Imishini yokugaya—ebuye yaziwe ngokuthi yimishini yokwenza izinto eziningi—ibalulekile ezitolo zensimbi nezezinkuni. Umshini wokugaya iyithuluzi elizungeza ithuluzi eliyindilinga elinemiphetho embalwa yokusika ehlelwe ngokulinganayo mayelana ne-axis yayo, esetshenziselwa ukususa impahla kucezu lokusebenza.

Akuyona imfihlo ukuthi umshini wokugaya wekhwalithi omuhle ungahlala iminyaka futhi usize abakhiqizi bahlangabezane nezindinganiso eziphakeme zokubekezelelana. Kodwa-ke, ukukhetha umshini wokugaya ophelele kuwumsebenzi ngokwako uma ungawazi kahle imininingwane.

Lo mhlahlandlela unikeza umbono osheshayo wemishini yokugaya kanye namathiphu ongayilandela ukuze uthole imishini yokugaya engcono kakhulu ukuze uhlangabezane nezidingo zamakhasimende akho wokugcina.

Okuqukethwe

Amandla emakethe yomshini wokugaya

Amathiphu wokukhetha imishini yokugaya efanele

Ucezu oluyisihluthulelo lomshini wokusebenza ngensimbi nokusebenza ngokhuni

Amandla emakethe yomshini wokugaya

Imikhiqizo yensimbi eyakhiwe isetshenziswa kabanzi emhlabeni wonke kusukela ezinhlosweni zasendlini kuye kwezimboni, okunikeza ukukhula okuqinile kwemishini yokugaya. Imakethe yomshini wokugaya ilinganiselwa ukuthi izofinyelela I-USD 102.3 billion ekupheleni kuka-2026, ikhula ku-CAGR ka-7.2%.

Ubuchwepheshe banamuhla obuthuthukisiwe bunikeza nobubanzi obuhle bemishini yokugaya ye-CNC ezenzakalelayo. Lo sayizi wemakethe usethelwe ukunwebeka ukuze I-USD 128.41 billion ngo-2028. Yize lokhu kuwukuqagela komhlaba wonke, imakethe yase-Asia Pacific kulindeleke ukuthi ifakazele ukukhula okuphezulu kakhulu. Ngaphezu kwalokho, imakethe yaseYurophu kulindeleke ukuthi ibone ukukhula okukhulu uma iqhathaniswa neNyakatho Melika, Middle East kanye ne-Afrika, kanye neLatin America.

Umgomo oyinhloko wokukhula kwemishini yokugaya ye-CNC kungabalelwa ekwandeni kokutshalwa kwezimali ku-inthanethi Yezinto (IoT) ngaphakathi komkhakha wokukhiqiza. Ngaphezu kwalokho, ukwamukela amasu okukhiqiza okungezayo nokukhiphayo ukuze kwakhiwe imikhiqizo eyinkimbinkimbi, enembayo ephezulu kuzonyusa isidingo sale mishini.

Amathiphu wokukhetha imishini yokugaya efanele

1: Inombolo yezimbazo

Imishini yokugaya iyizinhlobo ezintathu ezisekelwe enanini lezimbazo: mpo, ovundlile, kanye nendawo yonke. Umehluko phakathi kwale mishini yokugaya usezimbazweni lapho ukuphotha okukwazi ukunyakaza khona. Imishini eminingi yokugaya inama-eksisi amathathu: i-eksisi eqondile ebizwa ngokuthi i-Z-axis, i-axis longitudinal ebizwa ngokuthi i-X-axis, kanye ne-axis ephambanayo ebizwa ngokuthi i-Y-eksisi.

Umshini wokugaya ome mpo

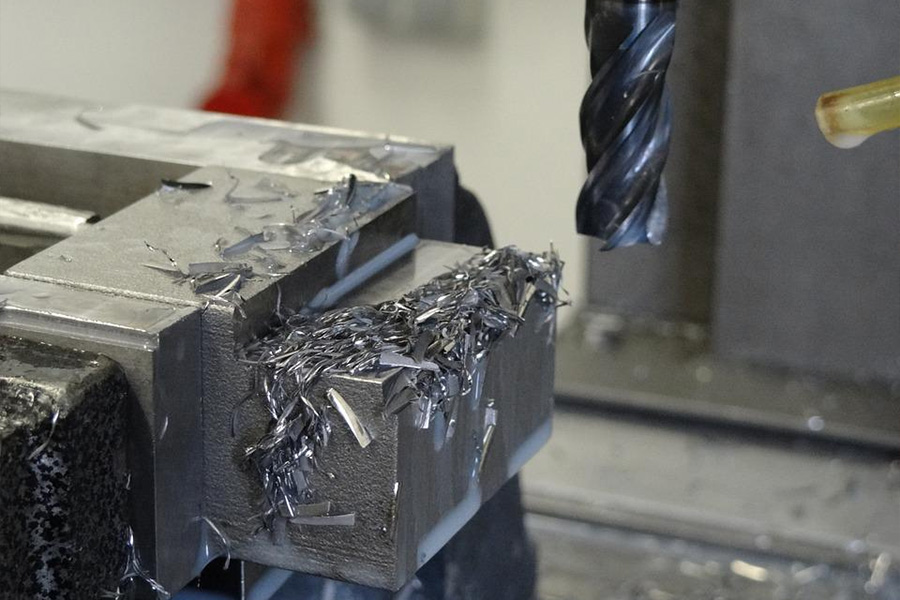

The umshini wokugaya ume mpo iyona esetshenziswa kabanzi. Inento yokuphotha eqondile ebheke kucezu lokusebenza. Emshinini wokugaya oqondile, ucezu lokusebenza luhlala luqinile ngenkathi itafula lihamba eduze kwalo. Le mishini yokugaya igudluka kalula, okuvumela opharetha ukuthi asuse impahla ku-workpiece ukuguquguquka okwengeziwe.

Ikhanda lomshini omile nalo lingahanjiswa ngezindlela ezihlukene. Lo mshini ngokuvamile usetshenziselwa ukusebenza endaweni eqondile yokugaya okuyi-angular, slot milling, T- slot milling, kanye nokugaya flat. Imvamisa, imishini yokugaya eqondile ingakwazi ukucubungula izingxenye ezifika ku-6000mm ububanzi, 2500mm ukuphakama, kanye no-700mm ukujula.

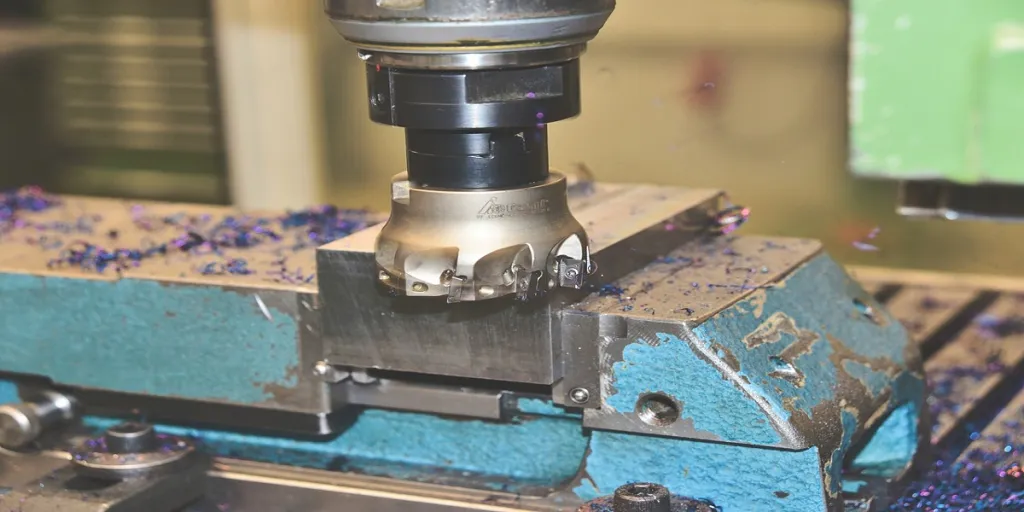

Umshini wokugaya ovundlile

Imishini yokugaya evundlile isetshenziselwa ikakhulukazi imisebenzi lapho imishini yokugaya eqondile ingafaneleki. Imishini yokugaya evundlile ine-spindle evundlile, futhi amathuluzi anamathiselwe ngokuhambisana netafula. Le mishini ilungile ezimeni lapho umsebenzi wokugaya uhlanganisa ukususa impahla eningi ngokunemba okuncane.

Kulo mshini wokugaya, ama-milling cutters amaningana angabekwa eduze komunye nomunye. Umshini ungakwazi futhi ukuthwala umthwalo osindayo wokusika futhi ungasika ngomshini wokugaya. Imishini yokugaya evundlile ngokuvamile zilungele ukwenza imifantu ngesikhathi esisodwa, ama-bevel, nezindiza futhi zisebenza kangcono ekukhishweni kwe-chip. Le mishini iphinde ibe usizo ekwenzeni ukusikeka okusindayo nokujula uma kuqhathaniswa nomshini wokugaya oqondile.

Ngokufanayo nemishini yokugaya eqondile, izigayo ezivundlile ziyatholakala ngosayizi wetafula abahlukahlukene ukuze kucutshungulwe izingxenye ezifika ku-6000mm ububanzi, 2500mm ubude, kanye no-700mm ukujula.

Umshini wokugaya we-Universal

Umshini wokugaya jikelele unento yokuphotha yendawo yonke exhunywe kuhinji, futhi ngokungafani neminye imishini yokugaya, ungasebenza ezimbazweni eziningi. Ama-saha blades amaningi angaboshelwa kanyekanye ku-a umshini wokugaya jikelele, okwenza isebenze kahle kakhulu. Ikhanda lokugaya lomshini lingakwazi ukushwiba ngo-45 degrees ukuya kwesokunxele nakwesokudla futhi linokuqina nokuqina okwanele. Imishini yokugaya i-Universal isetshenziswa ngokuyinhloko ukucubungula izindawo ezihlukene zezingxenye ezincane, ezinesisindo esiphansi kanye nokukhiqizwa kwe-serial.

Kungenzeka futhi ukusebenzisa okunamathiselwe okungeziwe njengokunamathiselwe kwe-slot, okunamathiselwe okujikelezayo, okunamathiselwe kokugaya okuqondile, nenhloko yenkomba noma ikhanda elihlukanisayo ukuze kuthuthukiswe umthamo womshini.

2. Uhlobo lokuphakelayo

Imishini yokugaya isihambe ibanga elide ngobuhlakani. Imishini yokugaya evamile isebenzisa amasondo ezandla u-opharetha awajikayo ukuze asuse ucezu lomsebenzi aye noma alususe endaweni yokubhoboza. Nokho, imishini etholakalayo namuhla idinga umsebenzi ongokomzimba omncane noma awukho nhlobo. Ngakho-ke, uma uhlose ukuthwebula imakethe embonini, unganikeza izinketho eziningi kumakhasimende akho, futhi uhlobo lokuphakelayo lokuhamba ngetafula kungenye yezindawo zokuthengisa ezibalulekile. Okuphakelayo okudume kakhulu ozokuthola emishinini yokugaya namuhla yilezi:

- Okuphakelayo kwendabuko

- Injini ephakelwa amandla

- Umshini wokugaya we-CNC

Okuphakelayo kwendabuko

Okuphakelayo kwendabuko kusengenye yezinketho ezidume kakhulu, ngenxa yemikhuba evamile yokugaya. Lokhu indlela yokuphakelayo isebenza kuma-axes angu-3 isebenzisa amasondo ezandla. Isondo lesandla lisetshenziselwa ukuhambisa ithebula, elimakwe ngezilinganiso ezifana namamilimitha ukuze linikeze ukulawula okwengeziwe ku-opharetha lapho ehambisa ithebula futhi athole ukunemba ngenkathi enza ukusikeka.

Injini yokuphakela amandla

Kulolu hlobo lomshini wokugaya, okuphakelayo kwamandla kunamathiselwe kuzikulufu zebhola zokubhola, ukugaya, neminye imishini ngenani elinembile, eliphindaphindwayo lokuphakela. Zenzelwe ukuhlinzeka ukushintshwa kokuphakelayo okuzenzakalelayo amasondo ezandla kumathuluzi omshini olawulwa ngesandla, okuvumela ithebula ukuthi linyakaze njalo. Indlela yokuphakela amandla isebenzisa i-DC geared motor ene-12V, amagiya e-bevel, nebhande lesikhathi.

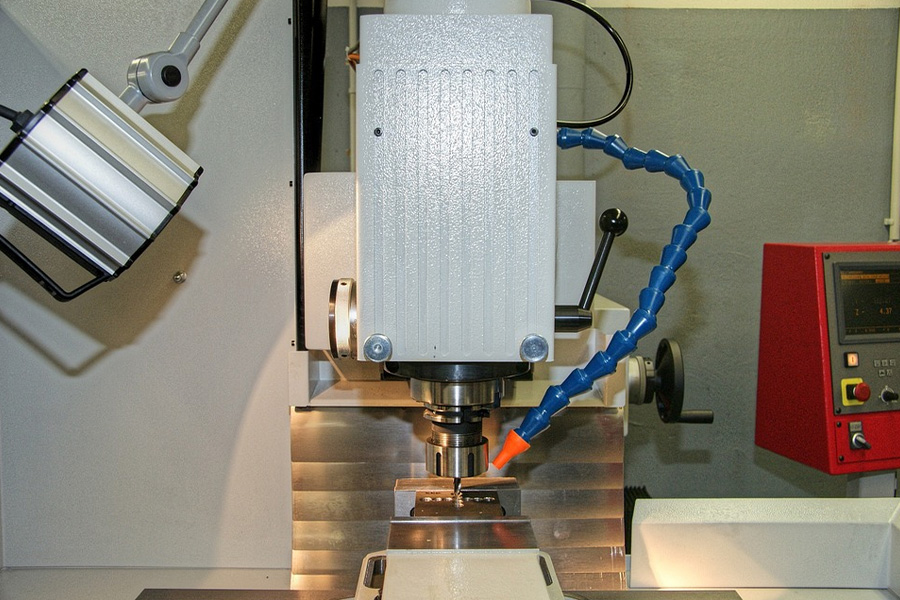

Umshini wokugaya we-CNC

I-Computer Numerical Control noma imishini yokugaya ye-CNC iyimishini ethuthukisiwe ngokobuchwepheshe esebenzisa isistimu elawulwa ngekhompuyutha.

I-spindle enikezwe kule mishini yokugaya ingahamba inhlangothi ezintathu, okusho ukuthi ingazungeza ama-degree angama-360. Umsebenzisi udinga nje ukulayisha umklamo we-workpiece, futhi umshini uzonakekela ngokuzenzakalelayo imisebenzi yokugaya. Lolu hlobo lomshini wokugaya lufana nohlobo lombhede noma inguqulo ethuthukisiwe yomshini wokugaya uhlobo lombhede.

Imishini yokugaya ye-CNC ziyavumelana nezimo futhi zinekhono eliphezulu lokukhiqiza. Bangakwazi futhi ukusika izimo eziyinkimbinkimbi nezinto zokwakha ngokunembile. Ngaphandle kwalokho, le mishini iza nomsebenzi wenkumbulo ovumela opharetha ukuthi baphindaphinde ukuhlinzwa izikhathi eziningi. Imishini yokugaya ye-CNC isithandwa kakhulu ngenxa yokusebenziseka kwayo kalula kanye nokuncipha komfutho wabasebenzi. Ngokuzibusa, ukunemba, nokunemba okunikezwa yile nkathi entsha yemishini yokugaya, imishini yendabuko iphelelwa yisikhathi ngokushesha.

3. Ijubane

Isivinini singesinye sezici ezibalulekile okufanele uzicabangele lapho ukhetha umshini wokugaya, njengoba uzoba nomthelela ngqo kwikhwalithi kanye nokuqedwa okuphelele kwengxenye yokugcina ecutshunguliwe. Inketho edume kakhulu ukuya emishinini ephakeme ye-RPM (yokuzungezisa ngomzuzu) enamathuluzi amancane amboziwe, esika ekujuleni okungashoni. I-RPM ephezulu iphumela ekuqedeni okuhlanzekile futhi idinga amandla amahhashi amancane.

4. Izinketho zokupholisa

Uwoyela wokusika usebenza njengesipholisi esihle ngenkathi ugaywa. Iphinde isebenze njengesithambiso futhi yehlise ingcindezi emshinini nasemsebenzini. Amafutha achitha ukushisa okukhiqizwa ethuluzini lokusika kanye nendawo yokusebenza, andisa impilo yomshini, futhi avimbele ukusonga nokubamba. Uwoyela wokusika futhi usiza ukusula ingaphezulu le-workpiece kuma-chips nama-shavings futhi kunciphisa ingozi yokusika okungafuneki namaphutha.

5. Ukunemba

Ukunemba kungenye yemingcele ebalulekile lapho ukukhetha imishini yokugaya. Kuwukucaciswa okuzokusiza ukuthi uqonde ukuthi umshini wokugaya unembe kangakanani ekwenzeni umsebenzi owufunayo. Isibonelo, uma imfuneko kuwukusika isiqeshana sokusebenza sibe ngu-50mm, umshini kufanele ubeke ithuluzi eduze naleli xabiso noma nini lapho umsebenzi uqala. Ukunemba kokumisa ithuluzi ngokuvamile kufanele kube ngaphansi kuka-0.05mm. Emisebenzini edinga ukunemba okukhulu, imishini yokugaya enemba ngo-0.01mm kufanele kukhethwe.

6. Usayizi wethebula

Lapho ukhetha umshini wokugaya ome mpo, enye yezinto ezibalulekile okufanele uzicabangele ubukhulu bawo. Ubukhulu bale mishini yokugaya bunqunywa ngokusekelwe kubude bobude betafula, ukuwela, nokuma mpo kanye nendawo yokusebenza yomshini. Lezi zilinganiso zizophinde zikunikeze umbono mayelana nosayizi wezingxenye ezingacutshungulwa kusetshenziswa umshini. Imvamisa, ubukhulu betafula buqala ukusuka ku-600X300mm futhi bufike ku-6000X2500mm, kuye ngohlobo lomshini wokugaya owukhethayo.

Ucezu oluyisihluthulelo lomshini wokusebenza ngensimbi nokusebenza ngokhuni

Imishini yokugaya yenza umsebenzi wensimbi nokusebenza ngokhuni kube nomoya ohelezayo. Ngohlobo olulungile lwemishini kukhathalogi yakho, amakhasimende azoba nesikhathi esilula sokwenza izinqumo zokuthenga. Cabangela zonke lezi zici ngaphambili ukuthenga umshini wokugaya futhi utshale imali yakho emishinini ehlangabezana ngokunembile nezidingo nokulindelwe ngabathengi bakho.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu