Ekuphenduleni izimfuno zezimboni zamazwe ngamazwe, ubuchwepheshe be-laser buthuthukile ukuze bunikeze imishini yokuqopha nokusika ye-laser esebenza kahle kakhulu enciphisa isikhathi sokukhiqiza phakathi. Le mishini isebenzisa amandla amancane, inekhwalithi eqondile, futhi ingasebenza ngezinto ezihlukahlukene. Qhubeka ufunda ukuze ufunde mayelana namathrendi akamuva embonini ye-laser nokuthi ungayikhetha kanjani imishini esebenza kahle kakhulu ngezidingo zakho.

Okuqukethwe

Imakethe yobuchwepheshe be-laser yomhlaba wonke

Amathrendi embonini yomshini we-laser

Ukuthuthukiswa kobuchwepheshe be-laser

Okunye ukuthuthukiswa kwemishini yokusika i-laser yesizukulwane esilandelayo

Amazwi wokugcina

Imakethe yobuchwepheshe be-laser yomhlaba wonke

Ngo-2022, imakethe yomhlaba wonke yobuchwepheshe be-laser yalinganiselwa ku-USD 16.7 ibhiliyoni, futhi kulindeleke ukuthi ikhule ngezinga lokukhula elihlanganisiwe lonyaka (CAGR) lika-8.9% ukuze lifinyelele ku-USD 25.6 billion ngo-2027. Lokhu ubuchwepheshe be-laser inikeza ukunemba okuphezulu, ukukhiqiza, kanye nokuguquguquka kwezicelo zokucubungula zezimboni ezifana nokukhiqiza.

Ukwenyuka kwesidingo emikhakheni kawoyela negesi, yezimoto, yezokwelapha kanye neyendwangu kuqhuba ukukhula kwemakethe. Ngaphezu kwalokho, ukusebenza okuphezulu kwe laser-based amasu ngaphezu kwezindlela zokucubungula zendabuko kuyisici esibalulekile esiqhuba ukukhula kwemakethe.

Lesi sihloko sizosiza abafundi ekuzulazuleni amathrendi emishini ye-laser abusa imakethe.

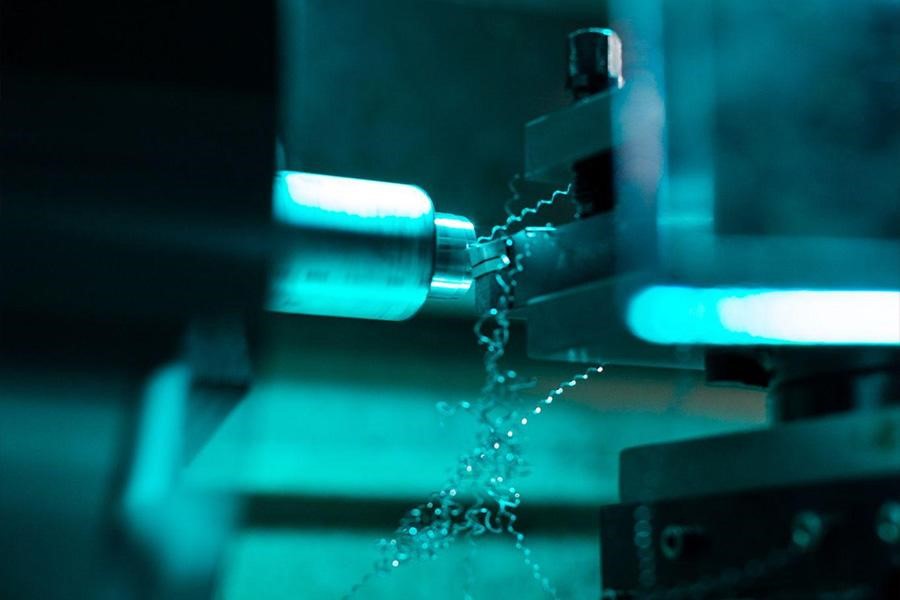

I-laser welding

The i-laser welding Imakethe yomshini kulindeleke ukuthi ikhule ku-CAGR ka-4.73% phakathi kuka-2021 no-2025 ukuze ifinyelele ku-USD. 373.97 million ekupheleni kwesikhathi. I-laser welding kuyindlela yokuhlanganisa izinsimbi ezahlukene usebenzisa i-laser beam. Lokhu Welding kwenziwa ngezindlela ezimbili: conduction Welding limited kanye keyhole Welding.

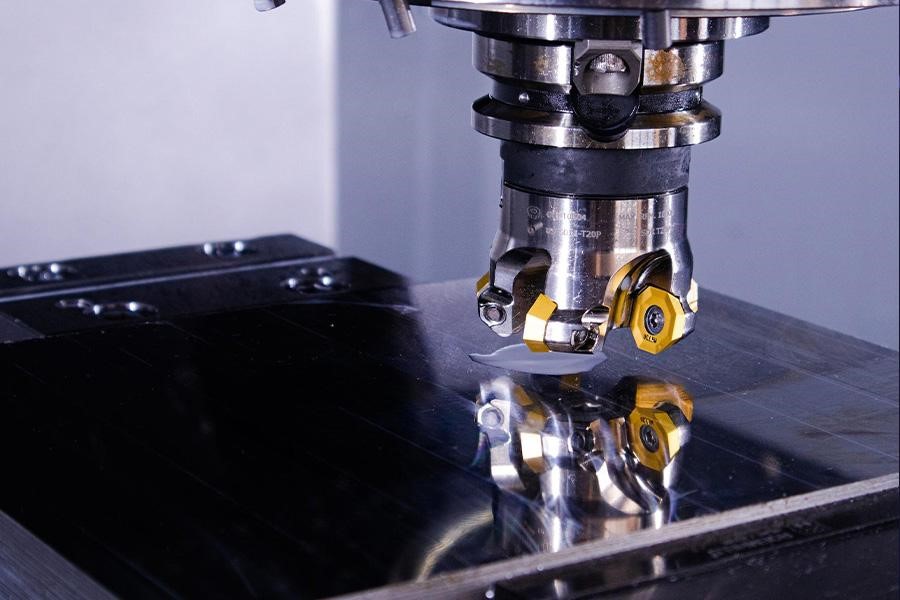

Ukusika kwe-Laser

The ukusika kwe-laser imakethe yomshini kulindeleke ukuthi ikhule nge-USD 1.02 bhiliyoni phakathi kuka-2020 no-2024. Le mishini isebenzisa ama-laser ukusika izinto ezahlukene kusuka kupulasitiki kuya ensimbi ngokunemba okuphelele. Angamathuluzi abalulekile asetshenziswa kabanzi ezimbonini eziningi, okuhlanganisa ezogesi nezezimoto.

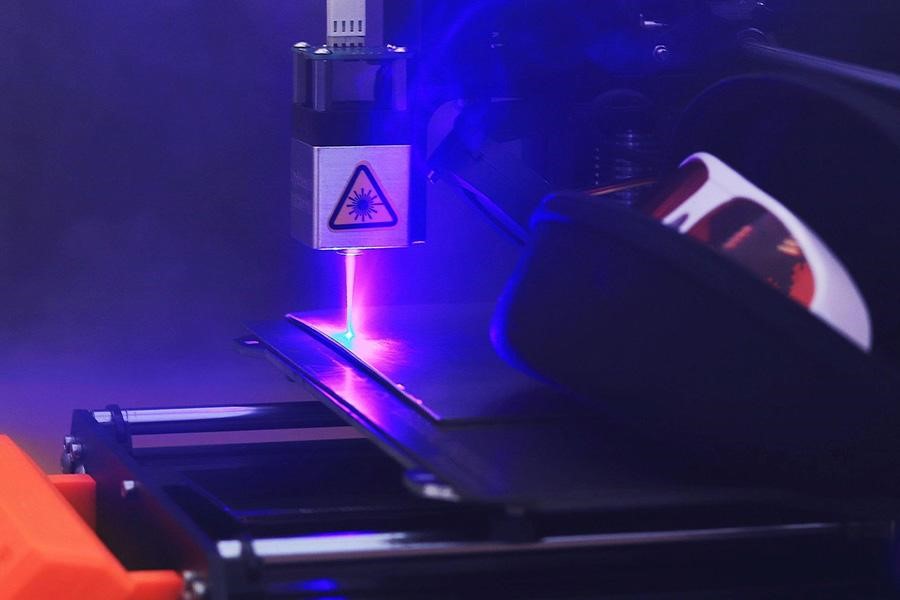

Ukudweba kwe-Laser

Imishini ye-laser etching isetshenziselwa ukuqopha amamaki ezindaweni ezahlukahlukene. Phakathi kuka-2021 no-2028, umhlaba jikelele laser wokugubha Imakethe kulindeleke ukuthi ikhule ku-CAGR ye 8.0%. I-Asia Pacific izoba yimakethe enkulu kunazo zonke yale mishini, ilandelwe yiNyakatho Melika kanye ne-Europe.

Ukuhlanza i-laser

Ukuhlanzwa kwe-laser noma ukukhipha i-laser kubhekisela endleleni lapho izinto eziphuma endaweni eqinile zikhanyiswa nge-laser beam. Le makethe yokuhlanza ibe nenani lama-USD 587.18 million ngo-2021 futhi kulindeleke ukuthi ikhule ku-CAGR ka-4.10% ukuze ifinyelele ku-USD 803.28 million ngo-2030.

Ukumaketha kwe-laser

Ngokuphikisana umbhalo we-laser, ukumaka nge-laser kumane kubeka ulwazi endaweni engenakho ukungena. Uma kuqhathaniswa nezinye izindlela zokumaka, lolu hlelo luhlinzeka ngokufundeka okuphezulu nokunemba kuyilapho lubiza kakhulu. Imakethe yokumaka nge-laser ibilinganiselwa ku-USD 2.9 billion ngo-2022 futhi kulindeleke ukuthi ikhule ku-CAGR ka-7.2% ukuze ifinyelele ku-USD 4.1 billion ngo-2027.

Amathrendi embonini yomshini we-laser

Umhlaba jikelele umshini we-laser imakethe ingahlukaniswa ngezigaba ezilandelayo: i-CO2 laser, i-fiber laser, nemishini ye-laser diode.

Imakethe yomshini we-CO2 laser

Ukumaka kwe-laser CO2 ifanele izinto eziningi ezingezona ezensimbi, okuhlanganisa ukhuni, ipulasitiki, i-acrylic, izindwangu, namatshe. Ngaphezu kwalokho, ubuchwepheshe be-laser ye-CO2 busetshenziswa kakhulu embonini yezemithi, ekufakweni kokudla, nasezimbonini zikagesi. Lokhu kungenxa yokuthi lasers kuyisinqumo esihle kakhulu sokusika izinto ezijiyile ngesikhathi sokubhoboza esisheshayo futhi kunikeza isiphetho esibushelelezi. Kodwa-ke, ama-lasers adla amandla amaningi kune-fiber, okuholela ezindlekweni zokusebenza eziphezulu.

The I-CO2 laser imakethe ihlukaniswe yaba izingxenye ezintathu ngokusekelwe ohlotsheni lwe-laser, imboni yokusetshenziswa kokuphela, kanye nezwe. Phakathi kwezigaba, ingxenye ye-laser yegesi ye-CO2 ikhombisa isithembiso esikhulu, kanye I-CO2 laser Imakethe iqhutshwa ikakhulukazi imboni yezimoto, ezokukhiqiza, ezokuvikela kanye nezokunakekelwa kwezempilo. Ngokwendawo, iNyakatho neNingizimu Melika, i-Asia Pacific, i-Europe kanye ne-Afrika zinamathuba amaningi okukhula kwemakethe.

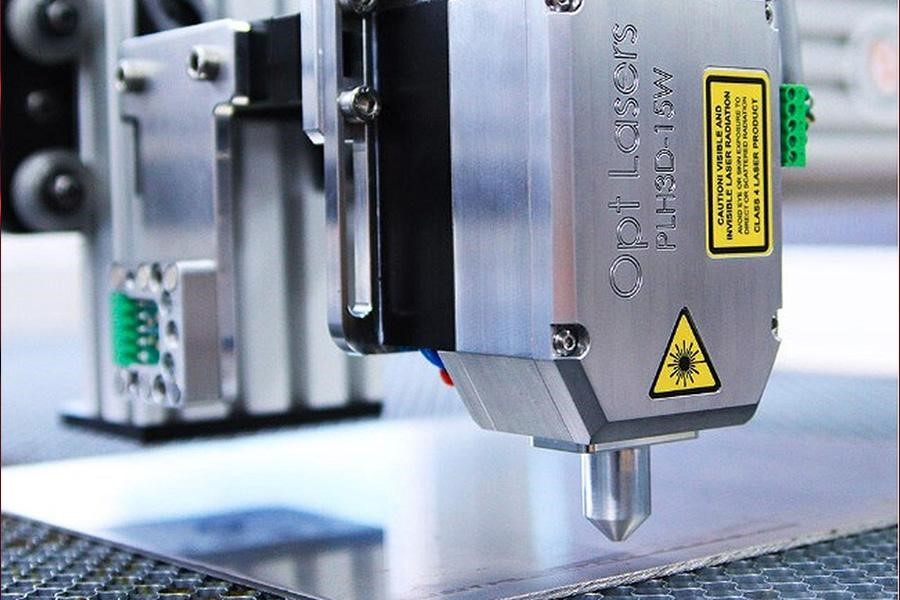

Imakethe yomshini we-fiber laser

I-fiber laser imishini ingaqopha, i-etching, i-annealing, kanye nokumaka okugqame kakhulu. Ngenxa yobubanzi bawo bokugxila obuncane, lawa ma-laser afaneleka kakhulu ukumaka idatha efana nezinombolo namabhakhodi ezinsimbi. I-Fiber lasers azinasondlo, zinempilo ende yesevisi, futhi zinezigxivizo ezincane kunama-laser e-CO2.

I-Fiber lasers babona isidingo sokuhlanza izicelo. Izimboni eziningi zisebenzisa imishini yokuhlanza i-laser ukusiza ukususa ukugqwala, upende, ama-oxide, nokungcola ezinsimbi. Imishini enamandla amakhulu okusika i-laser kusukela ku-20 W ukuya ku-6k W inamaphuzu amanani aphezulu.

The laser imakethe kulindeleke ukuthi ikhule ku-CAGR ka-10.9% phakathi kuka-2017 kuya ku-2023. INyakatho Melika kanye neYurophu zinamathuba aphezulu kakhulu okukhula kwemakethe, kanti i-Asia Pacific, Middle East, kanye ne-Afrika zonke zinendawo ebalulekile yokwanda.

Imakethe yomshini we-Diode laser

I-Diode laser ubuchwepheshe busetshenziswa kakhulu ezikhombi ze-laser, futhi bufana ngokuyisisekelo nama-diode akhishwa ukukhanya. Nakuba ekuqaleni kwakunzima ngamalaser e-diode ukusika insimbi, ukuthuthuka kwezobuchwepheshe kwawushintsha unomphela imboni. Umshini we-direct diode laser (DDL) uhlanganisa ukukhanya okuvela kuma-diode amaningi ukuze kwakheke i-beam eyodwa esuke iqondiswe phezulu kokuthakaselayo.

Ama-laser we-diode asebenza kahle kakhulu kune-fiber lasers ngoba angasetshenziswa ezindaweni ezicwebezelayo njengethusi ne-aluminium. Ngenxa yokuthi ubude begagasi be-laser diode bumuncwa kalula yi-aluminium, isivinini sokusika sishesha ngo-100%. Ngaphezu kwalokho, uma kuqhathaniswa nama-fiber lasers, i-diode enamandla amakhulu Imishini ingasebenza 10-20% ngokushesha ezinsimbi. Futhi okokugcina, bahlinzeka ngekhwalithi engcono yonqenqema lapho usebenza ngezinto eziminyene.

Ukuthuthukiswa kobuchwepheshe be-laser

Njalo ngonyaka, ubuchwepheshe be-laser obunamandla amakhulu buthuthuka, nama-laser we I-6kW noma ngaphezulu sekujwayelekile kakhulu uma kuqhathaniswa nezinguqulo ezindala zemishini yokusika i-laser engu-4kW. Inzuzo ebaluleke kakhulu ukuthi isikhathi sokukhiqiza sincishiswa ngesigamu.

Izigaba ezilandelayo zixoxa ngentuthuko ebaluleke kakhulu emakethe yokusika i-laser kanye nekusasa layo kanye nezinhlelo zokusebenza.

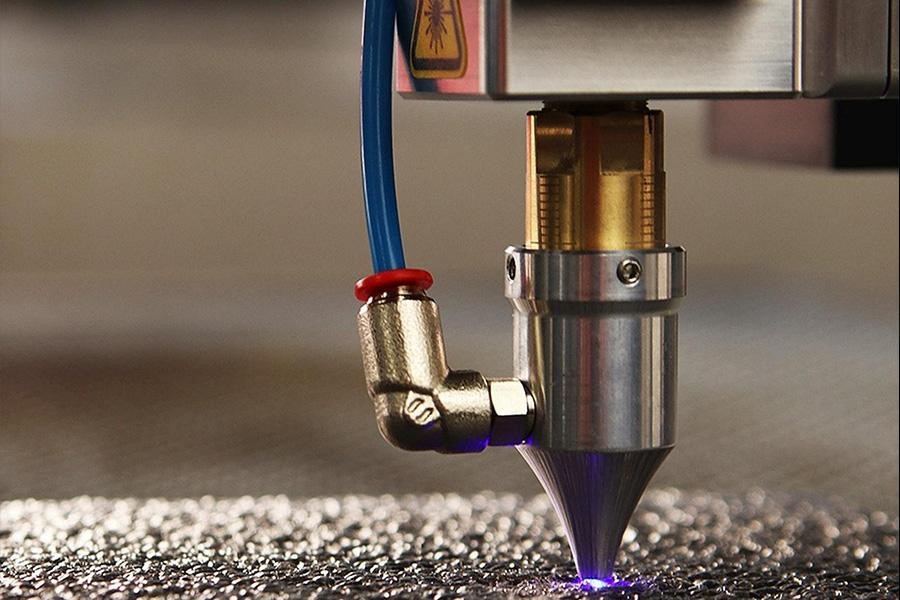

Ukusebenza okuphezulu

Ukusika i-Laser Imishini babe nemibhobho eyodwa, ekabili, noma esetshenziswa kancane. Ama-nozzles awodwa yiwona avame kakhulu futhi ahlonyiswe ngezindlela ezithembekile kodwa zokusika ezihamba kancane ezinokuteyipha okunomkhawulo. Ngenxa yalokho, imibhobho eyodwa idla igesi eningi. Imilomo emibili ingonga kufikela ku-50% kugesi uma kuqhathaniswa nemibhobho eyodwa. Imibhobho yokusetshenziswa kancane izohlinzeka ngendlela yokusika eshesha kakhulu nesebenza kahle kakhulu kumabhizinisi asebenzisa izinto eziwu-quarter-inch noma eziminyene.

Amandla aphezulu ngokuvamile athuthukisa ukusebenza kahle kanye nokusebenza kwesistimu. Ngenxa yalokho, amandla aphezulu imishini ye-laser ingasika ngesivinini esikhulu ngenkathi yengeza imingcele enembe kakhudlwana. Baphinde bathuthukise ukusebenza kwe-laser ngokuvumela izikali zokusika eziminyene. Idizayini ngayinye ye-nozzle ifanele izinto ezahlukahlukene namaphrojekthi.

Ukukhiqiza kwe-laser cutting

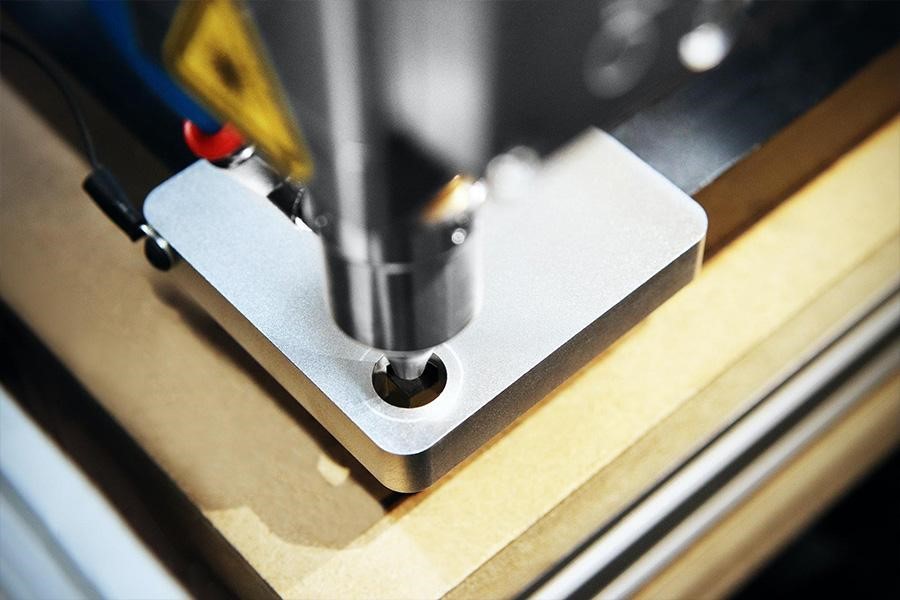

Ukusika i-laser, ukubhoboza, ukumaka, kanye nokushisela konke kuyimisebenzi yobuchwepheshe be-laser, futhi amanye amamodeli anganikeza nokuqoshwa kokuhlangenwe nakho komuntu siqu. Lezi Imishini ingasebenza ngezinto ezihlukahlukene, okuhlanganisa ukhuni, ama-alloys, izinsimbi, izitsha zobumba, nama-polymers.

Uma kuziwa ekwenzeni imikhiqizo ngendlela oyifisayo yamabhizinisi ahlukene, ukusika kwe-laser noma ukuphrinta kuyindlela yokuya, njengoba isebenza kahle ngezinto ezihlukahlukene. Ngenxa yekhono layo lokuhlinzeka ngomumo nosayizi abangaguquki kuhlanganiswe nokunemba kwe-2D ne-3D, le mishini inezinhlelo zokusebenza ezimbalwa embonini yezokwakha. Ngokwesibonelo, ukusika kwe-laser kuyindlela ephumelelayo yokwenza ngokwezifiso ukwakhiwa kwensimbi yeshidi ukuze kusetshenziswe indawo yokuhlala nokungeyona indawo yokuhlala.

Ukuthembeka kwe-laser automation

Imisebenzi eminingi yenziwe ngokuzenzakalelayo ngenxa yentuthuko yezobuchwepheshe, ukunciphisa umzimba wezindawo zokukhiqiza kanye nokwanda kwamathuba e-laser automation. Kunezinhlobo ezintathu zezinhlelo zokuphatha impahla laser ukusika i-automation: umshini ozimele onetafula le-shuttle, umshini we-laser wokulayisha umthwalo, nomshini we-laser onohlelo lokukhiqiza oluguquguqukayo.

Ngaphezu kwalokho, izingxenye ezinjengamatafula okusika, izikele, izilebula, noma izinqola zingasetshenziswa ngazinye kunoma iyiphi isistimu ye-automation. Lolu hlelo lokuzenzakalela lungakhuphula umkhiqizo kanye nokukhiqiza kuyilapho lwehlisa ukuthembela kubasebenzi. Imijikelezo yokuhlola okuzenzakalelayo nayo iba mifishane ukuze ihambisane nesidingo esikhulayo kuyilapho ihlinzeka ngesikhuthazo sentuthuko yesikhathi esizayo.

As CO2 futhi ama-fiber lasers ayaqhubeka nokubusa emakethe, imboni ibheka imishini yokusika i-laser enamandla nakakhulu. Imishini enebanga eliphezulu lamandla we I-6kW kanye nemibhobho enciphisa ukuthembela kugesi nesikhathi sokukhiqiza kuyakhethwa namuhla.

Okunye ukuthuthukiswa kwemishini yokusika i-laser yesizukulwane esilandelayo

Ukuguquguquka: Umshini wokusika we-laser we-G wakamuva ungafakwa esisekelweni semishini yokusika i-arc yangaphambili ye-plasma. Ingafakwa futhi isetshenziswe kusisekelo sokuqala, ukonga isikhathi nezindleko. Amakhasimende angenayo isisekelo sikasimende esikhona angafaka ngokushesha futhi aye esimweni sokukhiqiza ngokukhetha isisekelo sombhede ozikhethela sona.

Ukusika i-bevel: Ukucutshungulwa kwe-Bevel isici esikhona ochungechungeni lwe-G umshini wokwehlisa laser. Ama-bevel amise okwe-V, amise okwe-C, amise okuka-Y, kanye nanjengo-K ayizinhlobo ezivame kakhulu ezisetshenziswa ekukhiqizeni imishini yezolimo neyokwakha.

Ukuphepha okuthuthukisiwe: Imishini ye-laser yochungechunge lwe-G inamagrated okuphepha ngemuva nangaphambili kwe-beam. Uma into noma umuntu engena ebangeni eliphephile le-beam, uhlelo oluphuthumayo lusebenza ngokushesha.

Umsebenzi wokugwema izithiyo osebenzayo: Imishini ye-laser ingakwazi ukubona isithiyo esizayo futhi iphendule ngokushesha ukuze igweme ukungqubuzana. Lokhu kusabela ngokushesha kuzixazulula ngokuphumelelayo izinkinga zokusikwa kokuphazamiseka kanye nokushayisana kwekhanda le-laser phakathi nenqubo yokusika.

Amazwi wokugcina

Imakethe yemishini ye-laser ishintsha njalo ngenxa yentuthuko eqhubekayo kwezobuchwepheshe. Ngokusho kwezitayela zakamuva, i-CO2 nama-fiber lasers abusa imakethe ngenxa yokusebenza okuthuthukisiwe, kodwa izici zangaphandle nazo zinomthelela empumelelweni yazo.

Ama-laser diode aqondile azothola i-CAGR ephezulu kakhulu esikhathini esizayo ngenxa yomthamo wawo othuthukisiwe wokuphatha, ukusevisa kalula, kanye nokwethenjelwa okwandisiwe kuyilapho ehlisa izindleko zokusebenza. Ukusetshenziswa kwawo okusabalele e-ablation etching kanye ne-heat-affect zone etching nakho kube nomthelela ekukhuleni kwazo.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu