Ngohlu olubanzi lwama-extruder epulasitiki atholakalayo namuhla, ukukhetha okungcono kakhulu kungaba inselele. Lesi sihloko sizokuhambisa kulokho okudingeka ukucabangele lapho ukhetha ama-extruder epulasitiki ukusiza abathengi bathole amamodeli angcono kakhulu atholakalayo emakethe. Izophinde ihlanganise izinhlobo ezahlukene zama-extruder epulasitiki atholakalayo ukuze abathengi baqiniseke ukuthi bathola isixazululo esifanele sezidingo zabo.

Okuqukethwe

Ukukhula kwemakethe ye-plastic extruders

Amathiphu okufanele uwacabangele lapho ukhetha i-extruder yepulasitiki

Izinhlobo ezahlukene ze-extruder zepulasitiki

Imakethe eqondiwe yama-extruder epulasitiki

Ukuvala

Ukukhula kwemakethe ye-plastic extruders

Imakethe yomhlaba wonke yomshini we-plastic extrusion kulindeleke ukuthi ifinyelele inani lama-US $ 7.903 billion ngo-2027, ibhalise izinga lokukhula elihlanganisiwe lonyaka (CAGR) ngaphezu kwe-4.5% kusukela ngo-2020 kuya ku-2027. Isidingo esandayo emhlabeni wonke sama-extruder epulasitiki siqhutshwa ukwanda kokuqwashisa ngemishini yokonga amandla kanye ne-automation yezimboni esheshayo. Lesi sidingo sihlangatshezwa wukwanda kokuhlinzekwa kwemishini yokukhiqiza esebenza kahle kakhulu, kanti i-China iphethe imakethe yokuhlinzeka. Ukuze kuhlangatshezwane nezidingo zezinhlelo zokusebenza ezithile, abadlali bemakethe benza ama-extruder epulasitiki ezinhlobo ezahlukahlukene, osayizi, izinhlelo zokusebenza, nobunkimbinkimbi bomklamo.

Amathiphu okufanele uwacabangele lapho ukhetha i-extruder yepulasitiki

Ukusetshenziswa komshini we-extrusion kunquma ukwakheka kwawo, ngakho-ke kuyisinyathelo sokuqala sokunquma ukucaciswa kwe-extruder. Ngezansi kunencazelo eningiliziwe yalokho okudingeka ukucabangele lapho ukhetha i-extruder nezingxenye zayo.

Material

Ukukhetha izinto ezibonakalayo kubalulekile ukuze uqinisekise ukuthi umshini wakho we-extrusion usebenza ngempumelelo. Ukunquma impahla engcono kakhulu, cabangela lokhu okulandelayo:

- Ukuqina - Ukuthi umkhiqizo ungaba nengcindezi nesisindo esingakanani kubalulekile. Uma izosetshenziselwa ukubamba into esindayo, noma ichayeke ekuthinteni okungazelelwe noma ukungqubuzana, khona-ke ingxenye engamelana namandla anjalo kufanele icatshangelwe. Ngokunjalo, uma ingxenye kulindeleke ukuthi inwetshwe, icindezeleke, noma yiluphi olunye uhlobo lokucindezeleka, kufanele ukhethe umshini onokumelana nokukhathala okuhle. Okumbalwa kwalokhu kufaka phakathi: ama-extrusions e-PVC aqinile, amaselula e-PVC extrusions, kanye ne-polypylene.

- Ithempelesha - Uma i-extruder yepulasitiki izosetshenziswa nento eshisa kakhulu, kufanele ucabangele izakhiwo zayo ezishisayo. Kubalulekile ukunaka izinga lokushisa eliphezulu kakhulu umkhiqizo wakho ozobhekana nalo njengoba ukuchayeka kaningi ekushiseni kungabangela ukuhlanekezela komumo nokuqina. Izinyathelo zokuphepha kufanele futhi zicatshangelwe, ngokwesibonelo, uma okokusebenza kudinga ukumelana nelangabi kuzomele kusetshenziswe izinto ezithile nezithasiselo noma kugwenywe phakathi nenqubo.

- Izidingo - Kuya ngemboni ohlose ukuyisebenzisela umkhiqizo wakho wepulasitiki, kufanele uqinisekise ukuthi uphephile kulezi zinhlelo ezihlosiwe.

- Environment – Uma uhlose ukusebenzisa umkhiqizo wakho we-plastic extrusion ngaphansi kwamanzi noma uthintana noketshezi, kufanele ukhethe umkhiqizo ongazwani namanzi / uketshezi. Ngokufanayo, izinto ezisetshenziswa namakhemikhali kudingeka zingagqwali. Okokugcina, izinto okuhloswe ngazo ukugcinwa ngaphandle isikhathi eside zidinga ukugqunywa futhi ukumelana nogesi kuyadingeka lapho kunesidingo.

- Ukubukeka - Isiphetho sendaba yakho enye indawo ebalulekile okufanele uyicabangele ekuklanyweni kwakho. Ngokuphathelene nombala othize noma i-opacity oyifunayo ngomkhiqizo wakho, kukhona amapulasitiki angakhiqiza kangcono imiphumela oyifunayo.

Uma usunqume izici ezifanele zengxenye, yisikhathi sokusesha i-resin. Kubalulekile ukuqaphela ukuthi akuwona wonke ama-resin alungele inqubo ye-extrusion. Ngakho-ke, thintana nomphakeli wakho ukuze uthole izincomo ezisuselwe ekwakhiweni kwakho kanye nengxenye yezidingo zakho. Ngokuvamile, ukunciphisa ukwehluleka okuphelele kwe-extruder yepulasitiki, kungcono ukucabangela ukuklama nezinye izidingo zengxenye ebalulekile. Ungaqala ngokucabangela:

Ukubekezelelana, okuyinto kuye ngokuthi ubude bakho extrusion

Inkontileka ye-Thermoplastic futhi inwebe noma nini lapho ingaphansi kokushintsha kwezinga lokushisa. Ukusika amaphrofayili epulasitiki abe ngobude bawo obuqondile kungenisa izimfuneko zokucubungula eziphakeme futhi kuhehe izindleko zokuphatha ezingadingekile. Ngakho-ke, ama-extrusions kufanele abe nokubekezelela ubude obuncane obufakwe kubude obuphelele.

Ukujiya kodonga

Ukugeleza kwezinto kunquma inqubo ye-extrusion. Ubukhulu obuhlukahlukene bomklamo wezindonga bungenza ukuhamba kwezinto zepulasitiki kube nzima okuholela kuphrofayela ehlanekezelwe. Ukuze uthole iphrofayili elinganiselayo, izindonga kufanele zibe ubukhulu obufanayo.

Izigodi

Idizayini yephrofayili enhle kufanele ibe nemininingwane elinganiselwe ezigabeni ezingenalutho. Kodwa-ke, uma imbobo idingeka, amathiphu alandelayo okuqapha angasiza ekunciphiseni ubungozi obungaba khona:

- Gwema okungenalutho phakathi kwegodi njengoba kuzophoqa umklamo ohlosiwe ukuthi uphume esimweni ngaphambi kokuthi i-thermoplastic iqine.

- Gwema izingxenye ezingenalutho ezinemilenze yangaphakathi. Uma umlenze udingeka, akufanele udlule ubukhulu bodonga.

Irediyasi yekhona

Ngenkathi wonke amakhona wephrofayela ye-extrusion kufanele abe ne-radius, amakhona acijile angaholela ekugxilweni kwengcindezi futhi ekugcineni asonte futhi aphuke. Ukuze uthole udonga olufanayo, i-radii yangaphakathi nangaphandle kufanele ibe yi-offset eyodwa. Ikhona elingaphandle elicijile liyi-intshi engu-1/64, ngakho-ke irediyasi enconyiwe yangaphakathi kufanele ibe okungenani yiyintshi engu-1/64 ukuze kuncishiswe ithuba lokuphuka, ikakhulukazi ezintweni eziqinile.

Izinamathiseli

Amateyipu nezinamatheliso zandisa izindleko zabasebenzi nezokusebenza. Esikhundleni salokho, umshini we-extrusion kufanele ube nokunamathiselwe okuklanywe kahle komshini. Kodwa-ke, uma amateyipu noma izinto ezinamathelayo kufanele zisetshenziswe, okunamathiselwe noma indawo yokubeka kufanele ibe indawo eyisicaba ukuze kunamathele kahle futhi ibe ngaphezu kuka-⅛'' ububanzi. Ubukhulu be-adhesive kufanele bucatshangelwe lapho kukhishwa ubude bephrofayili.

Izinhlobo ezahlukene ze-extruder zepulasitiki

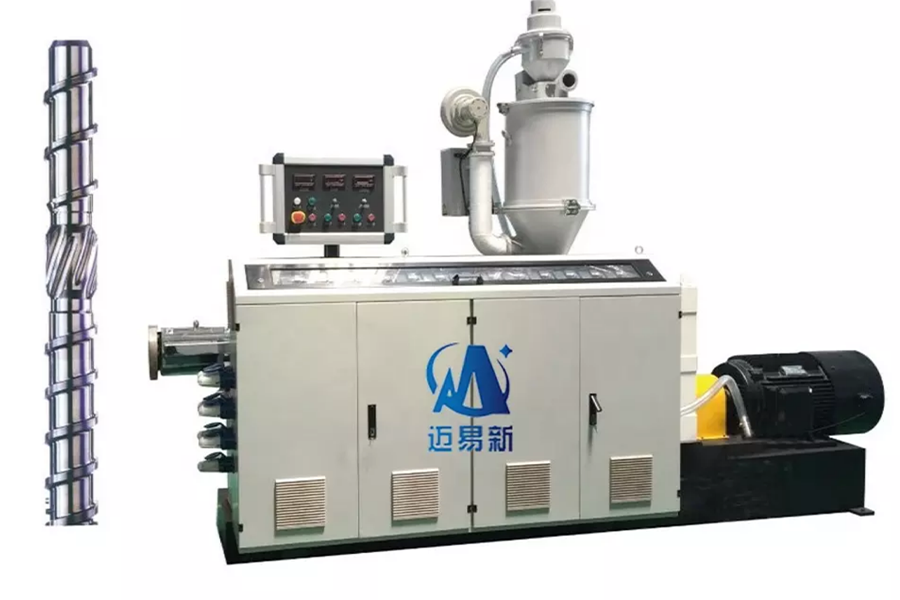

I-scruder yesikulufu esisodwa

The i-extruder yesikulufu esisodwa wuhlobo lwephampu yomjovo wepulasitiki esetshenziswa kakhulu njenge-extruder eqhubekayo ekusebenzeni kwe-polymer extrusion. Umsebenzi oyinhloko we-screw extruder eyodwa ukufaka kancane kancane ingcindezi ekuncibilikeni kwe-polymer ukuze i-polymer ikhishwe ngedayizi.

Lawa ma-extruder ashibhile futhi anezindleko eziphansi zokunakekela. Alula futhi ahlinzeka kalula ngokuphuma okuqhubekayo kwezinto ezifana ne-HDPE, LDPE, KANYE ne-PP, yingakho edumile embonini yokugaywa kabusha kwemikhiqizo yepulasitiki. Njengoba idizayini yezikulufu ze-extrusion iye yathuthuka ngokuhamba kweminyaka, iziqhumane zesikulufa esisodwa ezinezindiza zesibili zokuncibilika ngokushesha nazo ziyatholakala emakethe.

I-Asia-Pacific ingenye yezimakethe ezihamba phambili zama-single screw extruder, futhi ukukhula kwemakethe yomhlaba wonke kulindeleke ukuthi kukhule ku-CAGR ka-4.4% ngo-2026.

Izinzuzo

- Ukugunda okuncane

- Ukuhamba okuphakeme

- Ingcono ekukhipheni izinto ezijwayelekile uma kuqhathaniswa nama-twin screw extruder

- Kushibhile kakhulu kunamanye ama-extruder

- Ingasetshenziswa ekusebenzeni kwezinhlobonhlobo zezinhlobonhlobo zezinto ezibonakalayo

Okumbi

- Ukusebenza okulinganiselwe kokuphakelayo

- Izinqubo ezingafaneleki ngenxa yobunzima lapho uhlanganisa izinto ezifana nokunamathisela noma impushana

I-twin screw extruder

Ama-extruder ama-twin screw ube nezikulufu ezimbili ezihambisanayo zokuxhumanisa, ezijikelezayo ezifakwe kumashafu ukuze kuqinisekiswe ukuthutha okuphumelelayo, ukuminyanisa, ukuxutshwa, ukupheka, ukugunda, nokushisisa. Ama-twin screw extruder adumile, ngokulinganiselwa Inani lemakethe lase-US lama-US $253.5 wezigidi kanye nenani lokukhula komhlaba wonke ku-a (CAGR) ka-6.30% ngo-2026.

Izinzuzo

- Ukuzihlanza okuhle ngesikhathi sokungqubuzana kwezikulufu

- Kulula ukubheka ukuguga kwento efakwe imicu ukuze ishintshwe ngesikhathi nangempumelelo

- Izindleko zokukhiqiza eziphansi

- Ukusebenza okuthuthukisiwe kokugcinwa nokuphazamiseka kokukhiqiza ngesikhathi sokusetshenziswa

- I-torque ephezulu, isivinini esikhulu, nokusetshenziswa kwamandla okuphansi

- Isivuno esiphezulu nezinga eliphezulu uma kuqhathaniswa nama-single-screw extruder

Okumbi

- Izinga lokukhishwa okuphezulu

- Ukuwohloka okukhulu komgqomo kanye ne-screw edge endaweni ene-meshing

- Isikulufu esibizayo nomgqomo we-conical twin-screw extruder

- Ukushisa okuncane okukhiqizwa emgqonyeni

Umshini wefilimu oshaywayo

Imishini yefilimu eshaywayo khiqiza amafilimu e-polymer akhethekile asetshenziswa kakhulu emaphaketheni, njengezikhwama zokuthenga, amafilimu okuvimbela, ukunwebeka, nokugoqa. Ukucindezela komoya kusetshenziselwa ukwandisa ifilimu futhi ngemva kwalokho kupholiswe ukuze kuqiniswe i-polymer. Le extruder ine izakhiwo zefilimu eziningi eyenziwe ngefilimu i-coextrusion ehlanganisa izendlalelo ze-polymer ezincibilikisiwe ezimbili noma ngaphezulu. Inguquko esuka ekusebenziseni ama-polymer ajwayelekile ukuya kuma-polymer abolayo kanye nemboni yezokwelapha ekhula kancane iye yaba kwenyusa isidingo sisonke sefilimu eqhunyiswayo. Imakethe yemishini yokukhipha amafilimu emhlabeni wonke elinganiselwa ku-US $2,563.7 million futhi kulindeleke ukuthi ikhule ngesivinini esikhulu. I-CAGR ye-4.8% kuze kube ngu-2031.

Izinzuzo

- Ibhalansi engcono yezakhiwo zemishini

- Idinga izinga lokushisa eliphansi lokuncibilika kunamanye ama-extruder

- Yelula ifilimu kumadigri ahlukahlukene ngezikhombisi-ndlela ze-longitudinal neziphambene

- Ukulawula ukujiya okugcwele

- Ukuvumelana nezimo okuphezulu, ngaleyo ndlela ukukhiqiza okuphezulu

Okumbi

- Isebenza kancane ekupholiseni

- Indlela eyinkimbinkimbi futhi enephutha yokulawula ukushuba kwefilimu

- Ingabamba kalula umoya phakathi kwezingqimba zefilimu

Imakethe eqondiwe yama-extruder epulasitiki

Amapulasitiki anwetshiwe avame ukusetshenziswa kuzo zonke izimboni futhi isidingo kulindeleke ukuthi sikhule ku-CAGR ka-4.5% kusukela ngo-2020 kuya ku-2027. Lokhu kukhula kuwumphumela wokwanda kwesidingo sezingxenye ezisebenza kahle nezithembekile ezivumelana nemvelo futhi zisebenziseka kabusha. Amandla okuthenga emishini yokukhipha ipulasitiki kulindeleke ukuthi akhule ezimakethe zomhlaba ngo-6.9% esikhathini sokubikezela.

Ukwenyuka kwesidingo sama-extruder epulasitiki embonini yezokwakha neyokwakha kulindeleke ukuthi kukhuphule ukukhula kwemakethe yase-Asia Pacific, okuyimanje ephethe. Isabelo semakethe esingu-40.2%, esine-CAGR ephezulu kakhulu eqagelwayo engu-5.4%. Ukukhula kwemboni yezimoto eYurophu kuzokhuphula izinga lamanje Isabelo se-19.80% semakethe. Ngaphezu kwalokho, indlela yokuphila ematasa yabathengi emhlabeni wonke ikhuphule ukusetshenziswa kokudla okuqandisiwe, okuholele ekwenyukeni kwesidingo semishini yokukhipha ipulasitiki. INyakatho Melika, iYurophu, neLatin America, iMiddle East, kanye ne-Afrika (LAMEA) bangabadlali ababalulekile abangaba khona emakethe.

Ukuvala

Imakethe yepulasitiki ekhulayo emhlabeni wonke idale amathuba amaningi kubahlinzeki be-plastic extruder. Lesi sihloko sinikeze ukuqonda kwezinhlobo zemishini yokubumba ye-extrusion etholakalayo kanye nezici ezibalulekile okufanele zicatshangelwe phakathi nenqubo yokuthatha izinqumo. Ukuze uthole ukwaziswa okwengeziwe mayelana extruder plastic, futhi ukubheka onobuhle atholakalayo emakethe namuhla, hlola Chovm.com indawo emakethe.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu