Izindlela ezimbili zokusika ezidume kakhulu ekukhiqizeni i-laser nejethi yamanzi. Indlela engcono kakhulu izonqunywa uhlobo lwezinto okufanele zicutshungulwe kanye nomphumela oyifunayo. Kodwa ngaphambi kwalokho, kubalulekile ukucabangela ukuhluka okuyisisekelo phakathi kwezinqubo ezimbili kanye nezinto ezihambisana nazo. Qhubeka ufunda ukuze uqonde indlela yokusika ngayinye kahle.

Okuqukethwe

Imakethe yokusika i-laser nejethi yamanzi

Ukuqonda izinqubo zokusika i-laser nejethi yamanzi

I-Laser vs water jet cutting: iyiphi indlela ephumelela kakhulu?

Imakethe yokusika i-laser nejethi yamanzi

Imakethe yomhlaba wonke yomshini wokusika ijethi yamanzi ibibiza i-USD 969.2 million ngo-2019 futhi kulindeleke ukuthi ikhule ku-CAGR ka-5.1% kusukela ngo-2020 kuya ku-2027. Ukwamukelwa okwandayo kwezinqubo zokusika i-eco-friendly kuzo zonke izimboni ezihlukahlukene ezifana nendwangu, izimoto, ukupakisha, kanye ne-electronics kungenye yezinto eziyinhloko eziqhuba ukukhula kwemakethe. Ngaphezu kwalokho, ukwenyuka kwezinqubo ezishintshayo kukhuphule isidingo kuzo zonke izimboni zemishini esezingeni eliphezulu.

Imakethe yomshini wokusika i-laser yomhlaba wonke ibilinganiselwa ku-USD 5.96 bhiliyoni futhi kulindeleke ukuthi ikhule ku-CAGR ka-8.40% ngo-2030. Ukwanda kwezidingo zokukhiqiza kuzo zonke izimboni zokukhiqiza kanye nesidingo sokunciphisa ukuzibandakanya kwabantu ekuthuthukiseni imiphumela yokucubungula insimbi kuye kwakhuthaza ukukhula kulo mkhakha.

Ukuqonda izinqubo zokusika i-laser nejethi yamanzi

Kuyini ukusika kwe-laser?

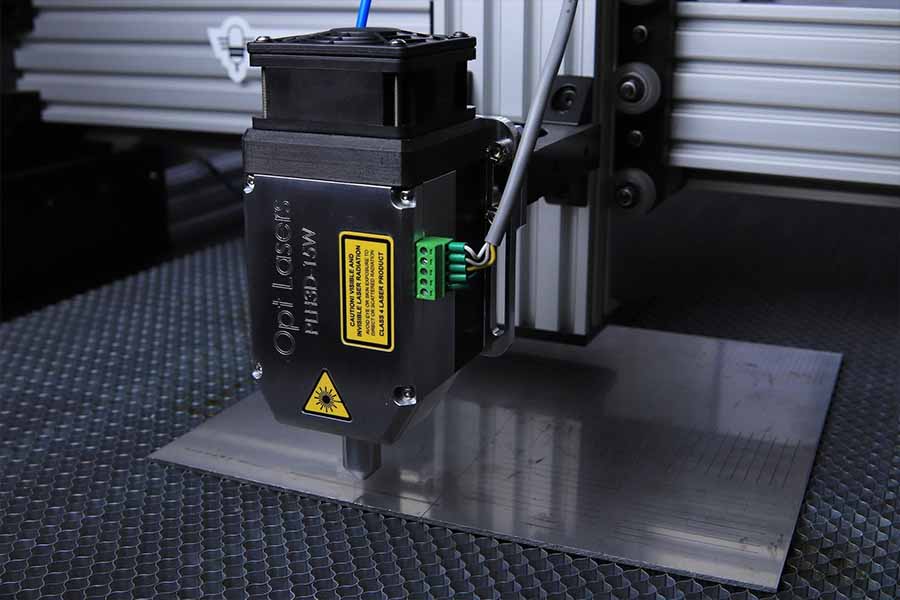

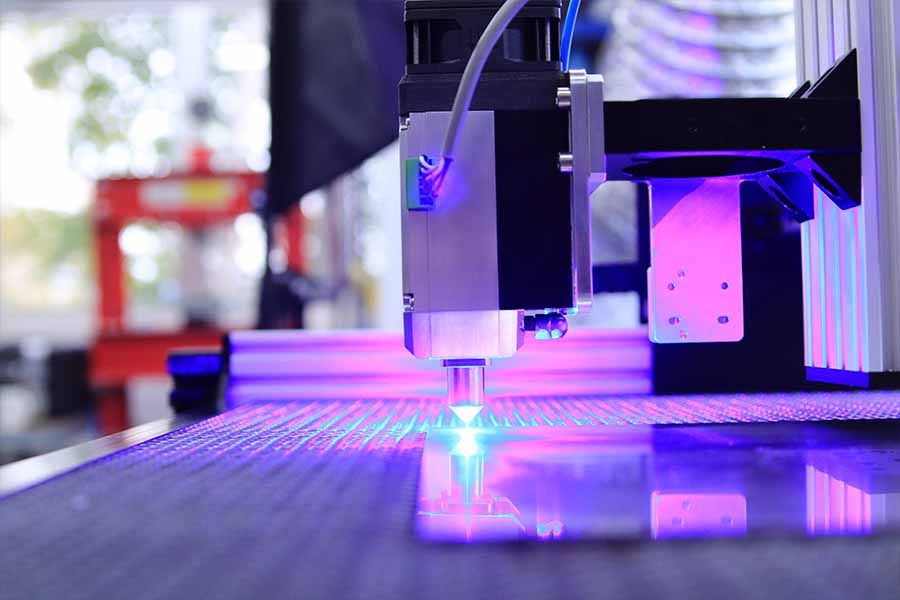

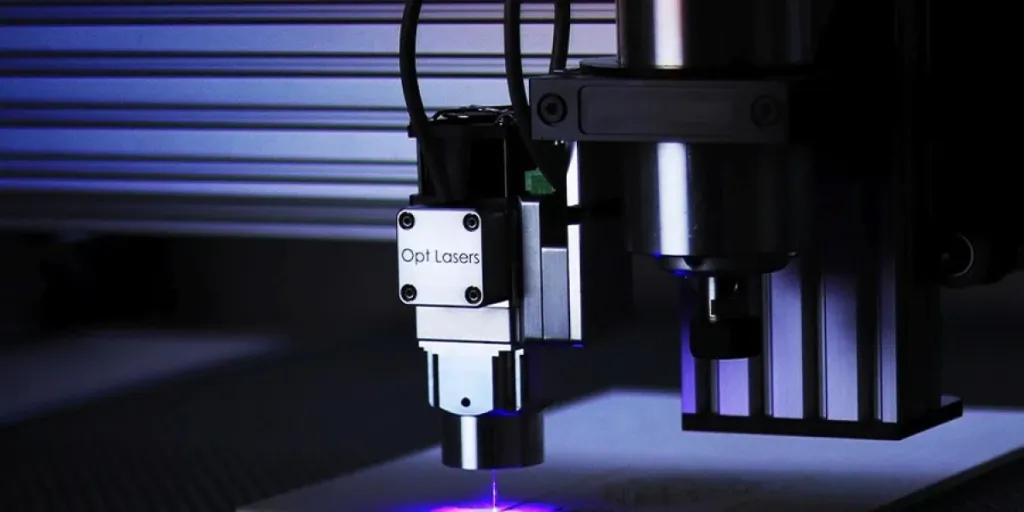

A laser umshini wokusika ukhiqiza amandla usebenzisa i-CO2 laser, edluliselwa nge-beam eqondiswa izibuko futhi iqondiswe ezintweni. I laser umthombo ungaphakathi komshini, futhi ugongolo lungakhiqiza phakathi kuka-1500 no-2600 watts. Asebenza ngezinto ezihlukahlukene, okuhlanganisa ukhuni, ingilazi, ipulasitiki, nazo zonke izinsimbi ngaphandle kwezinsimbi ezikhanyayo. Kodwa-ke, ukusika izinto ezixubile ezinamaphoyinti ahlukene okuncibilika kungaba yinselele ngama-lasers. Ngenxa yesiqondiso esiqinile se-beam, izakhiwo ezinezimbotshana nezinto ze-3D nazo kunzima ukuzisika nge-CO2 laser beam.

I-Laser ukusika isebenza kahle ezintweni ezinobukhulu obungu-0.12 no-0.4 futhi ijwayele ukusetshenziselwa ukusika amashidi asicaba anogqinsi oluphakathi nendawo. Ngaphezu kokusika, umshini wokusika we-CO2 laser ungenza ukukhipha, ukuqopha, ukushisela, ukubhola, nokuhlela.

Izinyathelo zokunemba nokuphepha

Ukunemba akuyona inkinga laser ukusika ngoba usayizi omncane wokusika ungafinyelela phansi ku-0.006 amayintshi, kuye ngesivinini se-laser. Ngakolunye uhlangothi, izinto ezizacile zingase zibe ngaphansi kwengcindezi yegesi uma ibanga elifanelekile linganakekelwa, okuholela ekushisweni kancane. Ingcindezi yokushisa ingase futhi ibangele ukuwohloka kanye nezinguquko ezincane zesakhiwo, futhi okubalulekile kungabonakala kune-striated.

Ukusika i-laser kungase kukhiqize intuthu nothuli; ezinye izinsimbi nepulasitiki kungakhiqiza intuthu enobuthi; ngakho-ke, kuyadingeka ukungena komoya lapho usebenzisa i-CO2 laser umshini. Nokho, ingozi iyonke yokusebenzisa umshini onjalo iphansi uma kuqhathaniswa, kanjalo nenani lemfucuza ekhiqizwayo kanye nesikhathi esidingekayo sokuhlanza.

Kuyini ukusika indiza yamanzi?

Indiza yamanzi ababazi sebenzisa amanzi acindezelwe ukusika izinto, futhi indawo yokusebenza kanye nepompo kuvame ukuhlukana, ngokungafani nabasiki be-laser, abanomthombo we-laser ngaphakathi komshini. Ama-abrasives afana ne-aluminium oxide nama-garnet avame ukusetshenziselwa ukuthuthukisa ikhono lokusika. Ingqikithi inqubo kufana nokuguguleka kwemvelo kodwa kushesha futhi kugxile kakhulu—iphampu enengcindezi ephezulu iletha amanzi ngepayipi eliqinile, okuholela kujethi yamanzi. Le jethi yamanzi inebanga lamandla kusuka ku-4 kuya ku-7 kilowatts.

Indiza yamanzi ababazi inganqamula noma iyiphi into, okuhlanganisa inhlanganisela yezinto ezibonakalayo, kodwa ibeka engcupheni yokuncipha. Le mishini ingakwazi ukuphatha ukusika impahla ye-3D ngezikhathi ezithile kodwa izabalaze ngezinto zesemishi nezimbotshana, futhi izinto zokusika ezinokufinyelela okukhawulelwe zingenzeka kodwa kuyinselele.

Amajethi amanzi ingakwazi ukukhipha, ukusika, nokuhlela futhi iwusizo ikakhulukazi ezintweni ezifana nezitsha zobumba, amatshe, nezinsimbi eziwugqinsi, ezinogqinsi olusuka ku-0.4 kuya ku-2 amayintshi.

Izinyathelo zokunemba nokuphepha

Indiza yamanzi ukusika inembe kancane kunokusika nge-laser ngoba ubuncane bosayizi bokusika bungamayintshi angu-0.2. Ngaphezu kwalokho, ngenxa yokuthi kusetshenziswa izinga eliphezulu lamandla, izinto ezincane azisebenzi kahle futhi kufanele ziphathwe ngobumnene.

Nakuba ukucindezeleka okushisayo akuyona inkinga, lapho ususa ukuvutha, ama-abrasives angeziwe ku- amanzi i-jet ingabangela ukuthi indawo yezinto ezibonakalayo ibonakale i-sandblasted. Ngakho-ke, izibuko kufanele zigqokwe ukuze kuvikelwe amehlo uma usebenzisa i- indiza yamanzi umsiki. Ukwengeza, yonke le nqubo inomsindo futhi idinga isikhathi esibalulekile sokuhlanza ngoba ama-abrasive ahlanganiswe namanzi.

Umehluko phakathi kwe-laser ne-jet jet cutting

Uhlobo lwezinto: Kokubili i-jet yamanzi kanye laser ziyasebenza ukusika izinsimbi. Kodwa-ke, ngenxa yokusebenza kwayo okuphezulu kwengcindezi, indiza yamanzi ifaneleka kangcono ezintweni eziqinile ezinobukhulu obusuka ku-0.4 kuya ku-2 amayintshi. Ngokuphambene, ukusika nge-laser kusebenza kangcono ezintweni ezizacile ezinobukhulu obungu-0.12- no-0.4-intshi.

Izinga lokunemba nesivinini: I-Laser ukusika kuyashesha kakhulu kunejethi yamanzi futhi kunamandla aphezulu wokunemba, nokubekezelela okungu-+/-0.005 amayintshi kuye ngesivinini somshini we-laser. Ngakolunye uhlangothi, indiza yamanzi ababazi ubekezelele +/-0.03 amayintshi.

Izindleko: I-Laser ababazi abanazo izindleko zamathuluzi futhi banezindleko eziphansi ngenxa yesidingo esikhulu senqubo. Ngakolunye uhlangothi, abasiki bezindiza zamanzi banesilinganiso esiphezulu sengxenye ngenxa yezinto ezisetshenziswayo kodwa azikho izindleko zamathuluzi. I-laser cutter ibiza kakhulu kunejethi yamanzi wokusika ngokuvamile, kodwa ngaphandle kwenani lokuqala lokuthenga, izindleko zokulungisa nokusebenza ziphansi kakhulu.

Isikhathi sokuhlanza: I-Laser ukusika ngezikhathi ezithile kungashiya kucwebezela ezindaweni ezisikiwe zezingxenye, okudinge ukuchithwa ukuze kusheleleke kakhulu, ukuphepha, nokusebenza. Ngokuphambene, indiza yamanzi ukusika ishiya izingxenye ezisikiwe zibushelelezi futhi zilungele ukusetshenziswa, ezidinga ukuhlanzwa okuncane ngemva kokusika.

Ukufana phakathi kwejethi lamanzi nokusika kwe-laser

Ukuvumelana nezimo: Kokubili laser futhi izinqubo zokusika indiza yamanzi ziningi kakhulu futhi zingasebenza ngezinto eziningi, ezihlanganisa izinsimbi, ukhuni, ithusi, nethusi. Ziyakwazi futhi ukuzivumelanisa nezimo kakhulu, okuvumela ukwenza ngezifiso ukuhlangabezana nezidingo ezithile zebhizinisi.

Idizayinelwe i-automation: Zombili izinqubo zinikeza ukunemba okuphezulu futhi Ukunemba ezinhlotsheni eziningi zezinhlelo zokusebenza, okuzenza zifanelekele ukuphindaphinda kwezinqubo ezizenzakalelayo. Bangakwazi ngokuphindaphindiwe ukwenza ukusikeka okufanayo ngokunemba, ukuqinisekisa ukuvumelana kuwo wonke amaqoqo omkhiqizo.

Ububanzi be-kerf obuncane: Igama elithi "ububanzi be-kerf" ekusikeni kwezinto ezibonakalayo lichaza inani lezinto ezilahlekile ngokusikwa ngakunye. I-Laser futhi ukusika ijethi yamanzi kokubili kukhiqiza ububanzi be-kerf obuncane, kanti eyokuqala inobubanzi obuncane be-kerf obuncane kakhulu futhi lokhu okugcina kuyisilinganiso esingama-intshi angu-0.01. Lezi zicucu ezithambile zivumela imiklamo eyinkimbinkimbi futhi esihle enemininingwane.

Izicelo zokusika laser

- Laser ukusika inikeza ukunemba okuphezulu, ukubekezelelana, nokunemba, kuyabiza, futhi isetshenziswa ezimbonini eziningi. Isibonelo, isetshenziswa embonini yezimoto ukusika izingxenye ezihlukahlukene njengama-hood, uphahla, nezicabha kanye nokuqopha ngaphakathi.

- Laser ukusika ibuye isetshenziswe embonini yesikhunta, i-die, kanye namathuluzi ngenxa yokubekezelelana kwayo okuphezulu, isivinini esikhulu, nekhono lokusika ekujuleni okuhlukene kwezinto, okwenza ifanele izinto eziqinile.

- Ukusika i-laser kuyathandwa embonini yobucwebe ngoba ingaqopha imiklamo eyinkimbinkimbi ibe izinto ezifana negolide, isiliva, namadayimane ukuze kukhiqizwe izingcezu eziyinkimbinkimbi. Iphinde ibe yiprimary ukusika inqubo kule mboni ngenxa kerf yayo encane, ukunciphisa imfucuza.

Izicelo zokusika ijethi yamanzi

– Ijethi yamanzi ukusika isetshenziswa kakhulu ezintweni ezinezidingo eziphezulu zokushisa. Isetshenziswa kabanzi embonini yezimoto ukukhiqiza izingxenye ezinjengamapuleti e-skid, ama-gaskets ensimbi, kanye nezingxenye zomzimba zemoto ngokwezifiso. Ngenxa yokuthi inqubo yokusika ayikhiqizi ukucindezeleka kwemishini, ifanele izingxenye eziwugqinsi.

– Amanzi i-jet ibuye isetshenziswe embonini ye-aerospace ukwenza izingxenye zama-turbine blades, ama-cabin panel, nezinjini ze-jet. Le ndlela idumile ngoba ayikukhiqizi ukushisa, okunciphisa amathuba okuqhekeka kwe-microscopic kanye nokungqubuzana kwezingxenye.

I-Laser vs water jet cutting: iyiphi indlela ephumelela kakhulu?

Lesi sihloko siphenye izindlela eziyisisekelo zezinqubo zokusika i-laser nejethi yamanzi ngaphandle kokunquma ukuthi yikuphi okungcono. Kunalokho, ifuna ukuhlonza ukufana nomehluko phakathi kwalezi zinqubo ezimbili. Eqinisweni, indlela engcono kakhulu yokusika izonqunywa ngokuphelele iphrojekthi kanye nezinto ezizosetshenziswa.

Ukufingqa, ukusika kwe-laser kunikeza ukunemba okukhulu futhi kulungele kangcono amaphrojekthi anemininingwane kanye nokuqoshwa. Ngakolunye uhlangothi, indiza yamanzi ifaneleka kakhulu ezintweni eziwugqinsi futhi ayinakho ukulinganiselwa kwezinto ezibonakalayo.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu