Iziteshi zokudayisa zibhekelela izidingo eziningi ezibalulekile embonini yokukhiqiza izinto zikagesi. Ziye zavela eminyakeni edlule ngokuhambisana nentuthuko yezobuchwepheshe. Ezinye iziteshi ze-soldering zingasetshenziswa futhi njengamathuluzi e-desoldering futhi zingabandakanya izandiso ezikhethekile ukwenza imisebenzi yonke ibe lula. Qhubeka ufunda ukuze uthole okwengeziwe mayelana nezingxenye ezibalulekile zeziteshi zokunamathisela.

Okuqukethwe

Ukuhlaziywa kwemakethe yeziteshi zokunamathisela

Yini isiteshi sokudambisa?

Izinhlobo zeziteshi zokunamathisela

Yini okufanele icatshangelwe lapho ukhetha iziteshi zokunamathisela

Isiphetho

Ukuhlaziywa kwemakethe yeziteshi zokunamathisela

Imakethe yemishini yokuthengisa kulindeleke ukuthi ikhule ku-CAGR ye 9.56% ukuze kufinyelele ku-USD 911.3 million ngo-2030. I-Soldering isetshenziswa ezimbonini ezihlukahlukene, ezihlanganisa ezezimoto, ezokwelashwa, izinsimbi zomculo, amaselula, namakhompyutha. Ukukhula ngesivinini kwemboni ye-elekthronikhi kusize ukuthuthukiswa kwemakethe yeziteshi zokubethela kanye nezinsiza.

Ukukhula kungase kubangelwe ukuthuthuka kwezimboni ngokushesha kanye nokusetshenziswa kwezithuthukisi i-soldering ezinhlotsheni ezahlukene zemishini. Abadlali abahamba phambili emakethe yi-Weller Tools, i-Kurtz Holding, ne-Jameco Electronics, phakathi kwabanye, kanti isifunda sase-Asia Pacific kulindeleke ukuthi sibe yimakethe enkulu kunazo zonke.

Yini isiteshi sokudambisa?

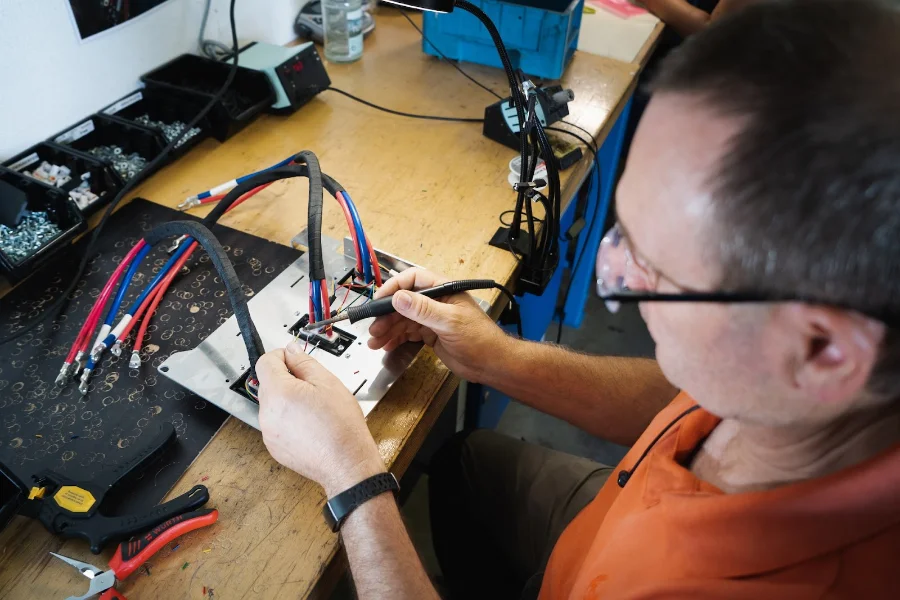

Isiteshi se-soldering iyisisetshenziswa se-elekthronikhi esisetshenziselwa ukuthengisa izinto ze-elekthronikhi ebhodini lesekethe eliphrintiwe (PCB). Iza nesici sokulawula izinga lokushisa kanye ne-solder iron iron. Iningi le-soldering Iziteshi zinezilungiselelo zokulawula izinga lokushisa futhi zisetshenziswa ngokuyinhloko ekuhlanganiseni kukagesi kwe-PCB nezitshalo zokukhiqiza. Zibuye zisetshenziselwe ukulungisa izinto zikagesi kanye nokulungisa kabusha amabhodi esekethe.

Ngaphambi kokuthi siqhubekele phambili, ake sibheke iziteshi zokunamathisela ezihlukene futhi sixoxe nezici zazo kanye nezicelo.

Izinhlobo zeziteshi zokunamathisela

Xhumana neziteshi zokunamathisela

Lezi yizinhlobo ezidume kakhulu ze-soldering isiteshi futhi ihluke kancane kunezinketho zendabuko. Nokho, ezinye izici zingathuthukiswa—njengoba zingakwazi ukulungisa izinga lokushisa le-heater, ngokuvamile zishisa kakhulu isici sokuzwa. Iziteshi ezixhumene nazo zineyunithi yokuphakela amandla edidiyelwe futhi zingashisisa kufika ku-400°C.

Abasebenzisi bangashintsha izinga lokushisa lokushisisa ngokulungisa i-voltage yento yokushisisa ngeyunithi yokuphakela amandla. Ezimweni eziningi, izinga lokushisa elifanele le-solder liphakathi kuka-250°C no-330°C.

Iziteshi zokudambisa umoya oshisayo

Isiteshi se-soldering somoya oshisayo sifakwe i-compressor eyenza ukugeleza komoya, okushiselwa ezingeni elithile lokushisa. Lokhu kugeleza komoya okukhiqizwa isibhamu sokushisa kuqondiswe endaweni yokunamathisela. Njengoba kunamaphedi okushisa amaningana atholakalayo, lesi yisisombululo esihle kakhulu sokunamathisela endaweni elinganiselwe.

Asetshenziswa kakhulu ukulungisa omakhalekhukhwini nezinye izinto zasendlini. Lokhu solder isiteshi ihambisana nakho kokubili okunomthofu kanye nama-alloys angenawo umthofu. Nokho, ukusetshenziswa kwayo kulinganiselwe. Ngokwesibonelo, ngeke isetshenziselwe solder noma desolder BGA chips ezinkulu.

Iziteshi ze-Digital ne-analog soldering

Iziteshi zokubethela zedijithali zivumela abasebenzisi ukuthi balawule izinga lokushisa ngezilungiselelo zedijithali. Zinesibonisi sedijithali esibonisa izinga lokushisa elimisiwe futhi sinikeza ukunemba okukhulu nokubekezelelana. Futhi zibiza kancane kuneziteshi zokunamathisela ze-analog.

Ngakolunye uhlangothi, i-analogue i-soldering iziteshi zifakwe ifindo lokulawula izinga lokushisa. Ngokungafani nozakwabo bedijithali, abanaso isikrini sokubonisa izinga lokushisa elimisiwe. Ngaphezu kwalokho, izilungiselelo zezinga lokushisa azinembile kakhulu. Zifanele imisebenzi emincane efana nokulungiswa kweselula, phakathi kwezinye izinto.

Ama-anti-static soldering iziteshi

Iziteshi zokudayisa zingaba yi-ESD (i-electrostatic discharge) ephephile noma cha. Ishaja emile ku-ayina ngeke inqwabelane eziteshini eziphephile ze-ESD, njengoba amandla kagesi engeziwe azokhishelwa ngokushesha emhlabathini. Imishini eminingi yesimanje kagesi, njengama-smartphones, idinga i-ESD-safe soldering Iziteshi ngoba aqukethe izakhi ze-elekthronikhi ezizwelayo kugesi omile futhi zingalimala kalula.

Iziteshi zokunamathisela eziholayo nezingenamthofu

Izinkampani eziningi ezikhiqizayo ziphendukela kuzinketho ezingenamthofu. I-solder engenamthofu Iziteshi zisebenza ngendlela efanayo nozakwabo bendabuko kodwa ziyahlukahluka kumandla wesici sokushisisa, asukela ku-75-80 W kuya ku-150-160 W. Indawo encibilikayo yocingo lwe-solder olungenamthofu ngu-217°C kuya ku-221°C, kanti leyo yentambo yokudayisela umthofu ingu-183°C.

Ngakho-ke, isiteshi se-soldering esinamandla aphuma ku-50 W kuya ku-60 W singaphezu kokwanele ukuthungatha i-lead solder wire. Kodwa-ke, isiteshi sokunamathisela esinamandla siyadingeka ukuze kufakwe i-lead-free soldering.

Yini okufanele icatshangelwe lapho ukhetha iziteshi zokunamathisela

Ukulawula ukushisa

I-solder eguquguqukayo isiteshi ngebanga lokushisa elibanzi liyadingeka ukuze usebenze kumaphrojekthi ahlukene. Imisebenzi ethile kuzoba nzima ukuyiqeda uma iyunithi inezinga lokushisa elilinganiselwe. Ngakho-ke bheka izinketho eziguquguqukayo nge-thermostat evala ngokuzenzakalelayo i-heater uma isifinyelele izinga lokushisa alimisile.

I-thermostat iyasiza ngoba ivumela abasebenzisi ukuthi balungise izinga lokushisa libe linani elidingwa yiphrojekthi. Uma lesi sici sishoda, insimbi izoqhubeka nokushisa kuze kube yilapho iswishi ye-PTC iyivala, okungenzeka inganikezi ukushisa okwanele kumaphrojekthi athile. Enye into okufanele icatshangelwe uma kuziwa ekushiseni ukuhambisana. Uma isifinyelele izinga lokushisa elifunekayo, isiteshi sokunamathisela esifanelekile kufanele sikwazi ukugcina izinga lokushisa ngokungaguquki.

wattage

Nakuba amanzi ehluka phakathi kwamamodeli, ukukhetha idivayisi okulula ukuyisebenzisa futhi enebanga lokushisa elibanzi kubalulekile. Amanye amadivaysi asebenzisa i-40 W, kanti amanye asebenzisa kufika ku-80 W. Uma uhlola i-soldering isiteshi, umthetho wesithupha uwukuthi i-wattage ephakeme yenza imisebenzi eyinkimbinkimbi ibe lula kakhulu ukuyiqeda.

Ukuthola kabusha okushisayo

Kungcono ukukhetha iziteshi ze-soldering ezinokubuyiselwa okuphezulu kokushisa, ikakhulukazi ukuhlanganisa njalo. Iziteshi ze-soldering ezinokululama okushisayo okuphansi zidala izinkinga ezifana namajoyinti abandayo e-solder. Ngokuphambene, isici sokubuyisa ukushisa sizokwazisa isiteshi sokunamathisela ukuthi kuthatha isikhathi esingakanani ukuthi ithiphu yokunamathisela ifinyelele izinga lokushisa elifunekayo.

I-Soldering iron amathiphu

Izinsimbi ezisongelwayo zinamacebiso ashintshashintshayo kushizolo kanye nokwakheka kwe-conical futhi ngokuvamile enziwe ngethusi ne-nickel solder. Atholakala ngamasayizi ahlukahlukene futhi angasetshenziswa ukuqedela imisebenzi ehlukene. Amathiphu e-solder angathinta ukuthi uthengisa kahle kangakanani, nethiphu ngayinye inezinzuzo zayo kanye nokubi. Ngakho-ke, ngaphambi kokuthenga ithiphu le-soldering, cabangela ukuhambisana kwayo ne-soldering isiteshi.

Ngaphandle kokuhambisana, enye into okufanele icatshangelwe ukuma kwethiphu. Ithiphu yeshizolo ilungele abaqalayo ngoba inendawo eyisicaba okulula ukuyibamba nokuyisebenzisa. Amathiphu enselo ayisinqumo esihle kakhulu kubasebenzisi abathuthukile kanye namaphedi okukhweza angaphezulu okuhudula. Zinhle kakhulu kumaphrojekthi e-soldering ayinkimbinkimbi, ikakhulukazi uma esetshenziswa nesiteshi sokunamathisela esifanelekile. Phakathi kwazo zonke izinhlobo zamathiphu, amathiphu angama-conical anzima kakhulu ukuwasebenzisa kodwa futhi anembe kakhulu.

Esinye isici okufanele sicatshangelwe yizinto zamathiphu e-soldering. I-ayoni ishibhile kakhulu futhi iqinile kodwa ayikwazi ukugcina noma ukudlulisa ukushisa ngokuphumelelayo njengamathiphu ethusi. Izeluleko ezisezingeni eliphezulu ze-solder zine-tip yethusi eboshwe ngensimbi, enikeza inketho enekhono kakhulu.

Maintenance

Lapho usebenzisa i-soldering isiteshi, kubalulekile ukuhlola ukuthi izingxenye ezisele zingatholakala kalula yini. Nakuba i-soldering iron ingasetshenziswa iminyaka eminingi, izinsimbi ze-iron soldering zinesikhathi esifushane sokuphila futhi zingadinga ukushintshwa ngezikhathi ezithile, kuye ngokusetshenziswa.

Isiphetho

Njengoba kuxoxiwe ngaphambili, iziteshi zokunamathisela zinawo wonke amathuluzi adingekayo ukuze usebenze kumasekethe futhi ulungise. Imakethe igcwele izinketho ezahlukene zesiteshi sokuthengisa, futhi lesi sihloko sicwebezela izinhlobo ezinkulu, izici zabo zokusebenza, kanye nezicelo zazo. Vakashela Chovm.com ukuze uhlole amadivaysi akamuva e-solder atholakalayo namuhla.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu