Ngalesi sikhathi se-Industrial 4.0, ukwenziwa kwedijithali kwenguquko yezezimboni yesithathu kuhlanganiswa nezinhlelo ezihlakaniphile nezizimele kanye nokufunda kwedatha nokufunda kwemishini ukuze kulethe iminyaka engakaze ibonwe ekuzishintsheni kwezimboni.

Kulesi sihloko, sizodlula amathrendi angu-7 abalulekile azobe ebumba i-automation yezimboni. Lezi zindlela zizonikeza abathengi ukuqonda lapho imboni iphokophele khona nokuthi yini abathengi abazoyifuna ukuze bathuthukise ukusebenza kwabo.

Okuqukethwe:

Uhlolojikelele lwemakethe yezimboni ezishintshayo

Amathrendi aphezulu abumba i-automation yezimboni

Inkathi entsha ye-industrial automation

Uhlolojikelele lwemakethe yezimboni ezishintshayo

Ubukhulu bemakethe ye-automation yezimboni yomhlaba wonke bukhombise amathemba amahle esikhathini sokubikezela sika-2020-2025. Ngokuvumelana ne Isitatimende, imakethe kulindeleke ukuthi ikhule ngenani lisuka ku-US $ 175 billion ngo-2020 liye emalini elinganiselwa ezigidini eziyizinkulungwane ezingama-265 ngo-2025.

Ikhula ngesilinganiso sokukhula sonyaka esihlanganisiwe (CAGR) sika-9%, imakethe ikhombisa izinkomba eziqinile zokukhula okuqhubekayo. Ngisho naphezu kwenhlekelele yezempilo emhlabeni wonke kanye nomphumela wokuphazamiseka kwe-supply chain, kunezimpawu zokubuyela emuva kwemakethe.

I-Fortune Business Insights ithole ukuthi abashayeli ababalulekile ekukhuleni kwemakethe ukufika kobuchwepheshe be-5G obuhlanganiswe nokukhuphuka kokwamukelwa kwe-Industry 4.0 phakathi kwamabhizinisi.

Amathrendi aphezulu abumba i-automation yezimboni

Manje njengoba sesinombono wayo yonke imakethe ye-automation yezimboni yomhlaba wonke, singakwazi ukuhlola izitayela ezibalulekile ezizoba nomthelela ekuqondeni komkhakha wokukhiqiza wonkana.

1. I-inthanethi Yezimboni Yezinto

I-Industrial 4.0 izobona ukuhlangana kobuchwepheshe bolwazi kanye nobuchwepheshe bokusebenza (i-IoT convergence) ezingeni elizodala uguquko lwedijithali olungakaze lubonwe ngaphambili. I-Industrial IoT izosiza ukuxhuma izimpahla zezimboni zamabhizinisi ngendlela esobala, elula, futhi ekhulisa umkhiqizo. Amabhizinisi azokwazi ukwenza lula isofthiwe yawo yaphansi yezitolo kuwo wonke umjikelezo wempilo futhi andise ukusebenzisana nokuvumelana nezimo zokusebenza kwawo.

Imboni yezokukhiqiza emhlabeni wonke kulindeleke ukuthi yonge ama-US $ 500 wezigidigidi minyaka yonke ngenxa ye-automation eqhutshwa yi-IoT. I-IoT iyakwazi ukusiza izimboni zibone ukungasebenzi kahle okumoshayo, zivikele ukwehluleka kwemishini, futhi ziqinisekise ikhwalithi yomkhiqizo. Ukuphendula Inhlolovo ye-RT Insight, izinzuzo ezicashunwe kakhulu ngabamukeli be-IoT yezimboni zifaka:

- Ukwehliswa kwezindleko zokusebenza (53%)

- Ukuthuthukisa ukuqoqwa kwedatha (48%)

- Ukwandisa imali engenayo evela emifudlaneni ekhona (42%)

I-Artificial intelligence (AI) izophinde ibe yingxenye ebalulekile ye-Industrial IoT njengoba izixazululo eziningi zezimboni zizosebenzisa ukuhlaziya okuthuthuke kakhulu kanye ne-edge and cloud computing ekuhlaziyeni idatha yomshini wabo.

Imininingwane Yasemakethe Yesikhathi Esizayo amaphrojekthi ukuthi imakethe yomhlaba wonke ye-AI ku-IoT, okwamanje enenani lamaRandi ayizigidi eziyizinkulungwane ezingama-78, izofinyelela ezigidini ezilinganiselwa ku-US$ 142.4 ngo-2032. Lokhu kukhula kuyaqondakala uma kucatshangelwa ukuthi ukufunda ngomshini (okuyi-subset ye-AI) kanye ne-IoT kunika amandla amabhizinisi ukwenza izibikezelo zokusebenza Izikhathi ze-20 ngokushesha kunobuchwepheshe bendabuko futhi inikeza ukunemba okuphakeme.

2. Shift usuka kokuzenzakalelayo uye kokuzimela

Intuthuko eyenzekile ekusetshenzisweni kwedijithali okumataniswe namazinga amasha okuzenzakalela kwenqubo evulekile inikeze abakhiqizi ithuba lokushintsha imisebenzi yabo isuke kokuthi “okuzenzakalelayo” iye “kokuzimela.”

Nge-AI kanye nedatha yomshini, ukuhlangana kwe-Industrial IoT okukhulunywe ngakho ngenhla kanye noguquko lwedijithali lwenza abakhiqizi bakwazi ukudala amasistimu azimele akwazi ukwenza izinqumo ezibalulekile zokukhiqiza noma zokusebenza kuyilapho abantu bemane besebenza njengababonisi.

Amasistimu azimele embonini yezimoto yase-US alinganiselwa ukuthi ahlinzeka ngokonga okuphelele konyaka okufika kokufika US$1 trillion, okuzoba nomthelela omkhulu emnothweni. Izitshalo ezisebenzayo zizokwazi ukuthuthukisa ngokuphawulekayo ukwethembeka nokubikezelwa kokusebenza kwazo. Imishini izokwazi ukuqeqeshwa ngedatha ebalulekile yomlando ehlanganiswe nedatha yesikhathi sangempela kanye nezinhlelo zokusebenza ezinikwe amandla i-AI ukuze ekugcineni kukhuliswe ukusebenza kahle kokusebenza.

3. Izindleko eziphansi zezingalo zerobhothi

I-Engineering 360 ibika ukuthi izindleko zamarobhothi empeleni zehle ngamaphesenti angaphezu kuka-25% kusukela ngo-2014, futhi kulindeleke ukuthi zehle nakakhulu ngokwengeziwe ngo-22% ngo-2025. Imakethe yamarobhothi yezimboni ibilinganiselwa ku-US$ 24.35 billion ngo-2020 futhi kulindeleke ukuthi ifinyelele ku-US$ 52.85 billion, ikhule ngaphezu kwe-CAGR yezigidigidi ezingu-2026 ngo-14.1%. Isikhathi sokubikezela sika-2021–2026.

Nakuba isidingo samarobhothi ezimboni siye sakhula, ukwehla kwezindleko ze izingalo zamarobhothi zezimboni ikakhulukazi ivumele ukusetshenziswa kwe izingalo zamarobhothi ukuba sande nakakhulu embonini yokukhiqiza.

Ukusebenzisa umbono womshini kanye nobuchwepheshe benethiwekhi, izingalo zamarobhothi zezimboni ukusiza amabhizinisi ukuthi enze izinqubo ezibalulekile ezigcina zibambe iqhaza ekwandeni kokuphepha kwezisebenzi, ukukhiqiza okusheshayo, kanye nokwanda kokukhiqiza. Ngezibalo zangempela, i-Boston Consulting Group izilinganiso ukuthi izingalo zamarobhothi zezimboni ingaletha ukonga okumaphakathi kwezindleko zabasebenzi emhlabeni wonke okungaba ngu-16% ngo-2025. E-US, lezi zonga zingafika ku-22%, futhi eShayina okungenani zibe ngu-18%.

Abakhiqizi bayakwazi ukuthenga izingalo zamarobhothi ezibiza kancane ngenani lezicelo, kusuka ukulayisha izingalo kuya ama-welder aqondile. Ngokuhamba kwesikhathi, lokhu kuzosiza amabhizinisi aqinise inzuzo yawo yokuncintisana njengoba ezokwazi ukugcina izindleko zawo ziphansi futhi adlulisele le nzuzo yezindleko kubathengi.

4. Ukwenyuka kokwamukelwa kwamarobhothi asebenzisanayo

Amarobhothi asebenzisanayo (owaziwa nangokuthi “ama-cobots”) abona ukwanda kokutholwa kokuzenzakalelayo kwemboni. Njengemishini ehloselwe ukunika amandla ukusebenzisana okuqondile kwerobhothi lomuntu ngaphakathi kwendawo yokusebenza okwabelwana ngayo, izikhwebu benza ukushintshela ekusebenzeni okuzenzakalelayo noma okuzimele kube lula kumabhizinisi emhlabeni wonke.

Ama-Cobots ziwumkhuba omusha kumarobhothi kodwa ziya zisabalele kakhulu ezinhlelweni zokukhiqiza zezimboni. Basatshalaliswa imisebenzi ehlukahlukene kuzo zonke izimboni eziningi kubandakanya yezimoto, electronics, general production, ukwakheka kwensimbi, emaphaketheni kanye nokupakisha ngokubambisana, amapulasitiki, nokudla nezolimo.

Embonini yokukhiqiza, zisetshenziselwa ukukhetha nokubeka, embonini yokudla asetshenziselwa ukusika futhi ukusika, futhi embonini yezokunakekelwa kwempilo, zisetshenziselwa ukuhlinzwa. Uma isetshenziswa ku yokukhiqiza, umshini obiza u-US$50,000 ungaletha imali engafika ku-US$150,000 ekongeni ezindlekweni zokupakisha.

Esinye sezizathu zokuduma kwawo ukuthi amakhobhothi aklanywe kucatshangwa ngabasebenza ngabantu, futhi asiza ukuqinisekisa indima yomsebenzi womuntu kuyilapho esiza ekusebenzeni kahle, ukunemba, nokuphepha kokusebenza.

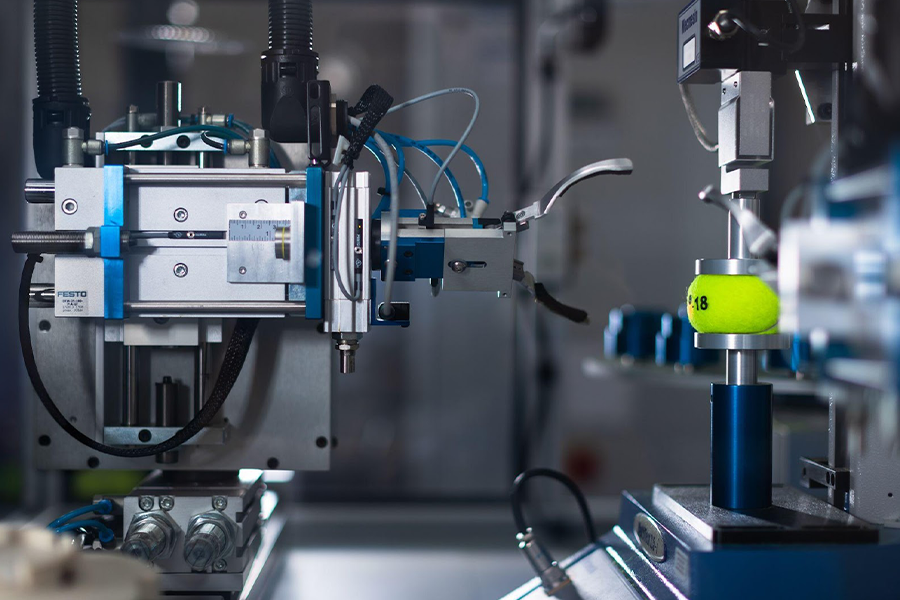

5. Intuthuko embonweni womshini

Intuthuko enkulu embonweni womshini ivumela imishini ezenzakalelayo ukuthi yenze imisebenzi ngokunemba okukhulu kanye nemisebenzi enzima kakhulu.

Ukubona komshini (MV) kubhekisela kubuchwepheshe nezindlela ezisetshenziswa ezishintshayo zezimboni ukuze kuhlinzekwe ngokuhlola okuzenzakalelayo okusekelwe emcabangweni kanye nokuhlaziya izinhlelo zokusebenza ezihlanganisa ukulawula inqubo, ukuhlola okuzenzakalelayo, ukulandelela ingxenye, nokuqondisa kwerobhothi.

Ngenxa yezinzuzo zejubane eliphezulu, ukusebenza kahle okuthuthukisiwe, nokunemba ekuvumelayo, iminyaka embalwa ezayo izobona ubuchwepheshe bokubona umshini busetshenziswa ngokwandayo futhi buhlanganiswe nezinhlelo ezizenzakalelayo.

6. Ukwethembela okwengeziwe ekuphrinteni kwe-3D

Obunye bobuchwepheshe obudala obuzothinta i-automation yezimboni ukuphrinta kwe-3D. I-Automation World iphawula ukuthi ukuphrinta kwe-3D kuzoshintsha igeyimu ngaphakathi kwemakethe ye-automation yomhlaba wonke njengoba kuzokwehlisa kakhulu izindleko zokukhiqiza.

I-Industrial automation ishintsha ngokushesha kanye nekhono lokwenza i-prototype ngokushesha ye-R&D evumela ukuphrinta kwe-3D kuvumela amabhizinisi ukuthi azivumelanise ngokushesha nezimfuno zemboni ezishintshayo. Ukuphrinta kwe-3D manje kuyasetshenziswa emaphaketheni, imfundo, imithi, Futhi ukwakhiwa.

Ngenxa ye-prototyping esheshayo, abakhiqizi bayakwazi ukuhlola imiqondo yabo ngokuqinile ngaphambi kokudlulela esigabeni sokuqalisa kanye nokukhiqizwa kwesilinganiso esigcwele. Izinzuzo zalokhu ukuthi imiklamo emisha ilethwa ngokushesha emakethe, izindleko ze-R&D ziyancipha, 40–70% impahla engaphansi isetshenziswa ekwenzeni imikhiqizo uma kuqhathaniswa nezindlela zendabuko, futhi abathengi bayakwazi ukuba nezingxenye emishinini yabo ezenzakalelayo ishintshwe ngokushesha.

7. Ukuqhubeka nokwamukelwa kwezinhlelo zokukhiqiza eziguquguqukayo

Ukwamukelwa kwezinhlelo zokukhiqiza eziguqukayo (FMS) kuqhubekile phakathi kwamabhizinisi akhiqizayo emhlabeni jikelele. I-FMS iyindlela yokukhiqiza ekhulisa ukuguquguquka kwenani noma uhlobo lomkhiqizo okhiqizwayo.

Ama-FMS anikeza ukuguquguquka komshini, okubhekisela ekutheni isistimu ikwazi ukushintsha kangakanani ukuze idale izinhlobo ezintsha zemikhiqizo noma ukushintsha ukuhleleka kokusebenza kwengxenye ethile. Ama-FMS aphinde anikeze ukuguquguquka komzila, okusho ikhono lesistimu lokusebenzisa imishini eminingi ukwenza imisebenzi efanayo engxenyeni eyodwa.

Nakuba lezi zinhlelo zingase zibhekwe njengezimba eqolo, zisebenzela ukukhulisa umkhiqizo kanye nokunciphisa izindleko zokusebenza. Ikhono labo lokuzivumelanisa nezinguquko liphinde lisize amabhizinisi avimbele imikhiqizo enesici nokumosha isikhathi nezinsiza.

I-BrainKart imibiko ukuthi ama-FMS aletha ukwanda kokusetshenziswa komshini uma kuqhathaniswa nemishini emikhiqizweni evamile yeqoqo, okwenza amabhizinisi akwazi ukusondela I-80-90% ekusetshenzisweni kwempahla. Amazinga aphezulu okukhiqiza kanye nokuncishiswa kokuthembela emsebenzini oqondile ama-FMS avumela amabhizinisi ukuthi enze ukonga abasebenzi abangafinyelela I-30-50%.

Inkathi entsha ye-industrial automation

Ngezindlela eziningi, sibona kuphela ukuqala kwe-Industrial 4.0 kanye nemithelela ezoba nayo kumabhizinisi, imboni yokukhiqiza, kanye nomphakathi wonkana. Okuqinisekisiwe ukuthi le nkathi entsha ye-automation yezimboni izovumela inani elingakaze libonwe lejubane nokunemba kokukhiqiza.

Ngesikhathi esifanayo, imboni yokukhiqiza iyabunjwa kabusha, okwenza indlela yokusebenza exhumeke kakhulu futhi enezinga elikhulu lokunemba nokuphepha.

Amathrendi abalulekile we-automation yezimboni okufanele uwabheke kuzoba:

- I-Intanethi Yezimboni Yezinto

- Susa kusuka kokuzenzakalelayo uye emisebenzini yokuzimela

- Izindleko eziphansi zezingalo zerobhothi

- Ukwemukelwa okwengeziwe kwamarobhothi asebenzisanayo

- Intuthuko embonweni womshini

- Ukuthembela okwengeziwe ekuphrinteni kwe-3D

- Ukuqhubeka nokwamukelwa kwezinhlelo zokukhiqiza eziguquguqukayo

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu