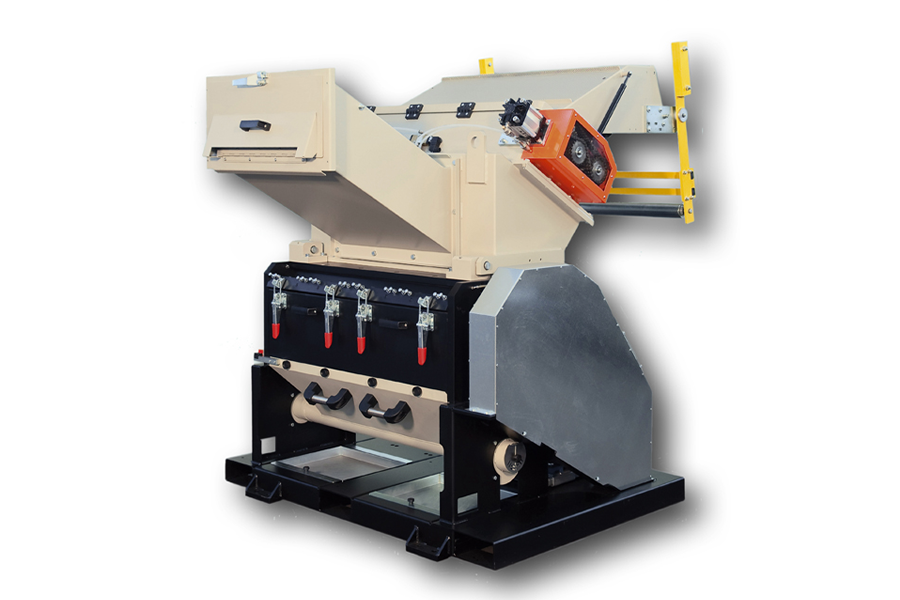

Ama-granulator epulasitiki imishini esetshenziselwa ukuvuselela imfucuza yepulasitiki. Lokhu bakwenza ngokusika amapulasitiki abe ama-flakes noma ama-regrind asetshenziswa kamuva ukwenza imikhiqizo ehlukene. Babonwa njenge kubalulekile ekuvimbeleni ukungcoliswa kwemvelo ngoba anciphisa inani lepulasitiki endaweni. Lo mhlahlandlela ugqamisa lokho amabhizinisi adinga ukukwazi mayelana nezimbudumbudu zepulasitiki.

Okuqukethwe

Ama-granulator epulasitiki: isabelo semakethe kanye nesidingo

Amathiphu Abalulekile okufanele uwacabangele lapho uthenga i-plastic granulator

Izinhlobo zama-granulator epulasitiki

Imakethe eqondiwe yama-granulator epulasitiki

Ama-granulator epulasitiki: Isabelo semakethe kanye nesidingo

Ama-granulator epulasitiki asetshenziselwa ukunika amandla amapulasitiki alahliwe ukuthi aphinde asetshenziswe ekukhiqizeni ipulasitiki. Isabelo semakethe sama-granulator epulasitiki singamaRandi ayizigidi eziyizinkulungwane ezingu-3.4. Amathrendi amanje emakethe yezimbudumbudu zepulasitiki ahlanganisa ukufaka ezinye izithasiselo ukusiza ukuthambisa noma ukwenza upulasitiki ube lukhuni, kuye ngokuthi uzophinde usetshenziswe kuphi, kanye nokuxuba ama-granules nokokusebenza okumsulwa ukuze yonke inhlaka igcine ikhwalithi ethile.

Amathiphu abalulekile okufanele uwacabangele lapho uthenga i-plastic granulator

Ukuthola i-granulator yepulasitiki kungaphansi kwamathiphu ambalwa okufanele wonke umnikazi webhizinisi awacabangele.

Ukujikeleza

Kunezinhlobo ezine zamarotha kuye ngokuthi yini ecutshungulwayo. Ivuliwe, ivaliwe/iqinile, iyadidizela, futhi ihlukaniswe. I-rotor evulekile ifanele ama-resin azwela ukushisa.

I-rotor evaliwe ayinaso isikhala phakathi kommese kanye ne-shaft. Ngakho-ke, ivumela ukusika phakathi kwama-feedstocks aminyene. I-rotor ehlukanisiwe ifanele ukusika phakathi kwezinto ezisindayo, kuyilapho i-rotor ehlukanisiwe inqamula izinto ezisindayo futhi inyusa inani lokusikeka ngokuzungeza ngakunye.

Umklamo wommese

Imimese ifakwe embhedeni omile noma ngqo ku-rotor. Isikhala phakathi kwemimese sizonquma uhlobo lwegranule. Isikhala sommese esincane sizophumela entweni ethambile, kuyilapho isikhala esikhulu phakathi kwemimese siphumela kuma-granules aqinile.

Maintenance

Ukugcinwa okufanele kubalulekile ukuze umshini ukhiqize ama-granules ekhwalithi ephezulu isikhathi eside. Ukugcinwa kuzonciphisa nothuli kuma-granules. Njengoba ama-granulator awaklanyelwe kucatshangelwa ukunakekelwa, ukugcinwa kochwepheshe kuyinto okufanele amabhizinisi ayicabangele ngaphambi kokuthenga.

Ukusetshenziswa okuhlosiwe

Amabhizinisi kufanele azi ukuthi azokusebenzisa kanjani i-granulator yepulasitiki. Amanye ama-granulator epulasitiki anomthamo we 1000 kg / hr, kuyilapho abanye bengakwazi ukucubungula 3000 kg / hr. Indlela ye-granulation nayo ibalulekile. Imishini ingasebenzisa noma iyiphi i-extrusion, shaya ukwakha, ukubumba umjovo, noma ukugaywa kabusha. Umkhiqizo ocutshungulwayo ungokunye ukucatshangelwa, kungakhathaliseki ukuthi amabhodlela noma amashidi.

Izinhlobo zama-granulator epulasitiki

Kunezinhlobo eziningana zama-granulator epulasitiki njengoba zibalwe ngezansi.

Ngaphandle komshini wokunyathelisa wepulasitiki

Ngaphandle kwama-granulators wokucindezela ingahlanganisa kunoma yikuphi ukubumba noma ukusebenza kwe-extrusion yokuqoqwa kwe-resin.

Izici:

- Iza ne-sound insulation.

- Inamagumbi okusika apholile ngamanzi.

- Ifaka izikrini zokubuka zokubuka ukugaya njengoba kwenzeka.

buhle:

- Ingalungiselelwa ukusetshenziswa mathupha noma okuzenzakalelayo.

- Ifanelekakhulu imigijimo emifushane yokukhiqiza.

bawo:

- Kubiza ukuyithola nokuyinakekela.

I-Thermoforming granulators

I-Thermoforming ama-granulators yakhelwe ukucubungula okungaphakathi nokungaxhunyiwe ku-inthanethi kwezinto eziyisicaba.

Izici:

- Inodayi kanye nonqenqema okuhanjiswa ngalo futhi kucutshungulwe.

- Izinto eziyisicaba zibe sezibalwa ngama-roller ngaphambi kokuya ku-granulator.

buhle:

- Ihlinzeka ngama-granules ekhwalithi ephezulu.

bawo:

- Ingakwazi ukucubungula izinto eziyisicaba kuphela.

Inhlanganisela granulator

Inhlanganisela granulator ube ne-shredder kanye ne-granulator emshinini owodwa.

Izici:

- Izinto ezisindayo, eziminyene kuqala zicutshungulwa ku-shredder ngaphambi kokuba ziyiswe ku-granulator.

- I-shredder inikeza usayizi wezinto ezingaguquki kanye nevolumu ku-granulator.

buhle:

- Ihlinzeka ngama-granules ekhwalithi ephezulu ngenxa yokucubungula kwangaphambili.

- Inezinga eliphezulu lokuphuma phambili.

- Kungaxhunywa uzibuthe kuwo ukuze kuhlukaniswe impahla eyinsimbi nepulasitiki.

bawo:

- Kuyinkimbinkimbi ngokwemishini ukusebenza.

Ama-granulators aphakathi

Ama-granulators aphakathi sebenza ngokulandela isimiso sokusika isikere esitsheke kabili.

Izici:

- Inikeza amajiyometri e-tangential noma e-offset yezinto zokusika.

- Igumbi lokusika lingahlelwa ukuthi lisike izingxenye eziminyene kakhulu.

buhle:

- Iyakwazi ukucubungula izingxenye ezinkulu nezincane ezinevolumu.

- Isebenza kahle ezinhlelweni ezisukela ezingxenyeni zemishini ukuya kumjovo omkhulu nezinto zikagesi zefenisha.

- I-tangential offset inikeza amandla okucubungula izinhlobo eziningi ze-scrap ngamandla aphansi.

bawo:

- Ingavala ngokushesha uma ilayishwe ngokungalungile.

- Kubiza ukuyithola.

Imakethe eqondiwe yama-granulator epulasitiki

Ama-granulator epulasitiki kulindeleke ukuthi akhule ku-CAGR ye 5.6% ngo-2027 kuya ku-$ 5.1 billion. Lokhu kukhula kubangwa yizici ezimbalwa, okuhlanganisa ukukhuphuka kwezimboni emhlabeni wonke kanye nokunciphisa izindleko zokukhiqiza ngenxa yokusetshenziswa kwama-granules. Isifunda sase-Asia Pacific kulindeleke ukuthi sibuse imakethe, silandelwe yisifunda saseNyakatho Melika.

Isiphetho

Kule nkathi lapho ukungcoliswa kwemvelo kugcwele khona, ama-granulator epulasitiki abaluleke kakhulu ekugayweni kabusha kwamapulasitiki. I-athikili igqamisa izici ezibalulekile okufanele zicatshangelwe kanye nezinhlobo zama-granulator epulasitiki atholakalayo. Ngakho-ke, kuyasiza emabhizinisini afuna ukungena ekugayweni kabusha kukadoti wepulasitiki.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu