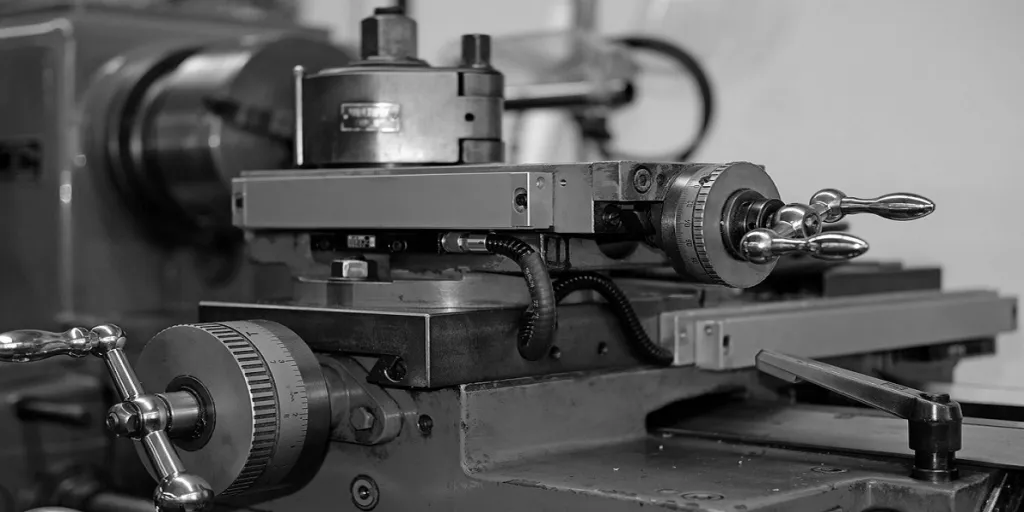

Imishini ye-lathe iwusizo kunoma iyiphi indawo yokusebenzela yensimbi, yenza imisebenzi esuka ekubumbeni izingcezu zokusebenza iye kumathuluzi okusika, okugoqa, nawokusika. Ngenxa yokubaluleka kwazo, ukugcinwa kwazo kubaluleke kakhulu uma ishabhu izosebenza ngaphandle komthungo isikhathi eside. Lo mhlahlandlela uchaza ukuthi amabhizinisi angayinakekela kanjani imishini ye-lathe ngokwawo.

Okuqukethwe

Kungani kubalulekile ukugcina umshini we-lathe

Isakhiwo somshini we-lathe

Ungawugcina kanjani umshini we-lathe

Imicabango yokugcina

Kungani ukugcinwa komshini we-lathe kubalulekile

Imishini ye-lathe idinga ukunakekelwa njalo ngoba kulula ukuguga uma isetshenziswa. Ukunakekela kuqinisekisa ukuthi lokhu kugqoka kuyaphathwa futhi umshini usesimweni esihle sokusebenza. Ngaphandle kwalokho, kunciphisa izindleko zokukhanda uma kuqhathaniswa nesikhathi lapho umshini uphuka ngenxa yokungalungiswa futhi kunganciphisa nenani lokulungisa okudingeka umshini. Okokugcina, ukulungiswa kusiza futhi ukukhulisa ukuphepha komsebenzi kwabaqhubi bemishini. Nakuba ukuphepha kwabasebenzi kuncike kubasebenzi, ukulungiswa kuvimbela ukuwohloka okungazelelwe okungase kulimaze izisebenzi.

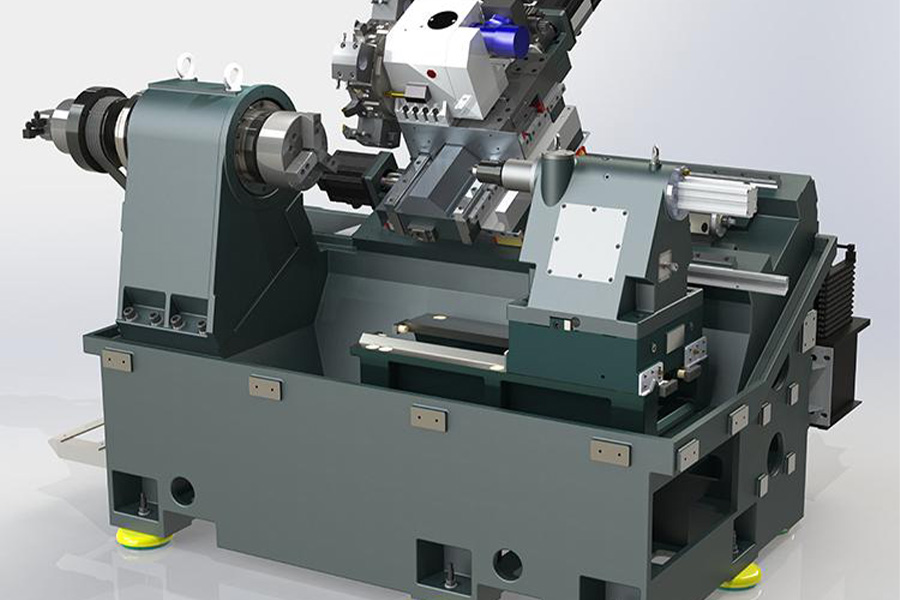

Isakhiwo somshini we-lathe

Umbhede: Iyingxenye eyisisekelo yomhlahlandlela onembile futhi iphethe zonke izingxenye zomshini we-lathe.

Ibhokisi le-spindle: Idlulisa amandla ukusuka kumotho iye ku-spindle ngokusebenzisa izindlela zokudlulisela.

Ibhokisi lokuphakelayo: Isetshenziselwa ukushintsha isivinini semoto ngaphambi kokudlulisela amandla kumphathi wamathuluzi.

Isiphathi samathuluzi: Isetshenziselwa ukufaka umsiki futhi ukushayela ithuluzi. Iqukethe ama-slide plate, uhlaka lommese, nesihlalo sombhede.

I-Tailstock: Igxunyekwe kumzila wesitimela wombhede bese inyakaziswa ukuze ilungise indawo yokusebenza.

Idivayisi yokupholisa: Ikhulula uketshezi lokusika endaweni yokusika ukuze kuncishiswe izinga lokushisa le-workpiece, lihlanze futhi ligcobe.

Ungawugcina kanjani umshini we-lathe

Kunezinto eziningana okufanele zicatshangelwe lapho unakekela umshini we-lathe. Ukunakekela kufanele kwenzeke njalo 40 amahora ukuqinisekisa ukuthi isebenza kahle.

Sebenzisa ibhodi lathe

Ibhodi le-lathe lisiza ukubamba izinto ekuweni. Lapho u-opharetha eshintsha izingxenye zomshini we-lathe, njengama-chucks, ama-centerpieces, noma i-workpiece, futhi ziyashelela, ibhodi le-lathe liyawabamba. Kuvimbela ukuba zingawi phansi, okungaholela ekulimaleni okukhulu kwezicucu.

Gcina amathuluzi ngaphandle kwezindlela ze-lathe

Noma yimaphi amathuluzi adingekayo ngenkathi usebenza nomshini we-lathe kufanele abekwe etafuleni elihlukile hhayi ezindleleni zezintambo. Nakuba kungase kubonakale kulula ukubeka amathuluzi ezindleleni ze-lathe, ukudlidliza lapho kusebenza kungase kubangele ukuthi bawele emshinini we-lathe. Lokhu kuyingozi empilweni kubasebenzi futhi kungadala nomonakalo omkhulu emshinini.

Gcoba

Umshini we-lathe ngokuyinhloko wenziwe ngezingxenye zensimbi. Abaqhubi bezintambo kufanele ngaso sonke isikhathi baqinisekise ukuthi umshini ugcotshwe kahle ngaphambi kokusebenza. Ukwehluleka ukwenza kanjalo kungaholela ekwehleni okukhulu ekunembeni kwamathuluzi okusika insimbi. Izinga likawoyela emathangeni echibi kufanele lihlolwe njalo futhi lifakwe phezulu uma lehle ngaphansi kophawu oluphakathi. Izikulufu zokuphakelayo, amalunga anyakazayo, nama-bearings kufanele futhi kugcotshwe ukuze kusebenze kahle ngaphambi kwanoma iyiphi iphrojekthi. Ngaphezu kokugcoba, indawo epholile kufanele ihlolwe ngezikhathi ezithile. Nakuba into epholisayo ingase ingasetshenziswa kaningi njengamafutha, kuyatuswa ukuthi kuqinisekiswe ukuthi indawo yokugcina amanzi igcwele.

Hlanza ama-spindle tapers

Ama-spindle taper angaba nokuphuma kwe-axial noma kwe-radial. Ukugijima kwe-axial kwenzeka lapho i-spindle izungeza ngaphandle kwe-eksisi yayo. I-radial runout iphutha elenzeka ku-motion perpendicular to the spindle axis. Ama-spindle taper kufanele ahlolwe futhi ahlanzwe ngendwangu ethambile, engenantambo uma amathuluzi eshintshwa. Ijazi lamafutha omshini wenhloso yonke kufanele futhi lisetshenziswe.

Hlanza uthuli

Ukusebenza ngensimbi ekhonjiwe, ipulasitiki noma izinkuni kuzokhiqiza uthuli. Lolu thuli lungabambelela ezintweni zokusebenza nasemshinini we-lathe. Uthuli olusuka ku-cast iron luyaqhuma futhi lunganamathela ekugcotshisweni komshini. Ama-opharetha adinga ukusula uthuli emshinini, izinto zokusebenza, kanye nezinto zokusula. Indlela yokusula kufanele ishintshwe uma isigugile. Ama-chips ensimbi amahle angabangela ukulimala ku-chuck uma engasuswa. Ngakho-ke imihlathi ye-lathe kufanele ikhishwe ngaphambi kokuhlola ama-chucks noma yiziphi izinsimbi zensimbi ezifakwe lapho ngesikhathi sokusebenza.

Vikela umshini ekugqwaleni

Ukugqwala kuhlale kuyisici esikhulu okufanele sicatshangelwe lapho usebenza ngemishini yensimbi. Ukuvikelwa okufanele kwemishini kufanele kwenziwe. Ibalulekile ngemishini eduze nezindawo ezinkulu zasolwandle ngenxa yamazinga aphezulu omswakamo. Ukugqwala kungabangela ukuba buthaka kwesakhiwo somshini we-lathe, ukugqwala, nezingxenye ezilimele. Ukuze ugweme ukugqwala, imishini ye-lathe kufanele ihlanzwe njalo futhi igcotshwe ngamafutha avimbela ukugqwala. Umshini kufanele futhi umbozwe lapho ungasetshenziswa. Isembozo kufanele sifakwe umoya uma umshini we-lathe uzohlala isikhathi eside.

Linganisa izinga lokunemba ngemva kokulungiswa

Ngemuva kokulungiswa komshini we-lathe, ezinye izilungiselelo kungenzeka ukuthi zonakalisiwe. Ukulungiswa kabusha komshini kunconywa ngemuva kokulungiswa. Lokhu kuzophinde kuvumele opharetha ukuthi aqonde imikhawulo yokunemba komshini we-lathe. Ukugcinwa okuvamile nokulinganisa nakho kuphumela ekukhiqizweni kwezingcezu zokusebenza ezinembile.

Imicabango yokugcina

Ngaphezu kokuchaza umshini we-lathe nezici zawo, lo mhlahlandlela ubheke amathiphu abalulekile ibhizinisi elingawasebenzisa ukuqinisekisa ukuthi i-lathe yabo isesimweni esihle sokusebenza kulo lonke. Ulwazi olwengeziwe mayelana nemishini ye-lathe lungatholakala ku Chovm.com.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu