Kokubili i-laser cutting kanye ne-EDM yocingo ilungele izinqubo zokusika ngokunemba. Lezi zindlela ezimbili zisika futhi zilolonge izinto ngokusebenzisa ubuchwepheshe be-fine-point thermal. Ukuthi lezi zindlela zombili zenza umsebenzi ofanayo futhi zisebenzisa ubuchwepheshe obufanayo akusho ukuthi zifana ncamashi. Kunomehluko omningi phakathi ukusika kwe-laser kanye ne-EDM yocingo okudingeka uyazi ngaphambi kokunquma ukuthi yimuphi umshini ozotshala kuwo.

Kulesi sihloko, ngeke sibheke umehluko wabo kuphela kodwa futhi nobuhle, ububi, kanye nezicelo zabo.

Okuqukethwe

Kuyini ukusika kwe-laser?

Iyini i-EDM yocingo?

Umehluko phakathi kokusika kwe-laser kanye ne-EDM yocingo

Isiphetho

Kuyini ukusika kwe-laser?

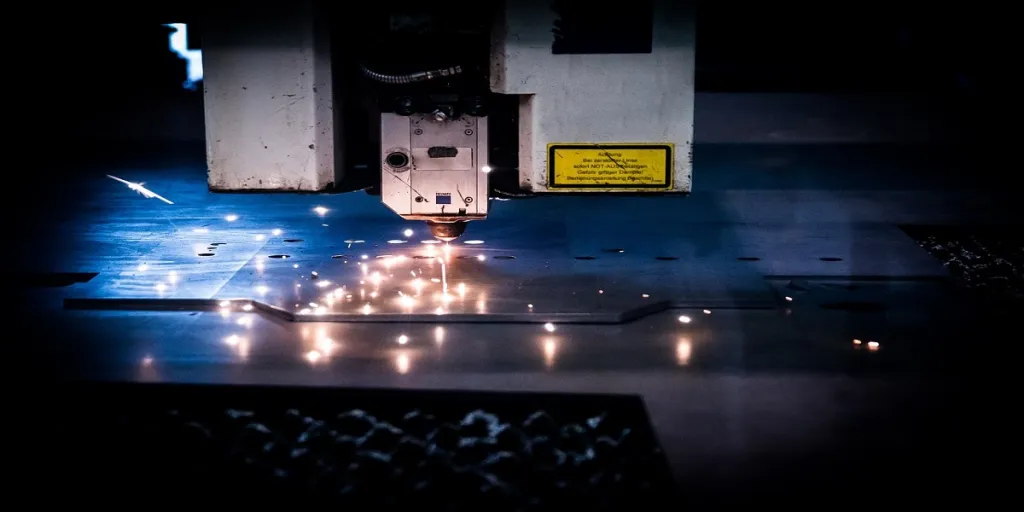

Ukusika i-Laser kuyindlela yokwenziwa ehlanganisa ukusika izinto zibe amaphethini adingekayo, imiklamo, namafomu kusetshenziswa ugongolo oluncane lwe-laser olugxilile. I-beam evela ku- umshini wokwehlisa laser iyashisisa, iyancibilika, futhi ihwamulise into. Le nqubo yokusika esekelwe ezishisayo futhi engathinteki isetshenziswa ezintweni ezihlukahlukene, kuhlanganise nokhuni, ipulasitiki, ingilazi, insimbi, namatshe ayigugu. Uma kuhlanganiswe nobuchwepheshe be-CNC, ukusika nge-laser kungacubungula uhla olubanzi lwemikhiqizo ngaphandle kokusebenzisa ithuluzi eliklanywe ngokwezifiso.

buhle

- Inikeza ukusikeka okuhlanzekile nokunembayo ngenxa yamandla athuthukisiwe wemishayo.

– Inezindleko zokunakekela eziphansi kanye nezikhathi zokuhola ezimfushane.

- Ilungele uhla olubanzi lwezinto zokwakha, kufaka phakathi izinsimbi ezivundile nezingezona ayoni, ukhuni, amapulasitiki, izindwangu ezithile, nezinhlanganisela.

- Inqubo ingakwazi ukusingatha imisebenzi eyinkimbinkimbi ngaphandle kokuhlanekezela isifunda esinqunyiwe.

bawo

– Ingakhipha intuthu eyingozi.

- Ingase ikhiqize ama-burrs kanye nokusikeka okungcolile uma izinto ziminyene kakhulu.

Izicelo

Ezinye zezinhlelo zokusebenza zokusika i-laser zifaka:

- Ukwakhiwa kweCeramic

- I-silicon processing

- Ukukhiqizwa kwemishini yezokwelapha

– Jewelry imboni

- Isikhunta, ifa, nezinye izimboni zamathuluzi

- Izimboni ze-Aerospace nezezimoto

Iyini i-EDM yocingo?

Imishini yokukhipha ugesi (noma ukusika kwe-EDM yocingo) kuyindlela ye-electrochemical yokusika izinto. Inqubo isebenzisa amathuluzi aklanywe ngokukhethekile akhipha izinhlansi ukuze asuse izinto ngosizo lwamashaji kagesi avamile, asheshayo, futhi alawulwayo. I-EDM yocingo isetshenziswa kuphela ezintweni ezisebenza ngogesi njengezinsimbi.

buhle

- Ayinawo umthelela omubi ezintweni eziqinile, ezintekenteke, nezincane ezikwazi ukugoba, ingcindezi, nokungqubuzana.

- Inokubekezela okuphezulu kunokusika nge-laser ngakho inembe kakhudlwana futhi inikeza izilinganiso ezinembe kakhudlwana.

- Ingakwazi ukusika izinto ezinobubanzi obubanzi bobulukhuni

bawo

– Kulinganiselwe kuphela ezintweni ezikwazi ukuqhuba ugesi.

- Inqubo inejubane lokusika elihamba kancane uma liqhathaniswa nokusika kwe-laser.

– Ayilungele ukusika ishubhu.

Izicelo

I-Wire EDM ngokuvamile isetshenziselwa:

- Izinto ezinkulu njengensimbi engagqwali ezidinga ukunemba kwekhwalithi ephezulu nokupholishwa

- Izingxenye ezintekenteke nezincane ezingalinyazwa ezinye izinqubo zendabuko

- Izingxenye ezidinga izikhala emincane namafomu ayinkimbinkimbi

- Izinto ezinkulu ezinokubekezelelana okuqinile

- Noma yiziphi ezinye izinto ezingajwayelekile, ezithambile, ezibizayo, neziqinile

Umehluko phakathi kokusika kwe-laser kanye ne-EDM yocingo

1. Ukubekezelelana

Ngokwesilinganiso, kuzo zonke izinto ezincane, ukusika kwe-laser kufinyelela ukubekezelelwa okungaba amayintshi angu-0.002. Ukubekezelelana kusekelwe ekubeni mncane kwempahla. Ngenxa yalokho, njengoba ubukhulu bezinto ezibonakalayo bukhula, ukubekezelelana kunciphisa. Ngaleso sikhathi, abasiki bezintambo be-EDM bathola ukubekezelelana okuqinile okungaba amayintshi angu-0.0001 ngokunemba nokunemba okwengeziwe. Lokhu kubangela ukusika kancane uma kuqhathaniswa nokusika nge-laser. Abathengi kufanele bakhethe i-EDM yocingo ngemikhiqizo ebekezelela ngokwedlulele noma edinga ukunemba okungaka.

2. Ijubane

Uma kukhulunywa ngesivinini, ukusika nge-laser kunikeza isivinini sokusika esisheshayo ezintweni ezinobukhulu obungama-intshi angu-0.25 noma amamilimitha angu-6.35. Lokhu kusho ukuthi izinto eziwugqinsi zidinga amandla aphezulu lasers namashubhu egesi ukuze kuzuzwe isivinini esifanayo. Ngokolunye uhlangothi, i-EDM yocingo ngokuvamile ihamba kancane kune-laser cutters kodwa inikeza ukunemba okwandisiwe. Ingakwazi ukusika izinto kusuka ku-0.001 kuya ku-16 amayintshi ubukhulu.

I-3. Izinto zokwakha

Ukusikwa kwe-EDM ngocingo kusetshenziswa ugesi ngakho-ke izinto ezinqunywayo kufanele zifake ugesi. Lokhu kusho ukuthi inqubo ilinganiselwe ezinsimbi noma ama-alloys. Ngakolunye uhlangothi, ama-laser cutters afanele izinto ezikhanyayo, ezithambile, nezingabonisi. Lokhu kungenxa yokuthi inqubo iqala ngendawo yokuxhumana okufanele ibhoboze kuqala yonke into yokusebenza.

4. Izinsalela

Zombili izindlela zokusika zikhiqiza izinsalela ngesikhathi nangemva kokusika. Kodwa-ke, ohlelweni lwe-EDM yocingo, okusele kungagezwa emanzini e-dielectric ukuze kuqedwe umphumela wawo ekubekezeleni. Ukusika i-laser, ngakolunye uhlangothi, kudala i-slag engabhaka phezu kwento.

I-5. Ukusika

Ukusika i-laser kusebenzisa ugongolo olushisayo ukusika izinto ngokushiswa, ukuncibilika, nokuhwamuka. Ngokuphambene, i-EDM yocingo isebenzisa intambo encane enamandla kakhulu ukusika izingcezu zokusebenza.

I-6. Ukulinganiselwa

Nakuba ukusika nge-laser kunqunyelwe ezintweni ezizacile, kusika ububanzi obubanzi bezinto ezilula, ezithambile, nezingabonakali njengensimbi, i-aluminium, ithusi, insimbi engagqwali, nethusi. Ngakolunye uhlangothi, i-EDM yocingo ifaneleka ukusika izinto ezisebenza ngogesi, okungukuthi, izinsimbi nama-alloys.

I-7. Izindleko

Ukusika i-laser kuhlotshaniswa nesivinini nokunemba ngakho kusebenza kahle futhi kubiza izindleko uma kuqhathaniswa ne-EDM yocingo. Ezimpahleni ezincanyana ikakhulukazi, ukusika nge-laser kwehlise izikhathi zomthofu futhi kunciphisa izinsalela zempahla ukuze kukhiqizwe imikhiqizo yekhwalithi ephezulu engabizi kakhulu. Kodwa-ke, ukuba khona kwe-slag nama-burrs kwenza izinto zibe messier njengoba ukujiya kukhula. Ngokuphambene, i-EDM yocingo ngokuvamile ihamba kancane njengoba isika kuphela izinsimbi nama-alloys aqinile futhi ashubile. Isebenzisa isikhathi esiningi futhi ibambezela ukukhiqizwa, yingakho yandisa izikhathi zokuhola. Futhi, i-EDM yocingo idinga amathuluzi angeziwe, okwenza inqubo ibize kakhulu.

Isiphetho

I-EDM yocingo nokusika kwe-laser kunokufana okuningi uma kuziwa ekusikeni nasekubumbeni izinto. Kodwa-ke, kusukela olwazini olungenhla, abathengi kufanele baqonde ukuthi i-EDM yocingo ifaneleka kakhulu ukusika izingxenye eziqinile, ezisebenza ngogesi ezivame ukuba nzima ukuzilawula usebenzisa ezinye izindlela zokusika. Ngakolunye uhlangothi, imishini yokusika i-laser isike ama-workpieces amancane njengamashidi ensimbi ngenani elisheshayo. Ngokuphawulekayo, yomibili imishini inezinzuzo nezansi. Lokhu kusho ukuthi abathengi kufanele bakhethe ubuchwepheshe bokusika obufanele phakathi kwalokhu okubili kuye ngezidingo zabo zokukhiqiza. Ukuthola ikhwalithi ye-laser yokusika kanye nemishini ye-EDM yocingo, vakashela Chovm.com.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu