Ukukhetha i-spot welder efanele kubalulekile ebhizinisini eliphumelelayo lokushisela. Ama-Spot welder aklanyelwe ukuhlanganisa izingxenye ezimbili zensimbi noma ngaphezulu ndawonye endaweni eyodwa kusetshenziswa ukushisa nokucindezela.

Kodwa-ke, ukukhetha i-welder yendawo efanele kungaba inselele. Ngenxa yalokho, lesi sihloko sizohlanganisa izinhlobo ezitholakalayo nezici okufanele zicatshangelwe lapho uthenga umshini wokushisela indawo. Ngalo mhlahlandlela, amabhizinisi angakwazi ukwenza isinqumo enolwazi futhi athole i-spot welder esebenza kangcono kakhulu ezinhlelweni ezahlukene.

Okuqukethwe

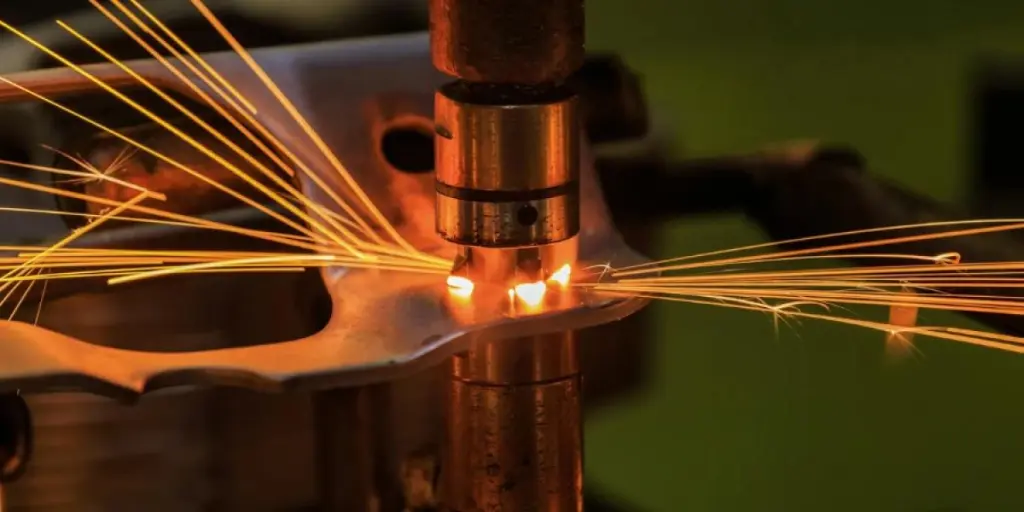

Uhlolojikelele lwemakethe yomhlaba wonke yabashiseli bendawo

Amathiphu okukhetha ama-spot welder

Izinhlobo zokushisela amabala

Isiphetho

Uhlolojikelele lwemakethe yomhlaba wonke yabashiseli bendawo

Imakethe yomhlaba wonke yabashiseli bendawo ibifaneleka US $ 2.53 billion ngo-2018, kanti lesi sibalo kulindeleke ukuthi sifinyelele ku-US $ 27.22 billion ngo-2030, sikhule ku-CAGR ka-7.6%.

Abashayeli abakhulu benkambiso yokukhula baqubuka esidingweni sezixazululo ezandisa izinga lokukhiqiza ezimbonini.

Izizathu ezengeziwe eziholela kusayizi wemakethe enkulu ukusetshenziswa okwandisiwe kwemishini ukushisela ngokuphepha nokuthuthuka kwezobuchwepheshe.

Amathiphu okukhetha ama-spot welder

Welding ukujiya

Lapho ukhetha i-welder yendawo, ukucabangela ubukhulu be-welding kubalulekile. Ukuhlola imininingwane yomshiseli kusiza ukuqonda ukuthi izifanele yini izinsimbi ezincane noma eziwugqinsi.

Ugqinsi lwe-welding luthonya inani lamanje, i-voltage, nesikhathi isishishi esizosidinga ukuze sishisele izingcezu ezimbili ndawonye ngendlela efanele. I-spot welder enezinto ezincane eziphumayo ifanela ukushisela ndawonye izinsimbi ezizacile, kuyilapho i-spot welder ephumayo ifanela izinsimbi ezishiselayo ezinkulu.

Ngakho-ke abasebenzisi kufanele baqaphele futhi bathole kuphela a umshiseli wamabala iyahambisana nobukhulu bensimbi abayishiselayo. Ukukhetha i-welder engahambelani kungenza ama-weld arcs ekhwalithi embi noma kulimaze insimbi.

Okukhipha amandla

Amandla okukhipha amandla e-spot welder inquma ukushuba kwezinto engazishisela. Ukukhipha amandla aphezulu kuzovumela ukushiselwa kwezinto eziwugqinsi, kuyilapho ukuphuma kwamandla aphansi kuzovumela kuphela ukushiselwa kwezinto ezincane.

Kubalulekile futhi ukucabangela izinhlobo zezinto ezishiselwe, njengoba ezinye izinto zingase zidinge ukuphuma kwamandla aphezulu kunezinye. Ukwengeza, ukuphuma kwamandla aphezulu kungasiza ekuqinisekiseni ukushisela kwekhwalithi ephezulu futhi kunciphise ubungozi bokushisela okungalungile. Ukukhetha i-spot welder enamandla okukhipha amandla afanele kubalulekile ukuze usize abathengi bathole ukushisela kwekhwalithi.

Temperature uhla

Lapho ukhetha i-welder, kubalulekile ukucabangela izinga lokushisa lohlobo lwensimbi oluzoshiselwa. Isibonelo, i-welder enebanga lokushisa eliphezulu iyadingeka ukuze ushise izinsimbi eziqinile njenge-titanium. Ngokuphambene, a welder ngebanga lokushisa eliphansi lilungele ukushisela izinsimbi ezithambile njengensimbi engagqwali. Ngaphezu kwalokho, abasebenzisi kufanele bacabangele usayizi wensimbi kanye nokuma ukuze baqinisekise ukuthi ukushisa kusakazwa ngokulinganayo lapho kushiselwa.

umthombo Power

Uhlobo lomthombo wamandla osetshenzisiwe luchaza ubukhulu nomthamo wendawo umshini wokufaka insimbi ukuthenga. Umshini onikwe amandla umthombo wamandla we-amperage ephezulu uzoba namandla okushisela anamandla futhi ngaleyo ndlela ube namandla aphezulu wokushisela izinto eziwugqinsi. Ngakolunye uhlangothi, umshini onikwe amandla umthombo wamandla we-amperage ephansi uzoba namandla okushisela aphansi futhi ungase ungasebenzi kahle ekushiseleni izinto eziwugqinsi.

Umthombo wamandla uphinde ube nomthelela kusayizi nesisindo somshini. Isibonelo, umshini onikwe amandla umthombo wamandla obalulekile uzoba mkhulu, kanti umshini onomthombo wamandla omncane uzoba minyene kakhulu. Uhlobo lomthombo wamandla luzophinde lunqume izindleko ze- umshini kanye nokugcinwa kwawo. Ama-Spot welders asebenzisa amandla aphezulu anezindleko zokuqalisa kanye nezokulungisa eziphezulu kunemishini enomthombo wamandla osezingeni eliphansi.

Izinketho zokulawula

Lapho uthenga indawo yokushisela, kunezinketho ezimbalwa zokulawula okufanele uzicabangele. Okokuqala, thola ukuthi ingabe abasebenzisi badinga imanuwali, i-semi-automatic, noma i-automatic spot welder. Abashisela bamabala okwenziwa ngesandla badinga ukuthi umsebenzisi aziqalele mathupha inqubo yokushisela, kuyilapho ezenzakalela kancane futhi abashiseli abazenzakalelayo ziyahleleka ukuthi zishise ngaphandle kokufaka okuqondile komsebenzisi.

Bese, cabanga uhlobo lwesixhumi esibonakalayo sokulawula. Abashisela okwenziwa ngesandla ngokuvamile banenkinobho yokushintsha noma yokusunduza kuyilapho abashiseli abazenza kancane nabazenzakalelayo bangasebenzisa i-pedal yonyawo, isibonisi sedijithali, noma isilawuli esihlelekayo.

Abathengi kufanele bahlole ukuthi i-welder inikeza izici zamanje kanye ne-voltage control. Ama-spot welders angathengeka ngezilungiselelo ezimisiwe zamanje kanye ne-voltage noma izilungiselelo ezilungisekayo ukuze umsebenzisi akwazi ukushintsha yamanje kanye ne-voltage njengoba kudingeka.

Izilawuli zezici zokuphepha ze-welder zibalulekile. Ama-spot welder amahle azoba nezici ezihlukahlukene zokuphepha, njengokunqanyulwa kwe-thermal, ukuvikelwa kwamandla kagesi aphansi, nokuvikela ukugcwala kakhulu. Zonke lezi zici zenza kube lula ukuthola i-spot welder enezinsizakalo ezithembekile.

Izinto ezisebenzayo

Lapho uthenga indawo yokushisela, kubalulekile ukuthi ucabangele izinto ezifanele ngaphambi kokuthenga. Ama-spot welder ahlukene aklanyelwe ukusebenza ngezinto ezihlukene, futhi ukukhetha uhlobo olungalungile lwe-welder kungaholela ekwehleni kwekhwalithi yejoyinti elishiselwe ngisho nokuhluleka ngokuphelele. Isibonelo, i-spot welder yensimbi emnene ayifanele ukushisela isiliva noma i-magnesium.

Izinhlobo zokushisela amabala

Umshini wokushisela we-resistance butt/upset

Abashiseli bezinqe zokuphikisa basebenzisa inqubo yokushisela ehamba kancane ehlanganisa ukusebenzisa igagasi eliqhubekayo phakathi kwezingcezu ezimbili zensimbi isikhathi eside. Umshini uvame ukusetshenziselwa ukushisela izingcezu zensimbi ezinkulu lapho kufunwa izinga eliphezulu lamandla.

buhle

- Ziyakwazi ukwenza izinto ezihlukahlukene.

- Zilungele ukugijima kokukhiqiza okuphezulu.

– Awongayo.

- Bakhiqiza ama-welds aqinile angakwazi ukumelana nokucindezeleka okukhulu namazinga obunzima.

bawo

- Zidinga ukunakekelwa okujulile, okujwayelekile.

– Ikhwalithi yokushisela ingase ithintwe ukujiya nobukhulu bensimbi.

Umshini wokushisela izinqe ze-Flash

Ama-flash welders asebenzisa amandla kagesi aphezulu adlula phakathi kwezingcezu ezimbili zensimbi ukuze azishisele ngokushesha kakhulu kunezinye izindlela. Imishini ifanele ukusetshenziswa lapho kudingeka khona isibopho esisheshayo nesiqinile kanye nokushisela izinsimbi ezizacile.

buhle

- Bakhiqiza ama-welds aqinile ngokushesha.

- Ziyakwazi ukwenza izinto ezihlukahlukene.

- Ayaguquguquka ekukhiqizeni ama-welds ekhwalithi ephezulu.

bawo

- Banikeza ukuphatheka okulinganiselwe njengoba benganyakazi.

– Anamazinga aphezulu okusebenzisa amandla.

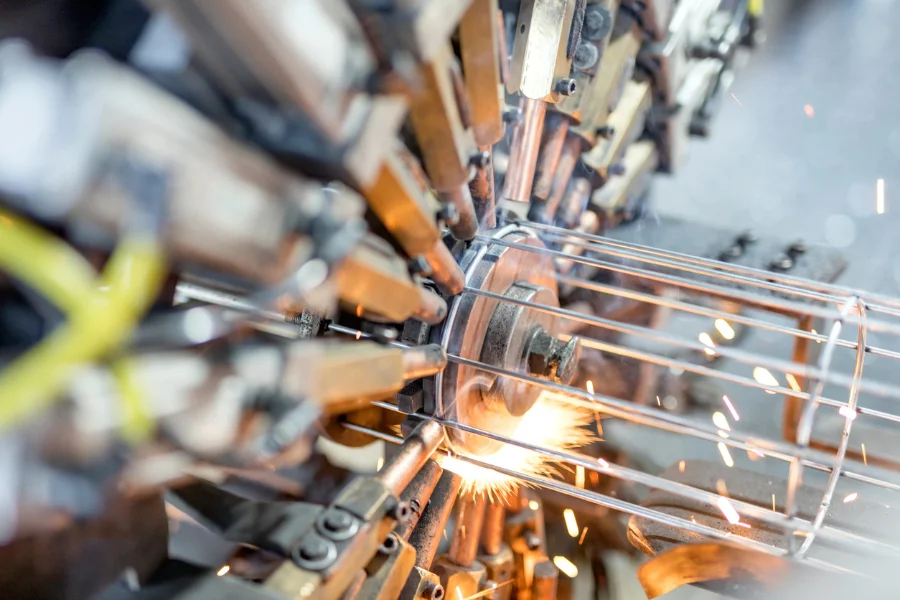

Umshini wokushisela umthungo

A umshini wokushisela umthungo iwumshini wokushisela okhethekile owakha ukushisela okuqhubekayo, okulinganayo kumashidi ensimbi. Kungumshini wokushisela indawo yokumelana ofanele ukushisela amashidi ensimbi azacile ndawonye ngaphandle kokudinga izinto ezixutshwayo noma zokugcwalisa.

buhle

- Bahlinzeka ngokushisela okunembile futhi okunembile, okubenza bafanele amaphrojekthi amaningi okwenziwa.

– Bangakwazi ukwakha izinhlobonhlobo zezinsimbi.

- Bangakwazi ukukhiqiza ama-welds aqinile njalo.

bawo

- Ukuze bathole izinga eliphezulu lokunemba, badinga ukunakekelwa okuningi.

- Ukusebenzisa imishini kudinga ukuqonda okuningi kwamasu okushisela kanye nemingcele.

Isiphetho

Ama-Spot welders angaba utshalomali oluhle kuwo womabili amabhizinisi amasha nanolwazi emkhakheni wokushisela. Lo mhlahlandlela ubonisa izinhlobo zokushisela amabala nokuthi yiziphi izici okufanele zicatshangelwe lapho ukhetha imishini ethembekile. Ngakho-ke izinqubo zokushisela kufanele zibe bushelelezi lapho usebenza nabashiseli bendawo abathembekile.

Futhi funda: Umehluko Phakathi kwe-MIG ne-TIG Welding