Ngo-2025, imakethe yomhlaba wonke ye-EDM Machine yenza isamba esingu-USD 4.5 bhiliyoni, siqhutshwa intuthuko kwezobuchwepheshe kanye nesidingo esikhulayo sokusebenza kwemishini enembile. Lesi sihloko sinikeza ukuhlaziywa okujulile kwezici ezibalulekile zokukhetha imishini ye-EDM, okuhlanganisa ukusebenza, izinhlobo, nokucatshangelwa kwezindleko, ukuletha ukuqonda okubalulekile nosizo lwabathengi abangochwepheshe ezimbonini ezihlukahlukene. Ukushintsha usuka ekubukezweni kwemakethe uye kuzinhlelo zokusebenza ezingokoqobo, lo mhlahlandlela uqinisekisa ukuthathwa kwezinqumo okunolwazi.

Okuqukethwe:

- Ukubuka konke kwemakethe yomshini we-EDM

- Isingeniso Esiningiliziwe Nokuhlaziywa Kwemakethe Yomshini We-EDM

- Izinto Ezibalulekile Lapho Ukhetha Umshini We-EDM

- Ukucatshangelwa kwezindleko kanye nesabelomali

- Izicelo Ezisebenzayo Zemishini Ye-EDM

- Ukugcinwa Nokugcinwa Kwemishini ye-EDM

– Imicabango yokugcina

I-EDM Machine Market Overview

Imakethe yomhlaba wonke ye-Electrical Discharge Machining (EDM) ibhekene nokukhula okuphawulekayo ngenxa yokuthuthuka kwezobuchwepheshe bokukhiqiza kanye nesidingo esikhulayo esivela ezimbonini ezihlukahlukene. Ngo-2025, imakethe ye-EDM inenani elilinganiselwa ku-USD 4.5 bhiliyoni, kanye nezinga lokukhula elihlanganisiwe lonyaka (CAGR) lika-6.1% ngo-2030. Lokhu kukhula kubangelwa isidingo esikhulayo somshini onembile emikhakheni efana nezimoto, i-aerospace, nokunakekelwa kwezempilo.

INyakatho Melika kanye ne-Europe ngokuhlangene zenza ngaphezu kuka-60% wesabelo semakethe ye-EDM yomhlaba wonke, kanti i-United States neJalimane ibambe iqhaza elibalulekile ngenxa yezisekelo eziqinile zezimboni kanye nentuthuko yezobuchwepheshe. Ngaleso sikhathi, isifunda sase-Asia-Pacific sibona ukukhula okusheshayo, ikakhulukazi eChina, eJapan naseNdiya, okuqhutshwa ukwanda kwezimboni kanye nokutshalwa kwezimali kubuchwepheshe bokukhiqiza obuthuthukile. Isifunda kulindeleke ukuthi sikhule ku-CAGR ka-7.3% ngesikhathi sokubikezela.

Imakethe ihlukaniswe ngezinhlobo ezahlukene zemishini ye-EDM, okuhlanganisa i-Die Sinking EDM, Wire EDM, kanye ne-Hole Drilling EDM. I-Wire EDM inesabelo semakethe esikhulu kunazo zonke, esibalelwa ku-45% wemakethe ephelele, ngenxa yokusetshenziswa kwayo kakhulu ekukhiqizeni izingxenye eziyinkimbinkimbi nezinembayo. Umkhakha wezimoto usalokhu uyimboni enkulu yabasebenzisi bokugcina, emele ama-35% engqikithi yesidingo semakethe, ilandelwa eduze imboni ye-aerospace kanye nezempilo.

Isingeniso Esiningiliziwe Nokuhlaziywa Kwemakethe Yomshini We-EDM

Imishini ye-EDM ibalulekile ezimbonini ezidinga ukunemba okuphezulu kanye namajiyometri ayinkimbinkimbi izindlela zendabuko zemishini ezingenakufinyelelwa. Izilinganiso zokusebenza ezibalulekile zemishini ye-EDM zihlanganisa ukunemba okuphezulu, ikhwalithi yokuqedwa kwendawo, namazinga okususwa kwezinto. Imishini yesimanje ye-EDM inikezela ngamazinga anembayo ngaphakathi kwama-microns, okuwenza abaluleke kakhulu ekukhiqizeni izingxenye ezibalulekile ku-aerospace namadivayisi wezokwelapha.

Amandla emakethe athonywa kakhulu ukwamukelwa kobuchwepheshe obuthuthukile obufana neComputer Numerical Control (CNC) kanye ne-automation. Imishini ye-CNC EDM, eyenza i-70% yemakethe, inikeza ukunemba okuphakeme nokuphindaphinda, ukushayela ukutholwa kwayo okubanzi. Ngaphezu kwalokho, izinto ezintsha ezifana nezinhlelo zokulawula eziguquguqukayo kanye nokuqapha kwesikhathi sangempela kuthuthukisa ukusebenza nokusebenza kahle kwemishini ye-EDM, kunciphisa isikhathi sokuphumula kanye nezindleko zokusebenza.

Izici zomnotho ezifana nezindleko ezikhulayo zezinto zokusetshenziswa kanye nezabasebenzi zikhuthaza abakhiqizi ukuthi batshale kubuchwepheshe be-EDM ukuze kuthuthukiswe ukukhiqiza nokunciphisa imfucuza. Ukwengeza, ukuziphatha kwabathengi kushintshela kumikhiqizo yekhwalithi ephezulu, ehlala isikhathi eside, okwandisa isidingo sezisombululo zemishini enembile. Iziteshi zokusabalalisa zemishini ye-EDM ikakhulukazi ngabathengisi nabasabalalisi, abanesabelo semakethe esingu-55% ngenxa yamanethiwekhi abo abanzi namandla okusekela ngemva kokuthengisa.

Izindlela ezintsha zakamuva emakethe ye-EDM zihlanganisa ukuhlanganiswa kwe-Inthanethi Yezinto (IoT) kanye Nobuhlakani Bezobuciko (AI) ukuze kugcinwe ukulungiswa okubikezelwayo kanye nokwenza ngcono inqubo. Isibonelo, imishini ye-EDM enikwe amandla i-IoT ingaqapha idatha yesikhathi sangempela ukuze ibikezele ukwehluleka kwemishini kanye nokugcinwa kwesheduli, inciphise isikhathi sokuphumula esingahlelelwe kuze kufike ku-20%. Ama-algorithms e-AI nawo asetshenziselwa ukuthuthukisa imingcele yemishini, ukuthuthukisa amazinga okususwa kwezinto kanye nokuqedwa kwendawo.

Umjikelezo wokuphila womkhiqizo wemishini ye-EDM ngokuvamile uhlanganisa iminyaka engu-10-15, nokuthuthukiswa okuvamile nokugcinwa okudingekayo ukuze kugcinwe ukusebenza okuphelele. Umkhuba wedijithali ushayela ukwamukelwa kwezixazululo ze-EDM ezihlakaniphile, ezinikeza ukuxhumana okuthuthukisiwe nekhono lokuhlaziya idatha, okuhlinzeka abakhiqizi imininingwane ebalulekile ezinqubweni zabo zomshini.

Izinto Ezibalulekile Lapho Ukhetha Umshini We-EDM

Ukukhetha umshini ofanele wokukhipha ugesi (EDM) kubalulekile ukuze kuzuzwe ukunemba nokusebenza kahle ezinqubweni zokukhiqiza. Izinto ezimbalwa okufanele zicatshangelwe ukuze kuqinisekiswe ukuthi umshini okhethiwe uhlangabezana nezidingo ezithile zezinhlelo zakho zokusebenza.

Ukusebenza kanye nokusebenza

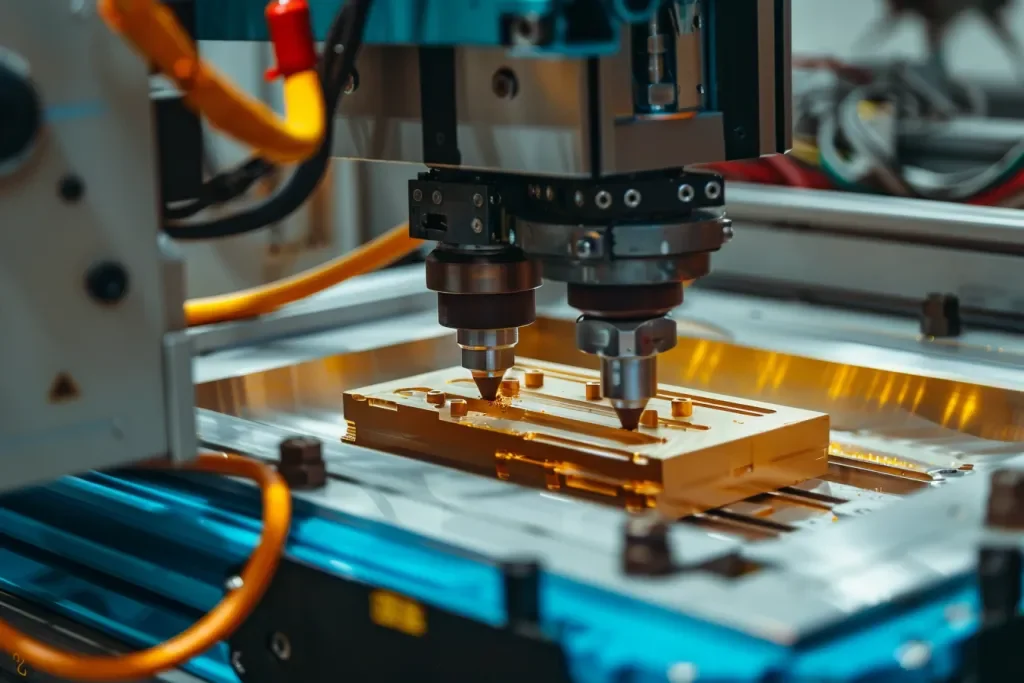

Ukusebenza nokusebenza kubaluleke kakhulu uma ukhetha umshini we-EDM. Le mishini isebenzisa ukukhishwa kukagesi ukuze igugule izinto, izenze zifaneleke izinsimbi eziqinile kanye nokwakheka okuyinkimbinkimbi. Amamethrikhi okusebenza angukhiye afaka isivinini sokusika, ukunemba, kanye nekhwalithi yokuqeda phezulu. Isivinini sokusika sithonywa ukunikezwa kwamandla kanye nohlobo loketshezi lwe-dielectric olusetshenziswa. Imishini ye-EDM enesivinini esiphezulu inganciphisa kakhulu isikhathi sokukhiqiza, esizuzisa ukukhiqizwa kwevolumu ephezulu. Ukunemba, okuvame ukukalwa ngama-microns, kungesinye isici esibalulekile. Imishini enamasistimu okulawula athuthukile kanye nezindlela zempendulo inganikeza ukusikeka okunembile, okubalulekile ezimbonini ezifana ne-aerospace kanye nokukhiqizwa kwemishini yezokwelapha. Ikhwalithi yokuqeda ingaphezulu inqunywa impahla ye-electrode kanye nezilungiselelo zamandla okukhipha. Imishini evumela ukulungiswa kahle kwale mingcele ingakhiqiza ukuqedwa okushelelayo, okunciphisa isidingo sokucutshungulwa ngemuva. Imishini ye-EDM ethuthukisiwe ivame ukufaka izinhlelo zokulawula eziguquguqukayo ezilungisa ngokuzenzakalelayo izilungiselelo ukuze zigcine ukusebenza kahle.

Izinhlobo zemishini ye-EDM

Ukuqonda izinhlobo ezahlukene zemishini ye-EDM kubalulekile ukufanisa umshini nezidingo zakho ezithile. Izinhlobo ezimbili eziyinhloko i-Die-Sinking EDM kanye ne-Wire-Cut EDM, ngayinye enezinhlelo zokusebenza nezinzuzo ezihlukile. I-Die-Sinking EDM, eyaziwa nangokuthi i-Ram EDM, isebenzisa i-electrode emise okwezimbotshana zokwenziwa komsebenzi. Lolu hlobo lulungele ukudala isikhunta esiyinkimbinkimbi futhi siyafa, ikakhulukazi ezimbonini zezimoto neze-electronics. Imishini ye-EDM eshonayo iyaziwa ngokukwazi kwayo ukuphatha amajiyometri ayinkimbinkimbi kanye nemigodi ejulile ngokunemba okuphezulu. I-Wire-Cut EDM isebenzisa intambo encane njenge-electrode ukusika ucezu lokusebenza. Isebenza kahle kakhulu ekwenzeni izimo eziyinkimbinkimbi namakhonsathi, iyenze ifanele izimboni ezifana ne-aerospace kanye nokukhiqiza amathuluzi. Imishini ye-EDM yokusika izintambo inikeza ukunemba okuphezulu futhi ingakhiqiza izingxenye ezinemininingwane emihle nokubekezelelana okuqinile. Ukwengeza, kunemishini ekhethekile ye-EDM efana ne-EDM yemigodi emincane yokumba izimbobo ezinhle kanye nemishini ye-CNC EDM ehlinzeka ngemisebenzi ezenzakalelayo nehlelekayo yokukhiqiza ivolumu ephezulu.

Izici Zobuchwepheshe Zakamuva

Isimo sobuchwepheshe be-EDM sihlala sishintsha, izici ezintsha ezithuthukisa amakhono omshini nolwazi lomsebenzisi. Imishini yesimanje ye-EDM ifakwe izinhlelo zokulawula ezithuthukisiwe, i-automation, nezinketho zokuxhuma. Amasistimu okulawula anokuxhumana kwesikrini esithintwayo kanye nesofthiwe enembile yenza kube lula ukusetha nokusebenzisa umshini. Lezi zinhlelo ngokuvamile zihlanganisa imijikelezo yomshini ehlelwe ngaphambilini kanye nokuqapha kwesikhathi sangempela, okuvumela opharetha ukuthi bathuthukise inqubo futhi banciphise isikhathi sokuphumula. Izici zokuzenzakalela, njengezingalo zerobhothi nezishintshi zamathuluzi ezizenzakalelayo, zingaqhubeka zithuthukise ukukhiqiza ngokunika amandla ukusebenza okuqhubekayo ngokungenelela okuncane komuntu. Lezi zici zizuzisa kakhulu ezindaweni zokukhiqiza ezinevolumu ephezulu lapho ukusebenza kahle nokuvumelana kubalulekile. Izinketho zokuxhumana, okuhlanganisa ukuhlanganiswa kwe-IoT nokuqapha okukude, kuvumela ukuphathwa nokugcinwa komshini okungcono. Ama-opharetha angafinyelela idatha yomshini nokuxilongwa ngesikhathi sangempela, okuvumela ukunakekelwa okuqagelayo nokunciphisa isikhathi sokuphumula esingalindelekile.

Yakha Ikhwalithi Nokuqina

Ikhwalithi yokwakha nokuqina komshini we-EDM yizici ezibalulekile ezithonya ukusebenza kwawo nokuphila isikhathi eside. Imishini eyakhiwe ngezinto zekhwalithi ephezulu kanye nezingxenye eziqinile ingakwazi ukumelana nobunzima bokusebenza okuqhubekayo futhi igcine ukunemba ngokuhamba kwesikhathi. Uhlaka lomshini kanye nezingxenye zesakhiwo kufanele zenziwe ngezinto eziqinile njengensimbi ecijile noma igwadle ukuze kuncishiswe ukudlidliza nokuqinisekisa ukuzinza. Imihlahlandlela yomugqa enembayo ephezulu nezikulufu zebhola nazo zibalulekile ekugcineni ukunemba nokunyakaza okushelelayo. Ukuqina kubuye kuthuthukiswe izici ezifana nezivalo ezivaliwe namakhava okuvikela avikela izingxenye ezibalulekile othulini nemfucumfucu. Ukunakekelwa okuvamile kanye nokugcotshwa okufanele kwezingxenye ezihambayo nakho kubalulekile ekwandiseni isikhathi sokuphila somshini.

Ukusebenza kahle kwamandla kanye nomthelela wemvelo

Ukusebenza kahle kwamandla kuwukucatshangelwa okubalulekile okukhulayo kubakhiqizi abafuna ukunciphisa izindleko zokusebenza futhi banciphise indawo yabo yemvelo. Imishini yesimanje ye-EDM iklanyelwe ukonga amandla kakhudlwana, enezici ezifana nezindlela zokonga amandla kanye nokunikezwa kwamandla okuphumelelayo. Izindlela zokonga amandla zinciphisa ukusetshenziswa kwamandla ngezikhathi zokungenzi lutho, kuyilapho ukunikezwa kwamandla okusebenzayo kuqinisekisa ukusetshenziswa okuhle kwamandla ngesikhathi sokusebenza komshini. Lezi zici azigcini nje ngokunciphisa izikweletu zikagesi kodwa futhi zifaka isandla enqubweni yokukhiqiza eluhlaza. Ukwengeza, ukukhetha uketshezi lwe-dielectric kungaba nomthelela endaweni yemvelo. I-Eco-friendly dielectric fluids engaboli futhi engenabuthi iyatholakala, enciphisa umthelela wemvelo wenqubo ye-EDM.

Ukucatshangelwa kwezindleko kanye nesabelomali

Ngenkathi ukhetha umshini we-EDM, kubalulekile ukulinganisa ukutshalwa kwezimali kokuqala nezindleko zokusebenza zesikhathi eside kanye nembuyiselo engaba khona ekutshalweni kwezimali. Intengo yemishini ye-EDM ingahluka kakhulu ngokusekelwe ezicini ezifana nohlobo, usayizi, nezici. Izindleko zokuqala zifaka inani lokuthenga, ukufakwa, nanoma yiziphi izinsiza ezidingekayo noma amathuluzi. Kubalulekile ukucabangela izindleko eziphelele zobunikazi, ezihlanganisa ukugcinwa, izinto ezisetshenziswayo, kanye nezindleko zamandla. Imishini enezindleko eziphakeme zokuqala ingase inikeze ukusebenza okungcono, ukuqina, nezindleko zokusebenza eziphansi, okuholela enzuzweni ephakeme yokutshala imali ngokuhamba kwesikhathi. Izinketho zezimali nezinhlelo zokuqashisa nazo ziyatholakala, okuvumela abakhiqizi ukuthi bathole imishini ye-EDM ethuthukisiwe ngaphandle kokutshalwa kwezimali okubalulekile kwangaphambili. Kutuswa ukuhlola izinketho ezahlukene zezimali bese ukhetha evumelana kangcono nesabelomali sakho nemigomo yezezimali.

Izicelo Ezisebenzayo Zemishini Ye-EDM

Imishini ye-EDM iguquguquka futhi ithola izinhlelo zokusebenza kuzo zonke izimboni ezihlukahlukene, ngayinye enezidingo nezinselele ezithile. Ukuqonda lezi zinhlelo zokusebenza kungasiza ekukhetheni umshini ofanele izidingo zakho.

Umkhakha Wezindiza

Embonini ye-aerospace, imishini ye-EDM isetshenziselwa ukukhiqiza izingxenye eziyinkimbinkimbi ngokunemba okuphezulu nokubekezelelana okuqinile. Lokhu kufaka phakathi ama-turbine blades, izingxenye zenjini, nezingxenye zesakhiwo. Ikhono lomshini wokwenza izinto eziqinile njenge-titanium ne-Inconel lenza i-EDM ibe inketho efanelekile yezinhlelo zokusebenza ze-aerospace.

Ukwenziwa Kwedivayisi Yezokwelapha

Ukwenziwa kwemishini yezokwelapha kudinga ukunemba okuphezulu kanye nokuqedwa kahle kwendawo ukuze kuhlangatshezwane nezindinganiso eziqinile zokulawula. Imishini ye-EDM isetshenziselwa ukukhiqiza izinsimbi zokuhlinza, izimila, nezinye izingxenye zezokwelapha. Amandla omshini wezingxenye ezincane, eziyinkimbinkimbi ngokunemba okuphezulu abalulekile kulo mkhakha.

Industry Automotive

Imboni yezimoto isebenzisa imishini ye-EDM ukukhiqiza isikhunta, i-dies, kanye nezingxenye ezinembayo. Le mishini ibalulekile ekwenzeni izingxenye eziyinkimbinkimbi ezinokuphindaphinda okuphezulu nokungaguquguquki. Ikhono lokuphatha izinto ezihlukahlukene, kuhlanganise nezinsimbi eziqinile, kuyinzuzo enkulu ekukhiqizeni izimoto.

Ukwenza Ithuluzi Nokufa

Imishini ye-EDM isetshenziswa kabanzi embonini yamathuluzi kanye nefa ekwakheni isikhunta, i-dies, kanye nezingxenye zamathuluzi. Ukunemba kanye nekhono lokukhiqiza amajiyometri ayinkimbinkimbi kwenza i-EDM ubuchwepheshe obubalulekile kulo mkhakha. Ukusetshenziswa kwama-electrode aphezulu kanye nezinhlelo zokulawula ezithuthukisiwe kuqinisekisa ukukhiqizwa kwamathuluzi anembile futhi anokwethenjelwa.

Ukugcinwa Nokugcinwa Kwemishini Ye-EDM

Ukugcinwa okuvamile nokugcinwa okufanele kubalulekile ukuze kuqinisekiswe ukusebenza kahle nokuphila isikhathi eside kwemishini ye-EDM. Umshini onakekelwa kahle ungaletha imiphumela engaguquki futhi unciphise ingcuphe yesikhathi sokuphumula esingalindelekile.

Ukulungiswa Kwesikhathi Eside

Imisebenzi yokulungisa njalo ihlanganisa ukuhlanza umshini, ukuhlola nokushintsha izinto ezisetshenziswayo, kanye nokugcoba izingxenye ezihambayo. Ukuhlolwa njalo kwezingxenye ezibalulekile, njengama-electrode, izihlungi, noketshezi lwe-dielectric, kuyadingeka ukuze kuqinisekiswe ukusebenza kahle. Ukugcina umshini uhlanzekile futhi ungenayo imfucumfucu kungavimbela izinkinga ezihlobene nokungcola nokuguga.

Ukulungisa Ukuzivikela

Ukunakekelwa okuvimbelayo kuhilela ukuhlolwa okuhleliwe kanye nokuseviswa ukuze kuhlonzwe futhi kulungiswe izinkinga ezingaba khona ngaphambi kokuthi ziholele ekuhlulekeni komshini. Lokhu kuhlanganisa ukuhlola ukuxhunywa kukagesi, ukuhlola izingxenye zemishini ukuthi zigugile, nokulinganisa umshini ukuze ugcine ukunemba. Ukusebenzisa uhlelo lokulungisa lokuvikela kunganweba isikhathi sokuphila komshini futhi kuthuthukise ukwethembeka kukonke.

Ukuthuthukisa kanye nokufakwa kabusha

Njengoba ubuchwepheshe buthuthuka, ukuthuthukisa noma ukufaka kabusha imishini ekhona ye-EDM kungathuthukisa amakhono abo futhi kwandise ukuphila kwayo okusebenzisekayo. Ukuthuthukiswa kungase kuhlanganise ukufaka amasistimu okulawula athuthukile, ukungeza izici ezizenzakalelayo, noma ukufaka izingxenye ezonga amandla. Ukulungisa kabusha kungathuthukisa ukusebenza komshini, kwehlise izindleko zokusebenza, futhi kwandise ukukhiqiza.

Imicabango Final

Kafushane, ukukhetha umshini we-EDM ofanele kuhilela ukucatshangelwa ngokucophelela kwezici ezihlukahlukene, okuhlanganisa ukusebenza, ukusebenza, ikhwalithi yokwakha, kanye nezindleko. Ukuqonda izidingo ezithile zesicelo sakho nokuhlola izinketho ezikhona kungakusiza wenze isinqumo unolwazi. Ukunakekelwa okuvamile kanye nokuthuthukiswa okungenzeka kungathuthukisa ukusebenza komshini nokuhlala isikhathi eside, kuqinisekise imbuyiselo ephezulu ekutshalweni kwezimali.