Phakathi nokuthuthuka okusheshayo kubuchwepheshe be-automation ngo-2025, isidingo semishini enembayo njengama-linear slide rails sesikhulile. Lesi sihloko sidingida izici ezibalulekile zokukhetha lezi zingxenye ezibalulekile, enikeza abathengi abangochwepheshe umhlahlandlela ophelele wokwenza izinqumo ezinolwazi. Ngokusebenzisa izinto ezintsha zakamuva namandla emakethe, lolu hlelo luhlinzeka ngemininingwane ebalulekile ukuze uthuthukise isu lakho lokuthenga futhi uqinisekise ikhwalithi ephezulu nokusebenza kahle ohlwini lwakho lwamagama.

Okuqukethwe:

-Imakethe Uhlolojikelele of Linear Slide Rails

-Ukuhlaziywa Okuningiliziwe Kwemakethe Yezitimela Eziyisilayidi Ezilayini

-Izici Eziyinhloko Lapho Ukhetha Izitimela Zesilayidi Eziwumugqa

-Izici Ezithuthukile Nezinto Ezintsha Kuma-Linear Slide Rails

Izicelo -Industry of Linear Slide Rails

-Isifinyezo

Uhlolojikelele lwemakethe yama-Linear Slide Rails

Imakethe kaloliwe yama-slide yomhlaba wonke ibone ukukhula okuqinile, isuka ku-USD 391.13 million ngo-2023 yaya ku-USD 419.14 million ngo-2024. Lokhu kukhula kulindeleke ukuthi kuqhubeke, ngesilinganiso sokukhula sonyaka esihlanganisiwe (CAGR) esingu-7.67%, sifinyelele ku-USD 656.24 wezigidi ngezinqubo zokukhiqiza ezikhulayo ngo-2030. ukwamukelwa kokuzenzakalela kuzo zonke izimboni ezihlukahlukene, kuqhuba lo mkhuba ophakeme.

Ngokwesifunda, imakethe yase-Asia-Pacific, ikakhulukazi i-China, ihola ngenxa yokukhula ngokushesha kwezimboni kanye nokutshalwa kwezimali okubalulekile kwezobunjiniyela obunembayo kanye nokukhiqizwa kwe-elekthronikhi. Amazwe aseMelika, aqhutshwa yi-United States, nawo akhombisa ukukhula okuqinile ngenxa yokwanda kokukhiqizwa kwemishini ezenzakalelayo kanye nokuphindaphindeka komkhakha wezimoto. I-Europe, nemboni yayo ethuthukisiwe yezimoto kanye ne-aerospace, isalokhu iyimakethe ebalulekile, kuyilapho iMpumalanga Ephakathi ne-Afrika kancane kancane ifinyelela ekutshalweni kwezimali okwandayo kwengqalasizinda kanye nokukhiqizwa kwezimboni.

Amandla emakethe athonywa isidingo sokuqondiswa kokungqubuzana okuphansi kanye nokuqina okuphezulu kwemithwalo esindayo, kanye nokwanda kokuthunyelwa kwama-linear slide rails embonini yokwakha kanye ne-aerospace. Kodwa-ke, izindleko eziphakeme zokuqala kanye nezidingo zokunakekela zibeka izinselele. Naphezu kwalezi zinselele, amathuba ayavama ngokwethulwa komzila wama-slide wamaslayidi osebenza kahle kakhulu futhi angabizi kakhulu kanye nokusetshenziswa kwawo okukhulayo kumishini yokubona neyezokwelapha.

Ukuhlaziywa Okuningiliziwe Kwemakethe Yezitimela Eziyisilayidi Ezilayini

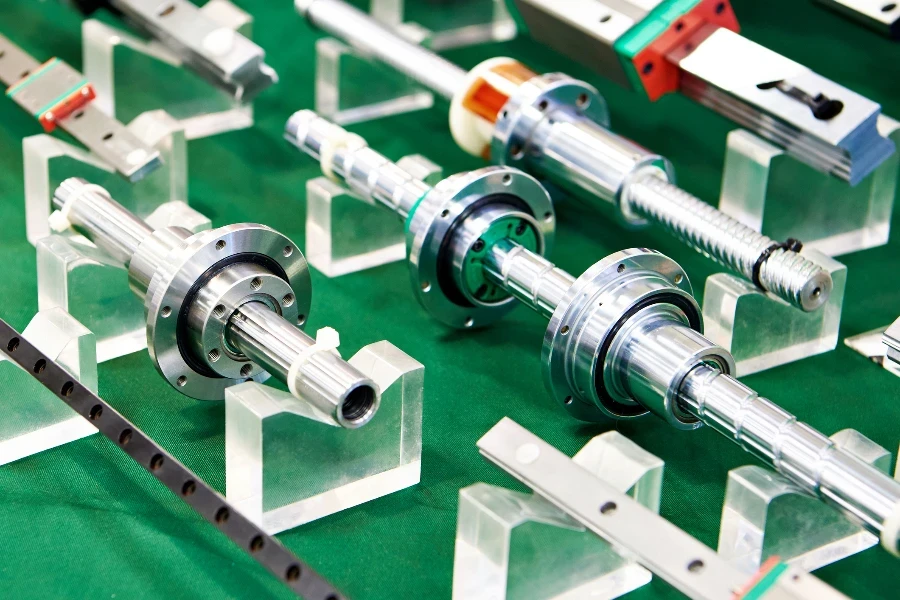

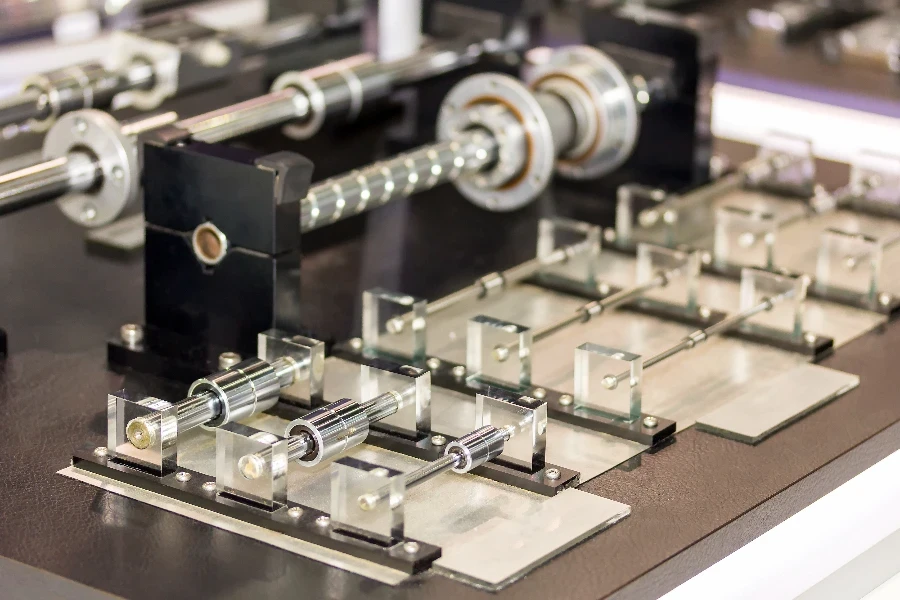

Ama-rails amaslayidi abalulekile abalulekile ezinhlelweni zokusebenza ezinemba okuphezulu njengomshini we-CNC, amarobhothi, nemigqa yokuhlanganisa eyinkimbinkimbi. Ahlanganisa ujantshi osebenza njengethrekhi kanye ne-bearing noma ibhulokhi ehamba kule threkhi, enciphisa ukushwibeka nokugcina uzinzo. Amabhentshimakhi okusebenza angukhiye afaka ukunemba, umthamo wokulayisha, nokuqina. Ukuqamba okusha okufana nezici ezimelana nokugqwala nezizithambisayo kuthuthukise kakhulu ukusebenza nempilo yokuphila yalezi zingxenye.

Imakethe ifaka uhla lwezinto ezisetshenziswayo ekwenziweni komugqa wama-slide rails, okuhlanganisa i-aluminium, ithusi, nethusi. I-Aluminium ayisindi futhi imelana nokugqwala, kuyilapho ithusi nethusi kunikeza ukuqina okuhle kakhulu nekhono lokuthwala umthwalo. Ukwakhiwa kwama-slide rails amancane emishini emincane kuphinde kwavula izimakethe ezintsha ze-niche, ikakhulukazi emishinini yezokwelapha ne-optical.

Ukuziphatha kwabathengi kushintshela kumasistimu ezishintshayo athuthukile, okuqhuba isidingo sezinhlelo ezithembekile nezisebenzayo zokulawula ukunyakaza. Iziteshi zokusabalalisa zishintshile, ngokuncanyelwayo kokuthengisa okuqondile kanye nobudlelwano besikhathi eside nama-OEMs ukuze kuqinisekiswe ukuhlinzekwa kwezingxenye zekhwalithi ephezulu. Umjikelezo wokuphila womkhiqizo wama-linear slide rails uthonywa kakhulu ukuthuthuka kwezobuchwepheshe kanye nesidingo sokunakekelwa okujwayelekile ukuze kuqinisekiswe ukusebenza kahle.

Izinto ezintsha ezisanda kwenziwa emakethe zifaka phakathi ukuthuthukiswa kwe-NSK kobuchwepheshe bokunyakaza obushelelayo bemihlahlandlela eqondile, ukuthuthukisa ukungaguquguquki okuguquguqukayo futhi ilungele ukuhlolwa okunembayo nemishini yokulinganisa. Ngokufanayo, i-Igus yethule umhlahlandlela womugqa wokuklama wenhlanzeko ozithambisayo futhi ofanele ukusetshenziswa ekucubunguleni ukudla nesiphuzo kanye nobuchwepheshe bezokwelapha, ekhuluma ngokukhathazeka ngokuhlanzeka nokuphepha komshini.

Imithelela yezomnotho efana nesidingo sokunciphisa isikhathi sokukhiqiza kanye nezindleko zabasebenzi iqhuba ukutshalwa kwezimali kubuchwepheshe bokuzenzakalela, lapho ama-linear slide rails edlala indima ebalulekile. Izimo zomphakathi ezibheke ekwandeni kwe-automation kanye nokunemba ezinqubweni zokukhiqiza ziqhubekisela phambili ukukhula kwemakethe. Kodwa-ke, amaphuzu obuhlungu bekhasimende njengezindleko eziphezulu zokuqala kanye nezidingo zokunakekelwa kufanele kubhekwane nazo ngokusebenzisa izinto ezintsha nezisombululo ezingabizi kakhulu.

Izinto Ezibalulekile Lapho Ukhetha Ojantshi Besilayidi Omugqa

Layisha amandla

Uma ukhetha ujantshi wesilayidi esiwumugqa, umthamo wokulayisha uyisici esibalulekile. Umthamo womthwalo ubhekisela esisindweni esiphezulu ujantshi ongasisekela ngaphandle kokushintshashintsha unomphela noma ukwehluleka, ngokuvamile kukalwa ngamaphawundi (lbs) noma amakhilogremu (kg). Isibonelo, ujantshi othwala umthwalo ongama-200 kg ulungele ukusetshenziswa kwezimboni ezisindayo, kuyilapho ujantshi omthamo omncane ungcono emisebenzini elula efana nemishini yaselabhorethri. Ukuqinisekisa ukuthi umthamo womthwalo uhambisana nezidingo zohlelo lokusebenza kubalulekile ekugcineni ubuqotho nokusebenza kwemishini.

Umthamo womthwalo uthonywa izici ezifana nempahla yesitimela kanye nohlobo lwamabheringi asetshenzisiwe. Ojantshi abenziwe ngensimbi yezinga eliphezulu noma ama-alloys e-aluminium ngokuvamile anikeza amandla okulayisha aphezulu ngenxa yamandla abo nokuqina. Ukwengeza, ama-ball bearings noma ama-roller enaliti angama-roller angathuthukisa amandla okuthwala umthwalo ngokusabalalisa umthwalo ngokulinganayo kuwo wonke ujantshi.

Kubalulekile futhi ukucabangela umthamo womthwalo oguqukayo, obhekisela emthwalweni umzila wesitimela ongawuphatha ngenkathi unyakaza. Lokhu kubaluleke kakhulu ezinhlelweni ezibandakanya ukunyakaza okuqhubekayo noma okuphindaphindayo, njengoba amandla omthwalo oguqukayo evamise ukuba ngaphansi kunamandla omthwalo omile ngenxa yokucindezeleka okwengeziwe okuvela ekuhambeni.

Ukunemba Nokunemba

Ukunemba nokunemba kubaluleke kakhulu ezinhlelweni ezidinga ukuma okuqondile nokuphindaphindwayo. Ama-rails amaslayidi anomugqa anembayo nokunemba okuphezulu aqinisekisa ukuthi izingxenye ezihambayo zigcina indlela yazo ehlosiwe ngokuchezuka okuncane. Lokhu kubalulekile ezinhlelweni ezifana nemishini ye-CNC, izisetshenziswa zezokwelapha, kanye nokukhiqizwa kwe-semiconductor, lapho ngisho namaphutha amancane angabangela izinkinga ezinkulu.

Ukunemba kuvame ukunqunywa inqubo yokukhiqiza kanye nekhwalithi yengxenye. Ujantshi ophansi uye ekubekezeleni okuphezulu ngokuvamile unikeza ukunemba okungcono kunalezo ezivele zenziwe ngomshini. Uhlobo lwama-bearings asetshenzisiwe nalo ludlala indima ebalulekile; amabhodi amabhola kanye nama-roller bearings ahlinzeka ngokunemba okuphezulu ngokunciphisa ukungqubuzana nokugcina ukuxhumana okungaguquki nojantshi.

Ukunemba kuthonywa indlela yokushayela. Amamotho alayini nezikulufu zebhola yizinketho ezivamile zezinhlelo zokusebenza ezinemba okuphezulu. Izikulufu zebhola, ikakhulukazi, zinikeza ukuphindaphinda okuhle kakhulu kanye nokuhlehla okuncane, okuzenza zilungele imisebenzi enembile. Ukunemba kukajantshi kulinganiswa ngamapharamitha afana nokuchezuka komugqa wohambo kanye nokunemba kwendawo, ngokuvamile ecaciswa umkhiqizi.

Ukufaneleka Kwemvelo

Indawo yokusebenza ithinta kakhulu ukukhethwa kwama-linear slide rails. Izindawo ezinjengamakamelo okuhlanza noma ama-vacuum adinga ama-rails aklanyelwe ukuhlangabezana nenhlanzeko eqinile kanye namazinga okulawula ukungcola. Ama-rails alinganiswe ngegumbi elihlanzekile akhiqizwa ukuze kuqinisekiswe ukukhiqizwa kwezinhlayiya ezincane futhi ngokuvamile enziwa ngezinto ezingakhiphi noma zingachithi izinhlayiya.

Ezindaweni ezinokhahlo, njengalezo ezinothuli, ukungcola, noma izinto ezonakalisayo, ama-rails adinga izici zokuzivikela. Izembozo noma izifutho zivikela ama-rails ekungcoleni, kuyilapho izinto ezifana nensimbi engagqwali noma izindawo ezimbozwe ngokukhethekile zinikeza ukumelana nokugqwala nokuguga. Ama-rails anama-wiper ahlanganisiwe noma ama-scrapers asiza ukugcina ukuhlanzeka ngokususa udoti ngesikhathi sokusebenza.

Ukweqisa kwezinga lokushisa nakho kuthinta ukusebenza kwesitimela sesilayidi esiqondile. Ojantshi abasetshenziswa ezindaweni ezinezinga eliphezulu lokushisa kufanele bagcine ubuqotho besakhiwo nokusebenza ngaphandle kokunwetshwa okuphawulekayo noma ukufinyela. Ngokuphambene, izicelo ezimweni ze-cryogenic zidinga izinto zokwakha kanye nezinto zokugcoba ezisebenza kahle emazingeni okushisa aphansi kakhulu.

Ukufakwa nokulondolozwa

Ukusebenziseka kalula kokufaka nokugcinwa kungenye indlela ebalulekile yokucatshangelwa lapho ukhetha ama-laini ama-slide rails. Ama-rails okulula ukuwafaka anganciphisa kakhulu isikhathi sokuphumula kanye nezindleko zomsebenzi. Izici ezifana nezimbobo ezigxunyekwe ngaphambili, amadowels okuqondanisa, kanye nemiklamo yemodular kusiza ukufakwa okusheshayo nokunembile. Amanye ama-rail ayatholakala ngezindlela zokushayela ezihlanganisiwe, okwenza kube lula inqubo yokufaka.

Izidingo zokunakekela ziyahlukahluka kuye ngomklamo wesitimela nezingxenye. Ojantshi abanamabherengi azigcobayo noma imiklamo engagcini ngokunakekela banciphisa isidingo sokugcotshwa okuvamile nokulungiswa. Lokhu kunenzuzo ezinhlelweni zokusebenza lapho ukufinyelela kukaloliwe kunomkhawulo noma izikhawu zokuwulungisa zidinga ukunwetshwa. Ojantshi abanezici ezishintsheka kalula, njengamabheringi noma ama-wiper, baqinisekisa ukunakekelwa okusheshayo nangempumelelo, behlisa isikhathi sokuphumula sisonke.

Ukunakekelwa okufanele kubalulekile ukuze kunwetshwe isikhathi sokuphila nokusebenza kwama-linear slide rails. Ukuhlola njalo ukuguga nokulimala, ukugcoba ngokuvumelana nezincomo zomkhiqizi, nokugcina ojantshi behlanzekile futhi bengenakho ukungcola kuyizinqubo ezibalulekile. Amanye ama-rail athuthukisiwe afika efakwe izinzwa nezinhlelo zokuqapha ezinikeza impendulo yesikhathi sangempela ngesimo sikaloliwe, okuvumela ukulungiswa okubikezelwayo kanye nokunciphisa ingozi yokwehluleka okungalindelekile.

Izindleko Nenani

Izindleko zihlale ziyisici esibalulekile ekukhetheni ama-rails amaslayidi aqondile, kodwa kufanele zicatshangelwe kumongo wenani lilonke. Ojantshi bezinga eliphezulu abanezici ezithuthukisiwe nezinto ezisezingeni eliphezulu bangase babe nezindleko eziphakeme zokuqala kodwa ngokuvamile banikeza ukusebenza okungcono, ubude besikhathi eside bempilo, kanye nezidingo zokunakekela eziphansi, okuholela ezindlekweni eziphelele zobunikazi.

Lapho uhlaziya izindleko, cabangela izidingo ezithile zohlelo lokusebenza. Isibonelo, isitimela esinembe kakhulu esinomthamo omkhulu womthwalo singase sidingeke emshinini we-CNC kodwa sigcwale ngokweqile kusistimu yokuthutha elula. Ukulinganisa izindleko nokucaciswa okudingekayo kuqinisekisa ukuthi ujantshi okhethiwe unikeza inani elingcono kakhulu lohlelo lokusebenza.

Ukwengeza, ukutholakala kwezingxenye ezishintshayo kanye nezinsizakalo zosekelo lomkhiqizi zingathinta inani lilonke. Ojantshi abavela kubakhiqizi abahlonishwayo bavame ukuza neziqinisekiso eziphelele, ukwesekwa kobuchwepheshe, nezingxenye ezisele ezitholakala kalula, eziqinisekisa ukuxazululwa okusheshayo kwezinkinga, ukunciphisa isikhathi sokuphumula kanye nezindleko ezengeziwe.

Izici Ezithuthukisiwe Nezinto Ezintsha Kuma-Linear Slide Rails

Ukuhlanganiswa ne-Smart Technologies

Ukuhlanganiswa kobuchwepheshe obuhlakaniphile kuma-linear slide rails kuguqule imboni yemishini. Ojantshi besimanje baya ngokuya bahlonyiswa ngezinzwa namandla e-IoT, bahlinzeka ngedatha yesikhathi sangempela kumamethrikhi okusebenza njengomthwalo, isivinini, izinga lokushisa, nokudlidliza. Le datha ingasetshenziselwa ukulungiswa okubikezelwayo, okuvumela opharetha ukuthi babhekane nezinkinga ezingase zibe khona ngaphambi kokuthi ziholele esikhathini sokungasebenzi.

Isibonelo, izinzwa ezishumekwe kumzila wesitimela zingaqapha ukuguga kwe-beraring futhi zinikeze izexwayiso uma ukulungiswa kuyadingeka. Le ndlela esebenzayo inweba impilo kajantshi futhi ithuthukise ukusebenza kahle kukonke. Ukwengeza, ama-rails anikwe amandla i-IoT angahlanganisa ezinhlelweni ezishintshayo ezinkulu, enze ukuxhumana okungenamthungo kanye nokuxhumana nezinye izingxenye.

Ukwenza ngokwezifiso kanye ne-Modularity

Ukwenza ngendlela oyifisayo kanye ne-modularity kuya ngokuya kubaluleke kakhulu ekukhetheni olayini bomzila wamaslayidi. Abakhiqizi manje banikeza izinketho ezihambisana nezidingo ezithile zohlelo lokusebenza, okuhlanganisa ubude obuhlukahlukene, amandla okulayisha, izinto zokwakha, nezindlela zokushayela. Lokhu kuvumelana nezimo kuqinisekisa ukuthi ujantshi ulungiselelwe izidingo ezithile, uthuthukisa ukusebenza nokusebenza kahle.

Imiklamo ye-modular ivumela ukuhlanganisa okulula nokuhlelwa kabusha kwesistimu yesitimela. Lokhu kunenzuzo ezinhlelweni zokusebenza lapho izidingo zingashintsha ngokuhamba kwesikhathi, njengasezindaweni zocwaningo nezokuthuthukiswa. Ama-modular rails anganwetshwa kalula, afushaniswe, noma amiswe kabusha ukuze ahambisane nokucaciswa okusha, anikeze isixazululo esingabizi futhi esivumelana nezimo.

Energy Efficiency

Ukusebenza kahle kwamandla kuwukukhathazeka okukhulayo embonini yemishini, futhi ama-linear slide rails nawo anjalo. Ukuthuthuka kwezinto zokwakha nokuklama kuye kwaholela ekwakhiweni kwamajantshi adinga amandla amancane ukuze asebenze. Isibonelo, ama-rail anamabhereng okushayisana kancane kanye nezindlela zokushayela ezithuthukisiwe zehlisa amandla adingekayo ukuhambisa inqola, okuholela ekusetshenzisweni kwamandla okuphansi.

Ukwengeza, ukusebenzisa izinto ezingasindi njenge-aluminium noma izinhlanganisela kunciphisa isisindo sesistimu kaloliwe, kuthuthukise ukusebenza kahle kwamandla. Amareyili awonga amandla ehlisa izindleko zokusebenza futhi afaka isandla emizamweni yokusimama ngokunciphisa izinga lekhabhoni lemishini.

Imboni Izicelo of Linear Amaslayidi Rails

Ukukhiqiza kanye ne-Automation

Ama-linear slide rails adlala indima ebalulekile ekukhiqizeni nasekuzenzeleni, ehlinzeka ngokunyakaza komugqa okunembayo nokuthembekile kwezinqubo ezihlukahlukene. Emishinini ye-CNC, ama-rails ama-slide aqondile aqinisekisa ukuma okunembile kwethuluzi lokusika, okuvumela ukukhiqizwa kwezingxenye ezinemba okuphezulu. Ngokufanayo, emigqeni yokuhlangana yamarobhothi, ojantshi besilayidi abalayini benza kube lula ukuhamba okubushelelezi nokunembile kwezingalo zamarobhothi, kuthuthukise ukusebenza kahle kwenqubo yokuhlanganisa nokunemba.

Imishini yokupakisha iphinde ithembele kakhulu kuma-linear slide rails ngemisebenzi efana nokugcwalisa, ukufaka uphawu, nokulebula. Ukunemba okuphezulu nokuphindaphindeka kwamareyili amaslayidi aqondile kuqinisekisa izinqubo ezingaguquguquki zokupakisha ezihlangabezana nezicaciso ezidingekayo. Ukwengeza, ukuqina namandla okulayisha ama-linear slide rails awenza afanelekele ukuphatha amaphakheji asindayo nezinto zokwakha.

Amadivaysi Ezokwelapha

Emkhakheni wezokwelapha, ama-linear slide rails asetshenziswa kumadivayisi ahlukahlukene namathuluzi adinga ukulawula ukunyakaza okunembayo nokuthembekile. Isibonelo, kumishini yokuthwebula efana ne-MRI kanye nezikena ze-CT, ama-linear slide rails aqinisekisa ukunyakaza okushelelayo nokunembile kwezingxenye zesithombe, ehlinzeka ngezithombe zekhwalithi ephezulu ukuze zixilongwe. Ngokufanayo, kumarobhothi okuhlinzwa, ama-linear slide rails anika amandla ukulawula izingalo zamarobhothi, athuthukisa ukunemba nokuphepha kwezinqubo zokuhlinzwa.

Izinguqulo ezikalwe ngegumbi elihlanzekile nezikalwe nge-vacuum zama-linear slide rails zibaluleke kakhulu ezinhlelweni zezokwelapha, lapho ukulawula ukungcoliswa kubaluleke kakhulu. Lawa ma-rail akhethekile aklanyelwe ukusebenza ezindaweni ezinezidingo eziqinile zenhlanzeko, ukuqinisekisa ukuthi izinto zokusebenza nemishini yezokwelapha ihlangabezana nezindinganiso ezidingekayo zokuphepha kwesiguli.

Aerospace nokuvikela

Izimboni ze-aerospace nezokuvikela zidinga ama-linear slide rails asebenza kahle kakhulu akwazi ukumelana nezimo ezinzima futhi anikeze ukusebenza okuthembekile. Ezicelweni ze-aerospace, ama-linear slide rails asetshenziswa ekukhiqizeni nasekunakekeleni izindiza, okuqinisekisa ukuqondana okunembayo nokunyakaza kwezingxenye. Umthamo omkhulu wokulayisha nokuqina kwama-linear slide rails kuwenza afaneleke ukuphatha izingxenye ezinzima neziyinkimbinkimbi ezisetshenziswa endizeni.

Ezicelweni zokuvikela, ama-linear slide rails asetshenziswa kumathuluzi nezinhlelo ezahlukahlukene, njengezinhlelo zokuqondisa ezicitshwayo, okokusebenza kwe-radar, nezimoto zempi. Ikhono lokusebenza ezindaweni ezinokhahlo, okuhlanganisa ukuchayeka emazingeni okushisa adlulele nezinto ezibolayo, libalulekile kulezi zinhlelo zokusebenza. Ukwengeza, ukunemba okuphezulu nokuthembeka kwamareyili amaslayidi aqondile kuqinisekisa ukuthi okokuvikela kusebenza ngempumelelo futhi kuhlangabezana nezidingo eziqinile zomkhakha.

Isifinyezo

Ama-linear slide rails ayingxenye ebalulekile ezimbonini ezihlukahlukene, ahlinzeka ngokunyakaza komugqa okunembayo nokuthembekile kwezinhlelo zokusebenza eziningi. Uma ukhetha ama-rails amaslayidi aqondile, kubalulekile ukucabangela izici ezifana nomthamo womthwalo, ukunemba nokunemba, ukufaneleka kwemvelo, ukufakwa nokugcinwa, kanye nezindleko kanye nenani. Intuthuko kwezobuchwepheshe iholele ekuthuthukisweni kwama-layini amaslayidi ahlakaniphile, enziwe ngendlela oyifisayo, futhi awonga amandla athuthukisa ukusebenza kwemishini nokusebenza kahle. Ngobubanzi bezinhlelo zabo zokusebenza, kusukela ekukhiqizeni nasekuzenzeni kuya emishinini yezokwelapha kanye ne-aerospace, ama-linear slide rails ayaqhubeka nokuba yinto ebalulekile embonini yemishini.