Isondlo kanye nesikhathi sokuphumula

Nakuba i-CNC lathe automation isho ukuphuma okuqhubekayo okunesikhathi esincane sokuphumula, lokhu akusho ukuthi asikho nhlobo isikhathi sokuphumula. Kubalulekile ukuvala umshini ngezikhathi zansuku zonke ukuze wenze ukuhlola nokunakekela okujwayelekile, okuhlanganisa ukuhlanza umshini, ukuhlola i-chuck ne-turret yamathuluzi, kanye nokuhlola amazinga okugcoba. Ukwengeza, opharetha kufanele ngezikhathi ezithile bahlole ukuhleleka komshini, balinganise izinzwa, bahlole noma yiziphi izingxenye zikagesi, futhi basebenzise ukuxilonga ukulungisa. Kodwa-ke, le misebenzi mifushane futhi izoqinisekisa impilo ende nokusebenza kahle komshini, okuthi ngokuhamba kwesikhathi wonge ngesikhathi nezindleko.

Amathrendi wesikhathi esizayo kubuchwepheshe be-lathe ye-CNC

Izintambo ze-CNC ziyimishini ezenzakalelayo ekwazi ukubumba izingcezu zokusebenza ngokushesha nangokunembile ngenxa yamathuluzi abo nokunyakaza okulula. Kodwa-ke, njengoba umshini uya ngokuya uhlanganiswa ne-AI kanye nobuchwepheshe obuhlakaniphile, ama-lathe e-CNC azongena esigabeni se-4.0 semboni. Lokhu kuzosho amaphutha ambalwa, izinqubo zokwenza imishini ezithuthukisiwe, ukulawulwa kwekhwalithi okuthuthukisiwe, namandla okulungisa abikezelayo, phakathi kwezinye izici ezinhle.

Ngaphezu kokuhlanganiswa kobuchwepheshe obusha, ama-lathe e-CNC azoqala ukusebenza ngohlu olubanzi lwezinto ezingavuthiwe futhi amelane nezindawo eziyingozi kakhulu. Ngenxa yalokhu, ama-lathe e-CNC angase aqale ukusetshenziswa nama-alloys asezingeni eliphezulu, okuyowavumela ukuba angene ezimbonini ezintsha—ngokwesibonelo, njengomkhiqizi wamathuluzi omshini emikhakheni enezimo ezimbi kakhulu noma eziguquguqukayo.

Isiphetho

Izintambo ze-CNC ziyimishini esetshenziswa kabanzi enikeza ukunemba, isivinini, kanye nokuguquguquka kuzo zonke izinhlobo zezimboni eziningi. Izinga labo eliphezulu lokuzenzakalela livumela izindleko ezincishisiwe zabasebenzi kanye nokumosha izinto ezibonakalayo, okubenza babe ukukhetha okuhle kumabhizinisi asebenzisa imigqa yokukhiqiza ekhiqiza imiphumela ephezulu edinga ikhwalithi nokungaguquguquki.

Ngokuzayo, njengoba amalebula e-CNC ehlanganiswa nobuchwepheshe be-AI, le mishini izokwazi kangcono ukubikezela izinkinga nokuzixazulula, futhi ikwazi ukukhiqiza ikhwalithi ephezulu nemiklamo eyinkimbinkimbi. I-CNC lathes iwumshini wokukhiqiza oyinhloko namuhla futhi izokhula ngokubaluleka kuphela ngokukhuphuka kokukhiqizwa kwesimanje, okubenza babe ukukhetha okunengqondo kokutshalwa kwezimali.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu