Unentshisekelo yokufunda ngezisekelo zokuphrinta kwe-FDM 3D? Lesi sihloko sihlola izimiso eziyisisekelo zobuchwepheshe be-FDM futhi sichaza ukuthi kungani kuyinketho esebenzayo nengabizi kakhulu yokwenza i-prototyping esheshayo. Qhubeka ufunda ukuze uthole imininingwane mayelana nobuchwepheshe bakamuva bokuphrinta be-3-dimensional ukuze wenze isinqumo esinolwazi lapho ubheka izinketho zokuphrinta ze-3D.

Okuqukethwe

Imakethe yokuphrinta ye-FDM 3D ekhulayo

Ukuqonda okuphelele kobuchwepheshe bokuphrinta be-FDM 3D

Izinzuzo kanye nobubi bendlela yokuphrinta ye-FDM 3D

Izicelo zokuphrinta kwe-FDM 3D

Imakethe yokuphrinta ye-FDM 3D ekhulayo

Imakethe yokuphrinta ye-3D yomhlaba wonke ibibiza i-US $13.84 ibhiliyoni ngo-2021 futhi kulindeleke ukuthi ikhule ngesilinganiso sokukhula sonyaka esiyinhlanganisela (CAGR) esingu-20.8% phakathi kuka-2020 no-2030. Imakethe ikhule ngenxa yokutshalwa kwezimali okukhulu ku-R&D ekunyatheliseni kwe-3D kanye nesidingo esikhulayo sezicelo ze-prototyping ezimbonini zezimoto, ezokunakekelwa kwezempilo, nezokuvikela.

Ukuphrinta kwe-FDM 3D kukhule ngokuduma eminyakeni yamuva nje ngenxa yokusebenza kwayo okuphezulu ngezindleko eziphansi, konga amabhizinisi afika ku-50% ohlelweni lwawo lwamathuluzi. Ezinye izinzuzo zifaka i-prototyping esheshayo, ukuphrinta okudingekayo, ukuguquguquka komklamo, ukumosha okuncane, nokunye.

Qhubeka ufunda ukuze ufunde mayelana nezisekelo ze I-FDM Ubuchwepheshe be-3D, izici zayo, kanye nezinzuzo zayo ngaphezu kwezinye izindlela zokuphrinta.

Ukuqonda okuphelele kobuchwepheshe bokuphrinta be-FDM 3D

Buyini ubuchwepheshe be-FDM bokuphrinta kwe-3D?

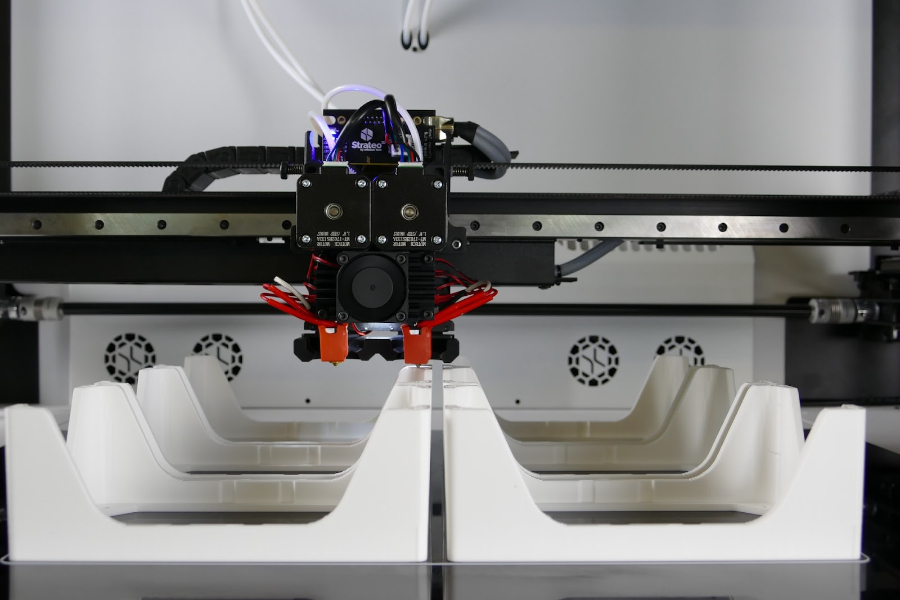

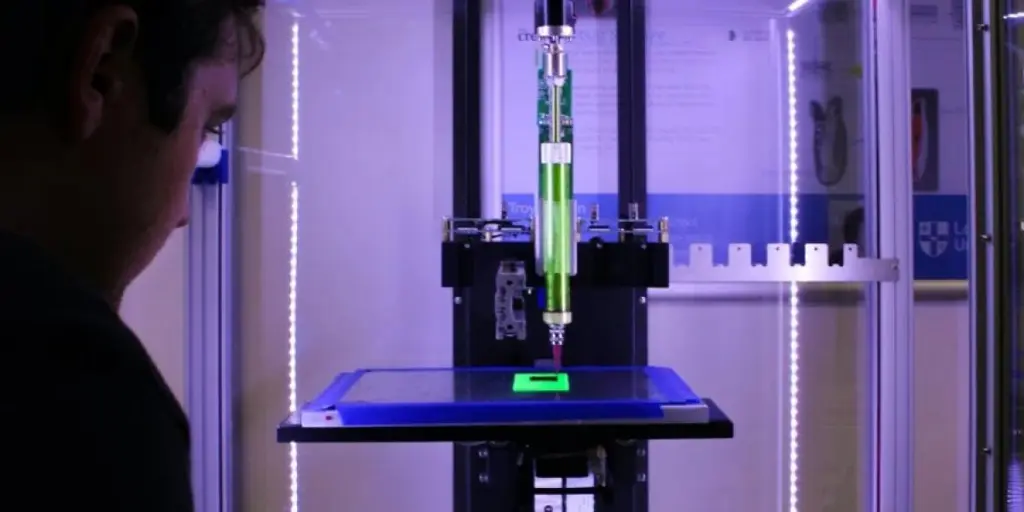

I-Fused deposition modelling (i-FDM) iyindlela yokukhiqiza eyisengezo ebandakanya ukukhipha izinto nge-nozzle nokuzihlanganisa ukuze kukhiqizwe izinto ezinezinhlangothi ezintathu. Uma kuqhathaniswa nokuphrinta kwe-3D kokhonkolo nokudla, inqubo ye-FDM ejwayelekile iyahluka kwamanye amasu okukhipha impahla. Isebenzisa i-thermoplastics njengezinto zokuphakelayo, ngokuvamile ngendlela yama-filaments noma ama-pellets.

Ngokuvamile, i-FDM 3D iphrinta incibilikisa izinto ngokuphusha intambo esekwe kwi-polymer ngokusebenzisa umlomo wombhobho oshisayo; izinto ezisetshenziswayo zibe sezifakwa endaweni yesikhulumi sezendlalelo ze-2D. Lezi zingqimba ekugcineni zihlangana ukuze zakhe izingxenye ze-3D.

Sekukonke, iphrinta ye-FDM iyindlela eshesha kakhulu yokuphrinta kwe-3D futhi iyafinyeleleka futhi iyasebenza. Lawa maphrinta abusa imakethe yokuphrinta ye-3D ngoba kulula ukuwasebenzisa kunamaphrinta e-resin 3D futhi abiza kancane kunozakwabo abasekelwe kumpuphu njenge-SLS.

Bethulwa nini ubuchwepheshe be-FDM?

Nakuba i-FDM njengamanje iyindlela yokuphrinta ye-3D esetshenziswa kakhulu, bekungeyona indlela yokuqala ye-3D eyakhiwe. Eminyakeni embalwa ngemva kokufakwa kwamalungelo obunikazi e-stereolithography (SLA) kanye ne-selective laser sintering (SLS), uScott Crump wahambisa ilungelo lobunikazi lokuqala le-FDM ngo-1989.

Ubuchwepheshe be-FDM babudume kuphela phakathi kwabasebenzisi abangebona abezentengiso, njengezifundiswa eNyuvesi yase-Bath, ababenentshisekelo enkulu yokwakha izisetshenziswa eziziphindaphindayo. Ilungelo lobunikazi le-FDM, nokho, laphelelwa yisikhathi ngo-2009, futhi abantu abaphayona lobu buchwepheshe basungula i-MakerBot Industries ukuze ihwebe nge-3D. amaphrinta.

Ngabe kusebenza kanjani ukuphrinta kwe-FDM 3D?

An I-FDM Iphrinta ye-3D idala izinto ngokufaka izinto zefilament ezincibilikisiwe phezu kwesendlalelo seplathifomu yokwakha ngosendlalelo uze ube nengxenye ephelele. Basebenzisa amafayela edizayini yedijithali alayishwe emshinini ukuze bathole ubukhulu bomzimba. Lawa maphrinta asebenzisa ama-polymers afana ne-PLA, i-ABS, i-PEI, ne-PETG, adluliswa njengezintambo ngombhobho oshisayo.

I-spool ye-thermoplastic filament ilayishwa kuphrinta ukuze kuqaliswe iphrinta. Uma umlomo wombhobho usufinyelele izinga lokushisa olifunayo, umucu udlula ekhanda le-extrusion kanye nombhobho.

Leli khanda le-extrusion lixhunywe kusistimu ye-axis emithathu futhi lingakwazi ukuhamba kuma-eksisi X, Y, kanye no-Z. Umshini ube usukhipha impahla encibilikisiwe ngezitendi ezincane, ubeke ungqimba ngongqimba ekwakhiweni okunqunywe kusengaphambili. Ekugcineni, impahla iyaphola futhi iqine.

Kuthatha amaphasi amaningana ukuqeda iphrojekthi. Inkundla yokwakha iyehla, futhi iphrinta iqala ukusebenza kusendlalelo esilandelayo ngemva kokuqeda isendlalelo sangaphambilini. Kweminye imishini, ikhanda le-extrusion liya phezulu naphansi kuze kuqedwe ucezu.

Yiziphi izici zokuphrinta kwe-FDM 3D?

Nakuba i-FDM 3D amaphrinta ziyahlukahluka ngokuya ngekhwalithi yengxenye kanye namasistimu azo okukhipha ngokuya ngohlobo nemodeli, izici ezimbalwa ziyahambisana kuyo yonke iphrinta ye-FDM.

1. Yakha isivinini kanye nezinga lokushisa

Cishe wonke amasistimu e-FDM avumela abasebenzisi ukuthi bashintshe izinga lokushisa, isivinini sokwakha, isivinini sokupholisa sabalandeli, nokuphakama kwesendlalelo njengoba kudingeka. Lezi zivame ukunqunywa umhlinzeki wesevisi yokuphrinta futhi ziyahlukahluka kuye ngezinto ezibonakalayo.

2. Yakha ivolumu

Ivolumu yokwakha ibhekisela kusayizi wengxenye engenziwa iphrinta. Iphrinta ye-DIY 3D ngokuvamile inevolumu yokwakha engu-200 x 200 mm, kuyilapho umshini wezimboni ungaba nevolumu yokwakha engu-1000 x 1000 x 1000 mm. Abasebenzisi kufanele bacabangele ivolumu yokwakha yephrinta kanye nomklamo wayo ohlongozwayo ngaphambi kokuthenga. Amamodeli amakhulu, nokho, angaphrintwa abe yizingcezu ezincane.

3. Ukunamathela kongqimba

Ekuphrinteni kwe-FDM, ukunamathela okuqinile phakathi kwezingqimba ezifakiwe zengxenye kubalulekile. Isendlalelo esiphrintwe ngaphambilini sihlanganiswe ne-thermoplastic encibilikisiwe iphrinta eyikhipha ngombhobho. Lesi sendlalelo sincibilika ngaphansi kwengcindezi ephezulu kanye nezinga lokushisa, okusivumela ukuthi sihlangane nesendlalelo sangaphambili.

Ukwengeza, ukuma kwento encibilikisiwe kuyashintsha ibe yiqanda njengoba icindezela ungqimba olunyatheliswe ngaphambili. Kungakhathaliseki ukuthi kusetshenziswa luphi ubude bongqimba, izingxenye ze-FDM zihlala zinendawo egagasi, futhi izici ezincane ezinjengezintambo noma izimbobo ezincane zingase zidinge ukucutshungulwa.

4. Ukuphakama kwesendlalelo

Emshinini we-FDM, ukuphakama kwesendlalelo kungaba phakathi kuka-0.02 mm no-0.4 mm. Izingxenye ezibushelelezi ziyakhiqizwa, futhi amajiyomethri agobile athwetshulwa ngokunembile ngobude obungaphansi kongqimba. Ngakolunye uhlangothi, izingxenye zokuphrinta ezinobude obuphezulu bongqimba ziyashesha futhi zingabizi kakhulu. Ubude besendlalelo obungu-0.2 mm ngokuvamile buwukulingana okuhle phakathi kwesikhathi, izindleko, nekhwalithi.

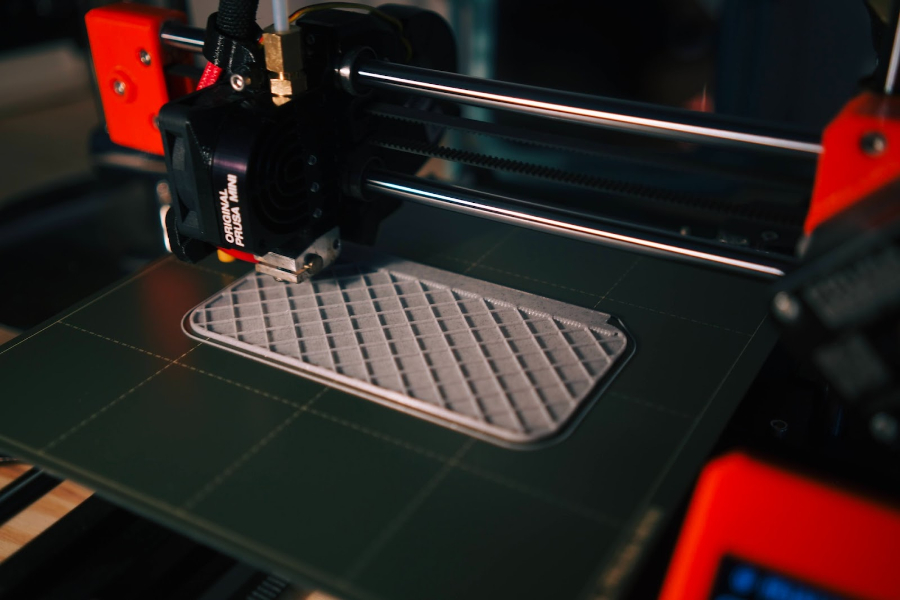

5. Ukugcwalisa nokuqina kwegobolondo

Amaphrinta e-FDM ngokuvamile awakhiqizi izingxenye eziqinile ukuze kusheshiswe isikhathi sokuphrinta nokumosha izinto. Kunalokho, iphrinta ilandelela umjikelezo wangaphandle wegobolondo izikhathi ezimbalwa ngaphambi kokugcwalisa ingaphakathi, okwaziwa ngokuthi i-infill, ngesakhiwo sangaphakathi, esiminyana kancane.

Amandla ezingxenye eziphrintiwe anqunywa ukugcwaliswa nokuqina kwegobolondo. Amaphrinta amaningi edeskithophu e-FDM anomthamo ozenzakalelayo wokugcwalisa ongu-20% nogqinsi lwegobolondo elingu-1 mm. Lokhu kubangela ukulingana okuphelele kwamandla nesivinini sokuphrinta okusheshayo.

6. Ukungqubuzana

I-Warping ingenye yamaphutha e-FDM avame kakhulu- lapho izinto ezikhishwe ziqina, incipha ngosayizi. Ngaphezu kwalokho, izingxenye ezihlukene zengxenye ephrintiwe zipholile ngamazinga ahlukahlukene, futhi ubukhulu bazo bushintsha ngesivinini esihlukile. Ngenxa yokwakheka kwengcindezi yangaphakathi okulethwa yilokhu kupholisa okuhlukile, isendlalelo esingaphansi siya phezulu futhi siyajika.

Nokho, kunezindlela ezihlukahlukene zokuvimbela impi. Enye indlela ukuqapha ngokuseduze izinga lokushisa lesistimu, ikakhulukazi iplatifomu yokwakha kanye negumbi. Isinyathelo sesibili ukuthuthukisa ukunamathela phakathi kweplatifomu yokwakha kanye nengxenye.

Izinzuzo kanye nobubi bendlela yokuphrinta ye-FDM 3D

Izinzuzo

Ukusebenza

- Ngokungafani nezinye izindlela ezifana resin 3D amaphrinta, FDM amaphrinta ingalinganiswa kalula kunoma imuphi usayizi, okuwukuphela kwemikhawulo kube ukunyakaza kwegantry ngayinye.

- Ngokuphathelene nezinto zokunyathelisa, imicu ye-FDM iyathengeka, ikakhulukazi uma kuqhathaniswa nezinto ezidingekayo kwezinye izindlela, njenge-SLS nokuphrinta kwe-resin.

- Uma kuqhathaniswa nezimbangi zabo, amaphrinta e-FDM avumelana nezimo. Ngokuthuthukiswa okumbalwa kuphela nokuguqulwa, bangaphrinta ububanzi obubanzi bezinto ze-thermoplastic, okungenakwenzeka ngezinye izindlela lapho impahla kufanele ibe yi-resin noma impushana emihle.

Ikhwalithi yokuphrinta

- Iphrinta ye-FDM iyavumelana nezimo futhi ingamukela izinto ezihlukile ze-FDM. Ingakha izingxenye ezinezakhiwo ezihlukene kanye nokubukeka ngokushintsha uhlobo lwefilament.

- Ikhwalithi yokuphrinta ayibhekiseli ekubukekeni kuphela kodwa nasekusebenzeni kwayo ngomshini. Uma kuqhathaniswa nokuphrinta kwe-3D resin ebuthakathaka, i-FDM ikhiqiza izingxenye eziqinile neziqinile.

- Amaphrinta e-FDM nawo asebenza ngezindlela ezihlukahlukene ukuthi ikhwalithi yokuphrinta inganikelwa ngenxa yesivinini kanye nobuciko, okuwenza abe ithuluzi elikahle lokudala izingxenye ezibukeka kahle nezisebenzayo.

Okumbi

- Ukuphrinta kwe-FDM 3D kulungele kangcono ukukhiqizwa kwezingxenye ezinosayizi omncane, kodwa imikhiqizo eqediwe kungenzeka ibe nezindawo ezimbi futhi idinga ukucutshungulwa kwangemuva ukuze ibe nesiphetho esishelelayo.

- Ngenxa yokuthi amaphrinta e-FDM abeka isendlalelo se-filaments ngokwesendlalelo, ajwayele ukuphuka, okwenza ukuphrinta kube yi-anisotropic.

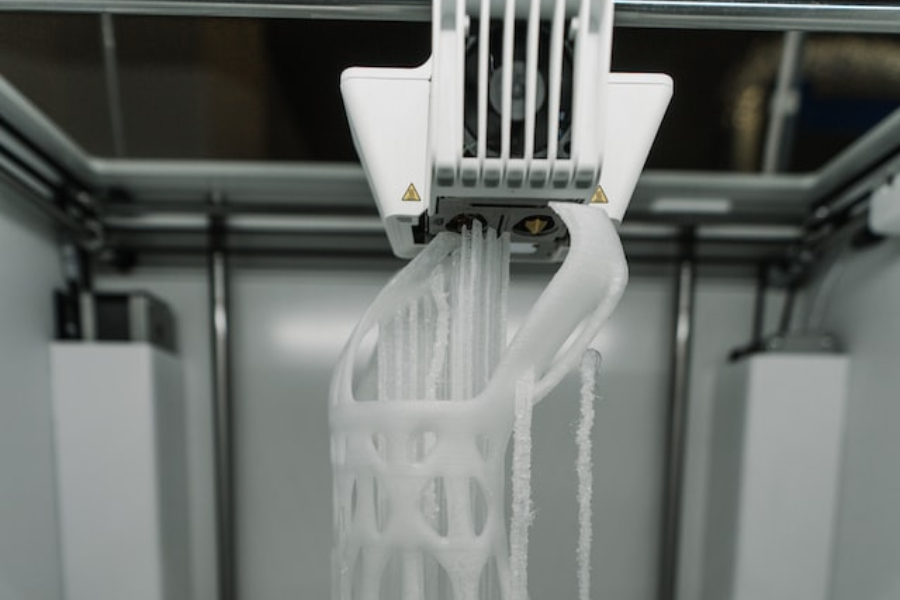

- Ukuphrinta kwe-FDM kudinga ukusetshenziswa kwezakhiwo zokusekela, ezingakhuphula izindleko.

Izicelo zokuphrinta kwe-FDM 3D

Ukumodela kwezakhiwo: Amaphrinta e-3D asetshenziswa kakhulu ukudala amamodeli ezakhiwo ngoba ayashesha futhi ashibhile kunezindlela ezijwayelekile. Umqulu owodwa we-filament ungakhiqiza amamodeli amathathu kuya kwamane, ukonga izindleko.

Ukukhiqizwa kwezimoto: Ukuphrinta kwe-3D kuvame ukusetshenziselwa ukuklama isakhiwo sangaphakathi semoto. Abasebenzisi bangakha izilinganiso ezinembile zokukhiqiza izimoto besebenzisa isofthiwe ye-3D.

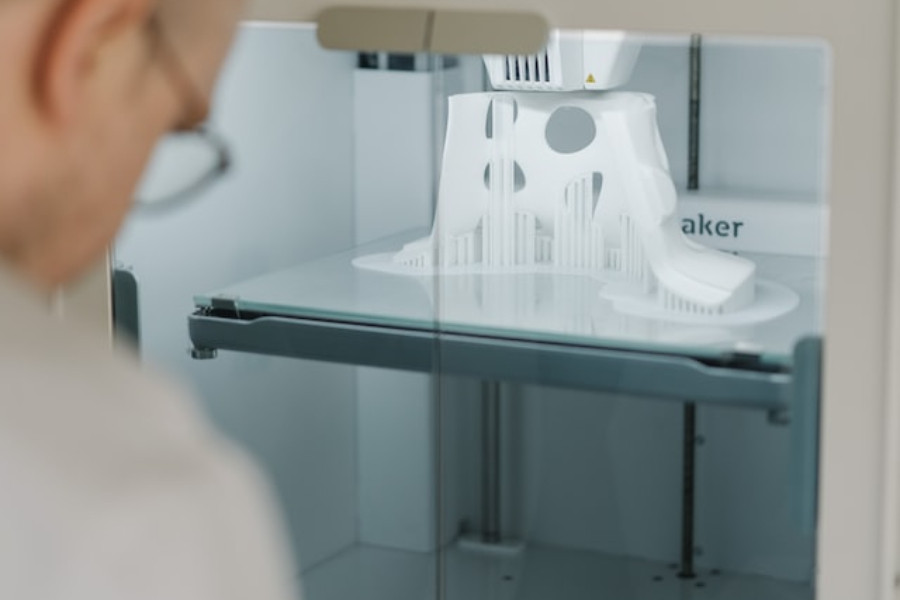

Amamodeli okuhlinza: the I-FDM Ubuchwepheshe be-3D buye benza odokotela bakwazi ukuhlela kangcono ukuhlinza ngokubanikeza izitho eziwumfanekiso wesiguli. Zinesakhiwo esinembile, zingenziwa ziqine noma zingabi nalutho, futhi zinganyatheliswa ngamahora.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu